Material flow shaping device

A shaping device and material technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of complex and changeable characteristics, unstable characteristics, difficult coal flow shaping, etc., and achieve simple and compact structure, The effect of preventing bridging and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

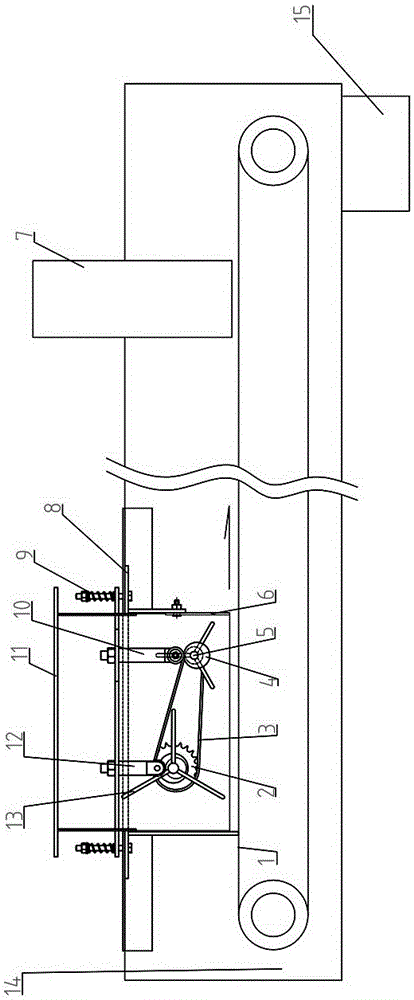

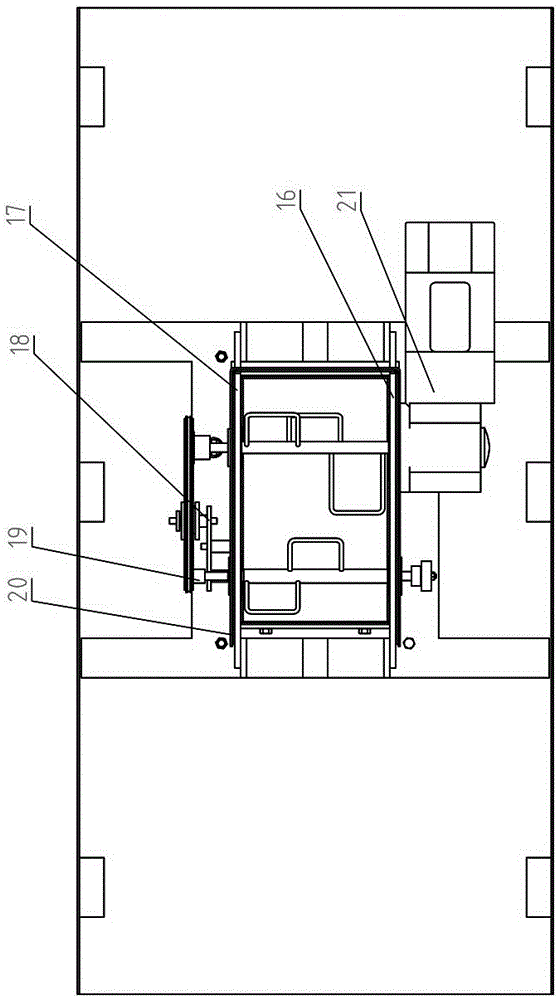

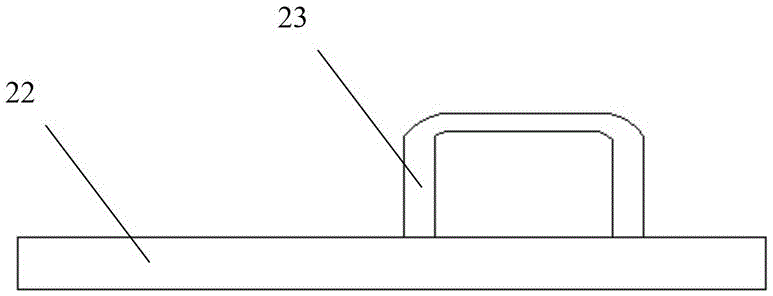

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] In the present invention, the coal sample is taken as a representative of the material flow as an example for the following description. In mechanized sampling and preparation systems, the primary sub-sample volume collected by the primary sampler is often much larger than the minimum sub-sample volume required in the standard. In order to reduce the load of the crusher, it is generally required to add a first-level reduction before crushing, so as to obtain a small number of secondary samples that can represent the quality of the primary sample. In the international standard, it is required that the shrinkage feeding material must be uniform, and the number of cutting samples of the shrinking equipment should also exceed the required minimum number of cutting samples. For this reason, there is generally a shaping belt before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com