Patents

Literature

82results about How to "Improve production safety level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform

InactiveCN103091096AGuaranteed Adaptive Accurate PartitioningAdaptive Precise Partition PreciseMachine gearing/transmission testingMachine bearings testingNODALDecomposition

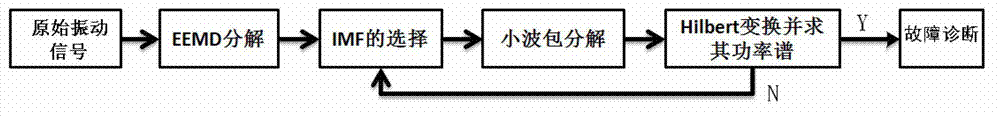

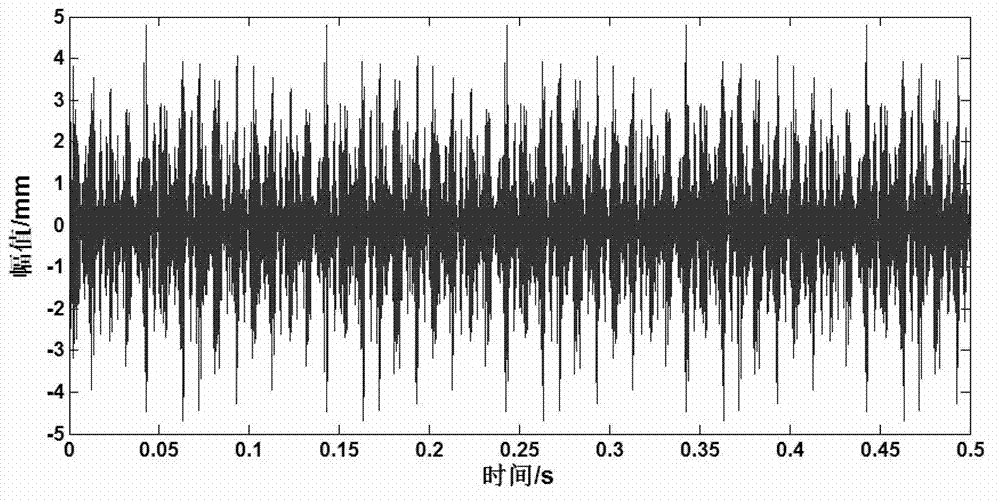

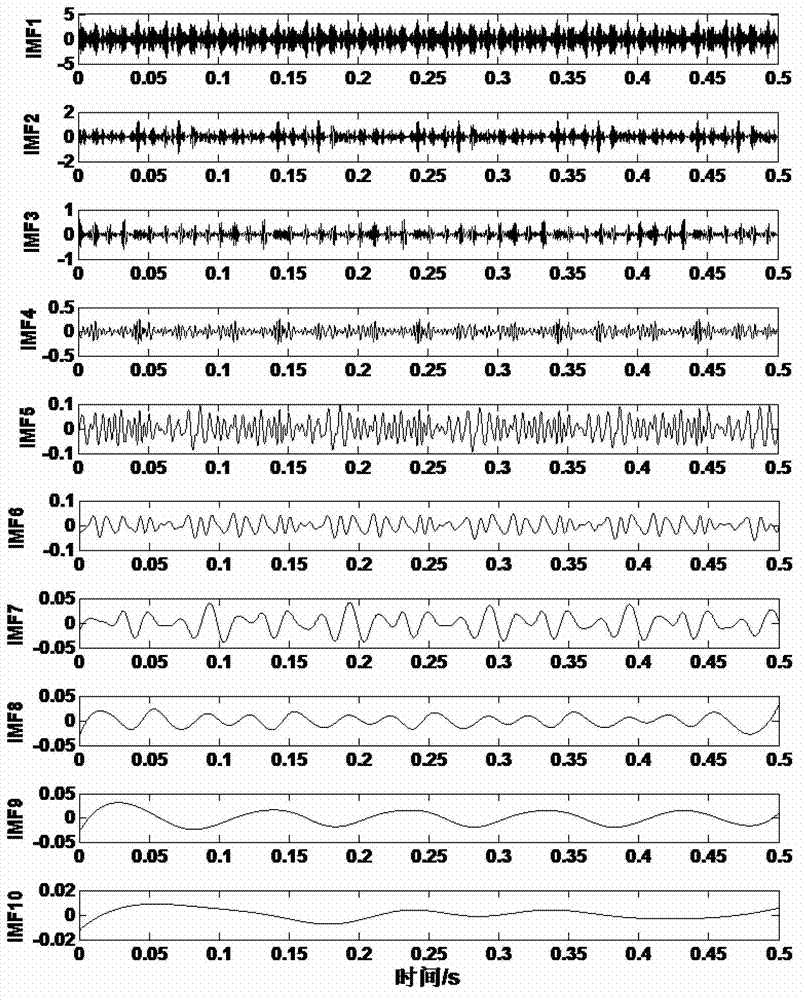

The invention relates to an extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform includes the following steps: (1), collected original vibration signals of mechanical and electrical equipment are decomposed according to the EEMD, white noise is added, and intrinsic mode function (IMF) components are obtained through decomposition; (2), the sensitive IMF components closely related to failure are chosen, and other irrelative IMF components are ignored; (3), the sensitive IMF components chosen through step (2) are decomposed in an orthogonal wavelet packet mode, and a wavelet coefficient of each node is obtained; and (4), envelopes are extracted from the obtained wavelet packet coefficients by adoption of the Hilbert transform and the Fourier transform, power spectrums are calculated, the power spectrum corresponding to each wavelet packet coefficient is obtained and serves as the early failure sensitive characteristic , and the sensitive characteristics are automatically obtained. Self-adapting signals can be decomposed, the sensitive characteristics can be convenient to obtain automatically, diagnosis precision and speed are improved, and a mechanical and electrical system can be diagnosed quickly, accurately and stably. The extraction method for the early failure sensitive characteristics based on the EEMD and the wavelet packet transform can be applied to the field of mechanical and electrical equipment failure diagnosis.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Safety production cloud service platform for industrial and mining enterprises

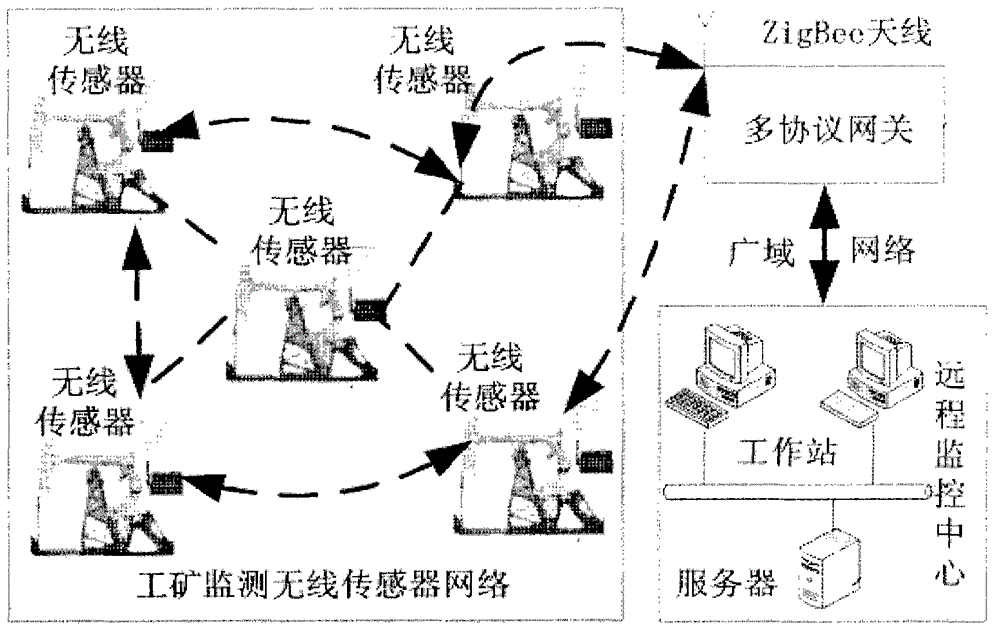

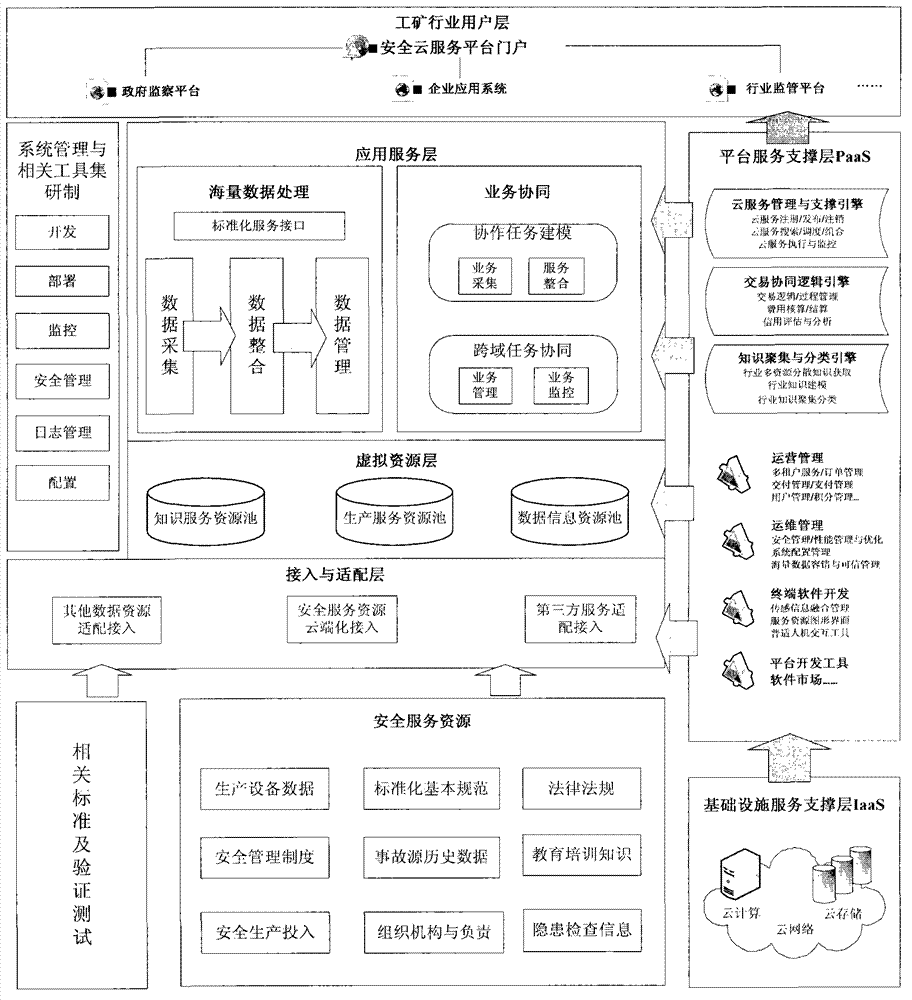

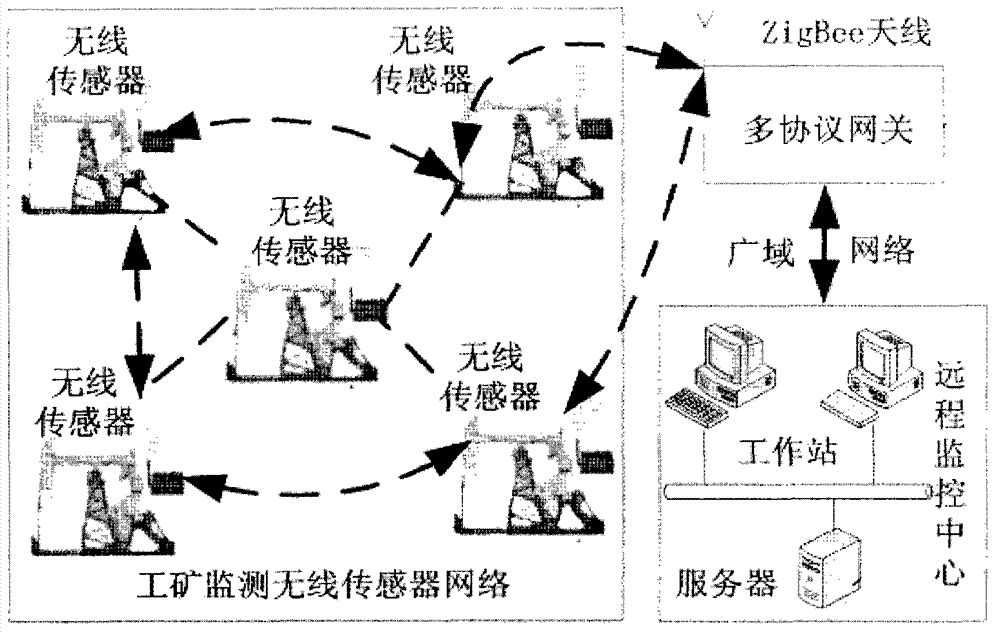

ActiveCN102882969AImprove production safety levelPromote safe productionTransmissionSystems managementDatabase

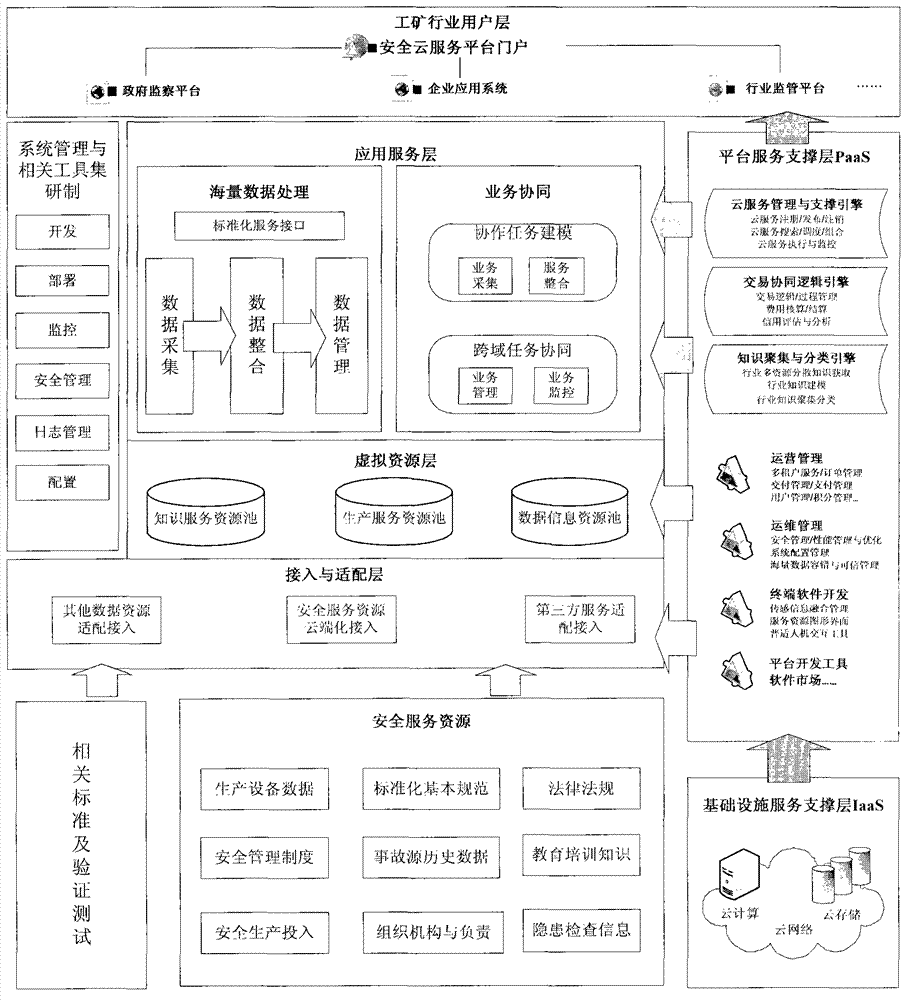

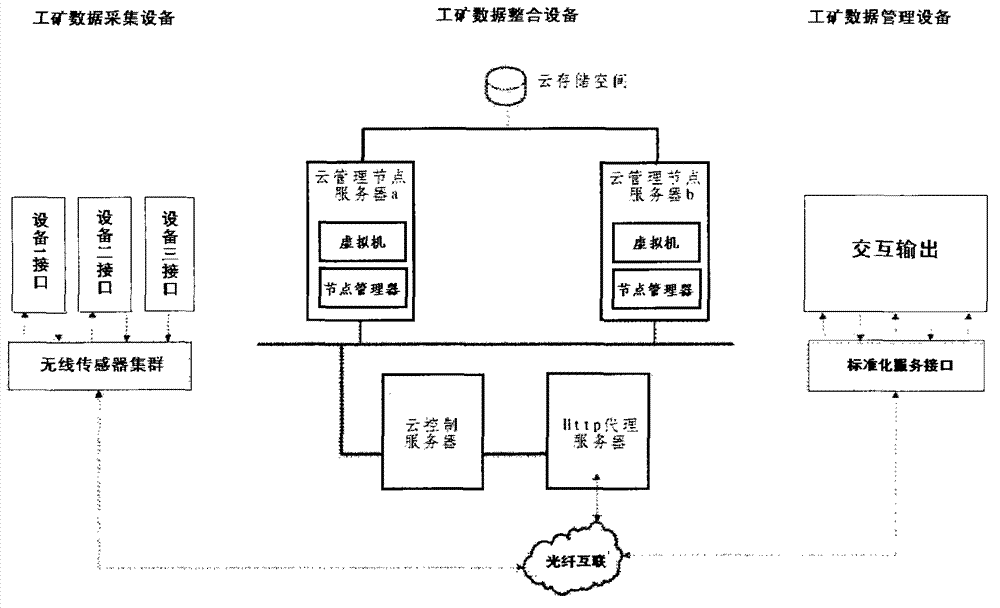

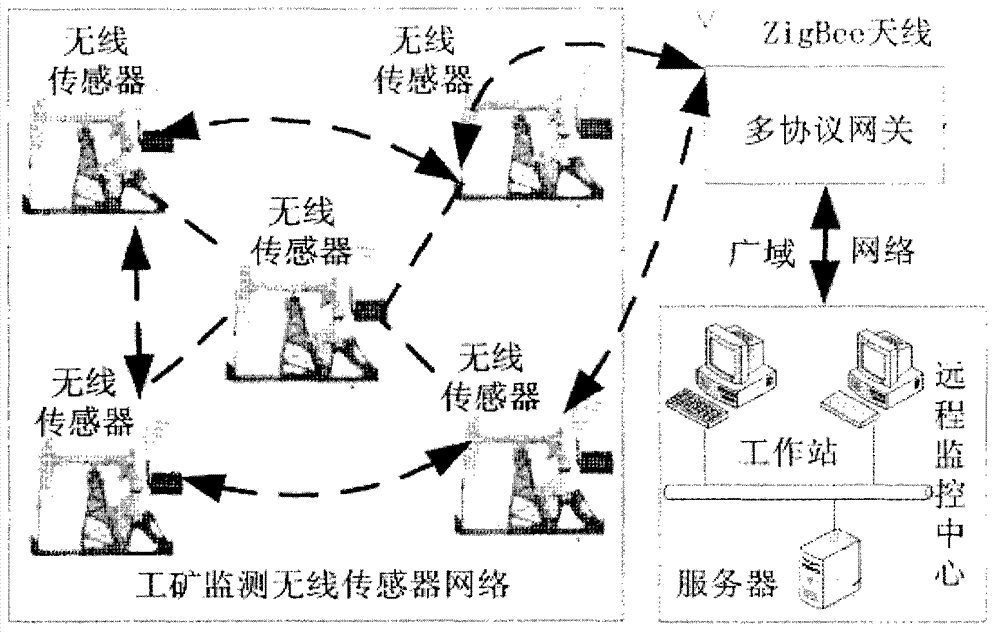

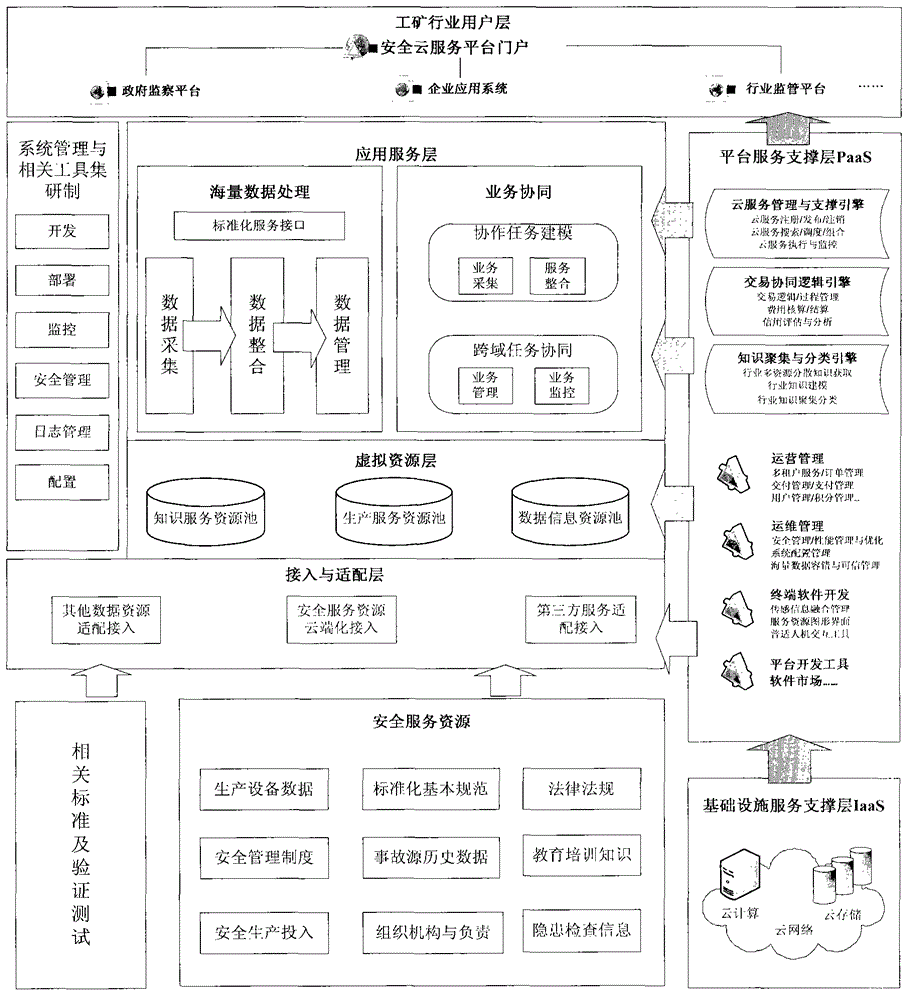

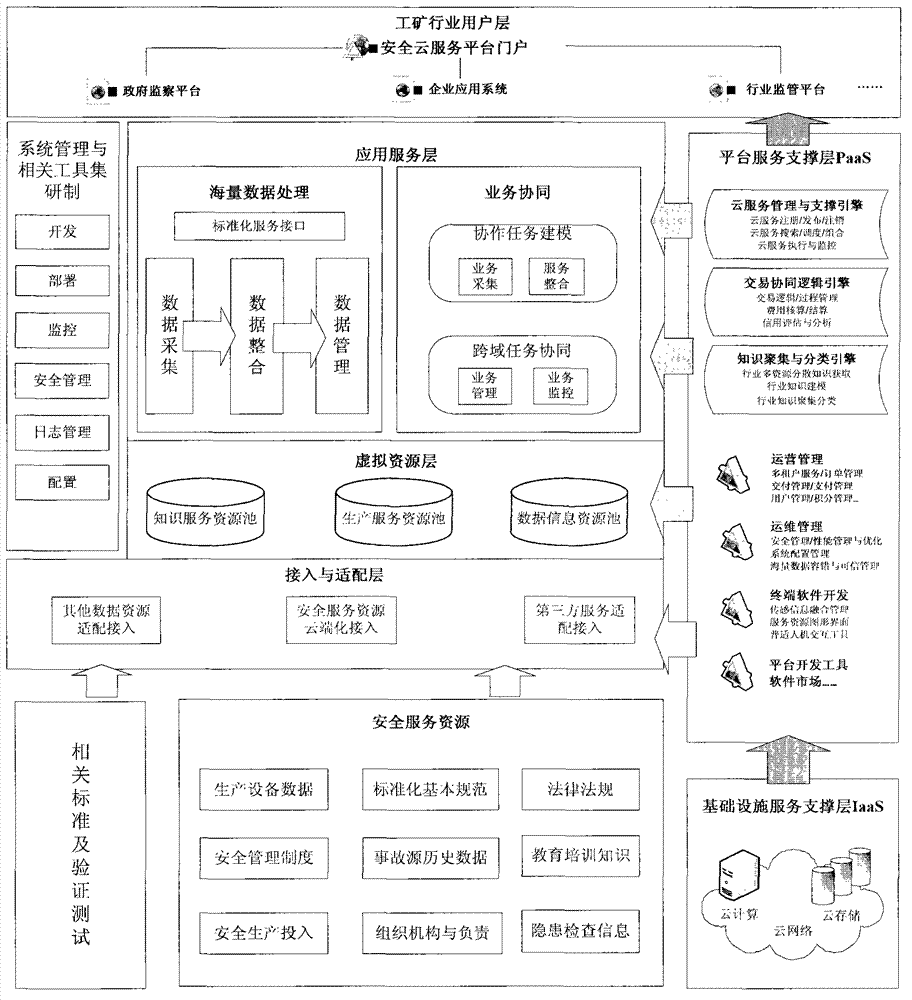

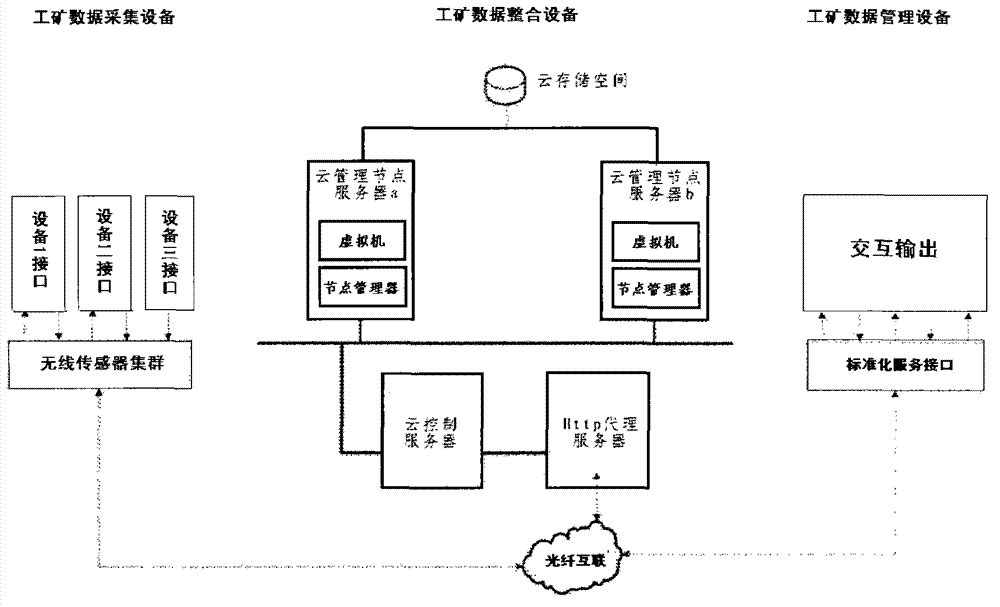

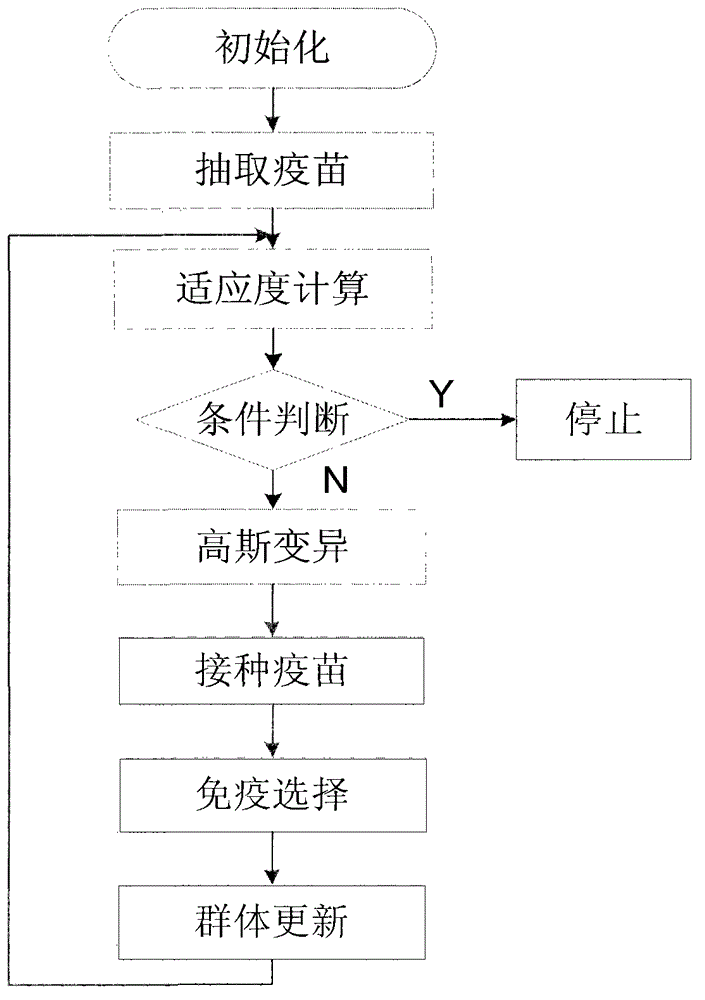

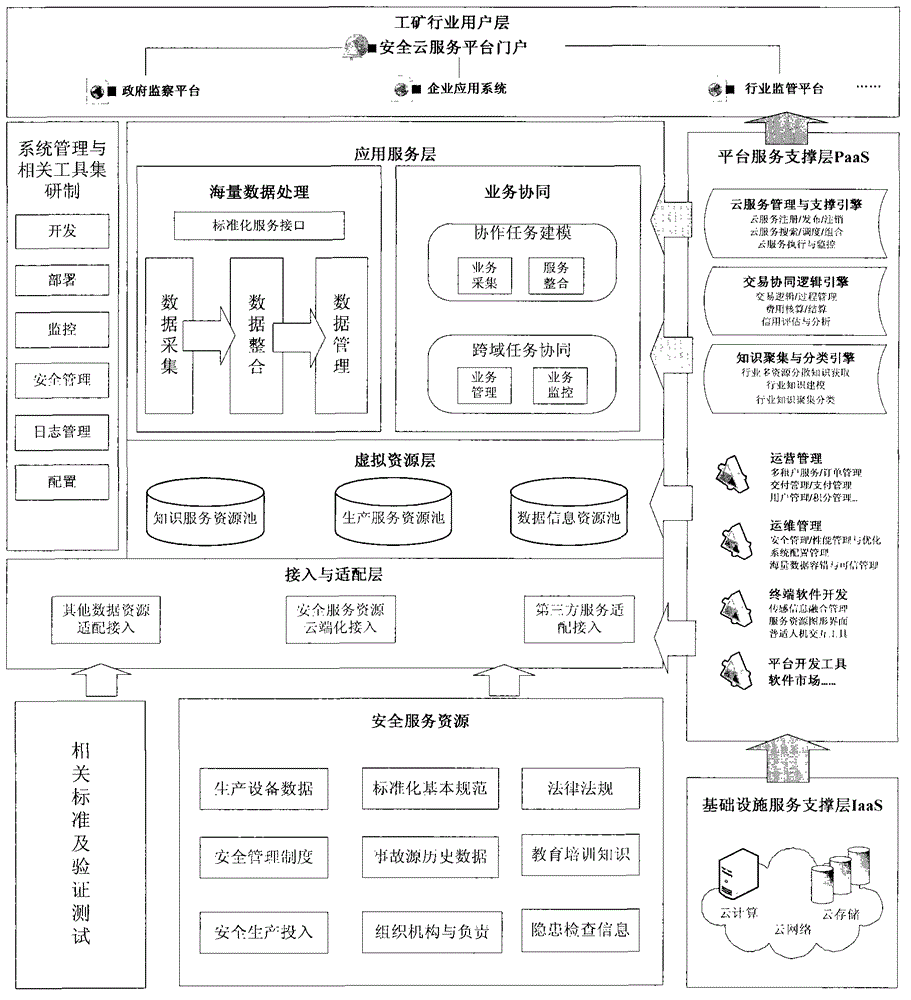

A safety production cloud service platform system for industrial and mining enterprises is characterized by comprising a safety cloud service platform portal subsystem, a system management and relevant tool set researching subsystem, an application service layer subsystem, a virtual resource layer subsystem, a platform service support layer subsystem, an access and adapting layer subsystem, a safety service resource subsystem and an infrastructure service support layer subsystem.

Owner:浙江图讯科技股份有限公司

Safety production cloud service platform for industrial and mining enterprises

ActiveCN102917032AImprove production safety levelImprove accident prevention and early warningResourcesTransmissionSystems managementDatabase

The invention relates to a safety production cloud service platform for industrial and mining enterprises, which is characterized by comprising a safety cloud service platform portal subsystem, a system management and related tool set developing subsystem, an application service layer subsystem, virtual resource layer subsystem, a platform service support layer subsystem, an access and adaptation layer subsystem, a safety service resource subsystem and infrastructure service support layer subsystem.

Owner:浙江图讯科技股份有限公司

Fatal danger fountainhead analysis and evaluation method for safety production cloud service platform system facing industrial and mining enterprises

ActiveCN102880802AImprove production safety levelPromote safe productionTransmissionSpecial data processing applicationsComputer science

Disclosed is a fatal danger fountainhead analysis and evaluation method for a safety production cloud service platform system. Evaluation of fatal danger fountainheads are performed from two aspects including inherent danger evaluation and real danger evaluation, offset factors for the external environment are added, an evaluation model is provided, relevant data of a database are searched according to codes of selected danger fountainheads and are analyzed so as to judge whether the varieties of substances contained in the data of the danger fountainheads are of danger or not, a circular area computed according to the formula is the range affected by the danger fountainheads, and the danger fountainheads are graded according the maximum death radius.

Owner:浙江图讯科技股份有限公司

Data analysis method for association rule of cloud service platform system orienting to safe production of industrial and mining enterprises

InactiveCN102930372AImprove production safety levelPromote safe productionForecastingResourcesAnalysis dataThree dimensionality

The invention discloses a data analysis method for an association rule of a cloud service platform system orienting to safe production of industrial and mining enterprises. The data analysis method comprises the following steps of: analyzing data in a platform service support layer subsystem based on the association rule; setting data attributes according to the characteristics of construction accidents and the reasons of the accidents; extracting accident data and exploratory data from a database to form accident sample data; establishing a data cube of the accident sample data from three dimensionalities of accident types, the occurrence time of the accidents and work parameters of equipment; and operating the data cube by using aggregation query and connection statements of SQL (Structured Query Language) to finish the search process of a frequent predicate set and a strong rule and generate the frequent predicate set.

Owner:浙江图讯科技股份有限公司

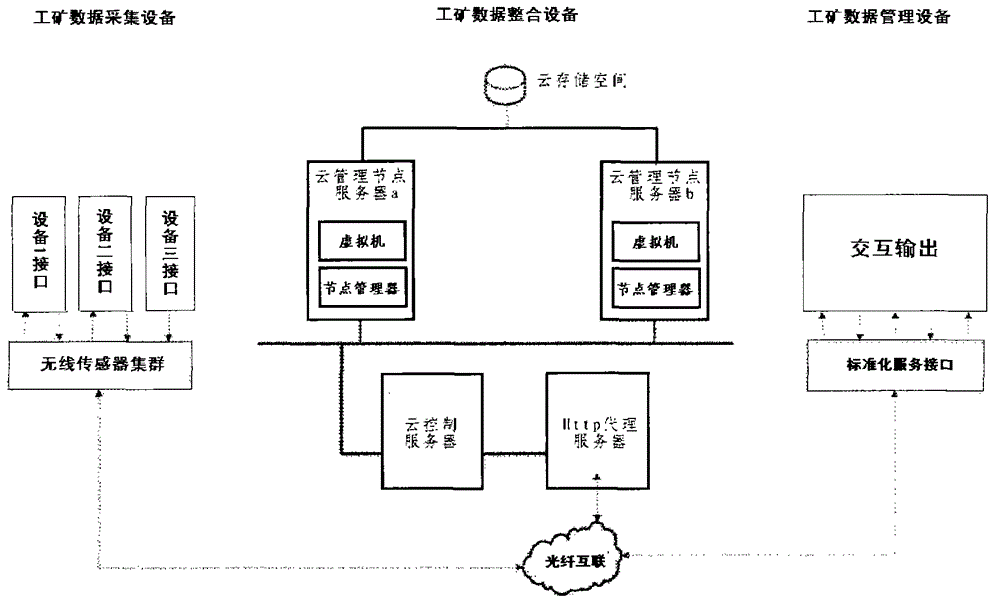

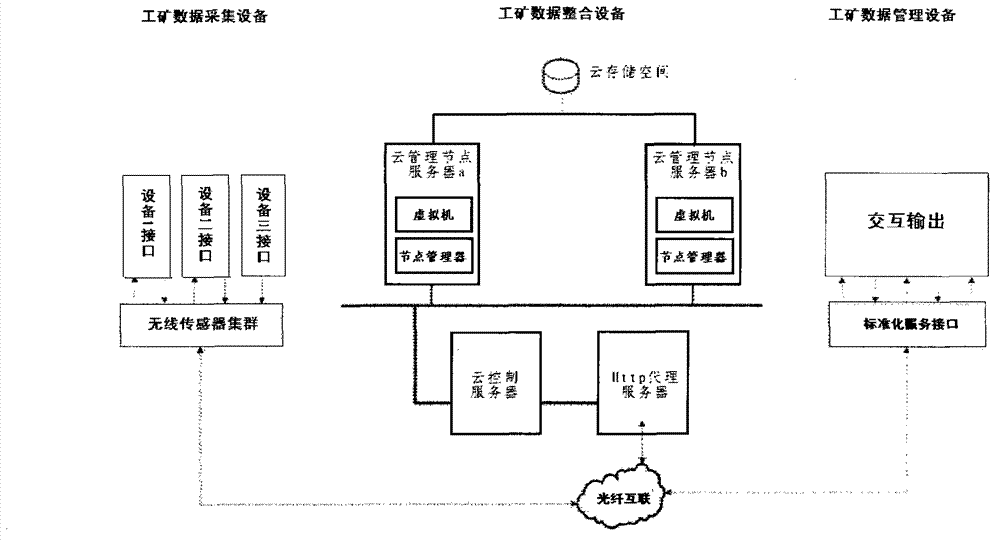

Data computing system of safety production cloud service platform for industrial and mining enterprises

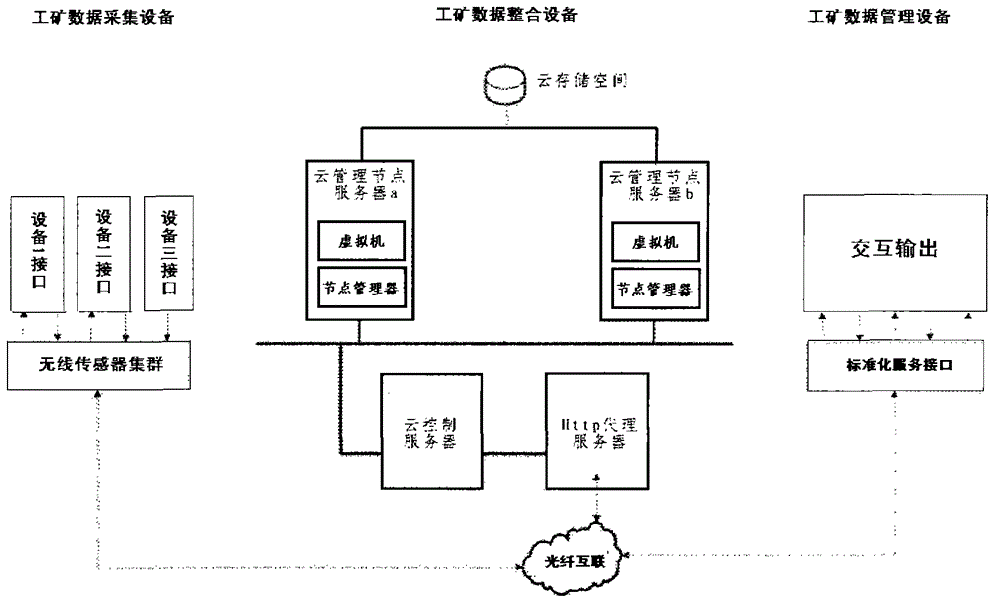

InactiveCN102917031AImprove production safety levelImprove accident prevention and early warningResourcesTransmissionComputer moduleCloud data

Disclosed is a data computing system of a safety production cloud service platform for a mining enterprise. Data management equipment corresponds to a cloud data computation module. The cloud data computation module is used for calling data collected in real time and stored in a cloud data storage pool, respectively computing characteristics of a mining system according to public relations of the mining system, establishing a universal data computing and analyzing model, and computing device performance, loading capability, working efficiency, safety degree and environmental parameters. The data computation module can be flexibly added and set, and corresponding computed value can be obtained by updating the data computation module.

Owner:浙江图讯科技股份有限公司

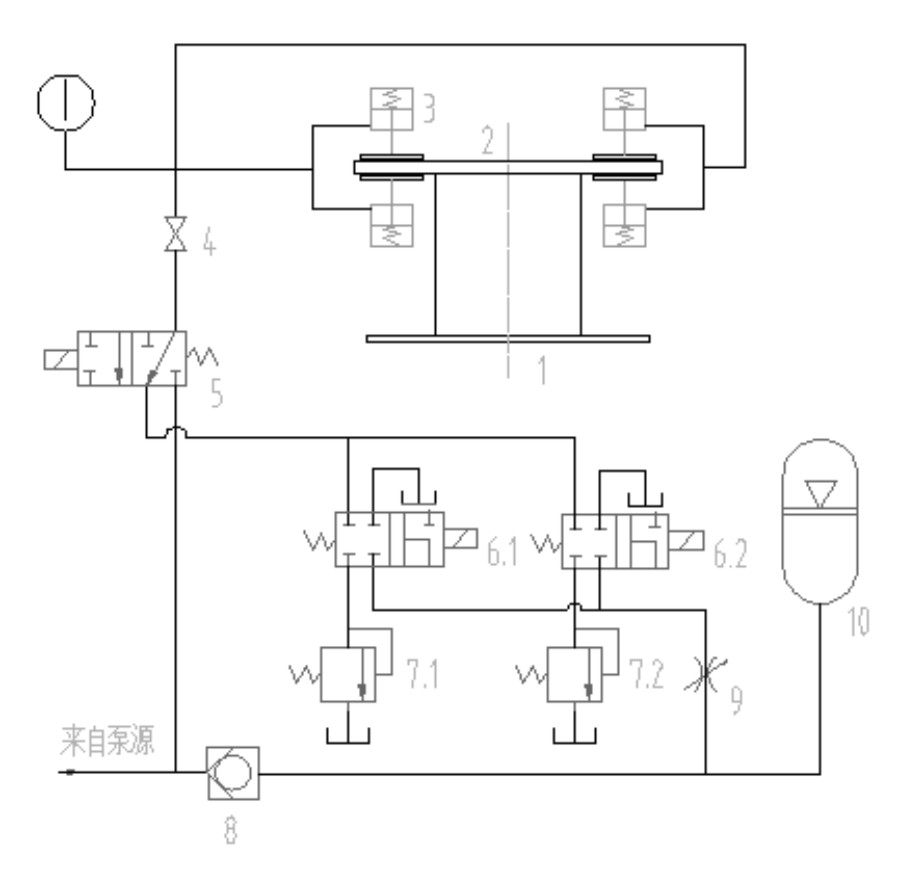

Synchronous concurrent multi-channel constant deceleration safety braking system and method for mine hoist

ActiveCN103950859AImproved safety braking reliabilityImprove production safety levelFluid-pressure actuator componentsHoisting equipmentsClosed loopElectrical control

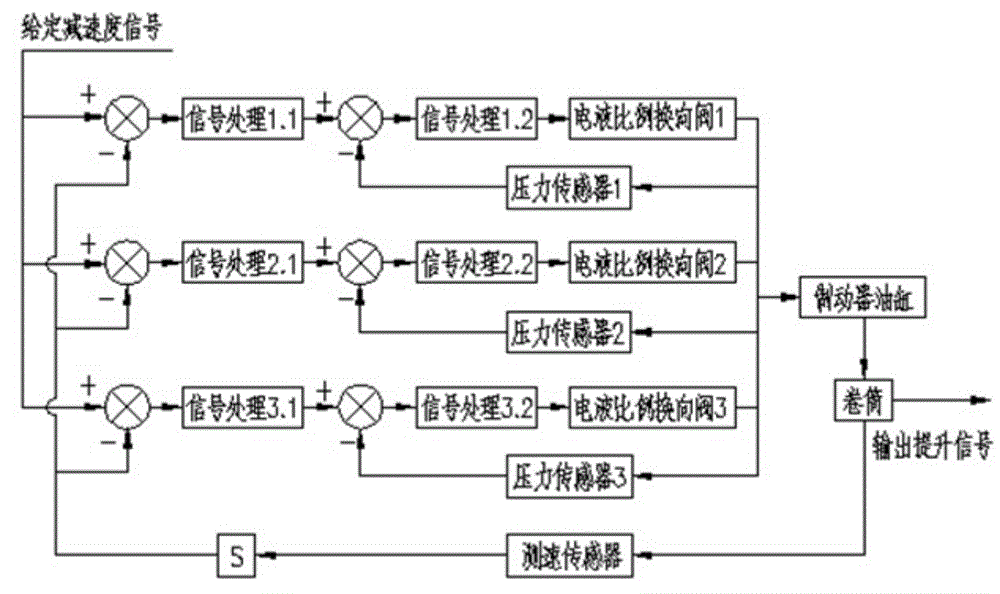

The invention discloses a synchronous concurrent multi-channel constant deceleration safety braking system for a mine hoist. The synchronous concurrent multi-channel constant deceleration safety braking system comprises braking loops consisting of hydraulic systems, constant deceleration closed-loop electrical control devices and detection feedback devices; the braking system comprises at least two parallel independent braking loops; the same constant deceleration set point command signal is input to the constant deceleration closed-loop electrical control device of each independent braking loop, the constant deceleration closed-loop electrical control device of each independent braking loop receives the same speed feedback signal, and a difference value obtained after the speed feedback signal is compared with the constant deceleration set point command signal serves as an input command of each independent braking loop to control the braking loop; each independent braking loop outputs a hydraulic medium to the same executive component; when any one or a plurality of independent braking loops work, the braking system works. The invention also discloses a safety braking control method for the mine hoist based on the system, so that any one or a plurality of braking loops in the effective working conditions output the hydraulic medium to the executive component to execute hoist drum braking work, and the safety braking reliability is improved.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

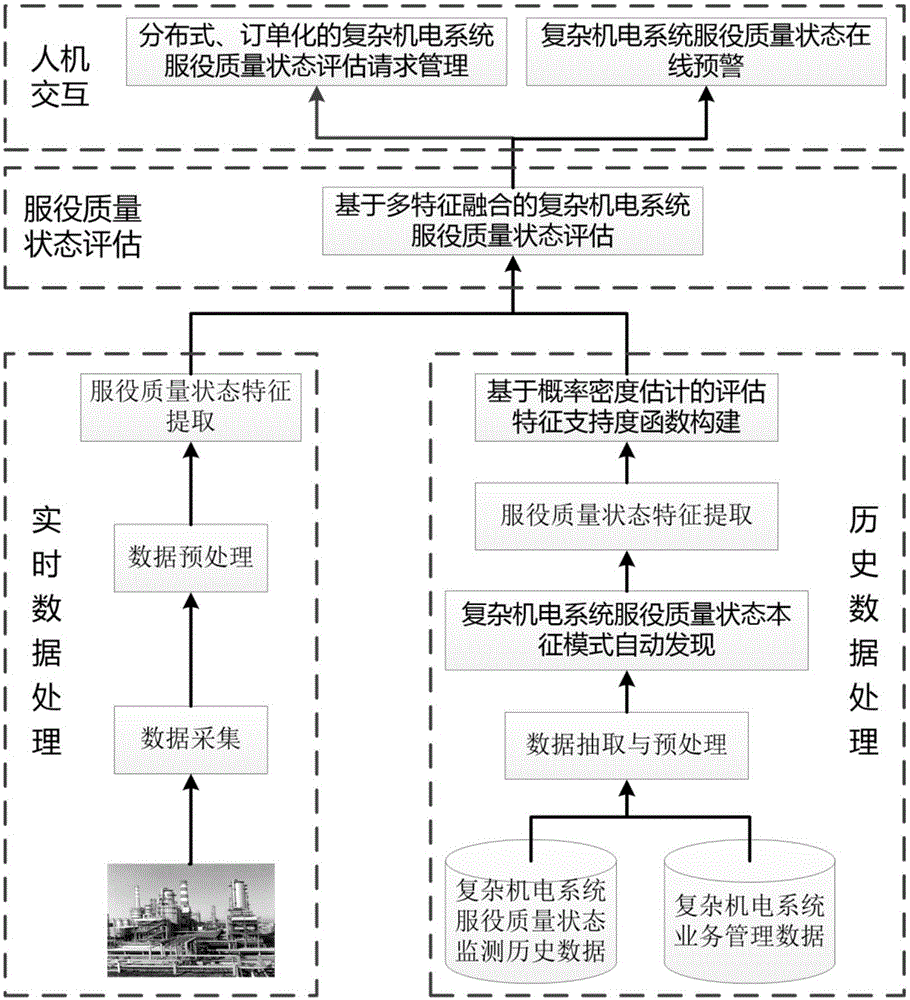

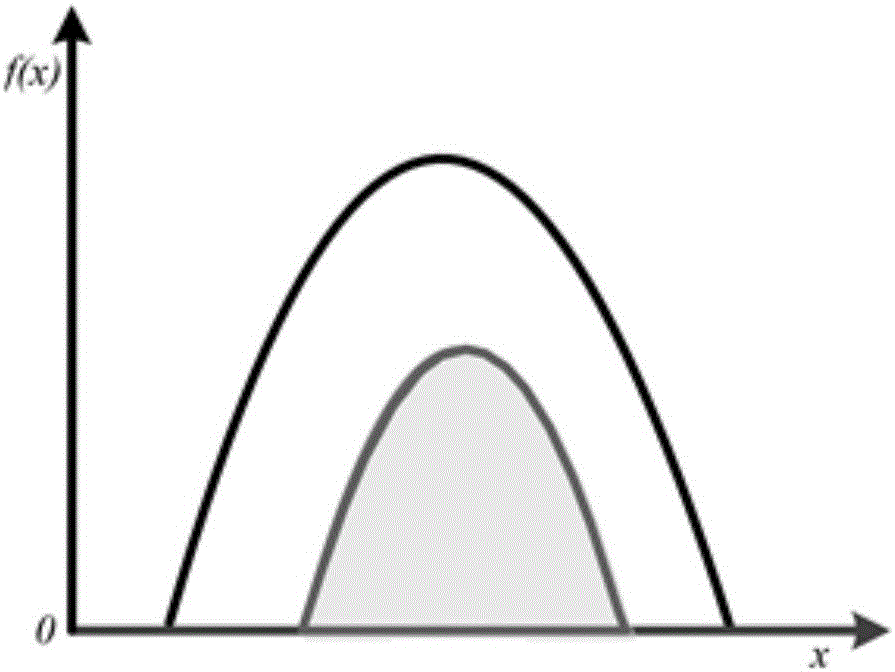

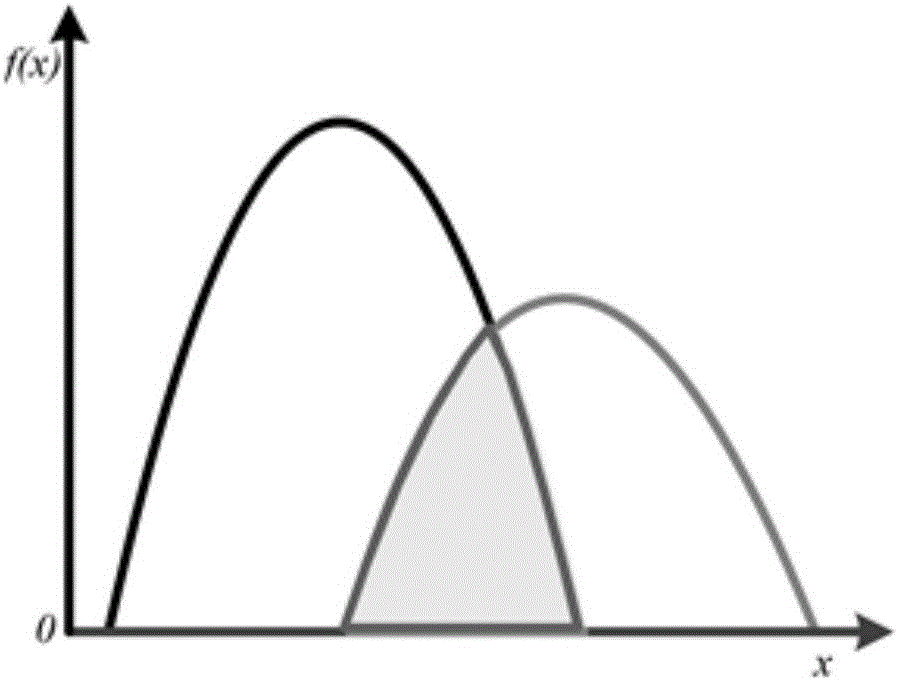

Data-driven complex electromechanical system service quality state evaluation method

ActiveCN106682835ARelaxed application conditionsAccurate assessmentRegistering/indicating during manufacturing processResourcesData-drivenComputer science

The invention discloses a data-driven complex electromechanical system service quality state evaluation method. Taking DCS state monitoring data and system service management data reflecting the system service quality state as the basis and depending on an information fusion theory, the data-driven complex electromechanical system service quality state evaluation method can perform real-time evaluation and early warning on the complex electromechanical system service quality state of an enterprise, and can perform early warning prevention on possible accidents in advance, and can assist scientific maintenance and repairing so as to improve the safety production level of the enterprise.

Owner:XI AN JIAOTONG UNIV

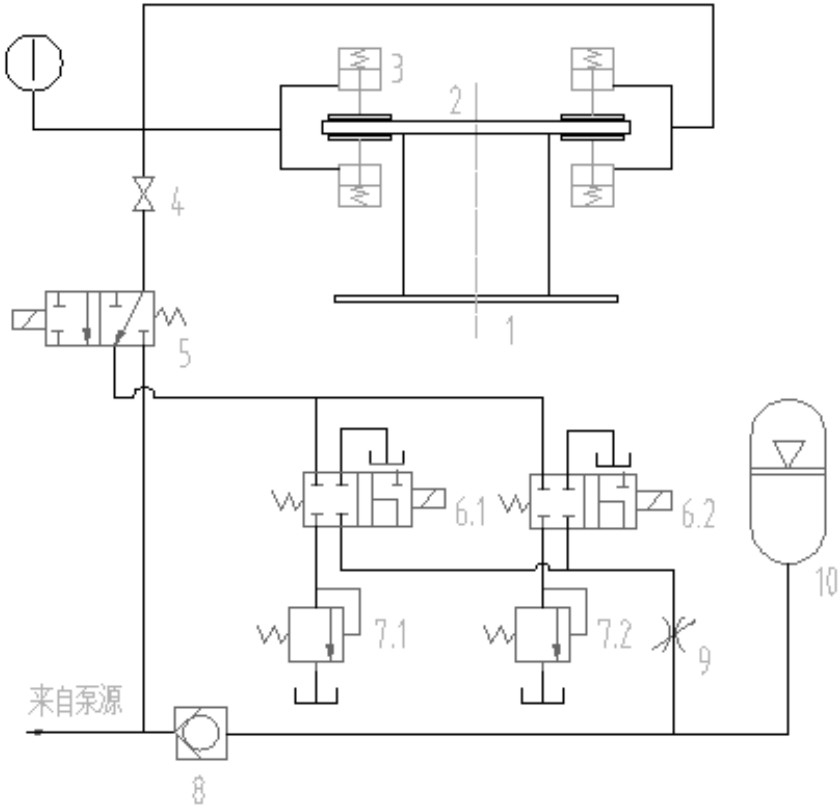

Dual-setting value constant torque secondary braking control system of mine hoister

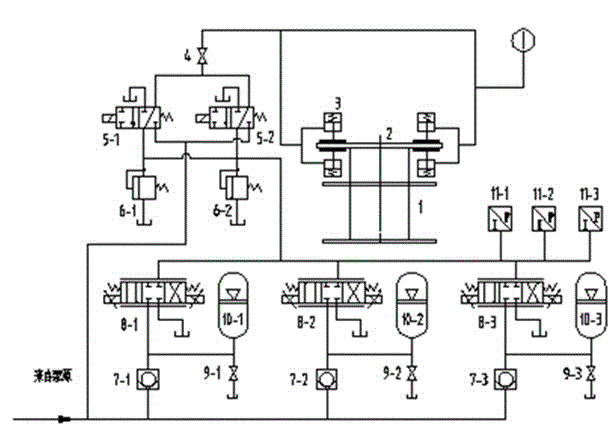

ActiveCN102139840AImprove production safety levelMeet the requirements of braking decelerationHoisting equipmentsHydraulic cylinderElectronic control system

The invention discloses a dual-setting value constant torque secondary braking control system of a mine hoister, which is designed to solve the situation that the existing constant torque secondary braking mode cannot cope with the variation of loading directions of the hoister. The system comprises a hydraulic pressure source, a directional control valve and a dual setting valve constant torque secondary braking hydraulic circuit, wherein the hydraulic pressure source comprises a pump and is used for supplying pressure oil to a hydraulic cylinder of a disc brake (3) during the period of the normal working mode; the directional control valve is arranged between the hydraulic pressure source and the hydraulic cylinder of the disc brake so as to realize the switching between the normal working mode and the safe braking mode of the hydraulic circuit; the dual setting valve constant torque secondary braking hydraulic circuit switches to a corresponding safe braking hydraulic circuit according to operational state signals of hoisting or lowering for a hoisting system, provided by an electronic control system, and selects an appropriate braking oil pressure value corresponding to the operational state of the hoisting system so as to brake the roller. The dual-setting value constant torque secondary braking control system of the mine hoister can preferably meet the safe braking requirements of the mine hoisting system under various conditions, thereby improving the braking performance and safety performance of the mine hoisting system.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

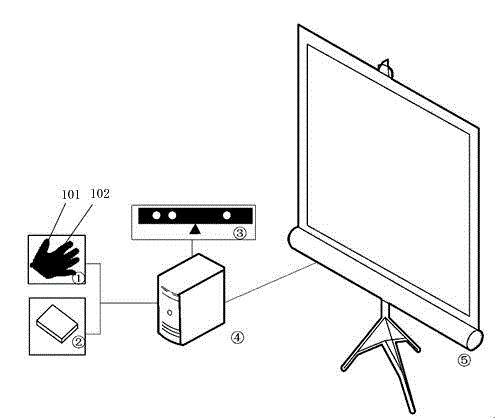

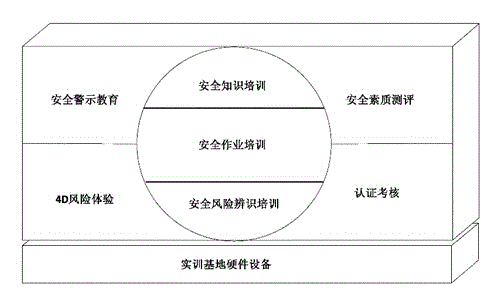

Precaution analysis system for distribution line and analysis method

InactiveCN104700679AImprove the quality of trainingImprove production safety levelCosmonautic condition simulationsSimulatorsHuman bodySomatosensory system

The invention discloses a precaution analysis system for a distribution line and an analysis method. The analysis system and analysis method are characterized by comprising gloves, a vibrator, a somatosensory device, a host machine and a display screen; the host machine is respectively connected with the gloves, the vibrator, the somatosensory device, and the display screen; the gloves are data gloves and internally provided with a temperature sensor and a humidity sensor which are used for sensing hand temperature and humidity data; the vibrator generates an impulse vibrating signal when wrong operation is happened, stimulates trainees and enhances the training effect; the somatosensory device catches movement action of human body, and displays corresponding operation action of a virtual person on the display screen. The precaution analysis system can realize interactively, lively and vividly staff safety training, and improve the electrical safety production knowledge and skill training quality.

Owner:JINZHOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +1

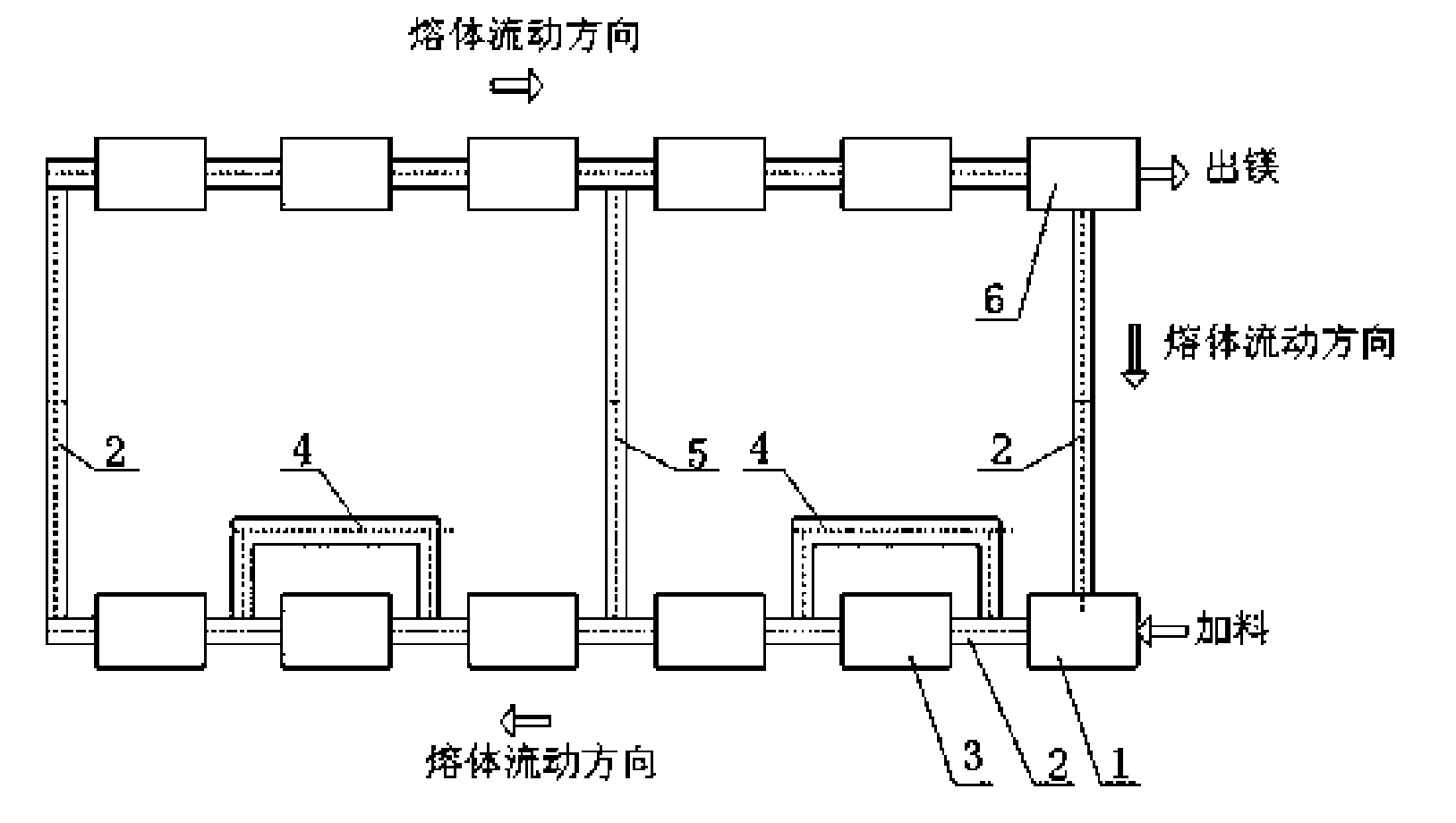

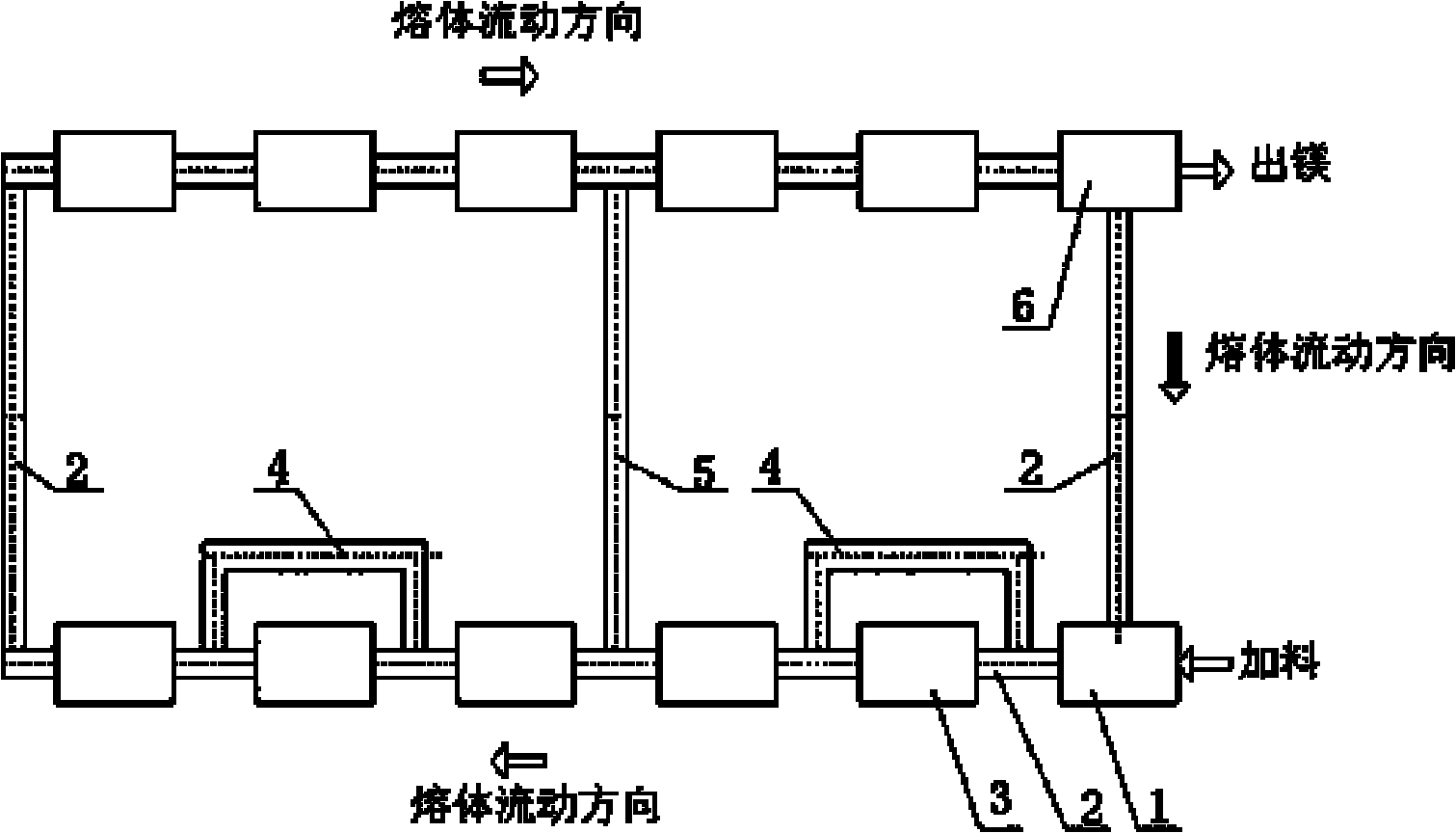

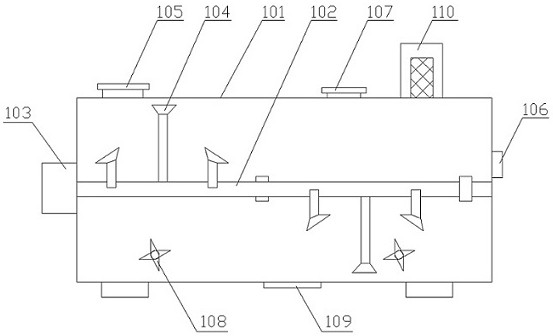

Flow line magnesium electrolysis production method

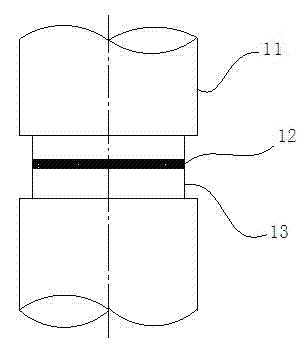

The invention discloses a flow line magnesium electrolysis production method. In the method, a head cell (1), a melt pipeline (2), an electrolysis cell (3) and a tail cell (6) are utilized; and the head cell (1), the electrolysis cell (3) and the tail cell (6) are connected in series through the melt pipeline (2) to form a closed cycle magnesium electrolysis production method. By adopting the method, the defect that the conventional magnesium electrolysis cell can only be operated independently is overcome, and centralized charging and centralized magnesium production of a magnesium electrolysis process are realized. The labor intensity of workers is reduced, and the frequency of conveying high-temperature melt through a crown block in a workshop is greatly reduced, so that the safety production level is improved.

Owner:GUIYANG AL-MG DESIGN & RES INST

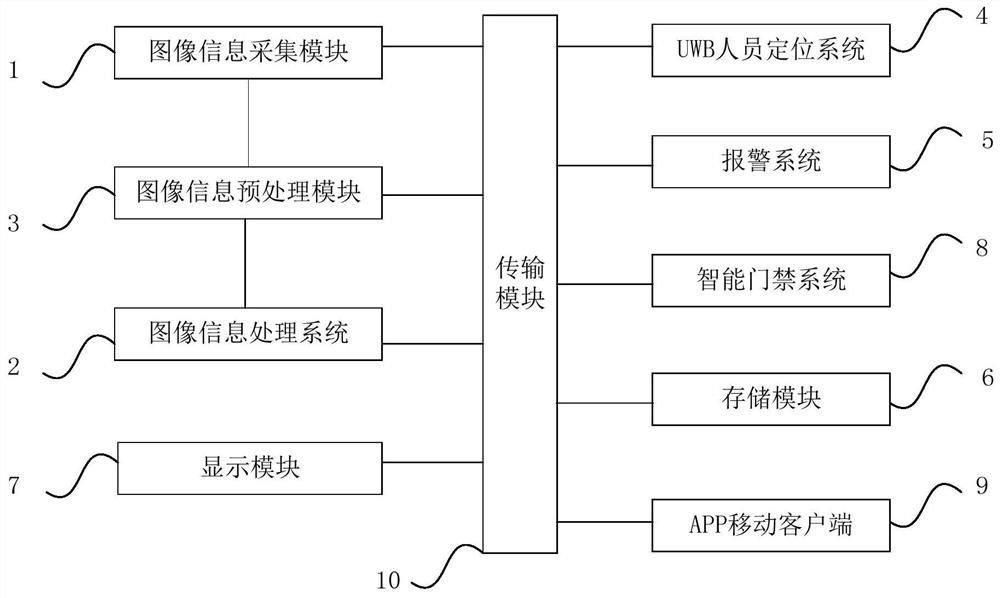

Substation operation site safety management and control system based on visual perception and spatial positioning

PendingCN112001310AEasy to understandAvoid safety accidentsCircuit arrangementsBiometric pattern recognitionInformation processingNerve network

The invention provides a substation operation site safety management and control system based on visual perception and spatial positioning, and the system comprises: an image information collection module which collects the image information of a substation operation site; an image information processing system which is used for identifying field personnel in the image information based on a firstneural network model, judging whether the field personnel wears safety protection equipment or not, judging whether the field personnel carry out illegal climbing operation or not and judging whetherthe field personnel are located in a non-operation live-line area or not, wherein the image information processing system further identifies a license plate number in the image information based on asecond neural network model; UWB personnel positioning system which is used for obtaining the position information of the transformer substation operation field personnel, obtaining the motion trailof the transformer substation operation field personnel according to the position information, and judging whether the field personnel is located in a non-operation live-line area, whether the distance from the field personnel to the high-voltage live-line equipment is smaller than a set distance threshold value and whether boundary crossing work is carried out according to the position information.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

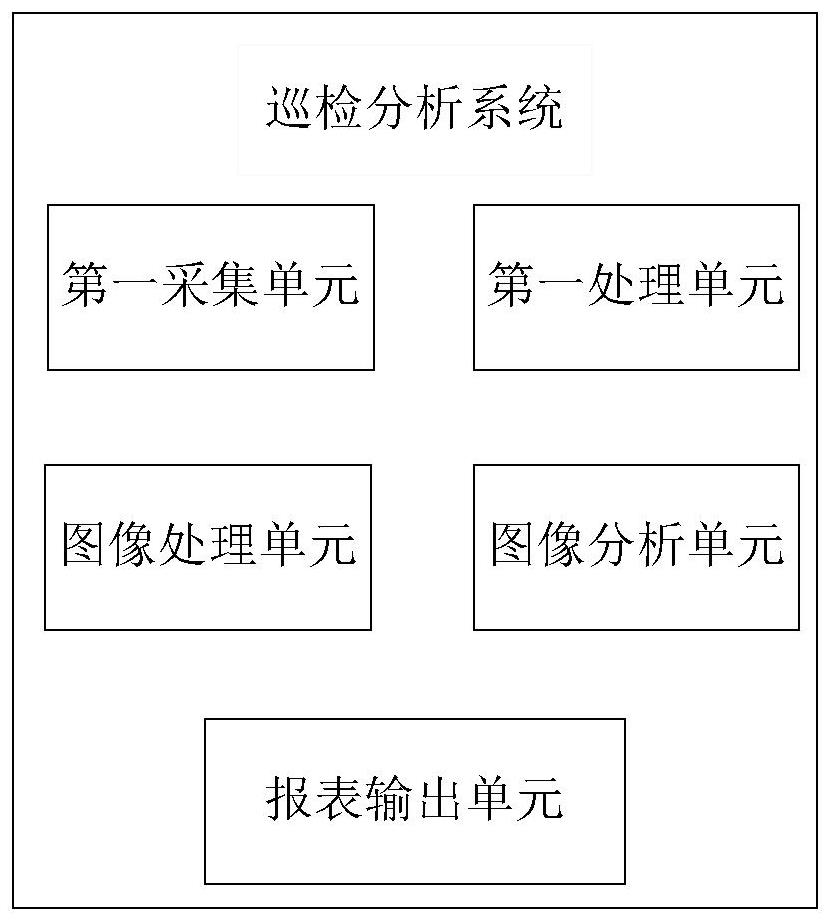

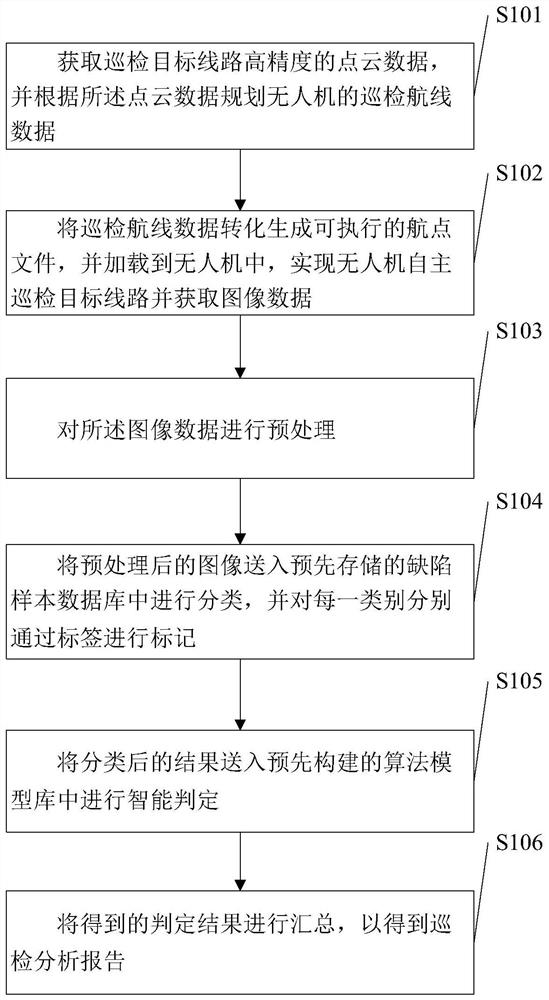

Inspection analysis system and method based on unmanned aerial vehicle

PendingCN114240868AEnhanced analysis and identification capabilitiesOvercoming the problem of adaptive detection of only a small number of defectsImage enhancementImage analysisImaging processingPoint cloud

The invention discloses an inspection analysis system and method based on an unmanned aerial vehicle, and the system comprises a first collection unit which obtains point cloud data, and plans the inspection route data of the unmanned aerial vehicle according to the point cloud data; the first processing unit is used for converting the inspection route data into an executable waypoint file and loading the executable waypoint file into the unmanned aerial vehicle to execute a flight task, so that the unmanned aerial vehicle autonomously inspects a target route and acquires image data; the image processing unit is used for preprocessing the image data; the image analysis unit is used for sending the preprocessed images into a pre-stored defect sample database for classification; sending a classified result into a pre-constructed algorithm model library for intelligent judgment; the report output unit is used for summarizing the obtained judgment results to obtain an inspection analysis report; the method has the advantages that the problem that only a small number of defects can be detected due to the adaptability of a single algorithm is solved, and the inspection quality and the inspection efficiency are improved while the engineering application detection accuracy is improved.

Owner:陕西省地方电力(集团)有限公司渭南供电分公司 +1

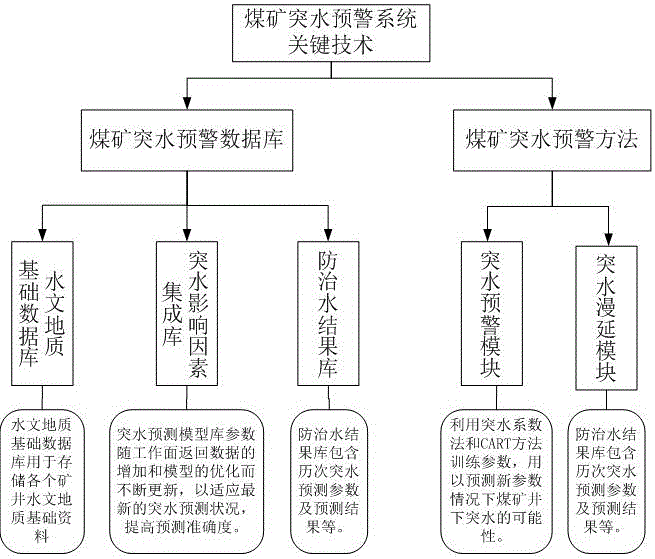

Coal mining water inrush early warning method based on GIS technology

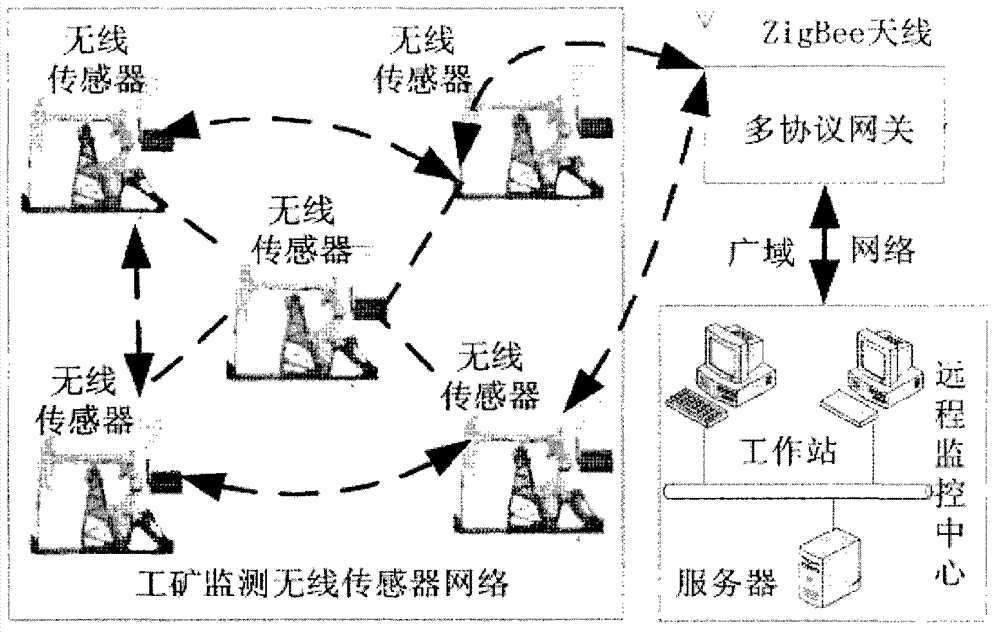

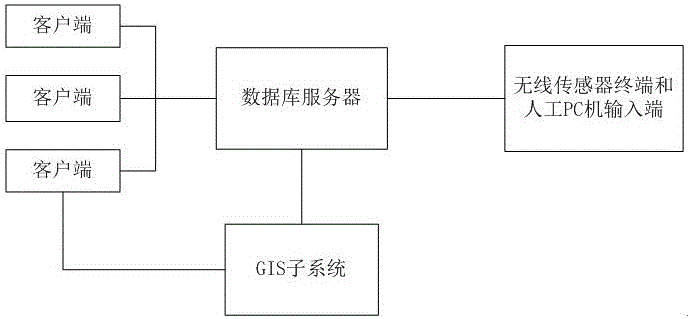

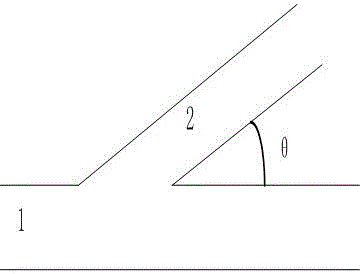

ActiveCN106453468AImprove production safety levelEasy to calculateNetwork topologiesTransmissionTime conditionSite monitoring

The present invention provides a coal mining water inrush early warning method based on a GIS technology. The system comprises one or more than one clients, a wireless sensor terminal and a PC input terminal; a GIS subsystem and a database server are connected with the PC input terminal through the wireless sensor terminal to store each real-time information; the wireless sensor terminal and the PC input terminal transmit the site monitoring information to the database server; the GIS subsystem requires updating the information in real time to the database and realizes the synchronization with the database server; and the clients synchronously receive the information from the database server and timely follow the real-time conditions of the downhole. The coal mining water inrush early warning method based on the GIS technology performs numerical modeling of underground coal mine multi-tunnel coupling with any angle to realize the visual and rapid display early warning of the macroscopic speed of each point of the virtual tunnel model.

Owner:TAIYUAN UNIV OF TECH

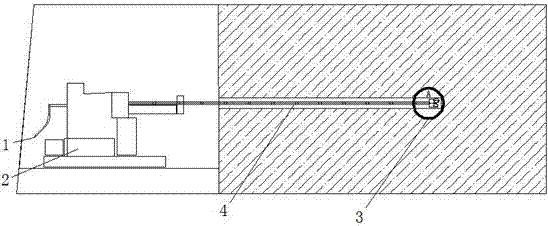

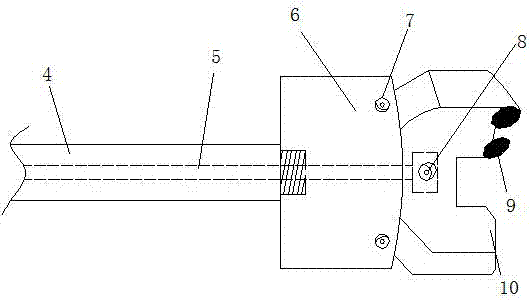

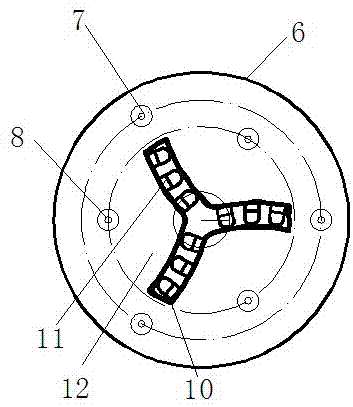

Hard coal anti-scouring pressure-relief boring construction method and equipment

ActiveCN107023295AIncreased pressure relief efficiencyImprove drilling efficiencyUnderground miningLiquid/gas jet drillingThree levelMechanical crushing

The invention discloses a hard coal anti-scouring pressure-relief boring construction method and equipment. A coal bed anti-scouring boring drilling technology integrating mechanical drilling and hydraulic jetting drilling is adopted. Firstly, high-pressure water is jetted to wash down coal mass, a drilling fracture surface is formed, then the coal mass washed down is crushed through a drill bit, and the high-pressure water flows back and carries out pulverized coal, so that the three-level boring drilling technology that rock is washed down hydraulically, crushed mechanically and carried out through backflow is achieved, and the effects of drilling, pore forming, dust settling, pulverized coal discharging and cooling are achieved. Through the crushing-after-washing drilling technology, the mechanical drilling mode is changed, characters of mechanical crushing are preserved, the boring drilling efficiency is improved, the hydraulic anti-scouring character is combined, and accordingly, the problems of low-efficiency drilling, getting stuck and stem loss, dust accumulation and the like of coal bed anti-scouring boring are effectively solved.

Owner:NORTH CHINA INST OF SCI & TECH +1

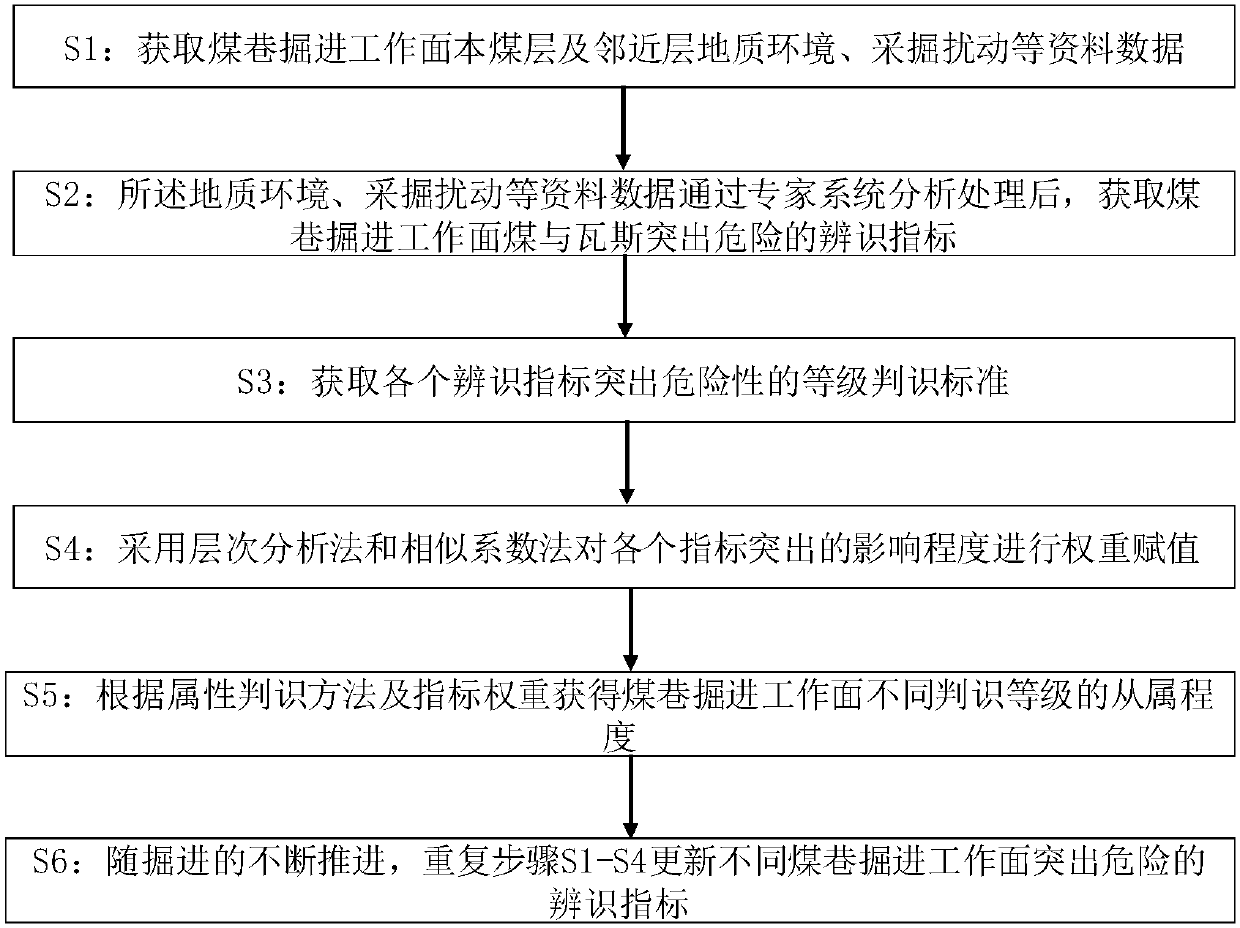

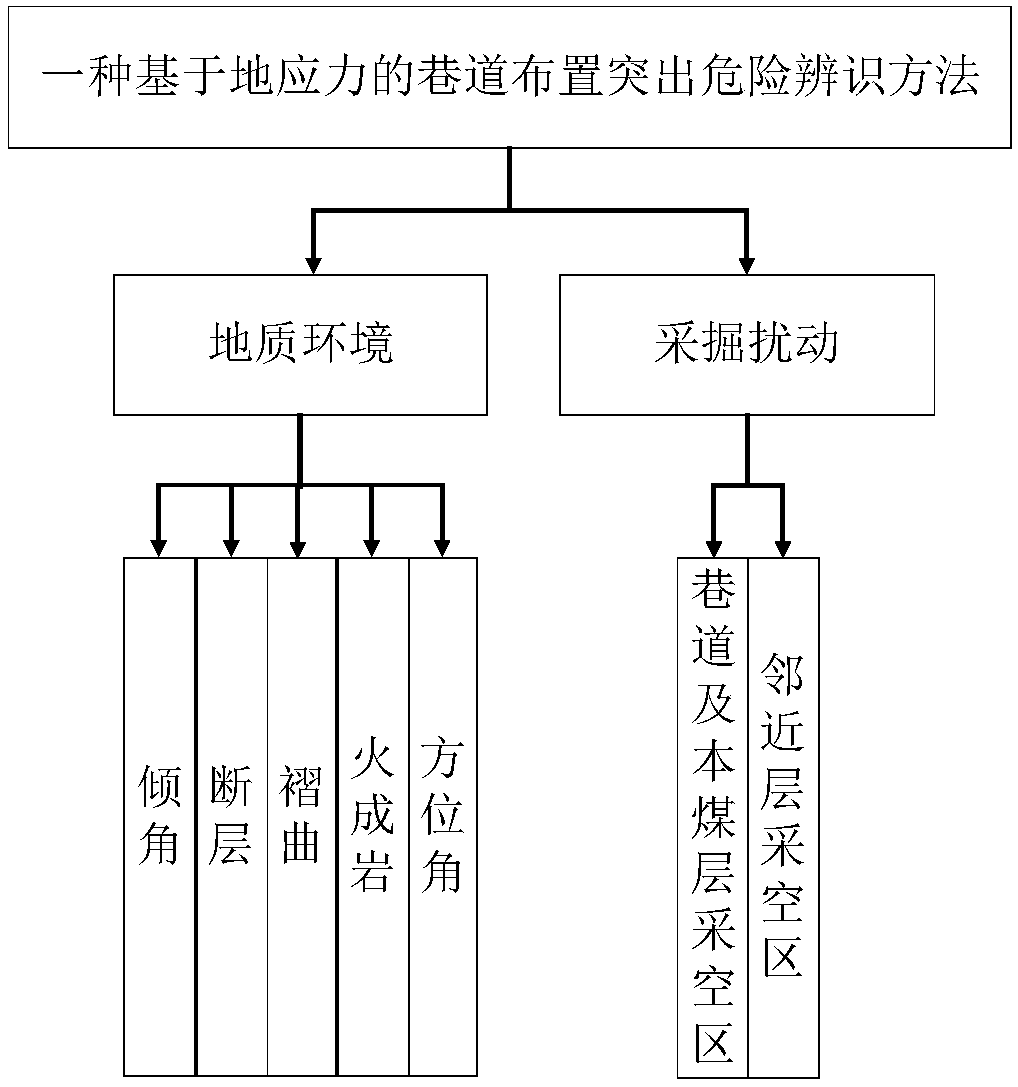

Stress concentration-based outburst risk identification method for coal roadway tunneling working surface

ActiveCN107784437AStrong index adaptabilityReduce outstanding disastersResourcesTechnical supportCoal

The invention discloses a stress concentration-based outburst risk identification method for a coal roadway tunneling working surface and belongs to the technical field of coal mine safety. The methodaims at solving the problem in the prior art that the outburst risk of the coal roadway tunneling working surface cannot be judged reasonably in the construction process. According to the method disclosed by the invention, main factors which influence the geological environment and the mining disturbance of the coal roadway tunneling working surface are quantified by adopting the stress concentration or superposition analysis method. A method for judging the stress concentration risk of the coal and the outburst risk of the gas is provided. Meanwhile, an important technical support is provided for the judgment of outburst risk-related stress concentration or superposition areas, and the outburst risk prevention of coal roadway tunneling.

Owner:CHONGQING UNIV

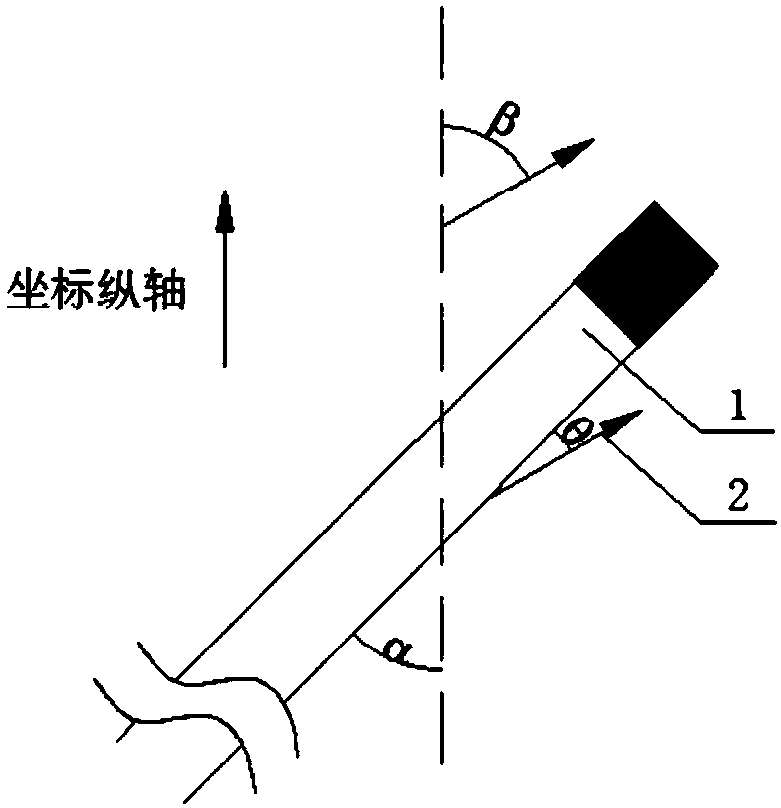

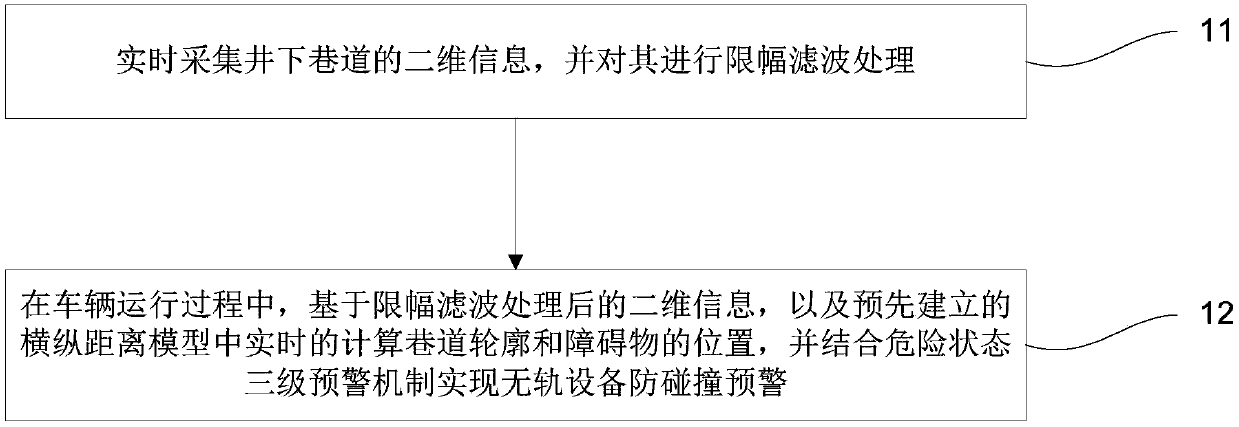

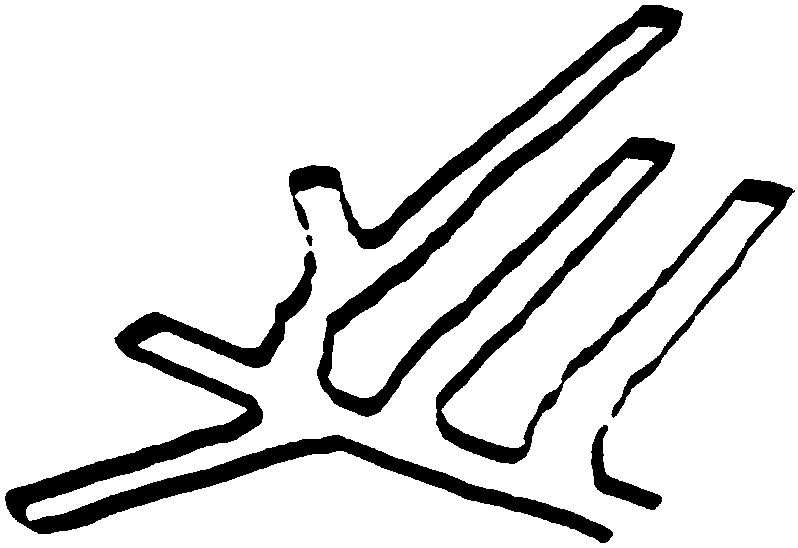

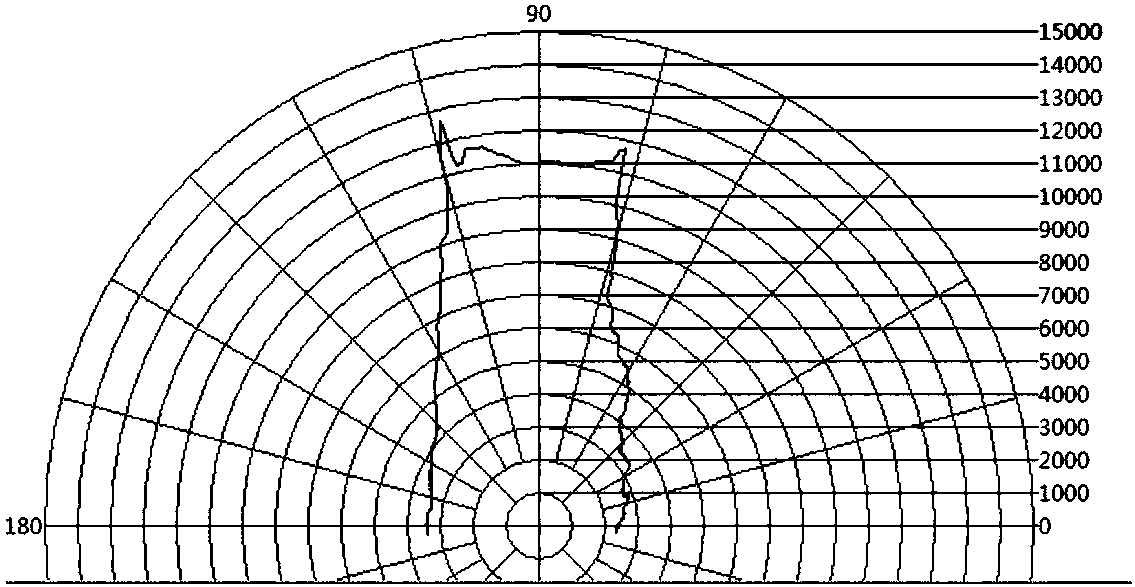

Collision avoidance method and device for underground mine trackless equipment

ActiveCN107561552AConstrained Movement Travel PathAvoid collisionElectromagnetic wave reradiationThree levelUnderground tunnel

The invention discloses a collision avoidance method and device for underground mine trackless equipment. The method comprises: collecting two-dimensional information of an underground tunnel in realtime and carrying out amplitude-limiting filter processing on the two-dimensional information; and during a vehicle driving process, calculating a tunnel contour and a obstacle location in real time according to the two-dimensional information after amplitude-limiting filter processing and a pre-established horizontal and vertical distance model, and carrying out anti-collision early warning of trackless equipment by combining a three-level dangerous state early-warning mechanism. With the method disclosed by the invention, mutual collision and person hitting accidents during the rapid drivingprocess of the trackless equipment can be avoided; and thus the accident risk of working of the underground trackless equipment is reduced.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

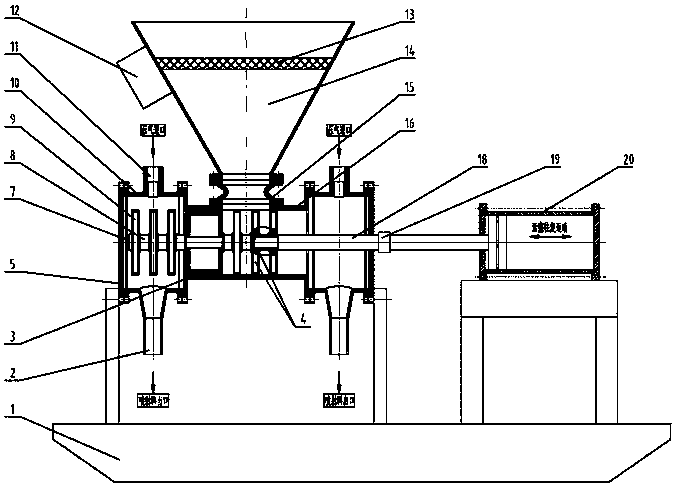

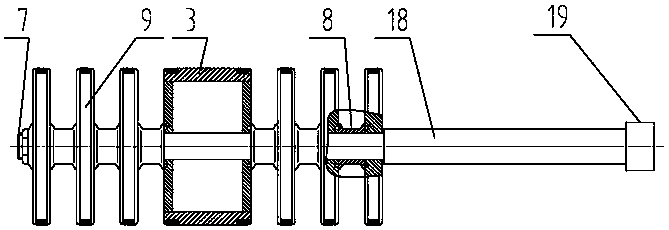

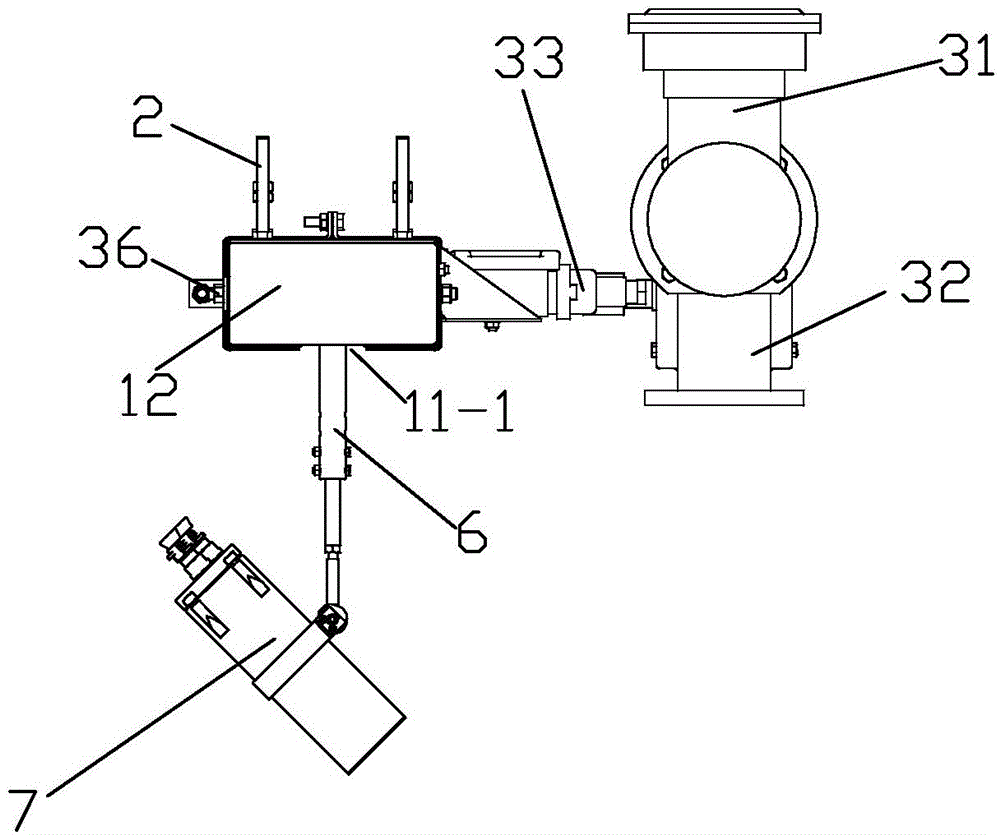

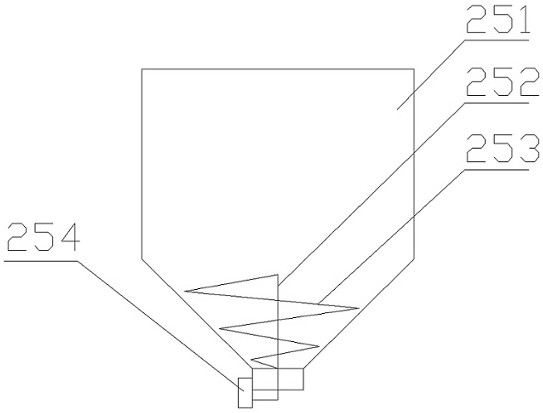

Sealed wet spraying machine

PendingCN110130351AImprove uniformityImprove construction levelUnderground chambersFoundation engineeringEngineeringPiston rod

The invention discloses a sealed wet spraying machine. The sealed wet spraying machine comprises a cylinder body, a material bin hopper, spraying material bins and a driving mechanism, wherein each spraying material bin is provided with a gas inlet and a spraying material outlet; a piston rod extending into the cylinder body is connected to the driving mechanism; material pushing assemblies and anintermediate sleeve are installed on the piston rod; aggregates entering the cylinder body through the material bin hopper can enter one side of the cylinder body at intervals through the intermediate sleeve; and the piston rod can move linearly in the cylinder body under the drive of the driving mechanism, so that the aggregates enter one of the spraying material bins through the material pushing assemblies. The sealed wet spraying machine has the advantages that compressed air in the spraying material bins is kept sealed with a concrete hopper, simultaneous feeding and spraying operations are realized, the working efficiency and the uniformity of concrete mixing are greatly improved, the structure design is skillful the occupied space is small, the maintenance and operation are convenient, the construction level and quality of support are greatly improved, the safety production level is greatly improved, and the construction site environment is greatly improved.

Owner:周常武

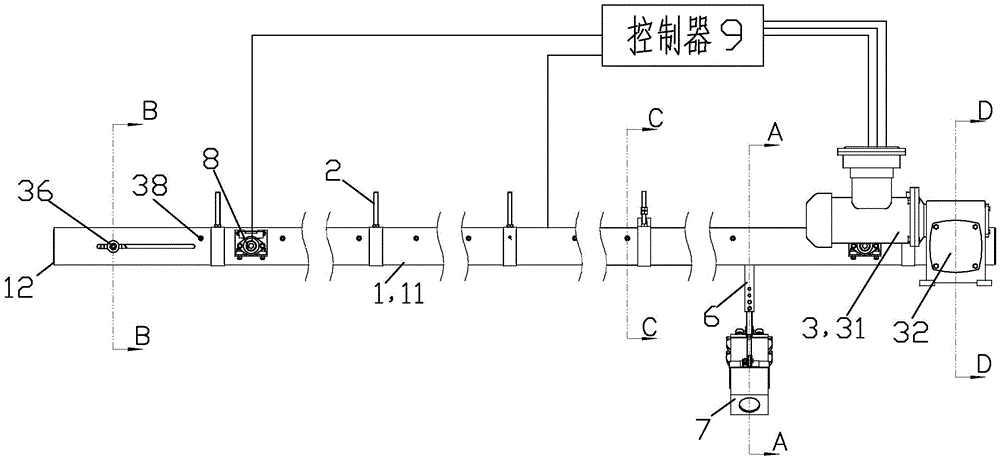

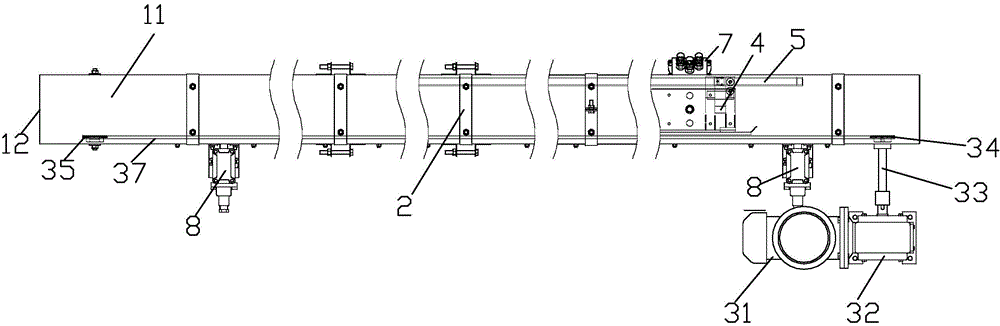

A mining explosion suppression moving camera-shooting system

ActiveCN104135602ASimple structureLow costTelevision system detailsMining devicesLinear motionVideo monitoring

The invention provides a mining explosion suppression moving camera-shooting system. The system includes: a rail, a suspending piece, a drive assembly, a moving trolley, a tank chain, a suspending arm, a camera-shooting instrument, explosion suppression travel switches, and a controller, wherein, the drive assembly includes a motor, a speed reducer, a drive shaft, a driving chain wheel, a driven chain wheel, a drive chain, a tightening screw, a chain supporting shaft, and a chain support; the suspending piece is connected fixedly to the rail and is used for installation of the rail 1; the tank chain and the suspending arm are connected fixedly to the moving trolley respectively; the controller controls the drive assembly, to drive the moving trolley to realize leftward and rightward linear motion, and correspondingly to drive the camera-shooting instrument to realize a leftward and rightward motion, thus moving camera-shooting function is realized; and the explosion suppression travel switches are configured to limit locations where the moving trolley moves in the leftward and rightward directions. The invention can be applied effectively to a particular explosion suppression usage environment of a coal mine, and can realize video monitoring in an environment where there is unattended operation of the coal mine, which improves effectively a safety production level of the coal mine, and the system of the invention has the advantages of simple structure, low cost and easy implementation and installation.

Owner:TIANDI CHANGZHOU AUTOMATION +1

Safe overhauling and monitoring method for substation primary equipment

ActiveCN103246964AImprove production safety levelImprove the level of safety maintenanceResourcesInformation technology support systemFixed frameInter frame

The invention discloses a safe overhauling and monitoring method for substation primary equipment. The method comprises the steps of utilizing an electrified interval to compute the distance between technical measuring work staff and a bus; utilizing a video speed measuring technology to measure the instant speed of a passing vehicle; directly obtaining the time variable by the fixed frame interval time of video signals, indirectly computing the changing distance of the vehicle or people in the fixed frame interval by other methods, measuring the speed of the vehicle or people, and alarming when the speed exceeds the set value; and computing the safe distance between equipment and the vehicle as well as the people, wherein the principle for measuring the instant speed of the passing vehicle is that the speed is the ratio of distance and time. The safe overhauling and monitoring method for the substation primary equipment can be widely applied to the overhauling and monitoring field, thus effectively improving the occurrence of accidents of people electric shock and equipment damaging; and the realizing of the overhauling and monitoring method can directly improve the safe overhauling level of electric enterprises.

Owner:STATE GRID CORP OF CHINA +2

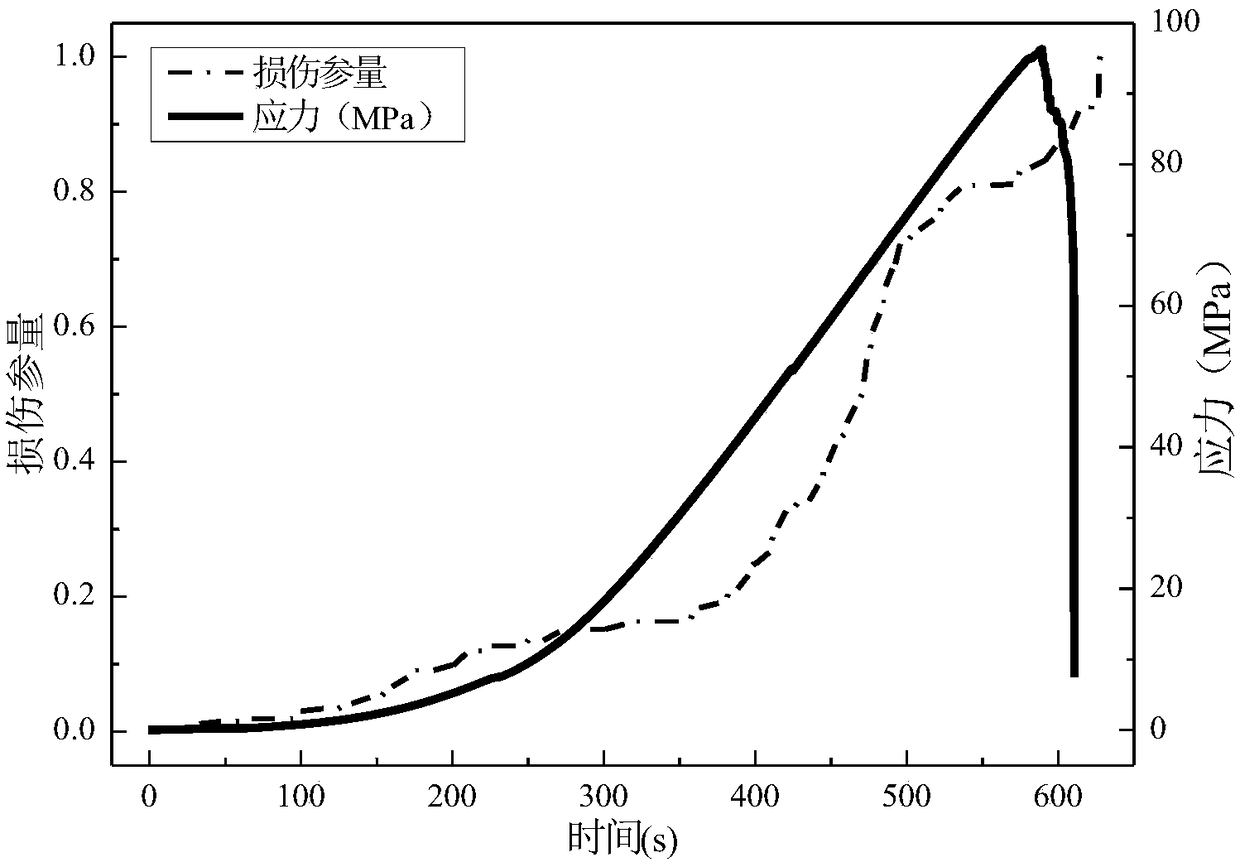

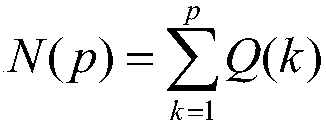

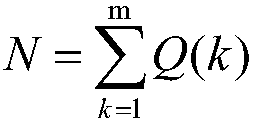

Infrared radiation quantification representing method for bearing coal rock damage evolution

The invention discloses an infrared radiation quantification representing method for bearing coal rock damage evolution. By using the method, a maximum value in a coal rock infrared radiation variabletemperature matrix is taken as a threshold value used for bearing the infrared radiation change of coal rock caused by micro-element damage, the cumulative number of infrared radiation in a bearing coal rock damage evolution process is screened, and the infrared radiation quantification representing method for bearing coal rock damage evolution is constructed based on a continuous damage mechanics theory. Through monitoring infrared radiation data in real time, the real-time process of coal and rock mass damage evolution can be dynamically and accurately evaluated, a mine safety production level is improved and the stability and the precision of coal and rock mass monitoring in modern rock mechanics and an engineering field are increased.

Owner:CHINA UNIV OF MINING & TECH

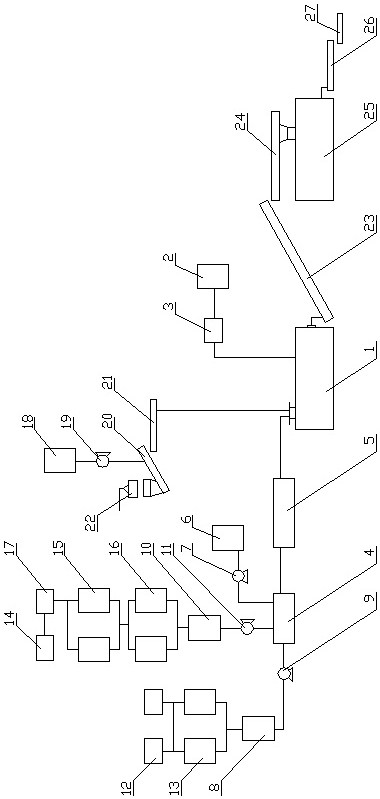

Continuous production line and continuous production method for emulsified ammonium nitrate fuel oil explosive

InactiveCN111892464AEnsure personal safetyIncrease productivityMixing methodsTransportation and packagingProduction lineExplosive Agents

The invention relates to a continuous production line and a continuous production method for an emulsified ammonium nitrate fuel oil explosive. The production line comprises a latex matrix continuouspreparation system, an ammonium nitrate fuel oil explosive continuous preparation system, continuous mixing equipment and an automatic filling system, material outlets of the latex matrix continuous preparation system and the ammonium nitrate fuel oil explosive continuous preparation system are connected with a material inlet of the continuous mixing equipment, wherein a continuous material outletof the continuous mixing equipment is connected with a material inlet of the automatic filling system, and the production method comprises the following steps of: simultaneously and continuously conveying the ammonium nitrate fuel oil explosive and the cooled latex matrix into the continuous mixing equipment for mixing, adding wood flour into the mixture, and continuously performing mixing to prepare the emulsified ammonium nitrate fuel oil explosive. Continuous production of the emulsified ammonium nitrate fuel oil explosive can be achieved, the production efficiency is high, the productivity is large, the automation level is high, no fixed operation post exists on the whole line, the number of operators is small, the production safety level is high, and due to the adoption of the continuous production mode, the product consistency is high, and the quality is stable and reliable.

Owner:北京京煤化工有限公司

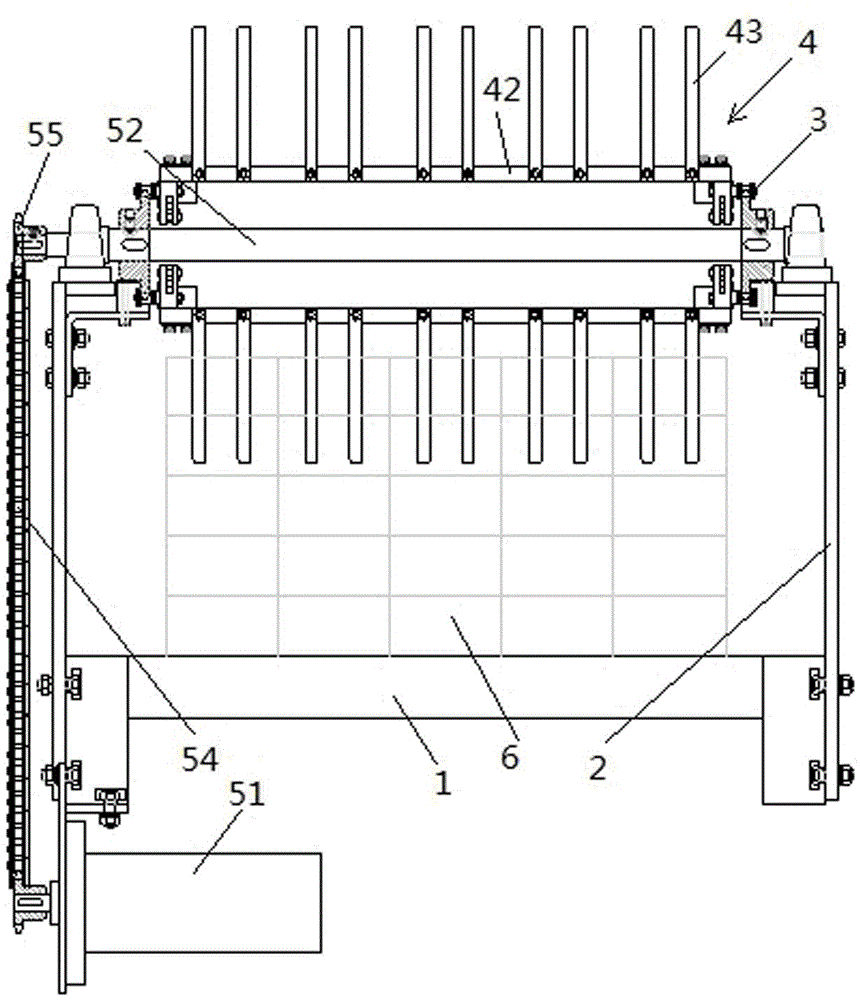

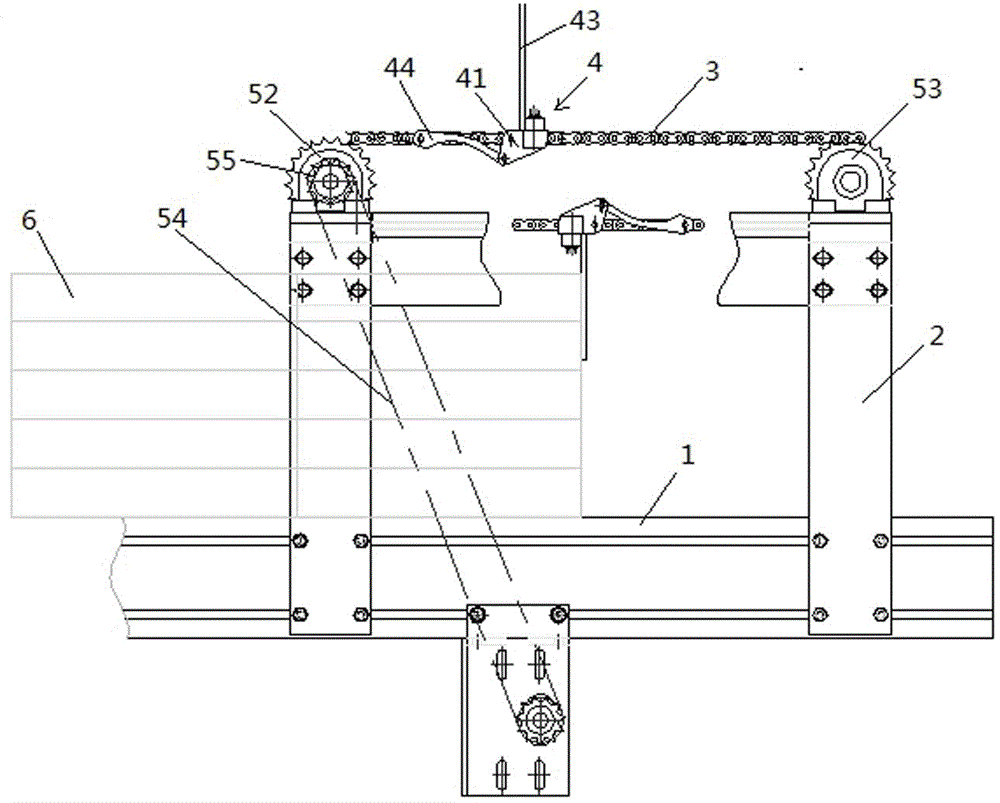

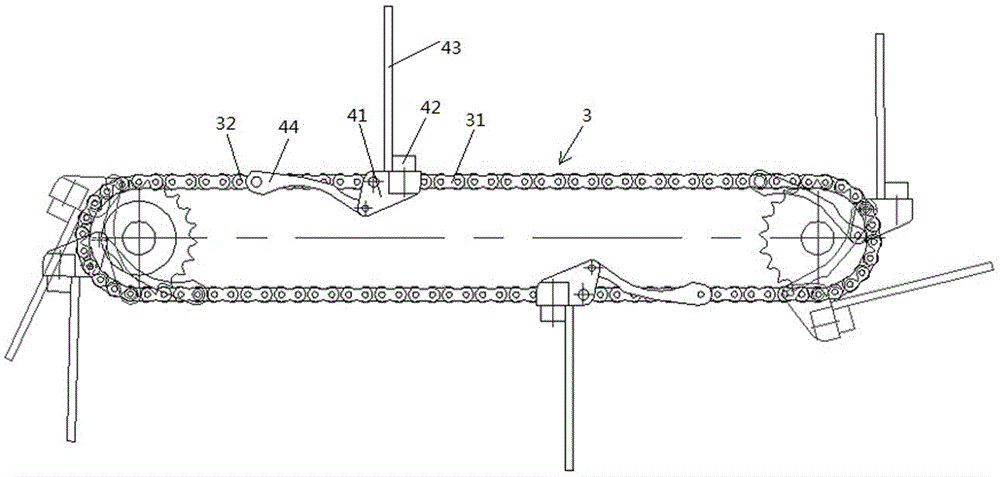

Semi-automatic sorting cigarette carton shifting device capable of preventing cigarette cartons from sliding

ActiveCN106144570ASave on maintenance and replacement costsImprove production efficiencyConveyor partsCartonSemi automatic

The invention relates to a semi-automatic sorting cigarette carton shifting device capable of preventing cigarette cartons from sliding. The semi-automatic sorting cigarette carton shifting device capable of preventing cigarette cartons from sliding comprises a conveyer belt mechanism which is longitudinally arranged, wherein one supporting frame is arranged on each of the two sides of the conveyer belt mechanism, each supporting frame is provided with a transmission chain which is driven by a driving mechanism to rotate coaxially, and shifting rod mechanisms are arranged between the two transmission chains at intervals in the circular direction of the transmission chains, are used for shifting the cigarette cartons to make the cigarette cartons to move forward so as to be conveyed and go up or down in an arc manner. The semi-automatic sorting cigarette carton shifting device capable of preventing cigarette cartons from sliding can be conveniently used for shifting cigarette cartons for conveying.

Owner:福建省烟草公司莆田市公司

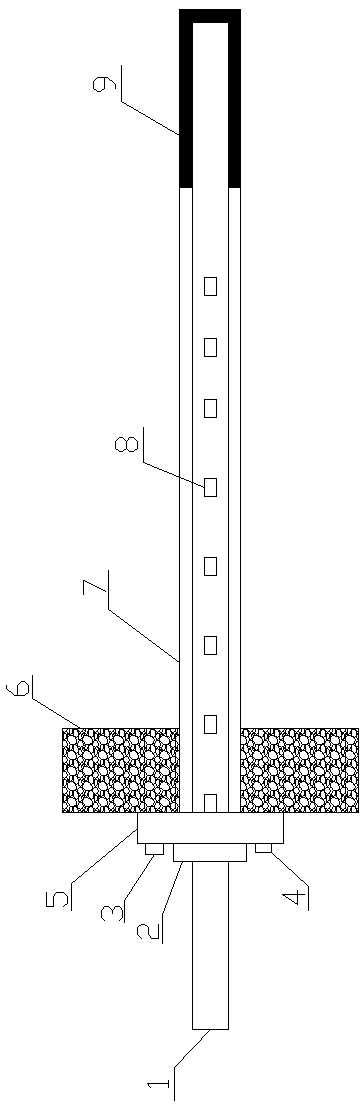

Mining monitoring early warning anchor rod

InactiveCN109578039AReal-time monitoring of force statusMaintain stabilityAnchoring boltsElectrical resistance and conductanceEngineering

The invention discloses a mining monitoring early warning anchor rod arranged in a rock wall. The anchor rod comprises a body and resistance strain gauges arranged on the body, the body comprises a rod body, a supporting plate and a screw cap, one end of the rod body extends into the rock wall, and the resistance strain gauges are uniformly arranged at the parts, extending into the rock wall, of the rod body; the resistance strain gauges are used for detecting the stress borne by different positions of the rod body, the supporting plate and the screw cap sequentially sleeve the portion, outside the rock wall, of the rod body, and the supporting plate is tightly attached to the rock wall; the screw cap is arranged on the outer side of the supporting plate; due to the screw cap, the rod bodyis fixed to the rock wall, a controller is arranged on the supporting plate, and the controller is connected with the resistance strain gauges. The stress state of the anchor rod can be monitored inreal time; when the anchor rod loses efficacy, people can quickly perceive and take corresponding measures to maintain the stability of a roadway support, casualties caused by improper supporting of aroadway are reduced, the safety production level of a mine is improved, and the safety of coal mine personnel and property is guaranteed.

Owner:HENAN POLYTECHNIC UNIV

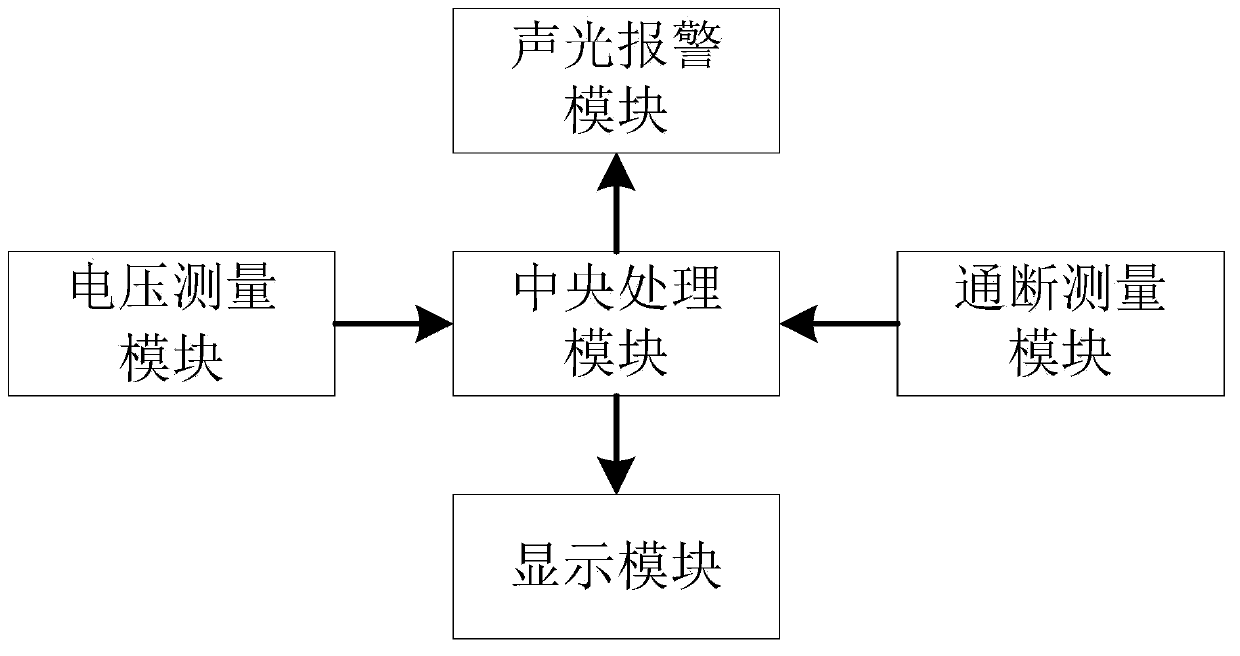

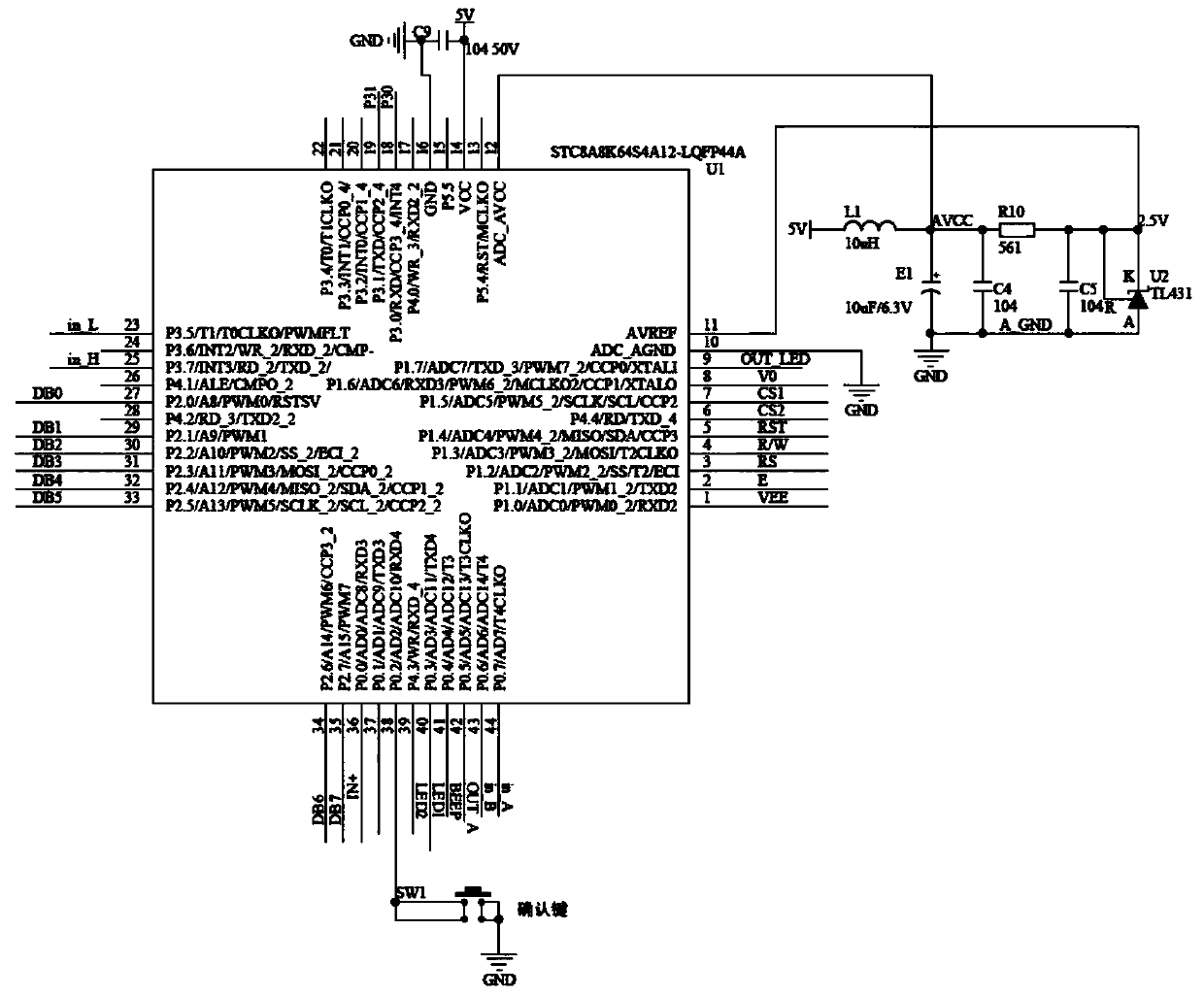

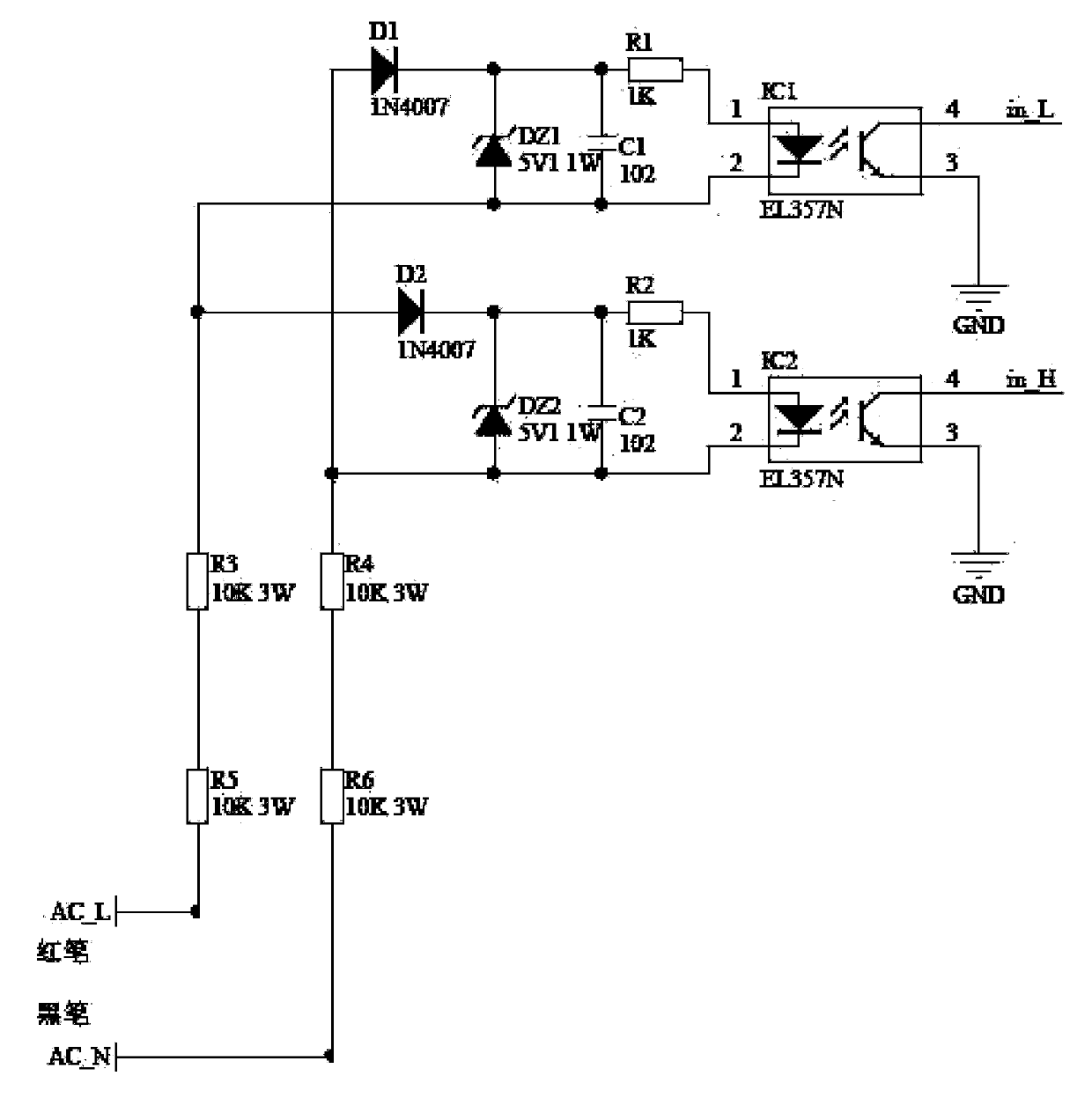

Substation secondary loop break-make measuring instrument

PendingCN109991504AImprove production safety levelEasy to operateElectrical testingElectricityMeasuring instrument

The invention discloses a substation secondary loop break-make measuring instrument. The substation secondary loop break-make measuring instrument is used for measuring a live secondary loop of a substation; the substation secondary loop break-make measuring instrument comprises a central processing module, a voltage measuring module, a break-make measuring module and a program module, wherein thevoltage measuring module is used for performing voltage measurement on the secondary loop and electrically connected with the central processing module; and the break-make measuring module is used for performing break-make measurement on the secondary loop during no-voltage of the secondary loop, and the break-make measuring module is electrically connected with the central processing module. Thesubstation secondary loop break-make measuring instrument has the beneficial effects that 1, the security production level is improved, and when break-make test of the secondary loop is carried out in a running substation, serious consequences that electric components incorrectly operate, a power source is grounded and the like due to the fact that the live loop is accidentally touched are solved; and 2, the working efficiency is improved, through an integrated design scheme of voltage measurement and break-make test, the operation is easy, and the labor operation level of workers is improved.

Owner:GUANGDONG POWER GRID CO LTD +1

Power transmission line concrete rod weld joint corrosion prevention method

InactiveCN102900155AReduce erosionReduce corrosionTowersBuilding insulationsHeat-affected zoneStructural engineering

The invention discloses a power transmission line concrete rod weld joint corrosion prevention method. According to the method, a protection device with the inner diameter equal to the outer diameter of a concrete rod and being provided with upper and lower seal rings is adopted to isolate the corrosive damage from corrosive gases of all kinds outside, ultraviolet as well as frost and rain water to the weld joints and the metal at the heat affected zone of the weld joints of the power transmission line concrete rod so as to improve the corrosion resistance of the concrete rod. The method has an obvious effect of preventing the corrosions at the weld joints and the metal at the heat affected zones of the weld joints of the power transmission line concrete rod, and can effectively prevent power failure in large area caused by collapse of the power transmission line concrete rod due to the cracking of the concrete rod caused by corrosion of the weld joints. Therefore, the method can improve the production safety level of power transmission and distribution. The method is applicable for protection for weld joints of power transmission line concrete rods and concrete frames of transform substations.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

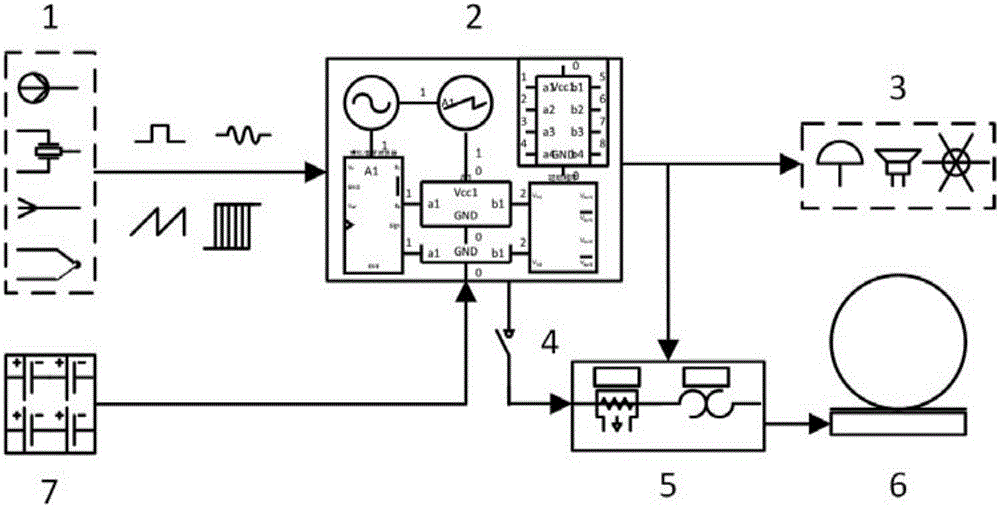

MVR mobile control system

InactiveCN107008022AReduce dependenceEasy to controlEvaporator regulation/controlProgramme control in sequence/logic controllersTablet computerDigital video

The invention discloses an MVR mobile control system, which comprises an industrial panel computer, Internet, a cable wire, an Ethernet module, a PLC (programmable logic controller), a camera, a coaxial cable, a DVR (digital video recorder), a wireless router, a gain antenna and a wireless signal. The industrial panel computer receives a wireless signal sent from the gain antenna; the wireless router is accessed into the Internet; the PLC is additionally provided with the Ethernet module; the Ethernet module is accessed into the wireless router through the cable wire; the camera is accessed into the DVR through the coaxial cable; the DVR recorder is accessed into the wireless router through the cable wire; the wireless router is connected with the gain antenna through the coaxial cable; the gain antenna transmits signals to the industrial panel computer. The MVR mobile control system disclosed by the invention has the gain effects that the relying of MVR evaporation equipment on the number of operators is reduced; the system operation and running problem is directly monitored and treated by a process inspector; the enterprise automation level is improved.

Owner:GUANGZHOU SCHIN TECH IND CO LTD

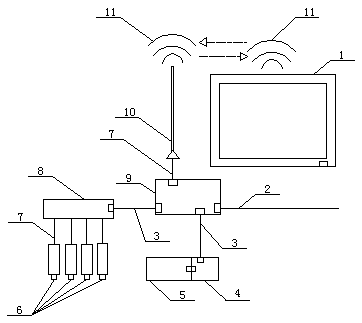

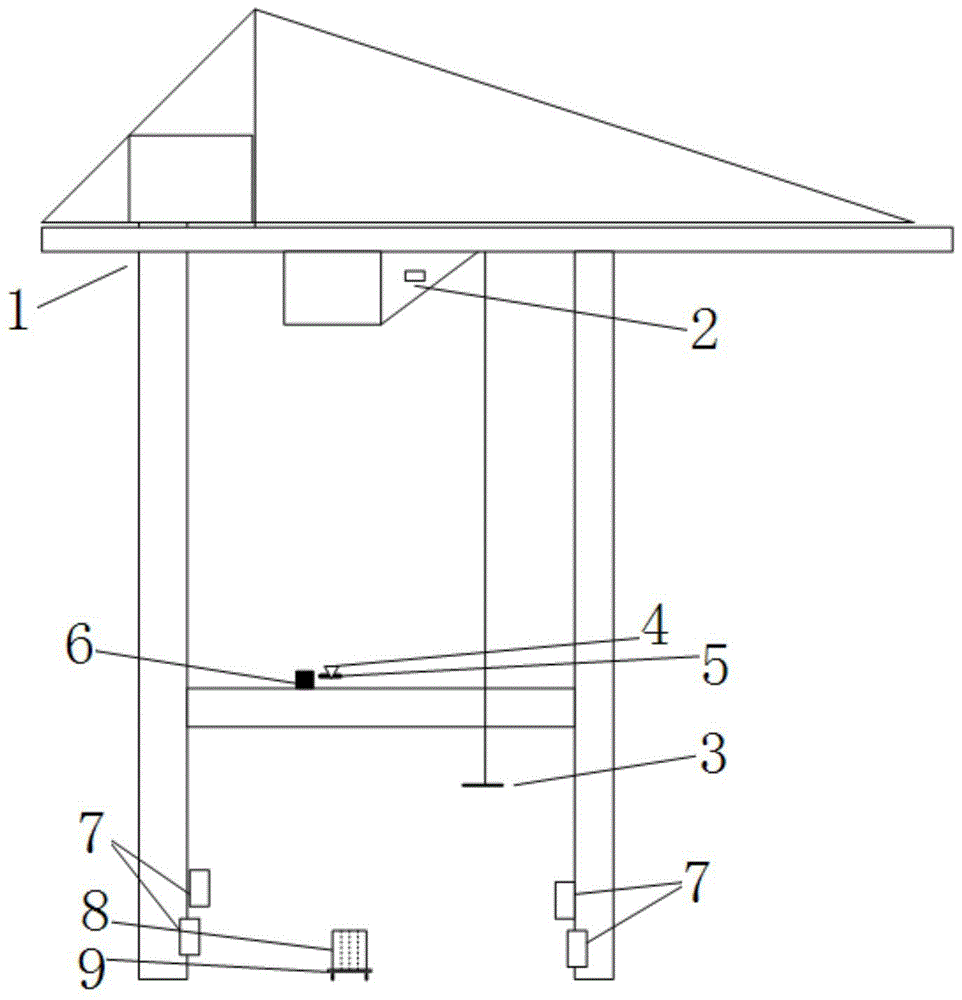

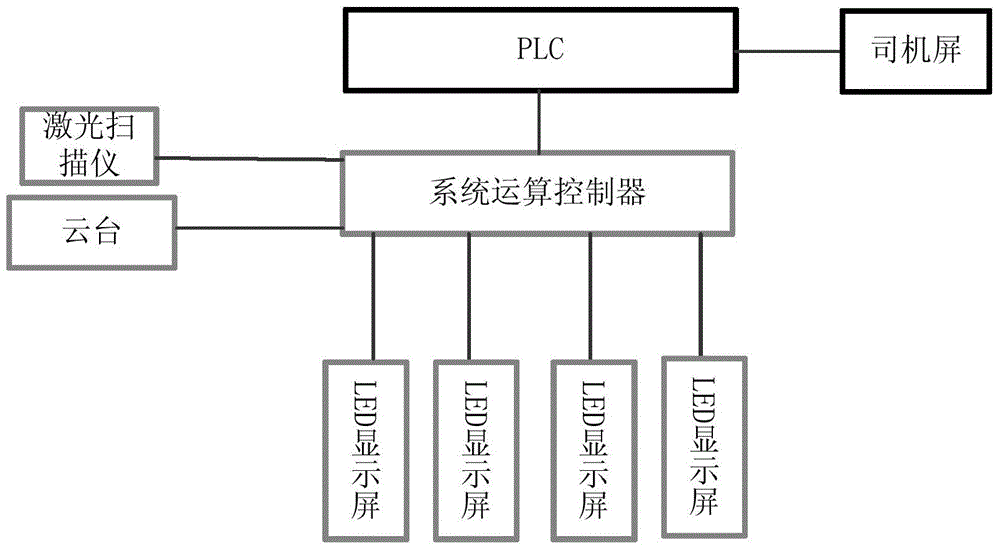

Alignment and safety control system and method for trucks under bridge crane in container wharf

The invention discloses a system and method for alignment and safety control of trucks under bridge cranes of container wharves. Through a rotating platform, a laser scanner, a system operation control unit and an LED display screen, the accurate identification of the deviation distance between the position of a truck and the benchmark lifting point of an offshore bridge is realized, and the direction of the truck deviating from the lifting point of the offshore bridge and the distance information are displayed on the LED display screen to prompt the driver of the truck to adjust the truck parking position; meanwhile, the operation control unit is connected with a PLC to obtain the type information of the container which runs at present so as to realize the guidance of the truck parking position; a control system of the PLC judges whether the truck is in place through the interface, and controls a lifting device to keep a safety height and forbids the lowering action of the bridge lifting driver when the truck is not aligned so as to prevent the truck from being damaged by the lifting device.

Owner:CATHAY NEBULA SCI & TECH CO LTD

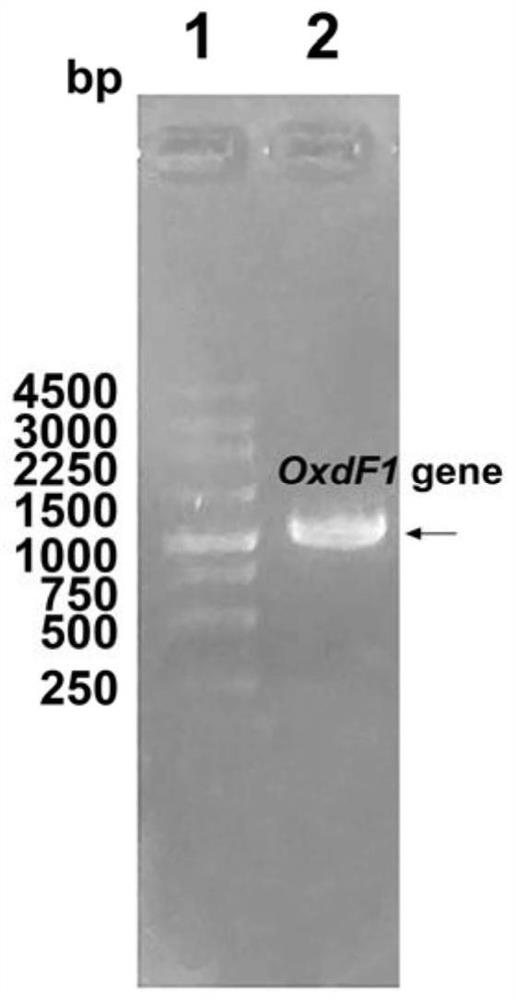

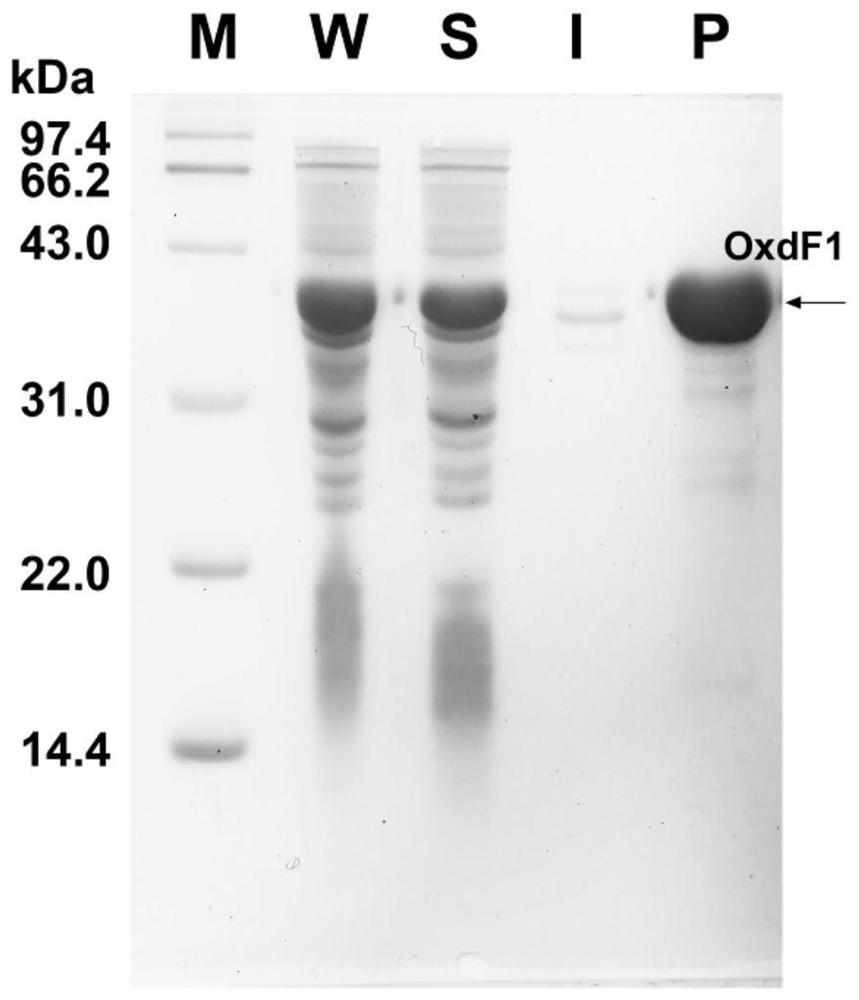

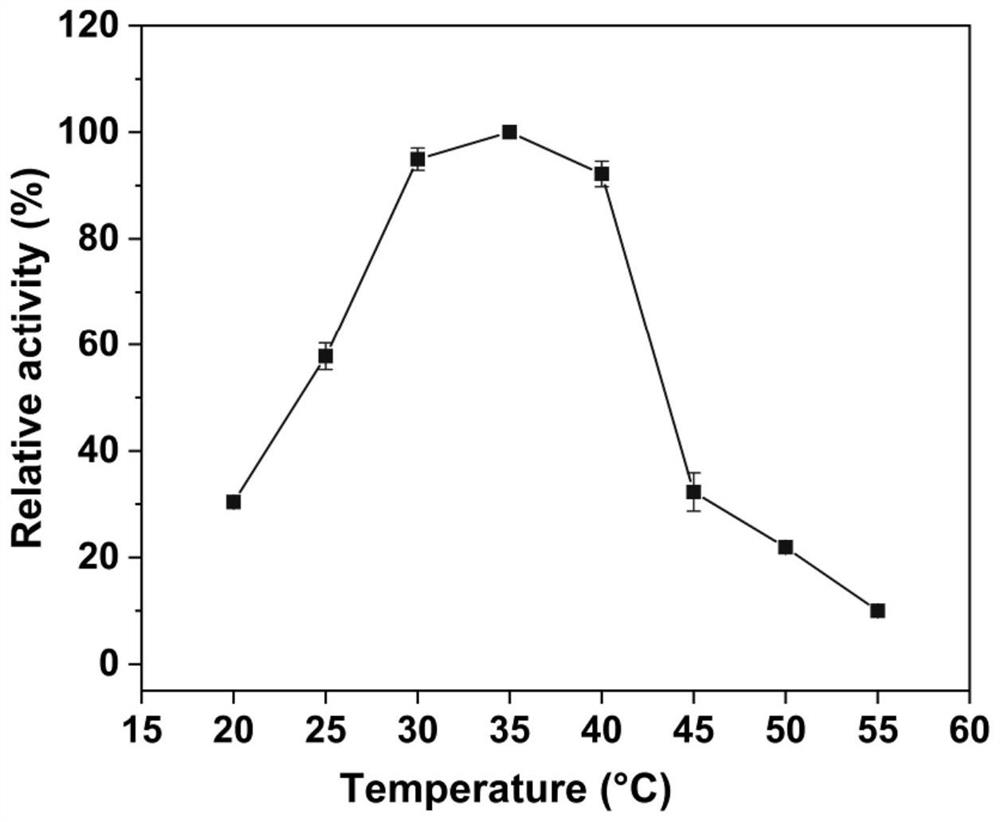

Aldoxime dehydratase and application thereof in catalytic synthesis of aromatic nitrile compounds

ActiveCN113388600AEfficient co-expressionImprove catalytic stabilityBacteriaMicroorganism based processesPseudomonas putidaChemical compound

The invention discloses aldoxime dehydratase and application thereof in catalytic synthesis of aromatic nitrile compounds, and belongs to the field of biological catalysis researches. The preparation method comprises the following steps: inserting an aldoxime dehydratase gene from Pseudomonas putida F1 into an expression vector, and constructing a recombinant expression plasmid; and introducing the aldoxime dehydratase into a host cell to construct a genetically engineered bacterium so as to realize efficient co-expression of the aldoxime dehydratase. Through the catalytic action of the engineering bacteria, the aim of efficiently producing the aromatic nitrile from the aldoxime compound can be achieved. The aldoxime dehydratase has the advantages of good catalytic stability, high catalytic activity and the like, is expected to become an excellent industrial catalyst for preparing aromatic nitrile by a biological method, and promotes upgrading of a nitrile compound synthesis process.

Owner:HANGZHOU NORMAL UNIVERSITY

Coal mine driving working face gas outburst obstruction system

InactiveCN106555610AGuarantee the safety of lifeAvoid fatal accidentsMining devicesProcess engineeringAirbag

The invention provides a coal mine driving working face gas outburst obstruction system, and belongs to the technical field of mining safety. The coal mine driving working face gas outburst obstruction system comprises a multi-modal signal sensor, a signal integrated processor, a sound-light alarm device, a starting switch, a gas generator, a semi-flexible air bag and a power supply. The multi-modal signal sensor detects parameters including temperature, humidity and gas concentration in the driving working space, signals are transmitted to the signal integrated processor for processing in real time, when signals are abnormal, the signal integrated processor outputs an early warning signal to the sound-light alarm device and the gas generator, the gas generator generates a lot of inert gas quickly to make the air bag inflate, the tunnel cross-section is obstructed, and the air bag plays a role in obstructing and buffering eruption of gas and coal rock solids towards the digging space. The coal mine driving working face gas outburst obstruction system protects life safety of workers in first time in case of emergency, and plays a buffering role in the coal and gas outburst accident, and can buy people time to escape safely.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com