Sealed wet spraying machine

A wet spraying and sealing technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of difficult maintenance, poor concrete mixing effect, unchanged operation, etc., to improve the construction level and quality, improve the Safety production level and the effect of improving the construction site environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

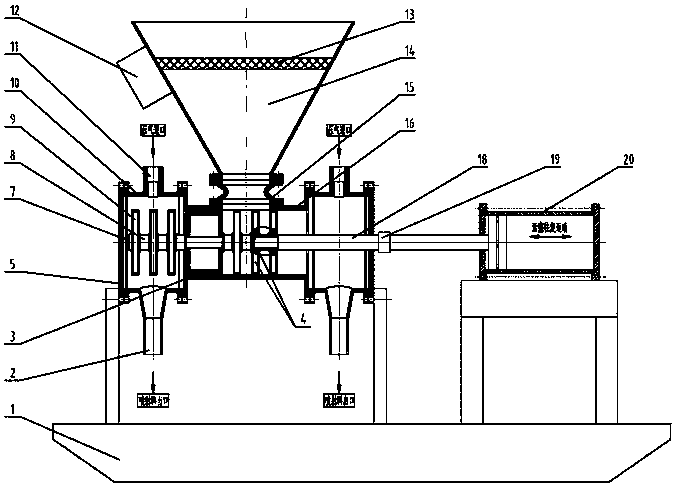

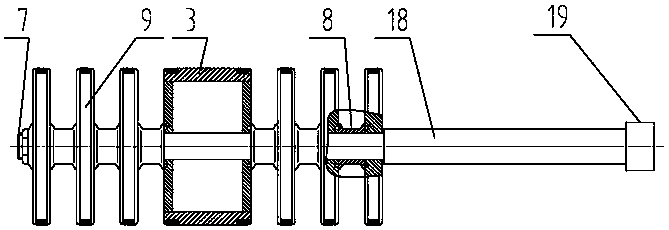

[0017] The pneumatic wet spraying machine of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0018] As shown in the figure, the pneumatic wet spraying machine of the present invention includes a cylinder 16, a hopper 14 installed on the top of the middle of the cylinder, two injection hoppers 10 symmetrically arranged on the left and right sides of the cylinder, and a cylinder located in it. A driving mechanism 20 on the side of the injection silo, the hopper 14 is installed on the top of the middle of the sealed cylinder so that the hopper 14 is facing the middle of the sealed cylinder, the said injection silo 10 includes a silo body and is installed on the silo body The connecting flanges on both sides, the top of the spray bin 10 is provided with a gas inlet 11, the bottom of the bin is provided with a spray outlet 2, the connecting flange on one side of the bin is connected with a flange cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com