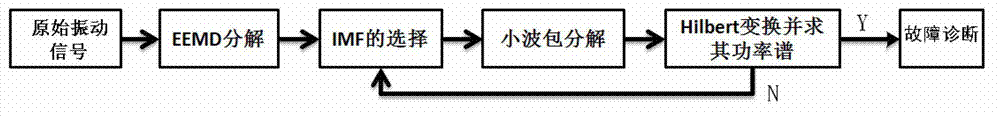

Extraction method for early failure sensitive characteristics based on ensemble empirical mode decomposition (EEMD) and wavelet packet transform

A wavelet packet transform and sensitive feature technology, which is applied in the testing of mechanical parts, the testing of machine/structural parts, measuring devices, etc., can solve the problems that self-adaptive decomposition cannot be achieved, and wavelet packet parameters cannot be automatically selected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1, analyzing the simulation signal: when the rolling bearing of the main shaft system fails, the load change caused by the failure will cause the rolling bearing to show non-uniformity during the rolling process, and at the same time act on the rolling bearing in the form of alternating force . When a gear in a spindle system fails (such as pitting on the gear face), severe gear mesh frequency modulation occurs due to the asymmetry of the load on the gear mesh. The mechanical structure may also be strongly excited during the gear meshing process, resulting in a stronger modulation effect of the mechanical resonance on the gear meshing frequency. The vibration signal of a faulty gear can be modeled as:

[0069] s m ( t ) = Σ k = 1 K A k ...

Embodiment 2

[0079] Embodiment 2, rolling bearing fault diagnosis:

[0080] This embodiment adopts bearing data from a rolling bearing fault simulation test bench of the Electrical Engineering Laboratory of Case Western Reserve University in the United States. The bearing to be tested supports the motor shaft. The model of the fan end bearing is SKF6205 deep groove ball bearing, and its specific specifications are shown in Table 1.

[0081] Table 1 Specification information of deep groove ball bearings

[0082]

[0083] The rotation speed of the bearing is 1797 revolutions per minute, that is, the rotation frequency is 29.95Hz, and the sampling frequency is 12000Hz. The fault frequency is shown in Table 2.

[0084] Table 2 Fault frequency of deep groove ball bearings

[0085] Inner ring failure

Outer ring failure

cage failure

rolling element failure

162.19Hz

107.36Hz

11.93Hz

141.17Hz

[0086] The local damage of the rolling bearing is a ...

Embodiment 3

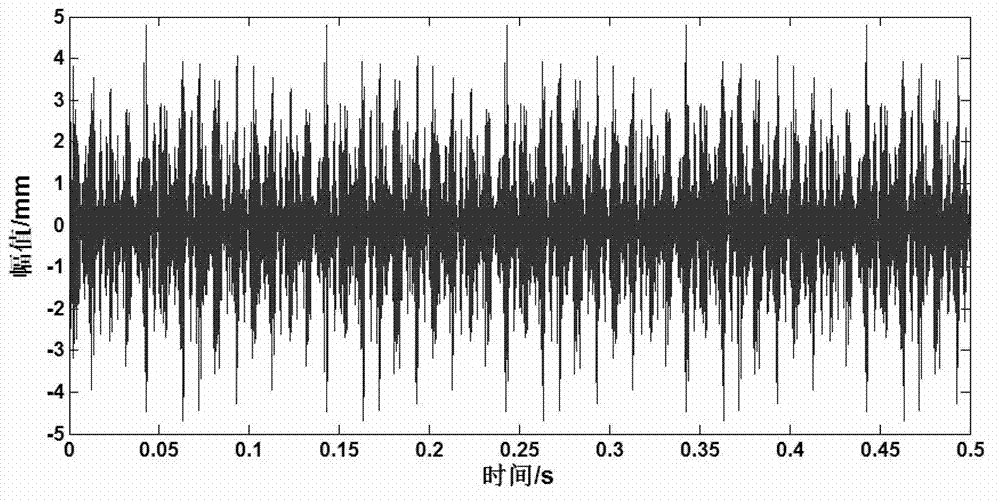

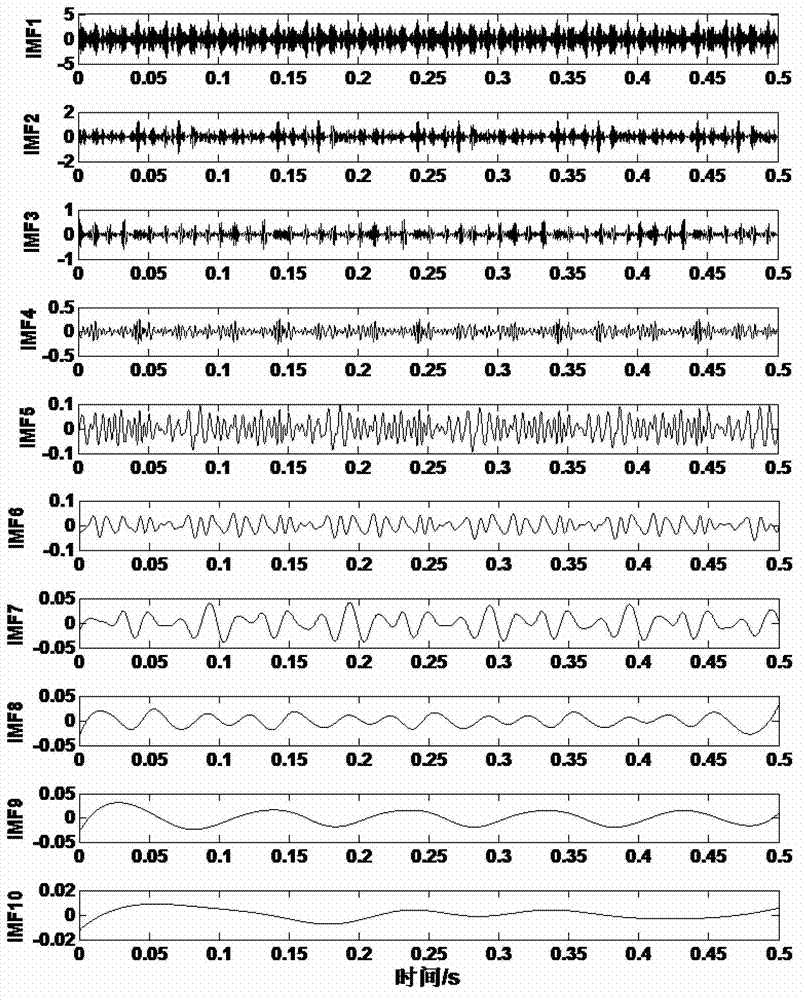

[0088] Embodiment 3, fault diagnosis of the rotor system:

[0089] The INV1612 multifunctional flexible rotor experimental system of Beijing Dongfang Vibration and Noise Technology Research Institute can perform experiments such as rotor dynamic balance, oil film whirl, friction vibration, etc. It mainly consists of two parts, the first part includes INV1612T multifunctional flexible rotor test bench and various sensors (1 vibration sensor, 1 photoelectric sensor and 2 eddy current sensors), and the second part includes INV306U acquisition and analysis system. The multi-functional flexible rotor experimental system is used to carry out experiments on normality, misalignment and rubbing of the rotor. The sampling frequency is set to 1024Hz, and the rotational speed of the rotor is 960rpm. The vibration displacement signals of the three situations of neutralization and rubbing, the length of which is 1024, the signals measured in the horizontal and vertical directions are set to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com