Continuous production line and continuous production method for emulsified ammonium nitrate fuel oil explosive

An ammonium explosive and production line technology, applied in chemical instruments and methods, explosives, mixing methods, etc., can solve the problems of many online operators, chaotic production sites, low production efficiency, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

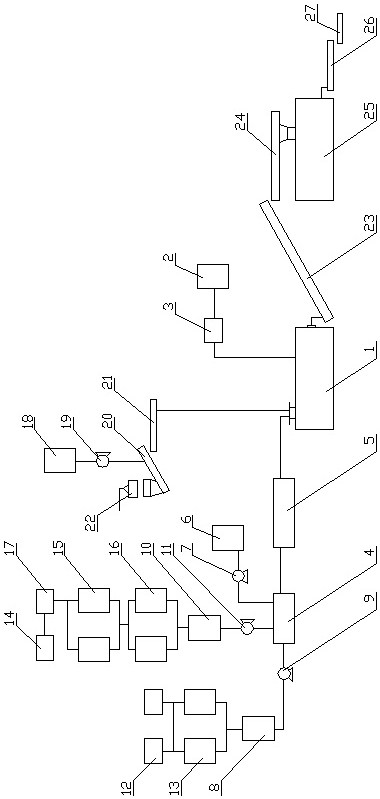

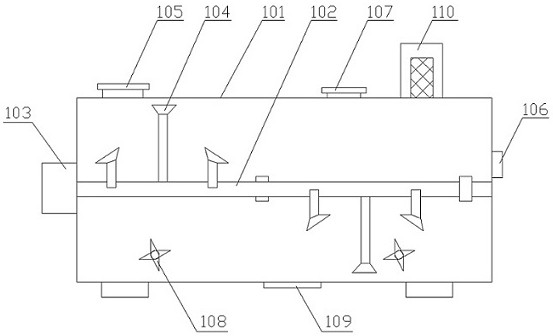

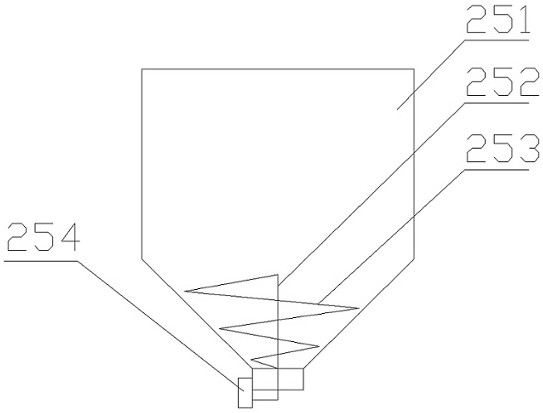

[0032] see figure 1 , figure 2 , image 3 and Figure 4 , the invention discloses a continuous production line for emulsified ammonium oil explosives, comprising:

[0033] The latex matrix continuous preparation system is used for continuously preparing the latex matrix and continuously transporting the prepared latex matrix to the continuous mixing equipment, and the latex matrix outlet is connected to the material inlet of the continuous mixing equipment;

[0034] The ammonium oil explosives continuous preparation system is used for continuously preparing ammonium oil explosives and continuously transporting the prepared ammonium oil explosives to the continuous mixing equipment, and the ammonium oil explosives outlet is connected to the material inlet of the continuous mixing equipment;

[0035] Continuous mixing equipment, used for continuous mixing of latex matrix and ammonium oil explosives to make emulsified ammonium oil explosives, with a continuous outlet for emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com