Straw distributing equipment

A straw and equipment technology, which is applied in the field of material distribution devices, can solve the problems of easy bridging and poor supply continuity, and achieve the effects of eliminating bridging, ensuring stability and improving continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

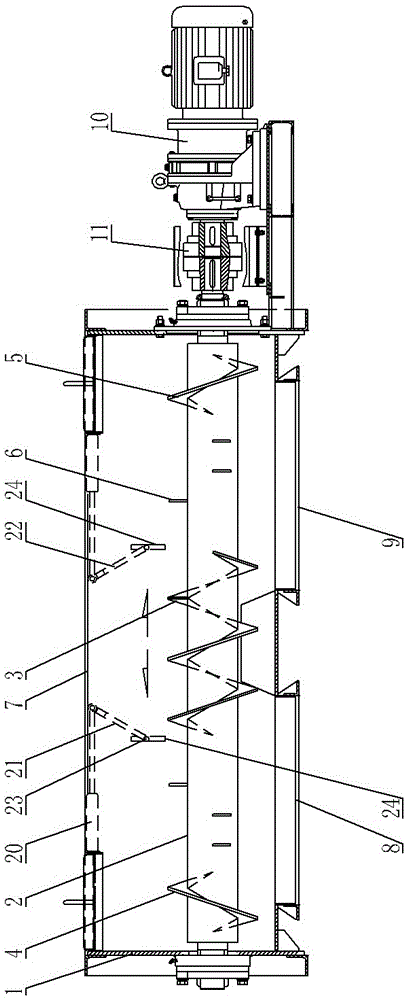

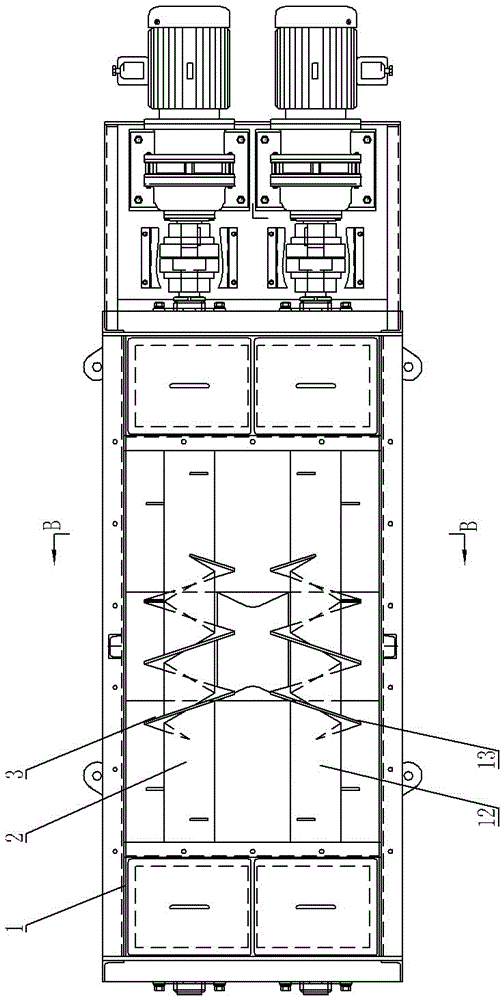

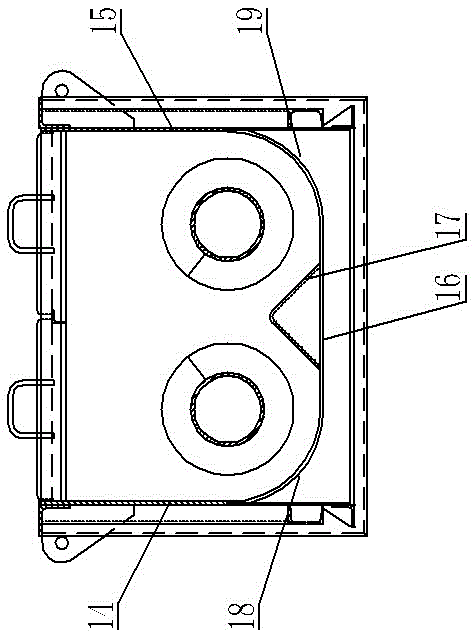

[0014] Such as Figure 1~Figure 3 As shown, it includes a housing 1, a material inlet 7 is opened on the top of the housing, and a material outlet 8, 9 is opened at the bottom of the housing. The rotating shafts 2, 12 are supported on the left and right side walls of the housing side by side. They are separately driven by a driving device, the driving device includes a geared motor 10, the output shaft of the geared motor 10 is fixedly connected to the corresponding rotating shaft through a coupling 11, and the geared motor is fixed on the supporting plate on the side of the housing through the motor seat;

[0015] Rotating shafts 2 and 12 are located below the feed inlet and are correspondingly fixed with middle helical blades 3 and 13, and are correspondingly fixed with stirring rods 6 at the part above the discharge opening, and the middle helical blades of the two rotating shafts are set in reverse;

[0016] Material guide plates 21, 22 are arranged symmetrically below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com