Aldoxime dehydratase and application thereof in catalytic synthesis of aromatic nitrile compounds

A technology of dehydratase and compound, applied in the field of biocatalysis research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Construction of recombinant expression plasmid pROxdF1

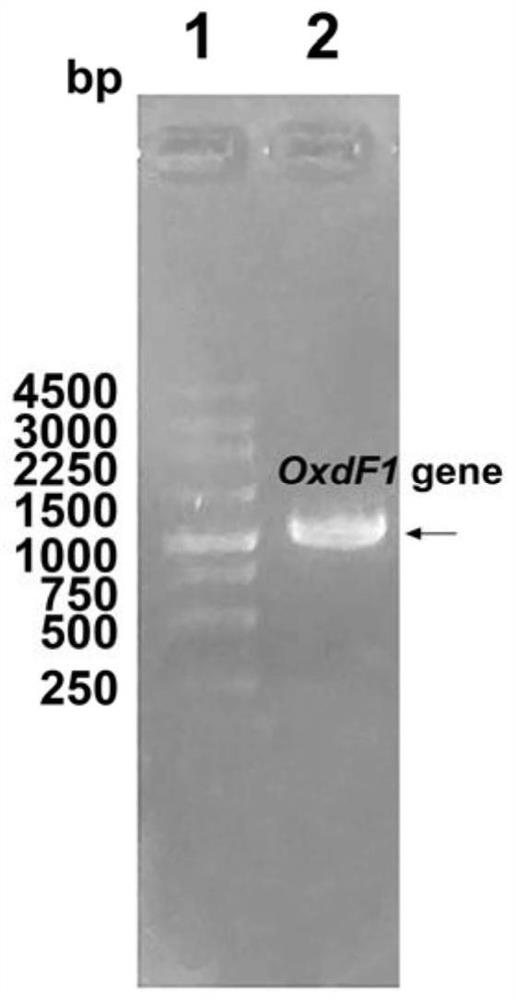

[0036]The aldoxime dehydratase Oxd gene ( figure 1 ), the nucleotide sequence of the gene is shown in SEQ ID NO.1. The nucleotide sequences of primers Oxd_UP and Oxd_down are respectively:

[0037] 5'-CGCGGATCCGATGGAATCTGCAATCGATAAACA-3';

[0038] 5'-ATAAGAATGCGGCCGCCTAGTTGGAACTGACTTTTGC-3'.

[0039] The Oxd-F1 gene was double-digested with Bam HI and Not I, and the digested gene fragment was recovered; at the same time, the expression plasmid pRSFDuet-1 was double-digested with Bam HI and Not I, and the plasmid fragment after digestion was recovered. T4 ligase was used for ligation, and the ligated product was transformed into the cloning host E.coli DH5α. Use LB solid plates containing kanamycin resistance to select positive transformants, and the sequencing results show that the recombinant plasmid after the gene sequence is correct is the recombinant expression plasmid pROxdF1, which is stored at...

Embodiment 2

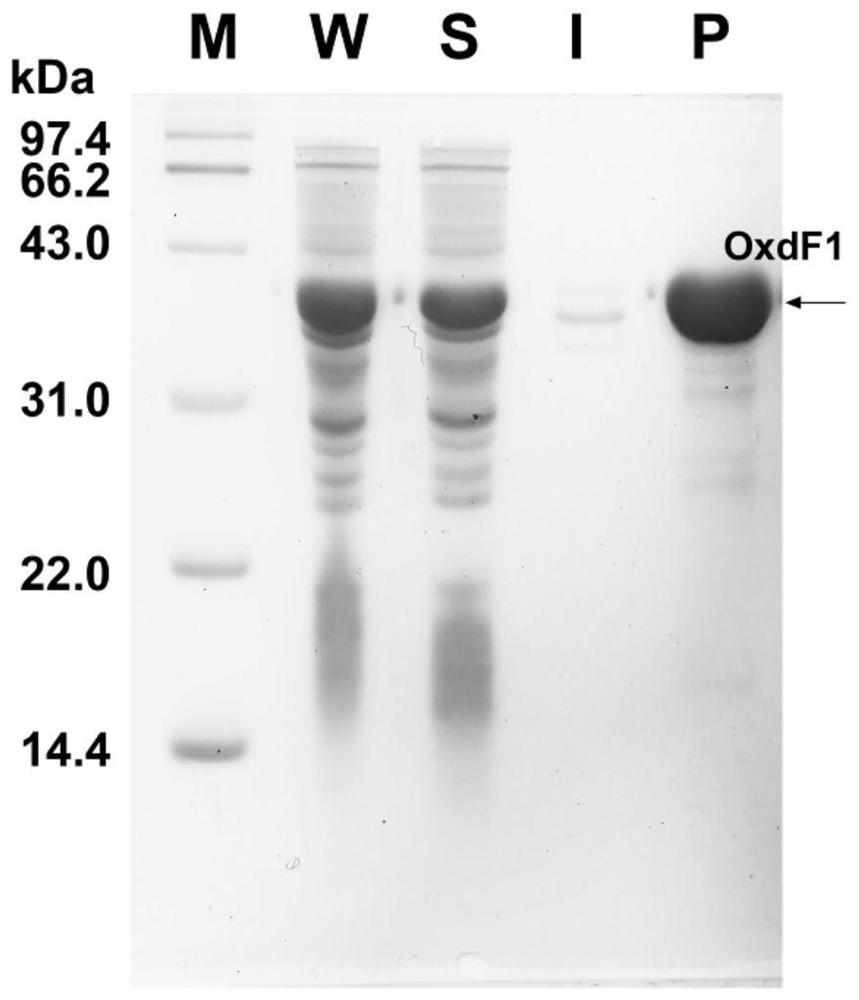

[0040] Construction and catalyst preparation of embodiment 2 genetically engineered bacteria BL21-pROxdF1

[0041] The recombinant expression plasmid pROxdF1 constructed in Example 1 was transformed into the expression host E. coli BL21(DE3) to obtain the genetically engineered bacterium BL21-pROxdF1. BL21-pROxdF1 was inoculated into liquid LB medium (38 μg / mL kanamycin) in a 10 mL test tube, and cultured with shaking at 37° C. and 200 rpm for 12 to 16 hours. The culture solution was inoculated into 50 mL of liquid auto-induction medium (38 μg / mL kanamycin) in a 250 mL conical flask at an inoculum amount of 1-5%, and cultured with shaking at 37°C and 200 rpm for 2-3 hours. When the strain density OD 600 When the value reaches 0.6-0.8, adjust the culture temperature to 18°C, and continue to culture at 200rpm for 12h.

[0042] The cells are collected by centrifugation for 5-10 minutes under the condition of 5000-10000×g, which is used as a catalyst for dehydrating and synthesi...

Embodiment 3

[0043] Example 3 Characterization of Aldoxime Dehydratase OxdF1

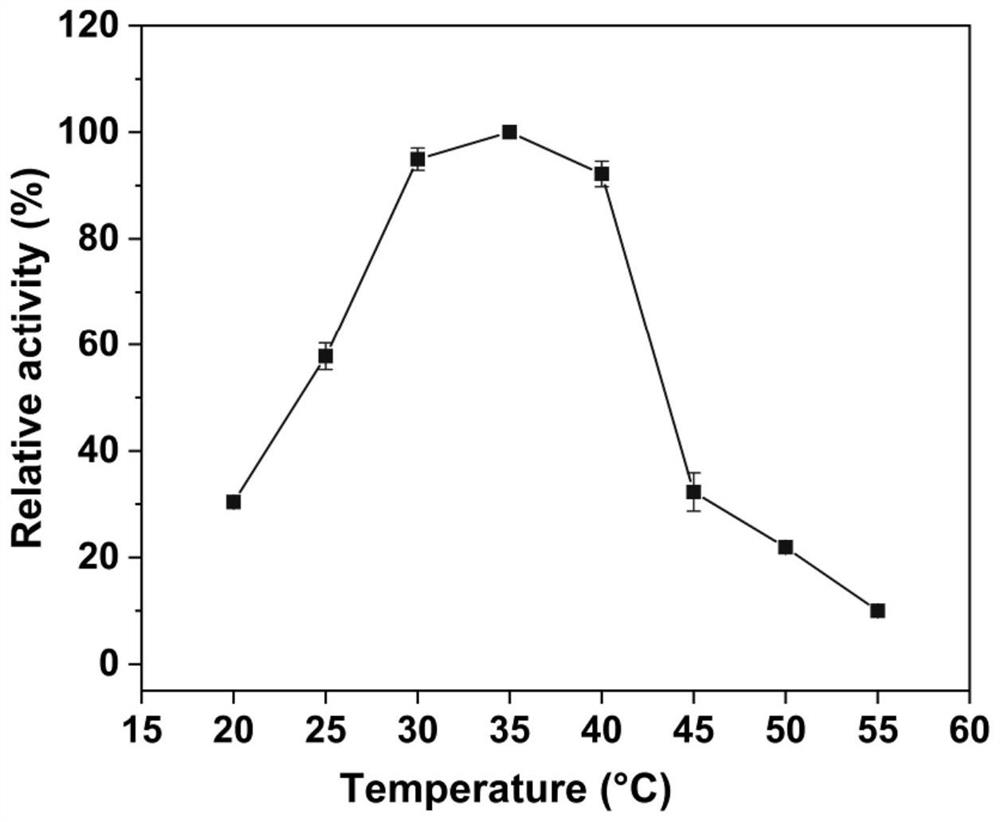

[0044] With 5mM 3-pyridine aldoxime as the substrate, in 0.5mL of 0.1M potassium phosphate buffer (pH 6.0) reaction system, add 50μL of genetically engineered bacteria BL21-pROxdF1 resting cells, and measure its catalytic activity in the range of 20~55℃ vitality, such as image 3 As shown, the optimum reaction temperature is 35 °C.

[0045] With 5mM 3-pyridine aldoxime as the substrate, add 50 μL of genetically engineered bacteria BL21-pROxdF1 resting cells in buffer systems with different pH values (pH4.0-9.5), and measure its catalytic activity at 35 °C. like Figure 4 As shown, the optimum reaction pH is 7.0.

[0046] Place the resting cells of the genetically engineered bacteria BL21-pROxdF1 in water baths at 30 and 35°C respectively, and measure their catalytic activity after keeping them for different times, as shown in Figure 5 As shown, its half-life reaches about 3.8 hours at 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com