Hard coal anti-scouring pressure-relief boring construction method and equipment

A technology of construction equipment and construction methods, which is applied in earth-moving drilling, drilling with liquid/gas jet, surface mining, etc. The cost of pressure relief, the effect of ensuring anti-scour effect, and the effect of broad market promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

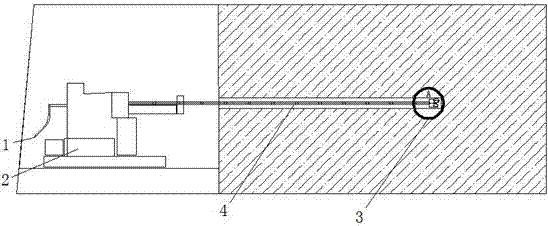

[0050] As a typical deep mine (mining depth exceeding 1000m), Yuncheng Coal Mine in Shandong Province is seriously threatened by rock burst disasters. In the past two years, there have been 6 occurrences of rock bursts in the Yuncheng mine field, causing damage to hundreds of meters of roadways, causing large economic losses to mining companies, and also seriously threatening the lives of underground personnel.

[0051] The mineable coal seam of Yuncheng Coal Mine is 3 coal seams, with an average thickness of 6.3m and a unidirectional compressive strength of 15MPa. During the process of roadway excavation and working face mining, it is threatened by rock burst. The Yuncheng Coal Mine used to use column-type pressure relief drilling rigs for construction. Three people worked as a shift. Under normal conditions where the drill did not get stuck, one shift constructed 3 pressure relief drilling holes, ie 75m.

[0052] The method of the present invention is used to implement large...

Embodiment 2

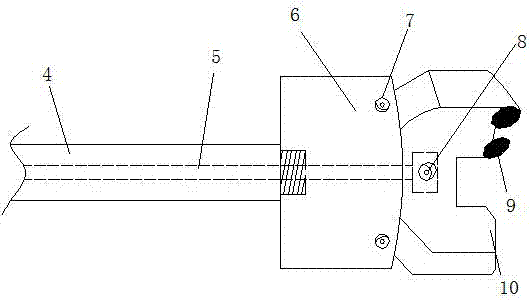

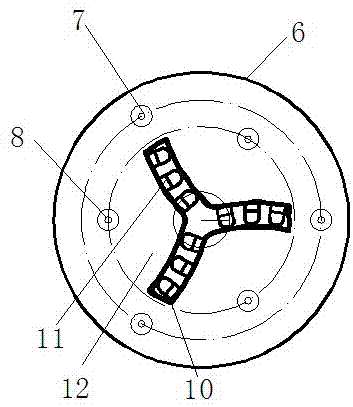

[0068] A kind of hard coal anti-scouring and pressure-relieving drilling construction method adopts the coal seam anti-scouring drilling technology of mechanical drilling and hydraulic jet drilling, and the steps are:

[0069] (1) First use high-pressure water to wash down the coal body and form a drilling section; the pressure of the high-pressure water flow is greater than the compressive strength of the coal body and is not greater than 30MPa. The drilling diameter after punching is 100-150mm.

[0070] (2) Reuse the drilling rig to break the washed down coal body;

[0071] (3) Then use the water flow to wash out the coal powder.

[0072] The hard coal refers to the Platts coefficient f>2.

[0073] A kind of hard coal anti-scouring and pressure-relief drilling construction method of the present invention adopts the coal seam anti-scouring drilling technology of mechanical drilling and hydraulic jet drilling, first uses high-pressure water to wash down the coal body and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com