Dual-setting value constant torque secondary braking control system of mine hoister

A mine hoist, secondary braking technology, applied in the direction of the hoisting device, etc., can solve the problems of reducing the safety performance and service life of equipment, wire rope overload safety accidents, safety accidents, etc., achieve good safety braking performance, improve mine The effect of safety production level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention is further described below in conjunction with preferred embodiments:

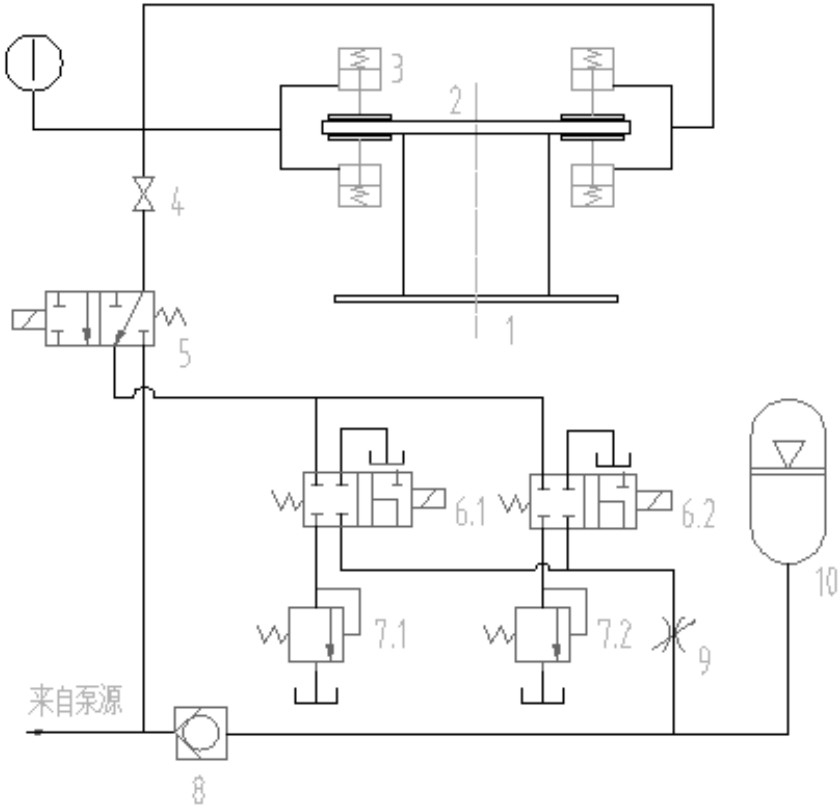

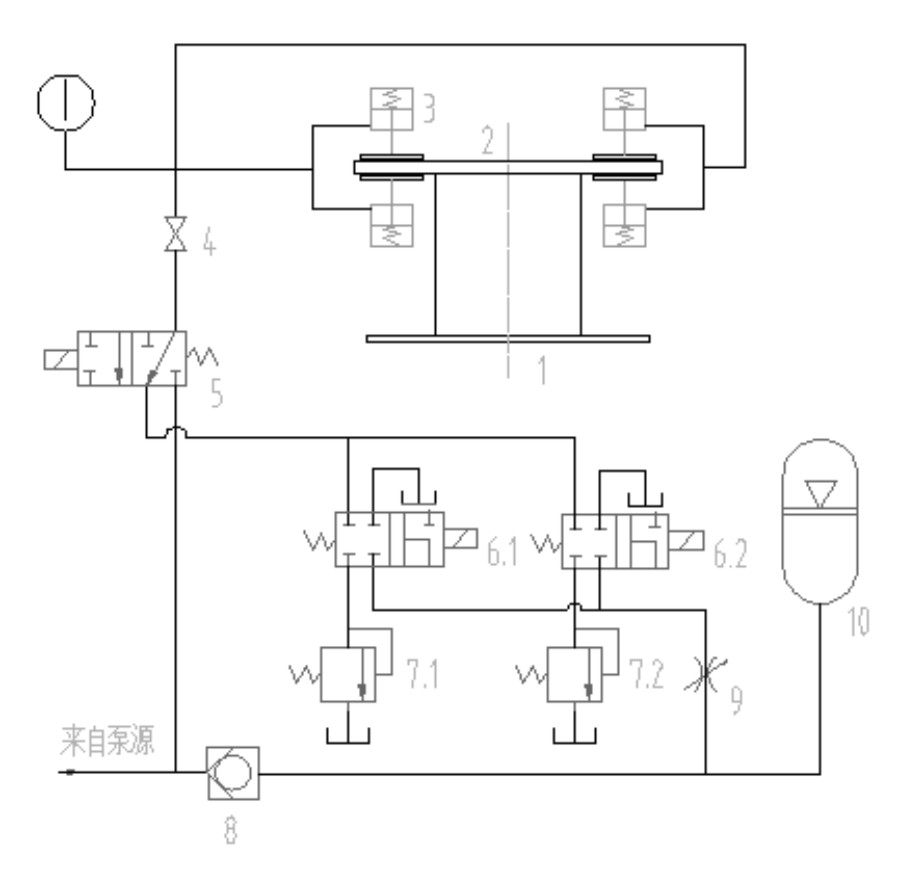

[0027] combine figure 1 , a mine hoist dual set point constant torque secondary brake control system, including a pump for supplying pressure oil to the disc brake hydraulic cylinder during the normal working mode of the hoist; an accumulator 10, as a backup oil source The accumulator 10 is supplied with hydraulic pressure through a hydraulic source, and a check valve 8 is provided on the hydraulic supply line for allowing hydraulic flow in one direction from the hydraulic source to the accumulator 10, and for preventing any hydraulic pressure in the opposite direction flow.

[0028] It also includes an electromagnetic reversing valve 5 arranged between the pump outlet passage and the disc brake hydraulic cylinder for switching the hydraulic circuit between the normal working mode and the safety braking mode of the hoist; Dynamic hydraulic circuit, which includes a dual brake hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com