Large-scale ion beam polisher for optical parts

A technology of optical parts and ion beams, which is applied in the field of ion beam polishing, can solve the problems of affecting the polishing efficiency of ion beam polishing machines, long set-up time, and high resource consumption, and achieves improved operability and convenience, simple structure, and easy work. The effect of clean environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

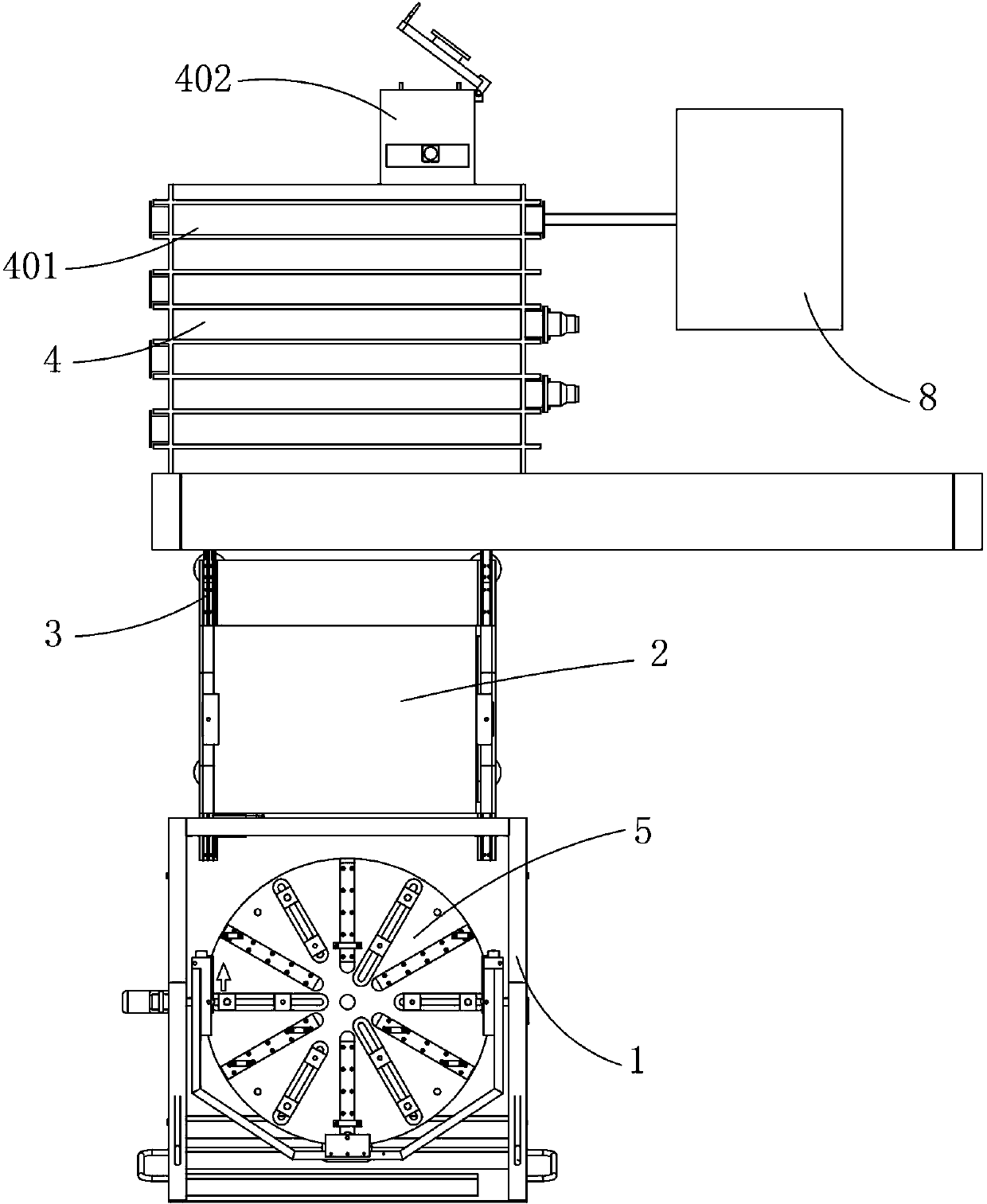

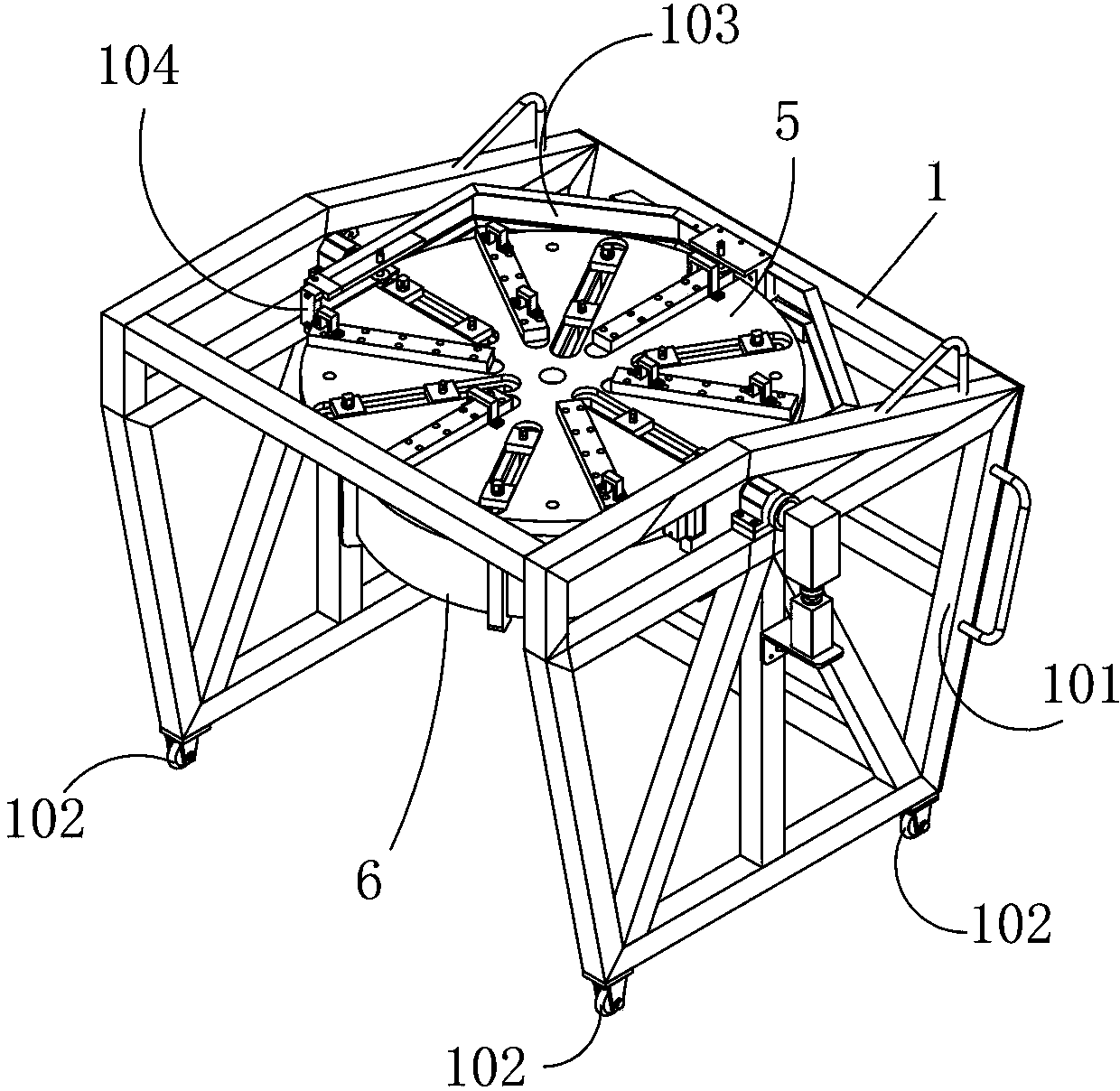

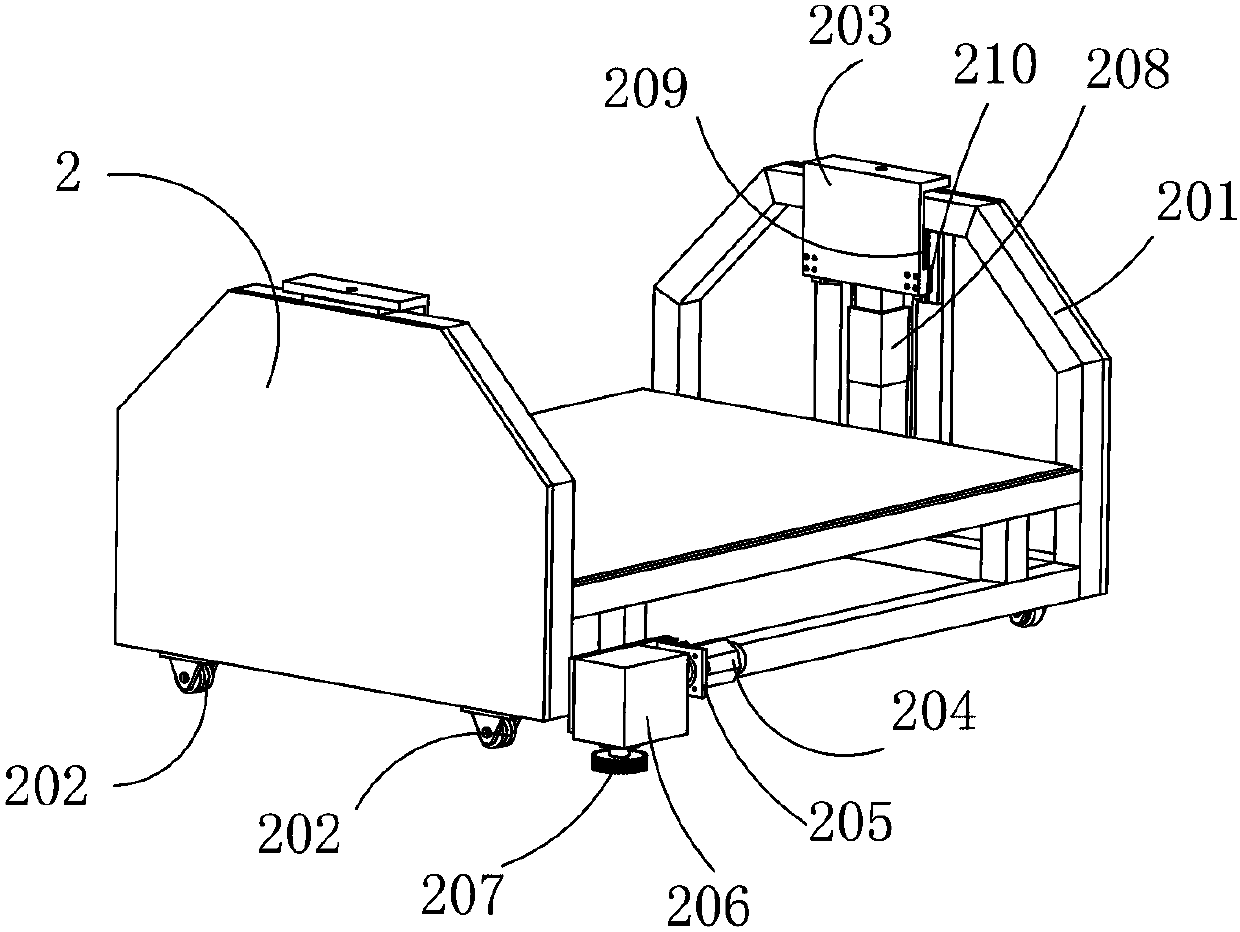

[0033] Figure 1 to Figure 11Shown is a large-scale optical part ion beam polishing machine of the present invention, including a vacuum polishing system 4, a carrying device 3, used for transporting the large-diameter workpiece 6 after measurement, and making the large-diameter workpiece 6 stand The overturning device 1 with the processing surface kept downward, and the conveying device 2 and the carrying device 3 for receiving the large-diameter workpiece 6 conveyed by the overturning device 1 and sending the large-diameter workpiece 6 to the main vacuum chamber 401 of the vacuum polishing system 4 It includes a guide rail 302 and an inner frame 301 arranged in the main vacuum chamber 401 and used to accept the large-diameter workpiece 6 conveyed by the conveying device 2. The conveying device 2 is arranged on the guide rail 302 and moves along the guide rail 302. The vacuum polishing system 4 Connected with a vacuum device 8, the main vacuum chamber 401 can be vacuumed thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com