Small rice cooker

A rice cooker, a small-scale technology, applied in the direction of food science, etc., can solve the problems of uneven heating of grain and affect the follow-up process, and achieve the effect of improving production efficiency and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

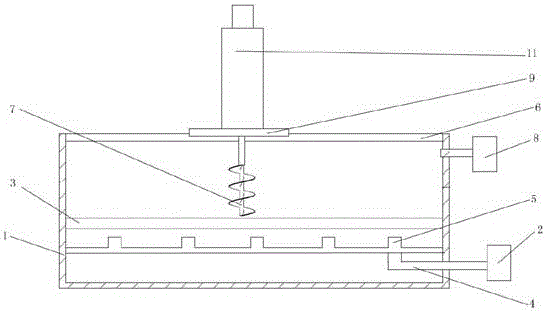

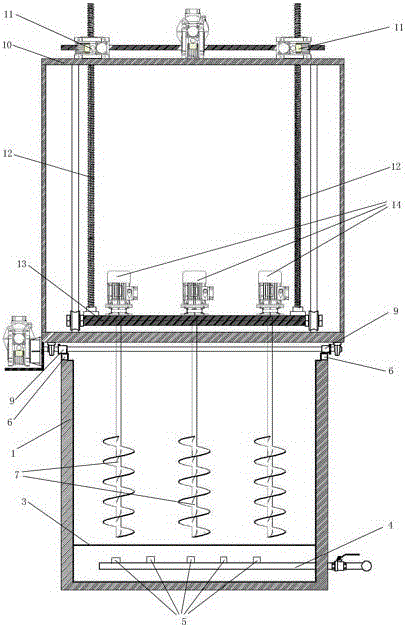

[0024] Such as Figure 1-2 As shown, a small rice cooker provided in this embodiment includes a working chamber 1, a stirring device, a steam source 2, and a mesh belt 3; the lower part of the working chamber 1 is laid with a mesh belt 3 covering its entire cross section, The bottom of the mesh belt 3 is provided with a steam pipe 4, and the steam pipe 4 is separated with a steam outlet 5; the upper edge of the working warehouse 1 is provided with a guide rail 6 along its longitudinal direction; the stirring The device is installed on the guide rail 6 and can be fed along the guide rail 6; the stirring device includes a lifting mechanism and a stirring paddle 7; the stirring paddle 7 is mounted on the lifting mechanism and extends vertically downward, and can be Driven by the lifting mechanism to lift in the vertical direction;

[0025] It also includes a blower 8, the blower 8 is arranged on the longitudinal side of the working chamber 1, is connected to the bottom of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com