Automatic feeding mechanism for minisized round bars and installation method of automatic feeding mechanism for minisized round bars

An automatic feeding and bar material technology, which is applied to machine tools, grinders, metal processing, etc. designed for grinding the rotating surface of workpieces, can solve the problems of serious bar material jamming, low efficiency, and unstable feeding, and achieve less jamming , high efficiency, stable feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

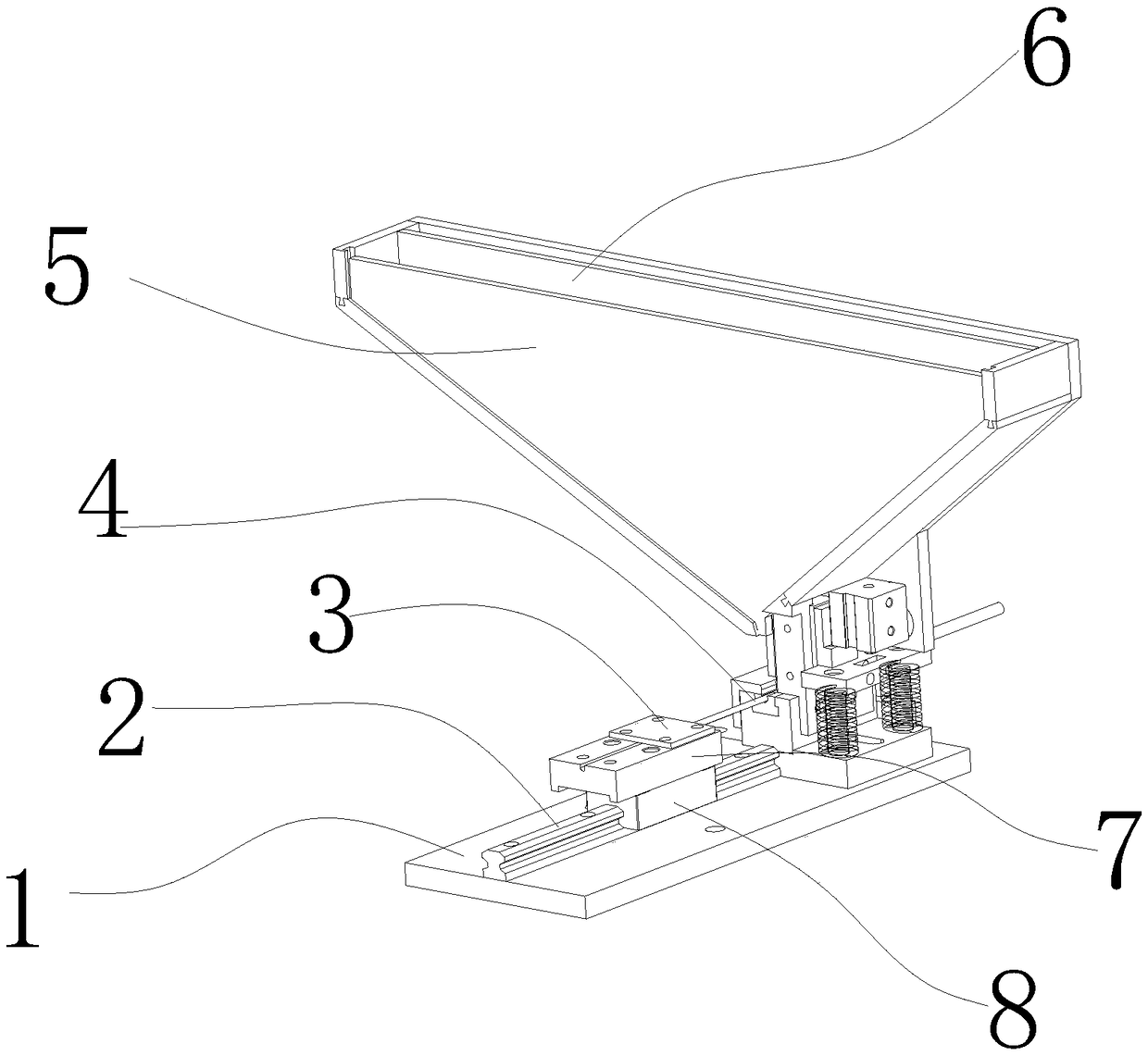

[0022] Such as Figure 1-3 As shown, a micro-bar automatic feeding mechanism includes a base 1, a linear guide rail 2, an ejector rod pressing plate 3, an ejector rod 4, a hopper front baffle 5, a hopper unloading mechanism 6, an ejector rod fixing block 7, Slider 8, the base 1 is fixed with a linear guide rail 2 by screws, the linear guide rail 2 is slidably matched with the slider 8, the slider 8 is fixedly installed with a fixing block 7 for the ejector rod, and the fixing block 7 for the ejector rod is provided with an ejector Rod 4 and ejector rod 4 are provided with an ejector rod pressure plate 3, which is fixed on the ejector rod fixing block 7 by screws, one end of the base 1 is fixedly installed with a hopper unloading mechanism 6, and one end of the hopper unloading mechanism A hopper front baffle 5 is inserted.

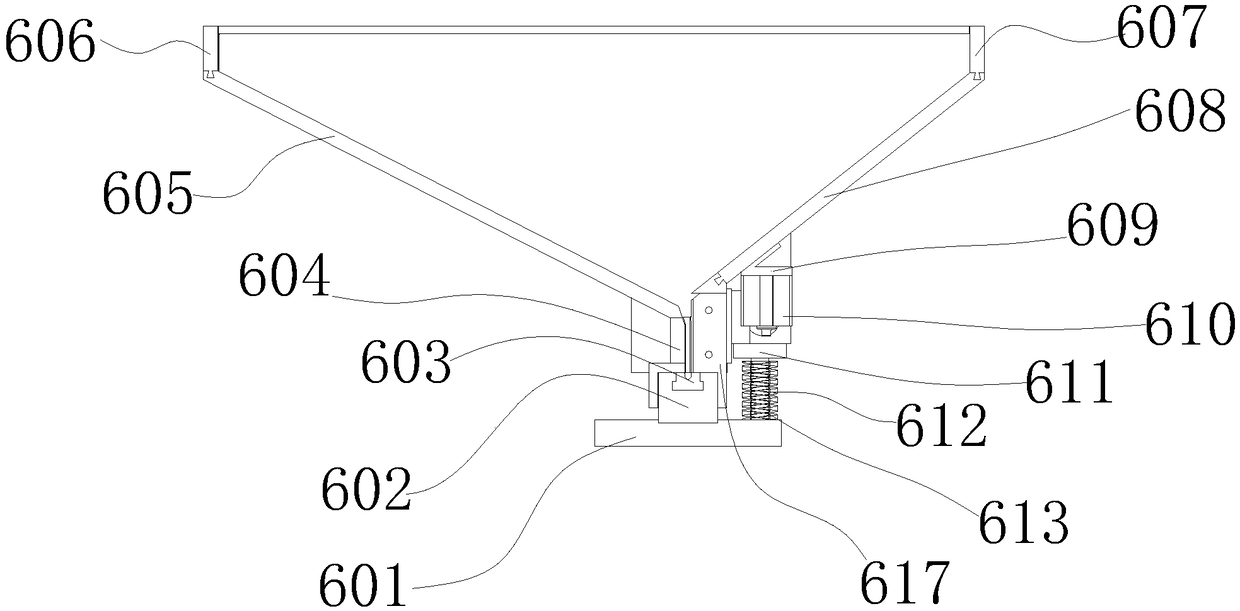

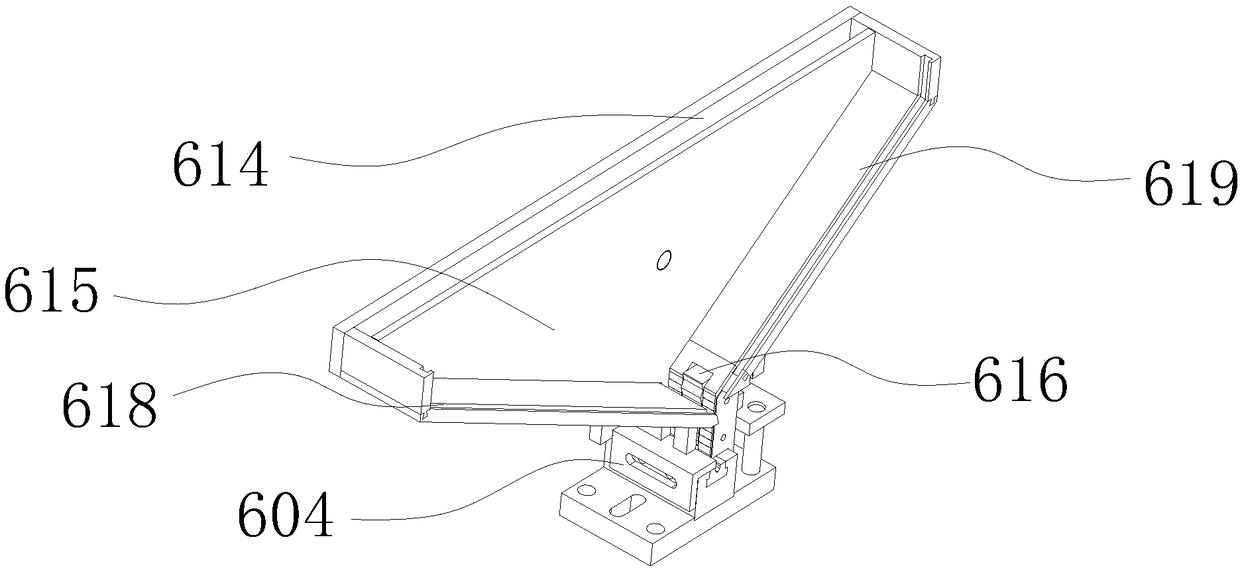

[0023] In this embodiment, the hopper feeding mechanism 6 includes a hopper base plate 601, an insert fixing seat 602, an insert 603, a hopper side plate...

Embodiment 2

[0032] An installation method of a micro-bar automatic feeding mechanism, including the following process, step 1, the assembly of the base, fixing the linear guide rail on the base through screws, installing the slider on the linear guide rail, and fixing the ejector rod on the On the fixed block of the ejector rod, cover the ejector rod pressing plate on the fixed block of the order rod, fix the ejector rod, and fix the fixed block of the ejector rod on the slider through screws; step 2, the hopper support Assemble, fix the insert fixing seat on the side of the bottom plate of the hopper, install the insert on the insert fixing seat, and put the V-shaped groove of the insert facing the ejector rod, so that the ejector rod and the V-shaped groove of the insert are in the same position On the straight line, fix and install the hopper base plate and the base with screws, and combine one side of the hopper base plate with one end of the linear guide rail; Step 3, assemble the hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com