Steam curing device for prefabricated part

A technology of prefabricated components and steam curing, applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve the effect of reducing requirements, reducing cross-flow of sewage, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

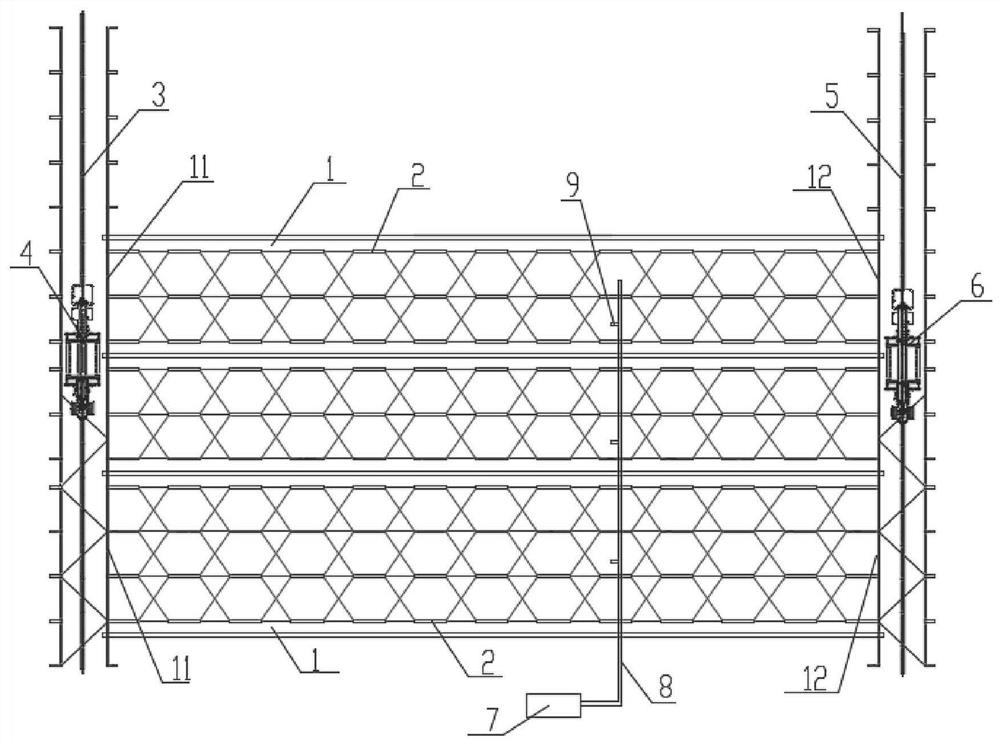

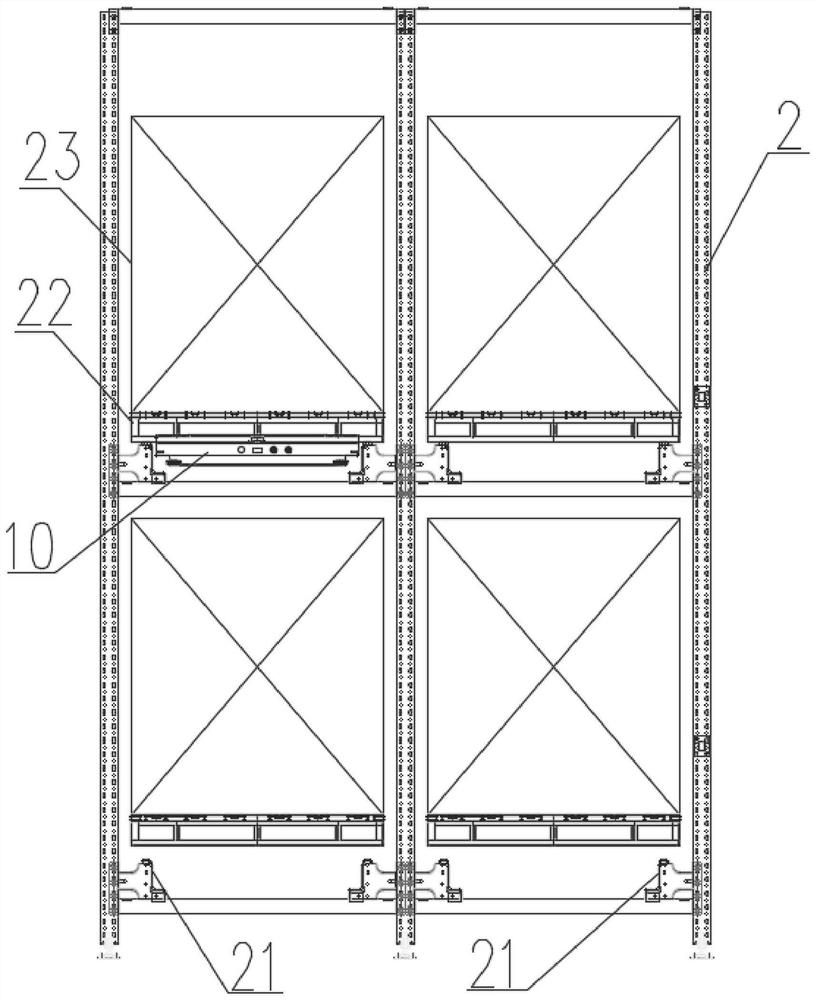

[0016] see figure 1 and figure 2 , using the scheme of three curing rooms 1 for detailed description.

[0017] The steam curing device for prefabricated components includes three curing rooms 1 arranged side by side. The curing rooms 1 are of a closed structure, and the two ends of the curing room 1 are respectively provided with an inlet 11 and an outlet 12 .

[0018] At least two rows of shelves 2 are arranged side by side in the curing room 1, and the shelves 2 are elongated structures. The two ends of the shelves 2 correspond to the entrance 11 and the exit 12 respectively, and the quantity of the entrance 11 and the exit 12 can be set according to the number of rows of the shelves 2. Make sure that a row of shelves 2 corresponds to an entrance 11 and an exit 12, so that the entrance 11, shelves 2 and exit 12 are in a straight line. A set of third rails 21 is provided on the inner bottom of the shelf, and the third rails 21 are provided for the shuttle car 10 to transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com