Rotary material-shifting type steaming warehouse

A technology of steaming bin and feeding disc, applied in the field of steaming bin, can solve the problems of short residence and steaming time, low moisture balance and buffering effect, low bin capacity utilization rate, that is, low material filling rate, etc. Physical properties, reduce chemical consumption, and improve the effect of warehouse capacity utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

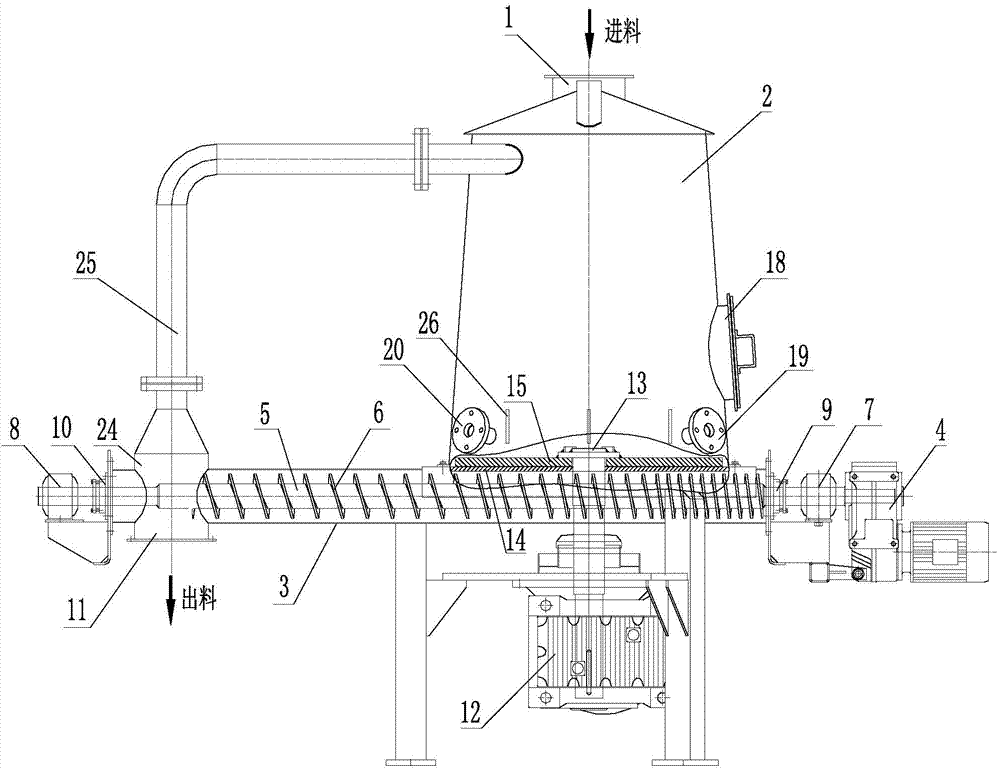

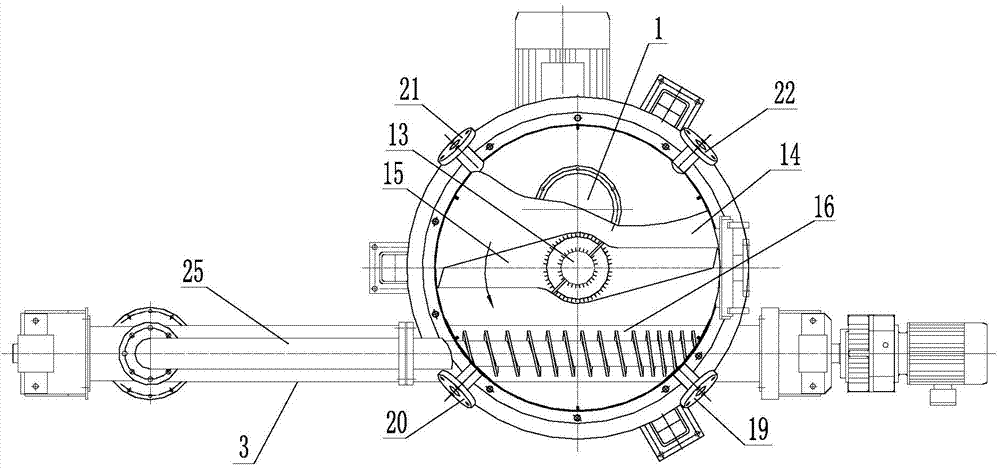

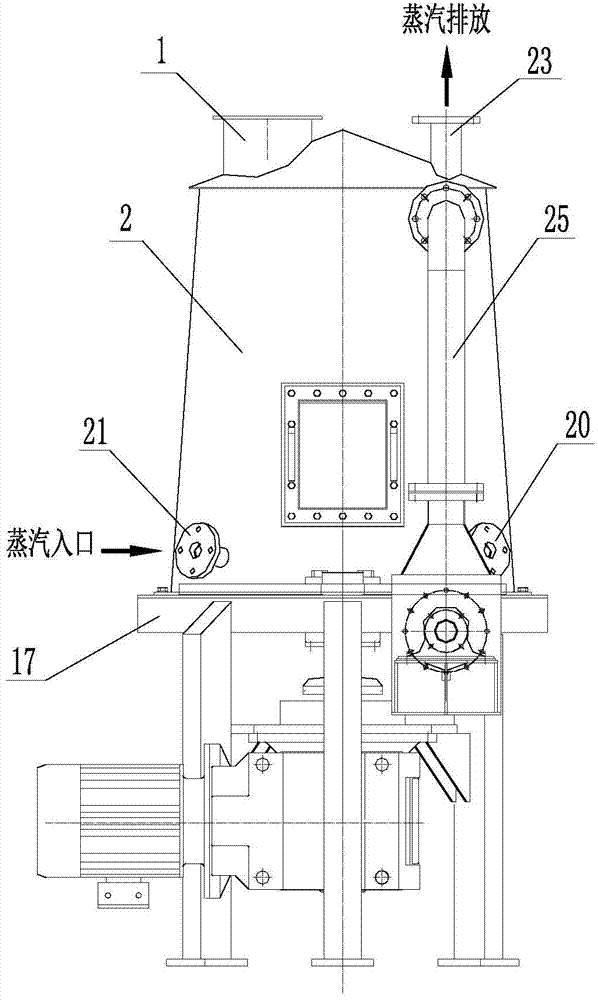

[0026] Example 1: Such as figure 1 The main view of the structural schematic diagram and figure 2 As shown in the top view of the structural schematic diagram, the steaming chamber includes a chamber body 2, a rotary material pulling device, and a material discharging device.

[0027] The rotary shifting device includes a shifting motor 12, a central shaft 13, and a shifting disc arranged at the bottom of the bin body. The shifting disc includes a chassis 14 and a shifting piece 15 that can rotate on the chassis; the center of the chassis 14 is provided with A through hole; one end of the central shaft 13 passes through the through hole and is fixedly connected to the material shifting piece 15, and the other end is connected to the material shifting motor 12 through a coupling. In this embodiment, the central shaft 13 is integrally welded with the paddle 15 . The central shaft 13 is rotated by the driving motor 12, and the transmission connection between the two can also...

Embodiment 2

[0035] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0036] The central shaft on the rotating material shifting device and the material shifting piece are fastened and fixedly connected together by bolts.

[0037] The discharge device is located below the dial plate, and a blanking opening is provided at the part where the shell of the discharge device is docked with the chassis of the dial plate, and the blanking opening is located at an eccentric position of the chassis. The chassis is a regular polygonal chassis, and the edge of the blanking opening is the butt line between the regular polygonal chassis and the casing of the discharge device. Certainly also can be on regular polygonal chassis, be positioned at chassis and the area that the docking line outlines of discharge device housing has blanking opening, the area of this blanking opening is smaller than the area area th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com