Recycling device for carbon powder

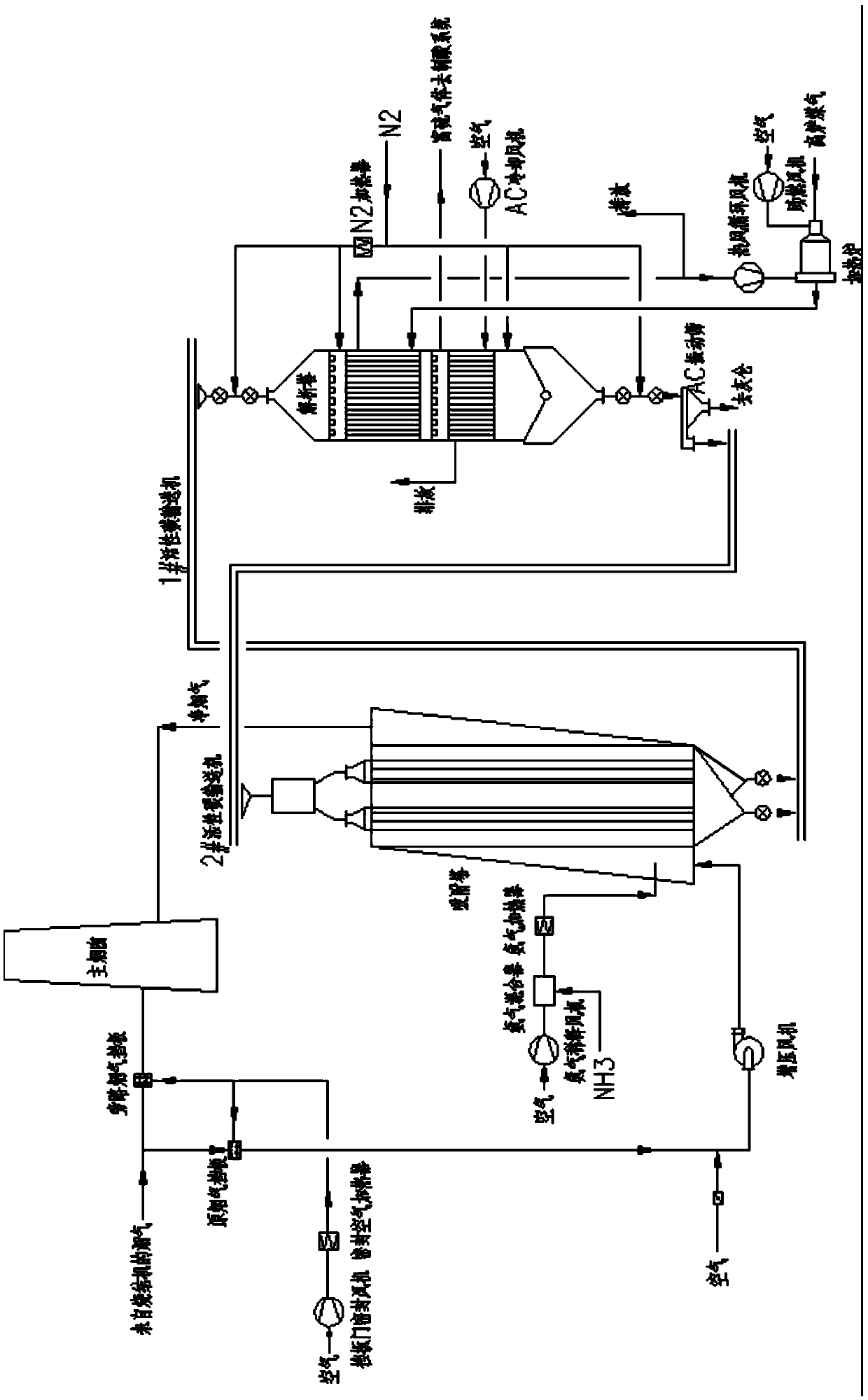

A technology of carbon powder and activated carbon, which is applied in the direction of separating solids from solids with airflow, filtering screens, grids, etc., which can solve the problems of uncontrollable materials, large quantities, continuous operation loss of processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

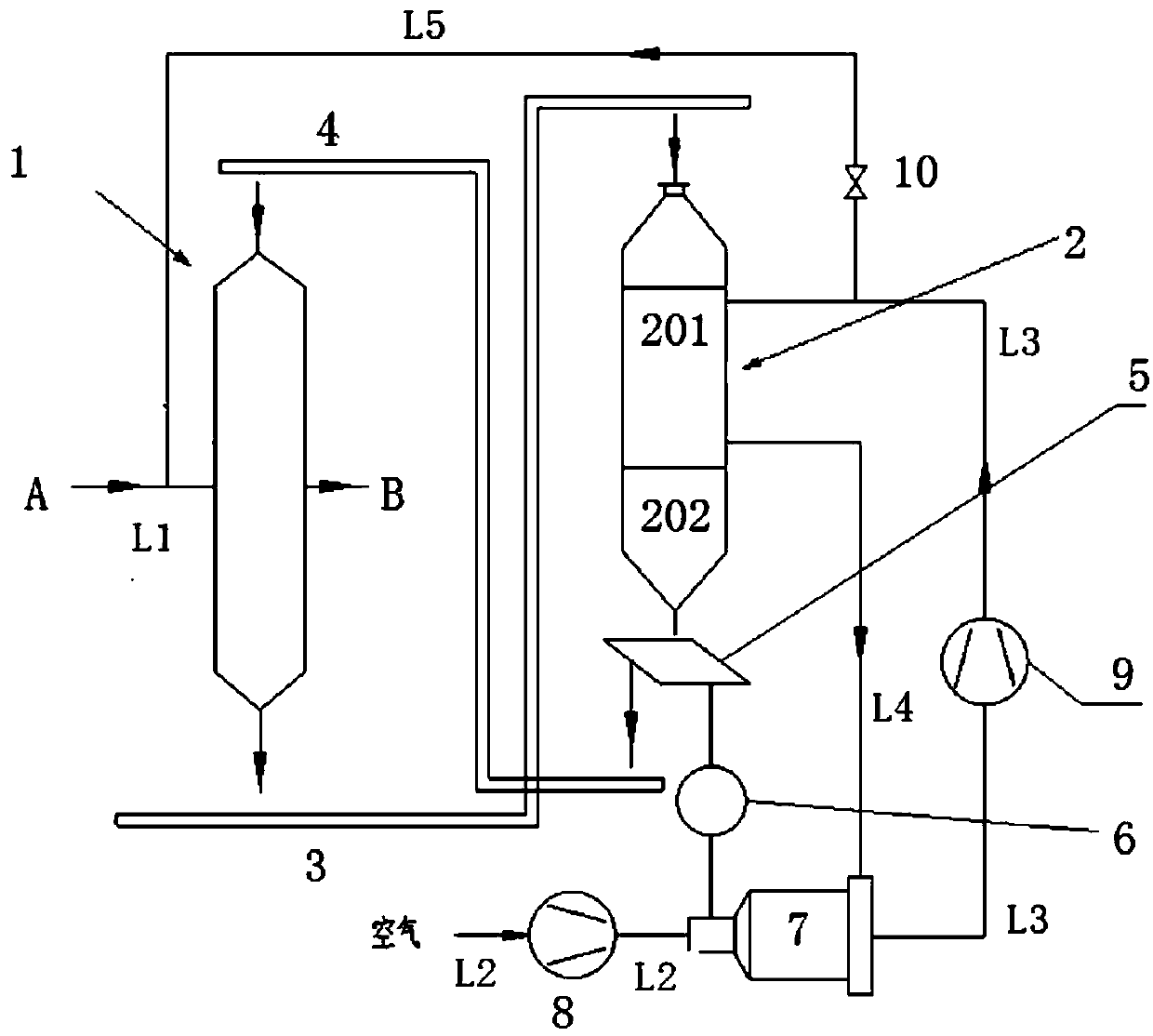

Embodiment 1

[0086] see figure 2 , provide the recycling device of charcoal powder, the recycling device of this charcoal powder comprises: adsorption tower (1), has the desorption tower (2) of heating section (201) and cooling section (202), the first activated carbon conveyor ( 3), the second active carbon conveyer (4), be positioned at the vibrating screen (5) below the discharge port of desorption tower (2) or downstream, pulverizer (6), heating furnace (7), the blast blower of hot blast stove ( 8), and hot blast circulation fan (9); wherein the hot blast outlet of heating furnace (7) is connected to the hot blast inlet of the heating section (201) of desorption tower (2) via hot blast pipeline (L3), the heating of desorption tower (2) The air outlet of section (201) is connected to the circulating cooling air inlet of heating furnace (7) via circulating cooling air duct (L4); A conveying device is arranged between the machine (6) and the heating furnace (7). Therefore, the fine car...

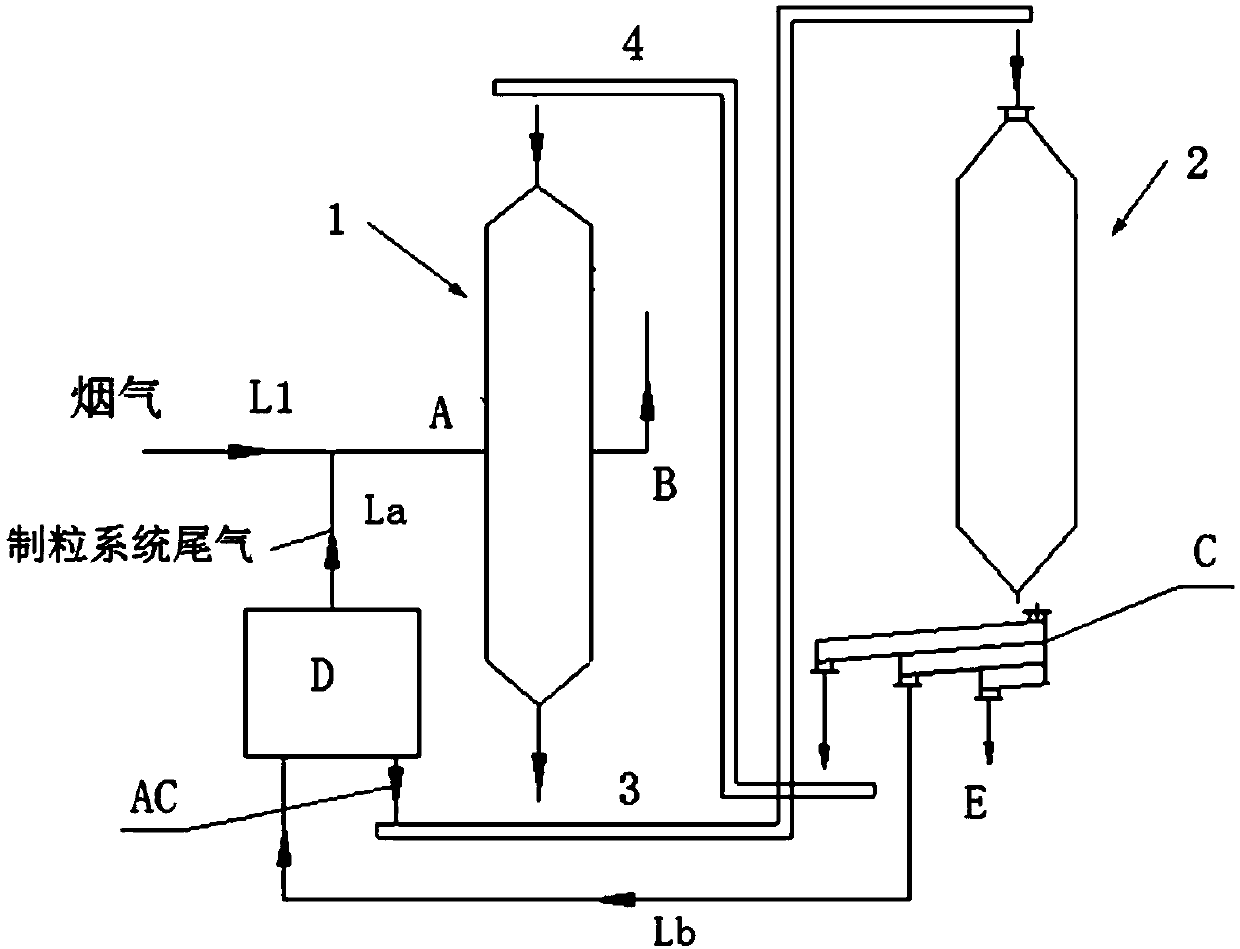

Embodiment 2

[0092] see image 3 , provides the recycling device of charcoal powder, the recycling device of this charcoal powder comprises: adsorption tower (1), desorption tower (2), the first activated carbon conveyor (3), the second activated carbon conveyor (4), located at The multi-stage or multi-layer vibrating screen (C) below or downstream of the discharge port of the analysis tower (2), and the granulation system (D); wherein the flue gas delivery pipeline (L1) is connected to the flue gas of the adsorption tower (1) The gas inlet (A), the tail gas outlet of the granulation system (D) are connected to the flue gas delivery pipe (L1) via the tail gas discharge pipe (La), and, among them, the multi-stage or multi-layer vibrating screen (C) and the manufacturing A conveying device (Lb) (such as a conveying pipeline) is provided between the granulation system (D) for conveying the fine activated carbon particles screened by the multi-stage or multi-layer vibrating screen (C) to the g...

Embodiment 3

[0099] see Figure 4 , provides the recycling device of charcoal powder, the recycling device of this charcoal powder comprises: adsorption tower (1), desorption tower (2), the first activated carbon conveyor (3), the second activated carbon conveyor (4), located at The multi-stage or multi-layer vibrating screen (C) below or downstream of the discharge port of the analysis tower (2), the sulfur-rich gas acid production system (F), and the waste water purification system (G); wherein the flue gas delivery pipeline (L1 ) is connected to the flue gas inlet (A) of the adsorption tower (1), and the sulfur-rich gas outlet in the middle of the desorption tower (2) is connected to the acid-making system (F) through the sulfur-rich gas pipeline (Lc), and the acid-making system (F) The acid product outlet is connected to the acid liquid inlet of the wastewater purification system (G) through the acid liquid delivery pipeline (Ld), and the tail gas outlet of the acid making system (F) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com