Synchronous concurrent multi-channel constant deceleration safety braking system and method for mine hoist

A mine hoist and safety braking technology, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc., can solve problems such as brake failure, improve reliability, improve safety production level, The effect of avoiding major vicious safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

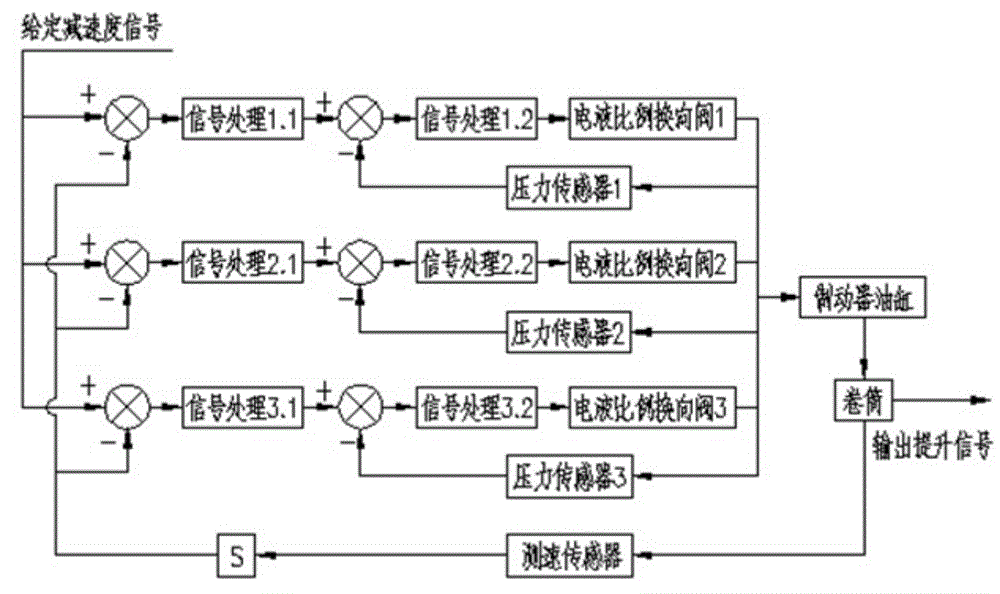

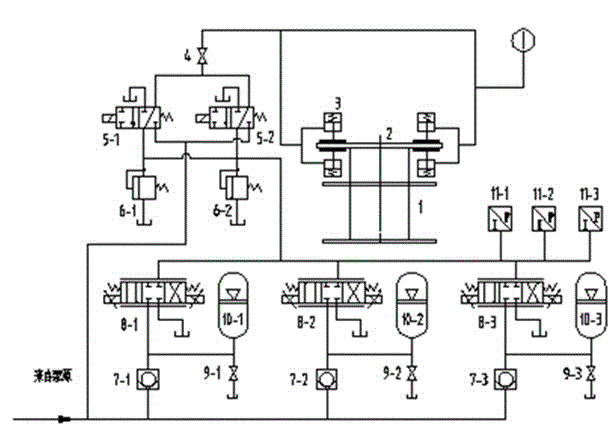

[0037] combine figure 1 and figure 2 , the mine hoist safety brake control system of this preferred embodiment includes three brake circuits consisting of a hydraulic system, a constant deceleration closed-loop electrical control device and a detection feedback device. The three brake circuits are arranged in parallel, and each brake The loop structures are functionally identical and independent of each other. The following will take brake circuit 1 as an example for specific description.

[0038] Among them, the hydraulic system includes an electro-hydraulic proportional reversing valve for electro-hydraulic signal conversion, a conductive hydraulic medium, and an actuator (disc brake) for performing braking; the detection and feedback device is used to collect signals and feed them back to the constant deceleration closed loop Electric control device: The constant deceleration closed-loop electric control device receives the feedback signal, compares the feedback signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com