Patents

Literature

45results about How to "Solve loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

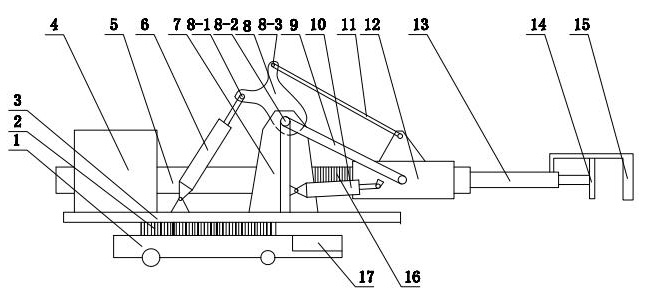

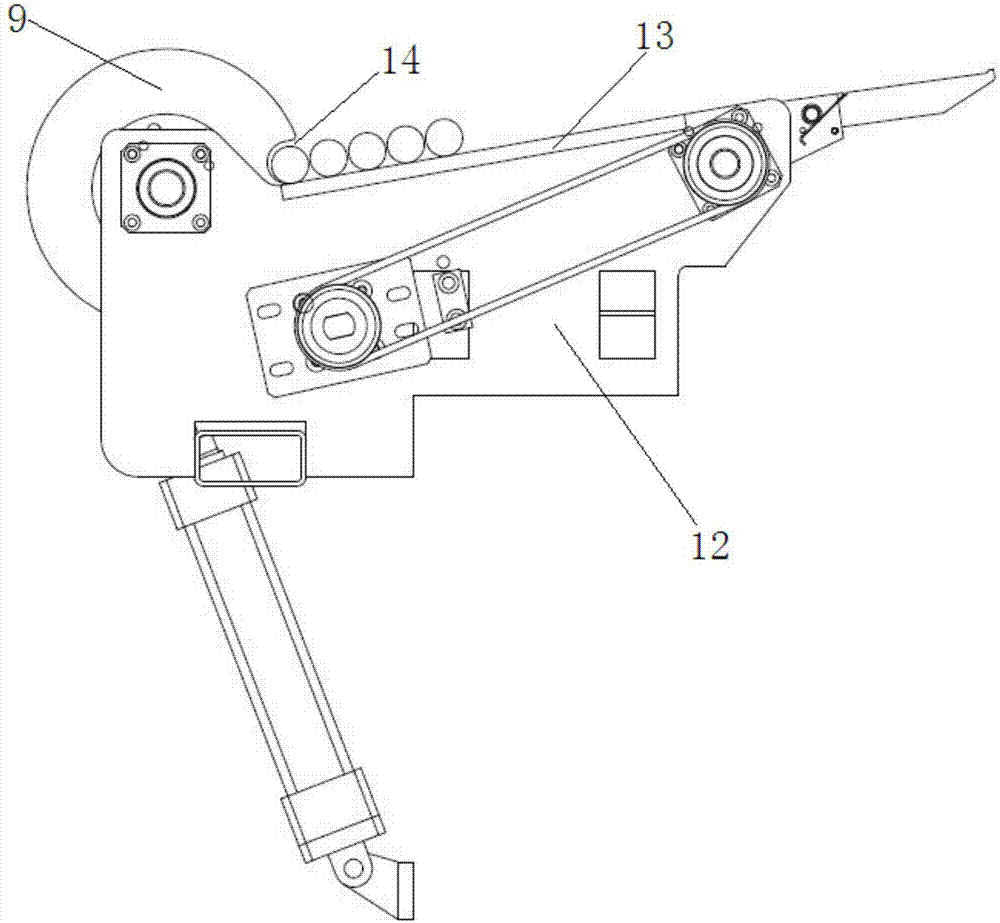

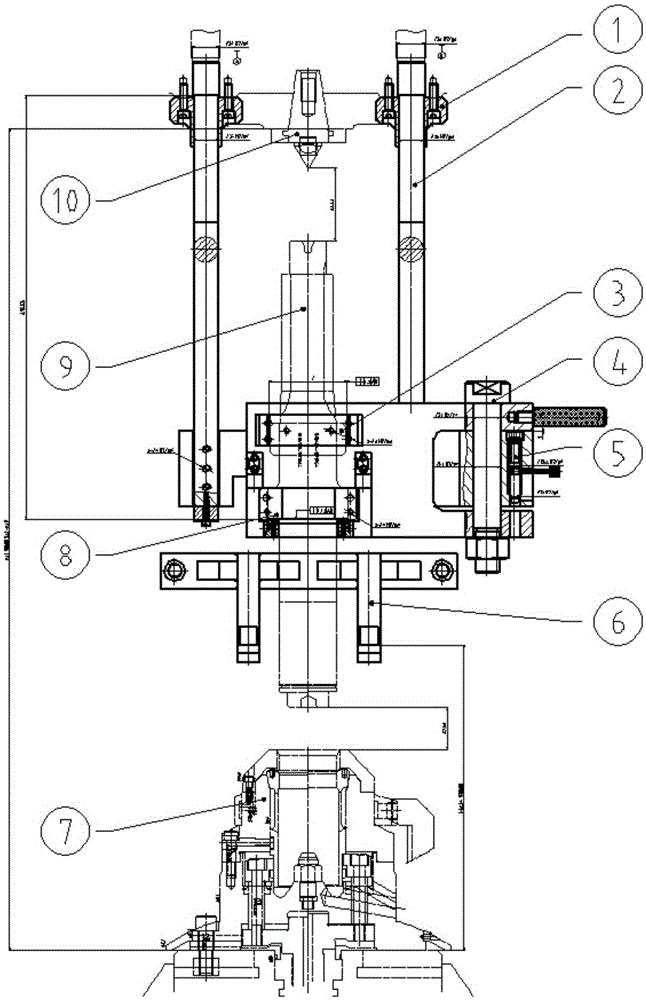

Feeding and discharging mechanical arm for pipe forming machine

ActiveCN102125960AFlexibleEasy to put inMetal-working feeding devicesPositioning devicesHydraulic cylinderGear drive

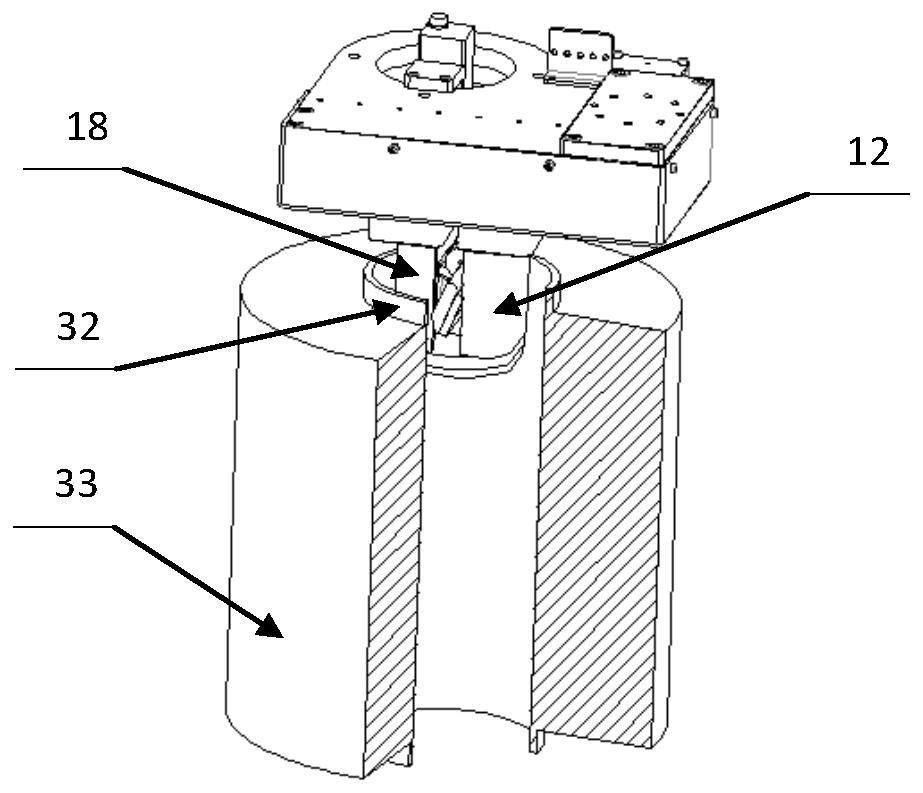

The invention relates to a feeding and discharging mechanical arm for a pipe forming machine. The font of a moving trolley is connected with a rotary table through a rotary gear; a parallelogram mechanism consisting of a connecting arm, a guide cylinder, an upper connecting rod and a lower connecting rod is formed on the rotary table, and is driven by an elevating hydraulic cylinder and a nose-down pitching hydraulic cylinder; the guide cylinder is provided with a gear driven by a telescopic motor, and the gear is meshed with a rack on the outer side face of a cantilever; an overturning arm and a clamp extend out of the front end of the cantilever; and each hydraulic cylinder is driven by a hydraulic control system. By simulating steps of a manual feeding and discharging method, the feeding and discharging mechanical arm can flexibly complete seven actions, namely clamping materials, stretching a nippling lever, horizontally lifting the nippling lever, pitching the nippling lever, overturning the nippling lever, rotating a frame in a 360-degree range, and walking the trolley, greatly lightens labor intensity of workers, improves work efficiency, and is safe, flexible and easy to operate.

Owner:WUXI XINFENG TUBE IND

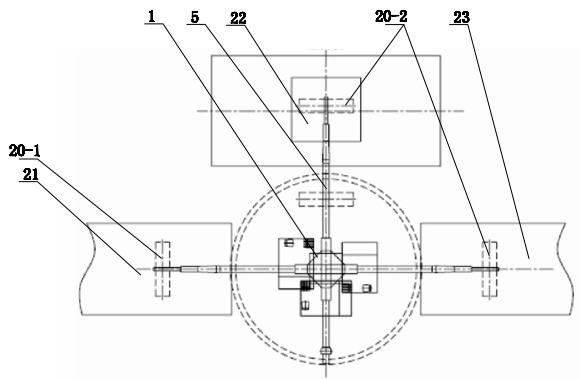

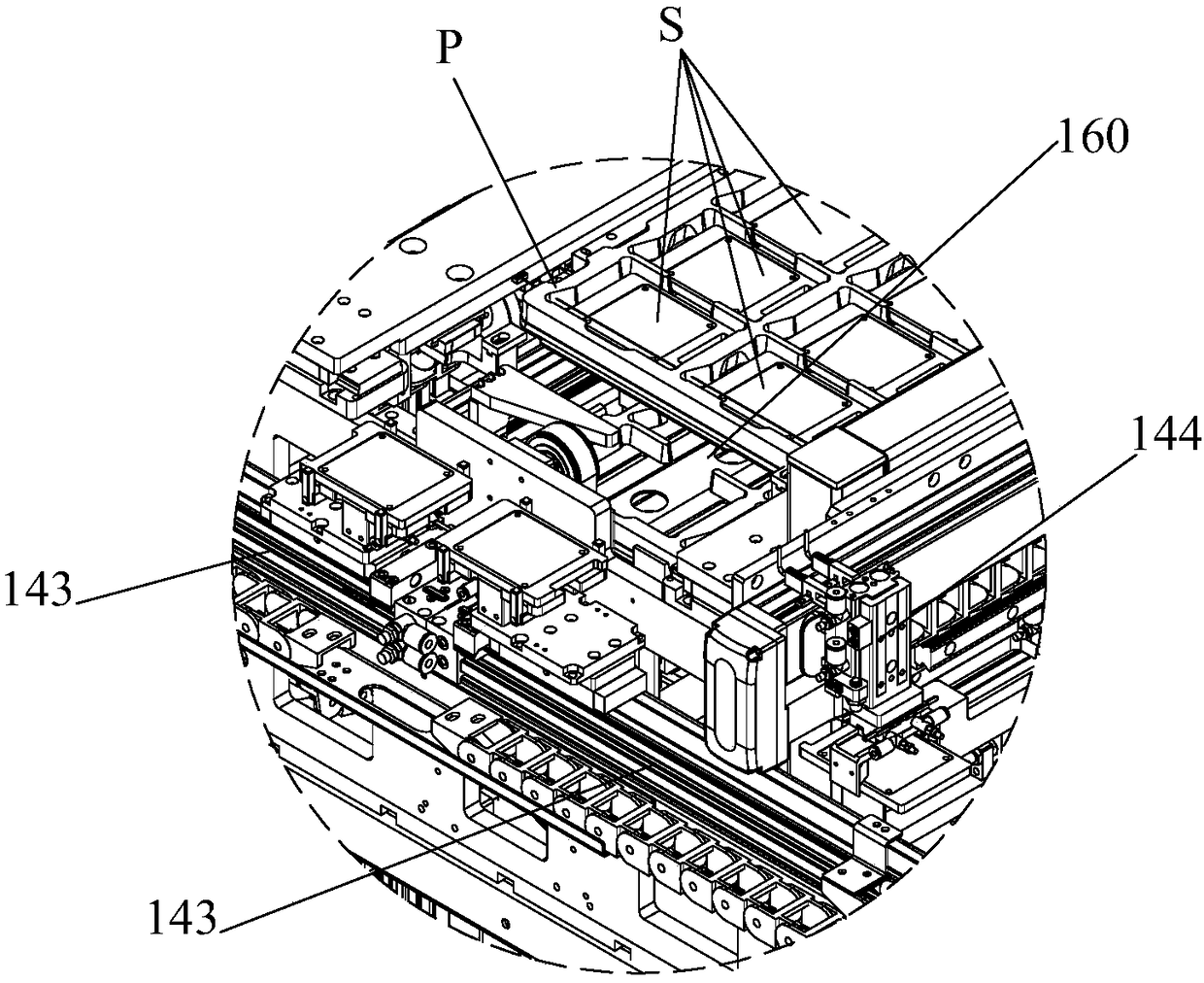

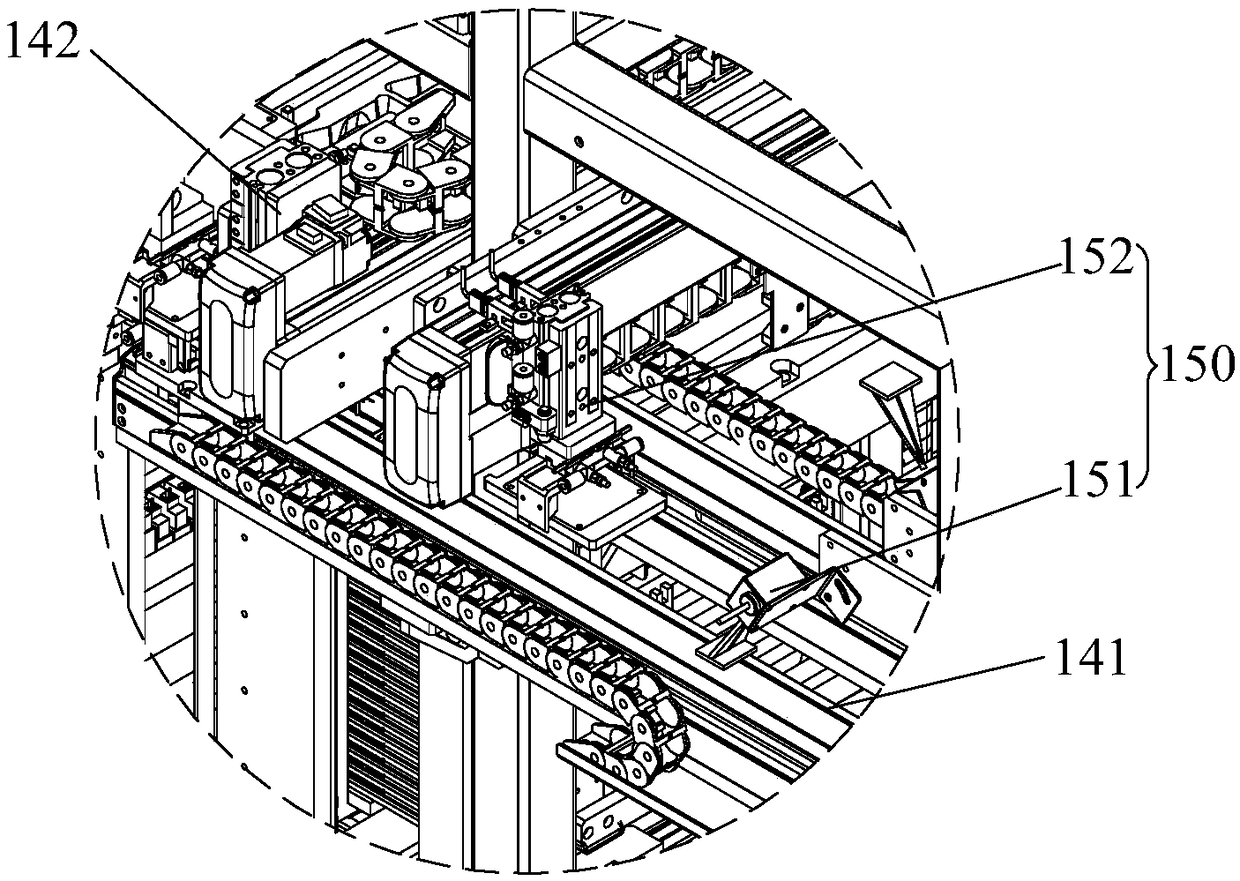

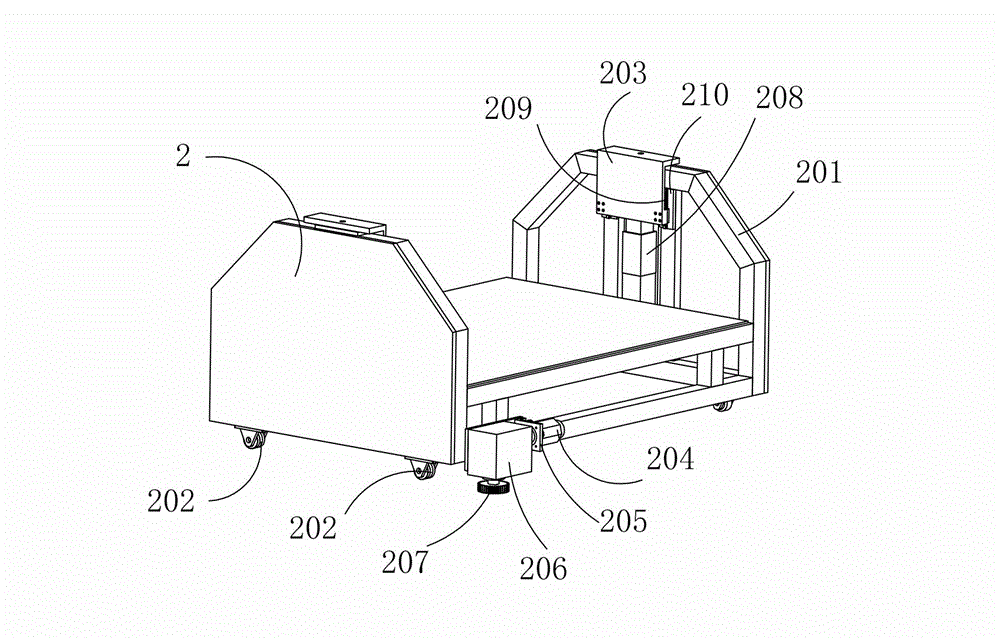

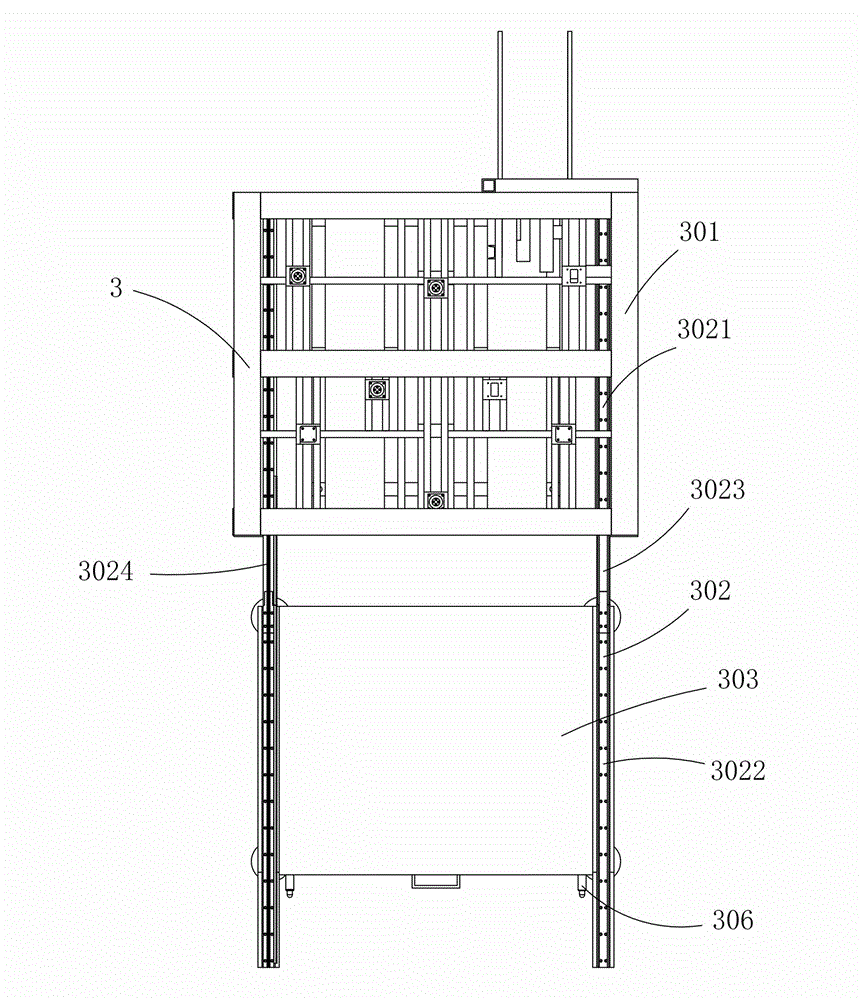

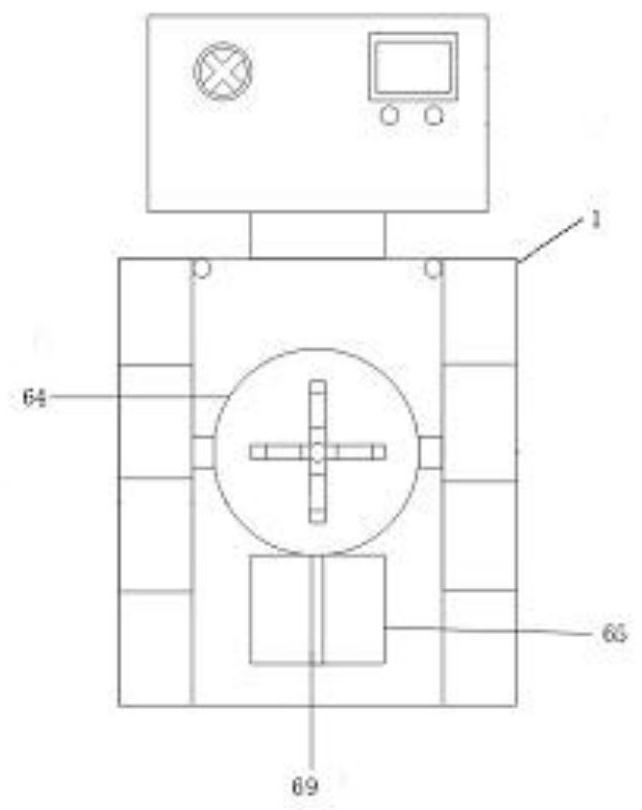

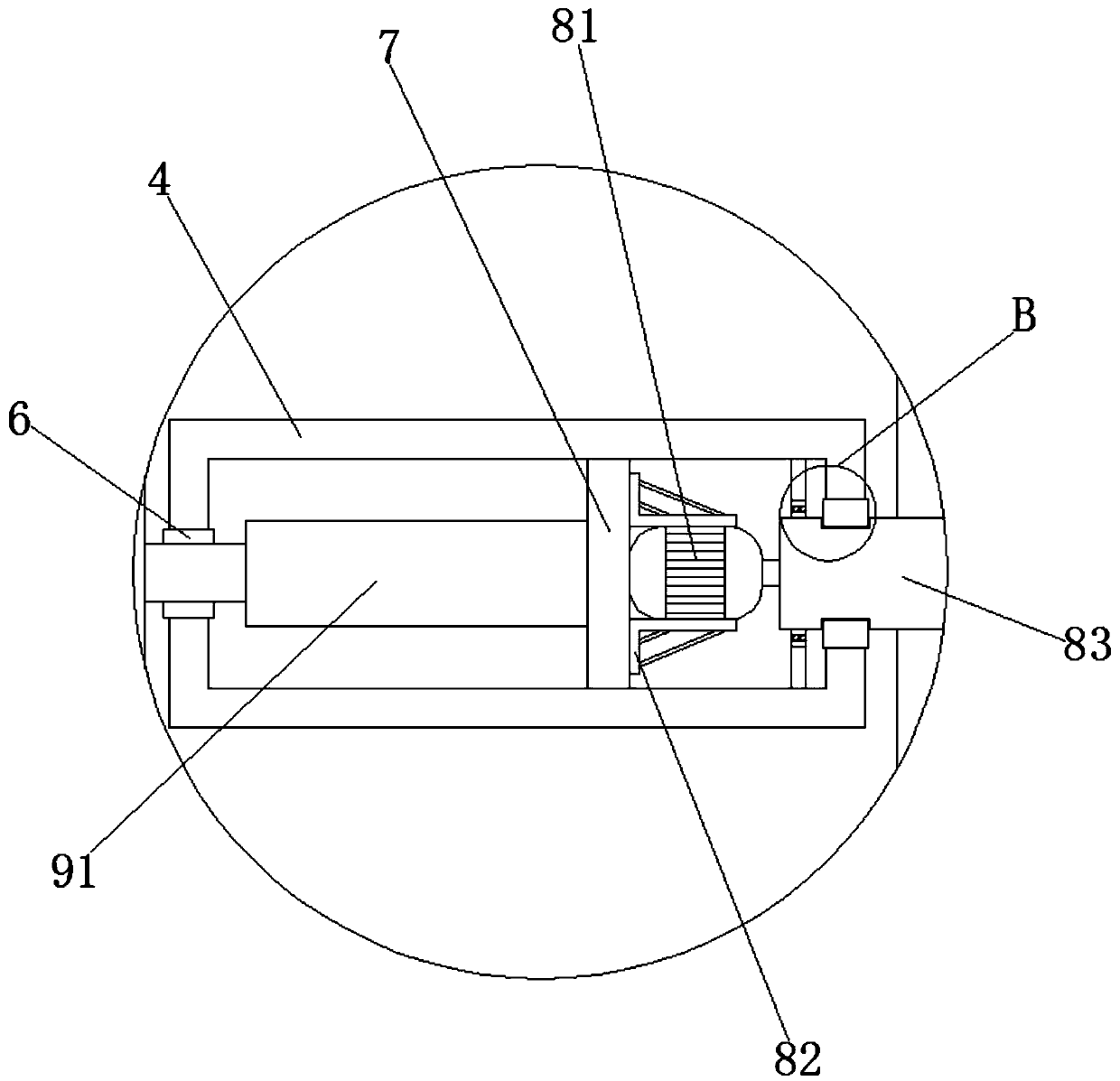

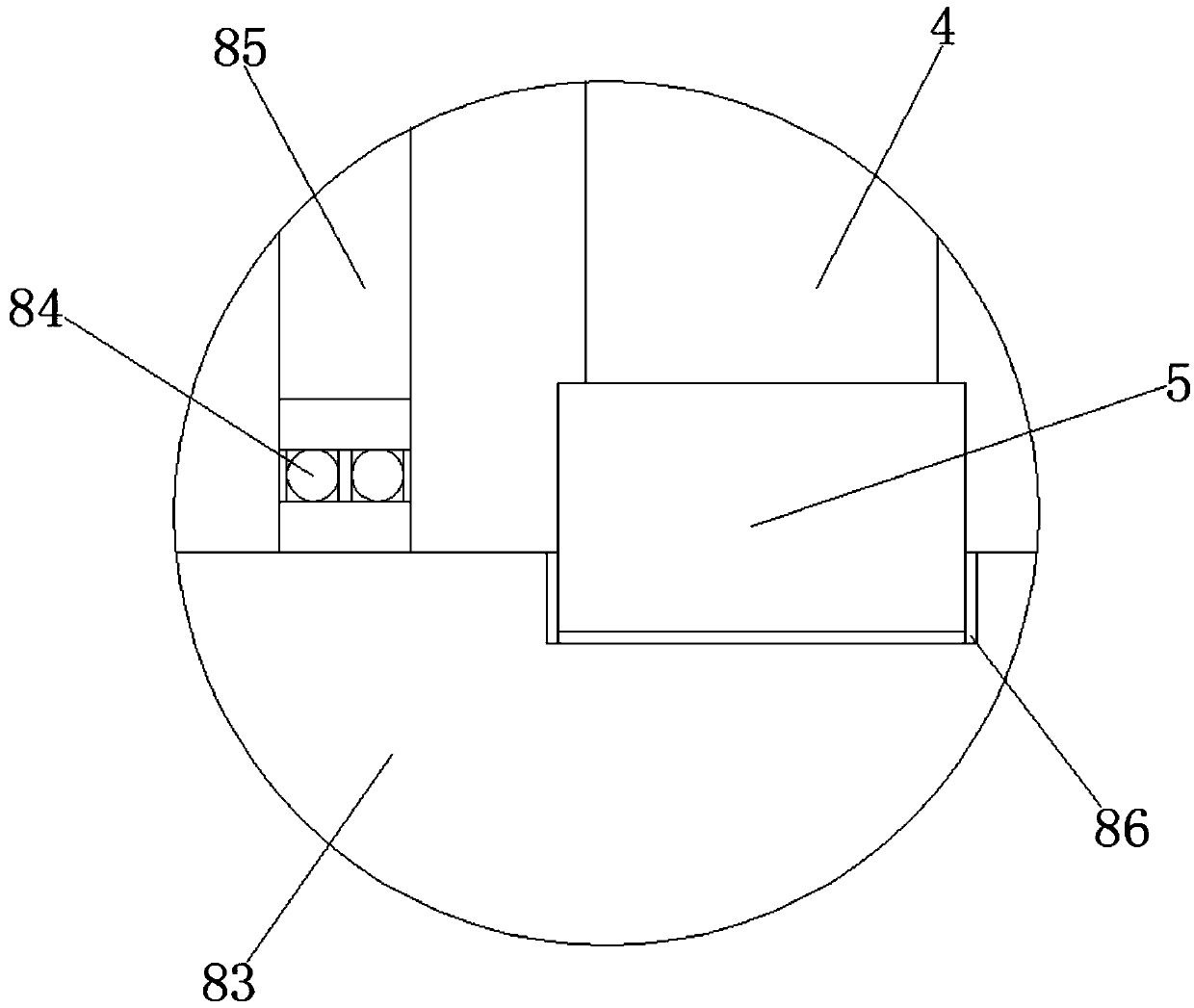

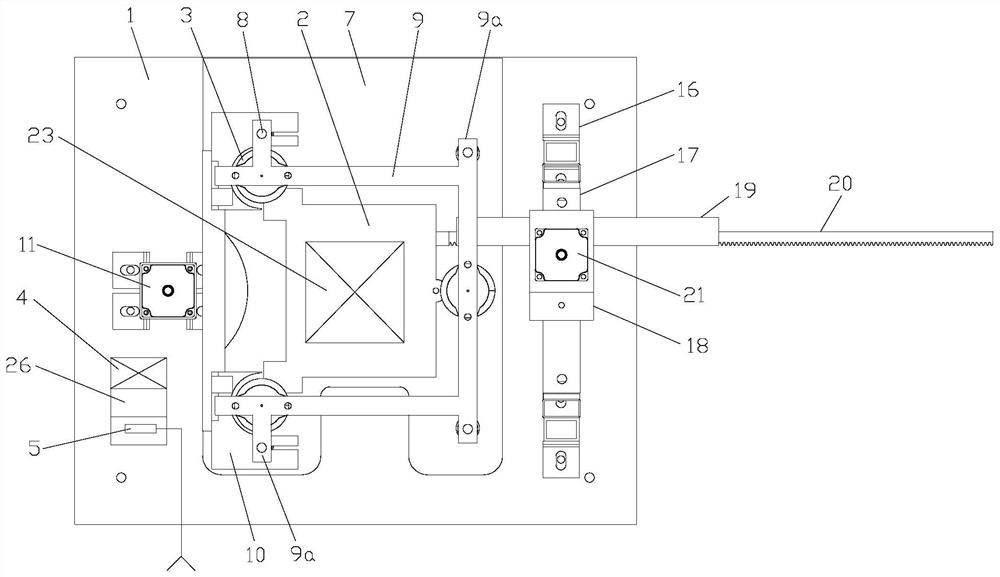

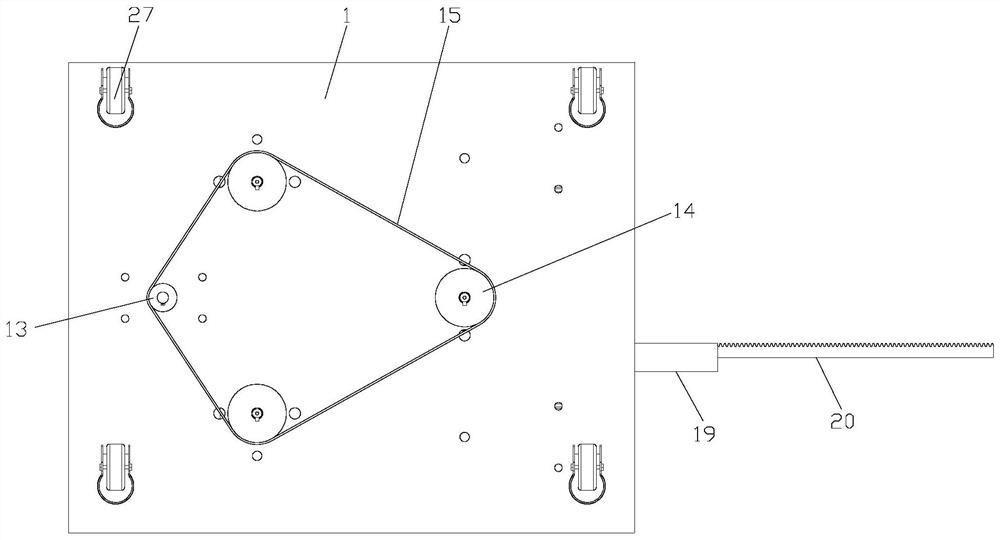

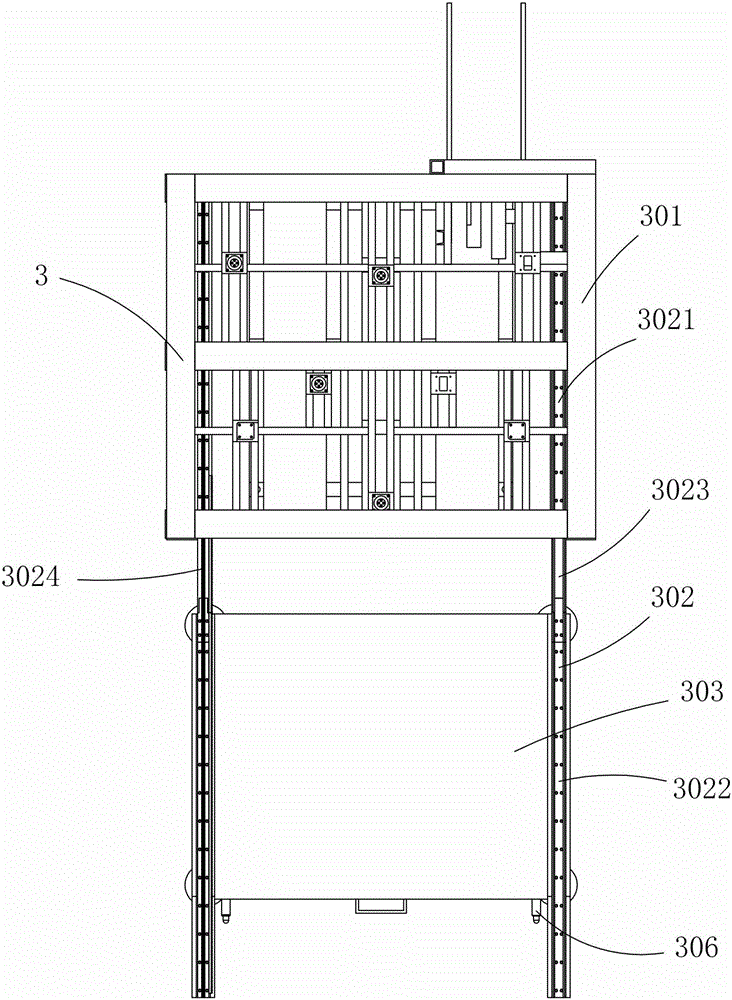

Solid state disk test system loading and unloading integrated machine

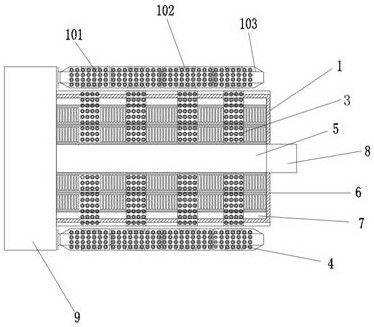

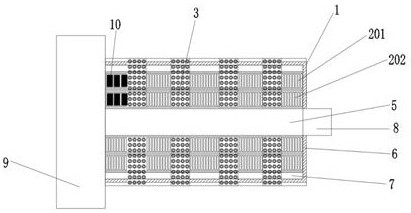

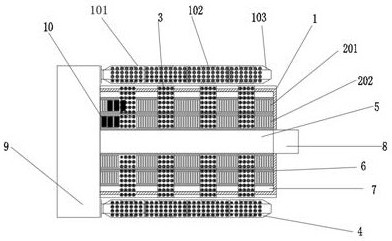

PendingCN108499893ASolve loading and unloadingSmall footprintElectrical testingRack/frame constructionSolid-state driveTransfer mechanism

The invention discloses a solid state disk test system loading and unloading integrated machine, which is suitable for taking and placing a solid state disk located at a test position of a solid statedisk test machine. The solid state disk test system loading and unloading integrated machine comprises a sorting and feeding device arranged in parallel with the solid state disk test machine, and atransfer device arranged at one side, provided with the test position, of the solid state disk test machine; one side, far away from the transfer device, of the sorting and feeding device is a loadingand unloading position; the sorting and feeding device is used for pushing the solid state disk to be tested to the side close to the transfer device from the loading and unloading position, receiving the tested solid state disk from the transfer device and moving back to the loading and unloading position; the transfer device comprises a transfer mechanism and a pluggable mechanical arm; the pluggable mechanical arm moves relative to the test position under the drive of the transfer mechanism, so as to insert the solid state disk, which is to be tested and pushed by the sorting and feeding device, into the test position, or pull out the solid state disk tested at the test position and transfer to the transfer device.

Owner:WORLD PRECISION MANUFACTURING (DONGGUAN) CO LTD

Loading and unloading system and loading and unloading method of automatic container terminal

PendingCN110040527ASolve loading and unloadingSolve the problem of less work pointsStorage devicesEngineeringFrontage

The invention discloses a loading and unloading system and loading and unloading method of an automatic container terminal, and relates to the technical field of container terminals. The loading and unloading system comprises a terminal body, a container ship, a front edge automatic loading and unloading system and a container yard loading and unloading system, wherein the front edge automatic loading and unloading system comprises a front edge automatic loading and unloading area and a front edge special container loading and unloading area; and quayside container loading and unloading bridges are arranged on the front edge automatic loading and unloading area and the front edge special container loading and unloading area. A container terminal yard is perpendicular to a frontage, and anoff-port container truck swinging space is arranged at the seaside end of a yard, so that horizontal container transport vehicles inside and outside a port directly enter the yard for loading and unloading; the functional area layout of the terminal is compact; the boundary between the automation area and the non-automation area is clear; the operation is free of interference and has low energy consumption; the loading and unloading in the yard is flexible; and the problem that the container area of an existing automatic vertical container terminal yard cannot be overlong can be solved well.

Owner:CCCC FHDI ENG

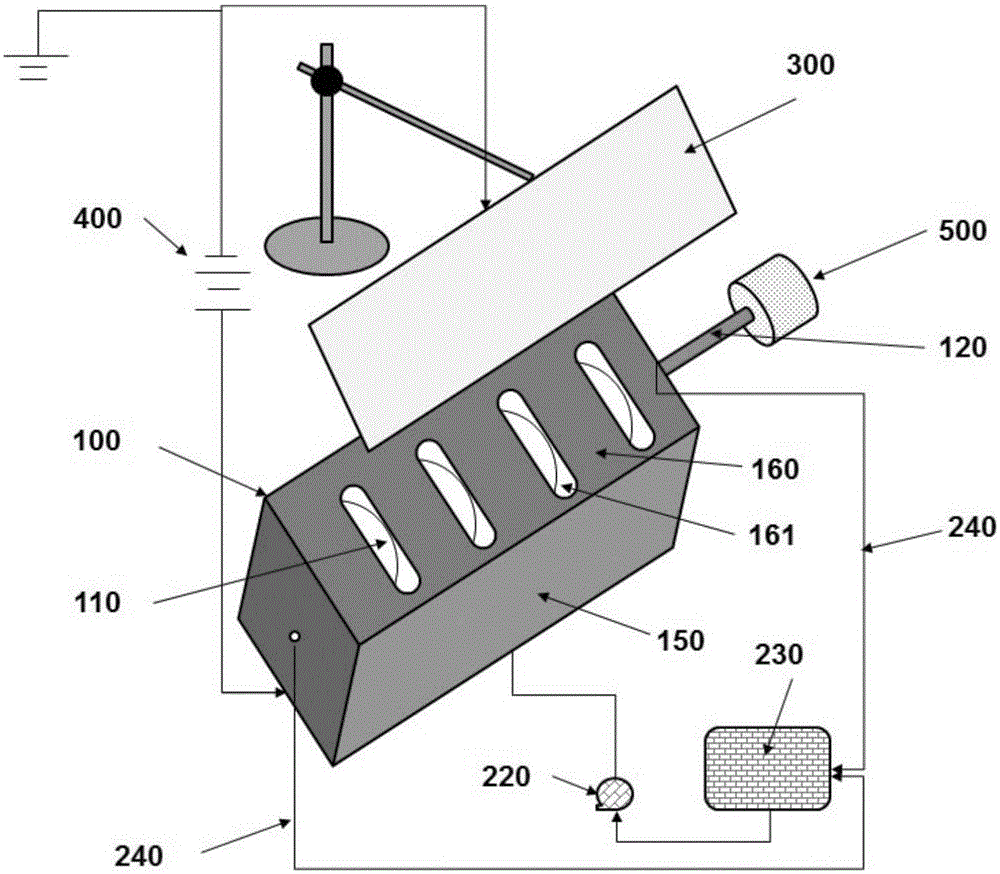

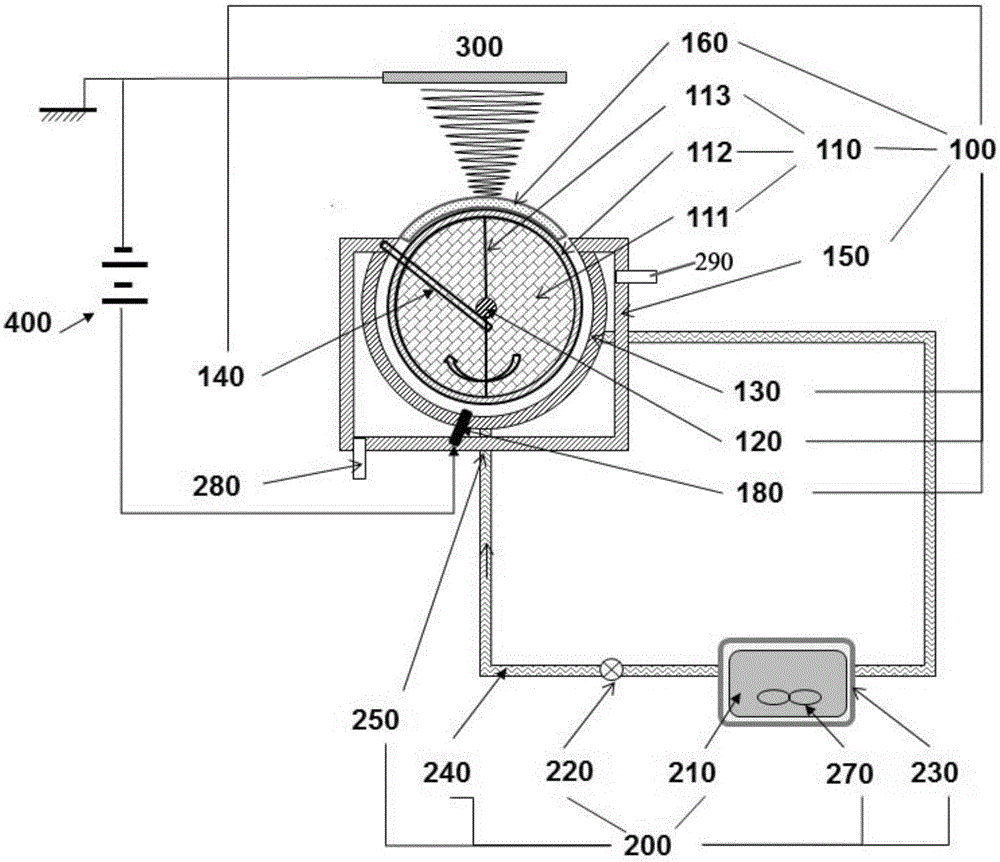

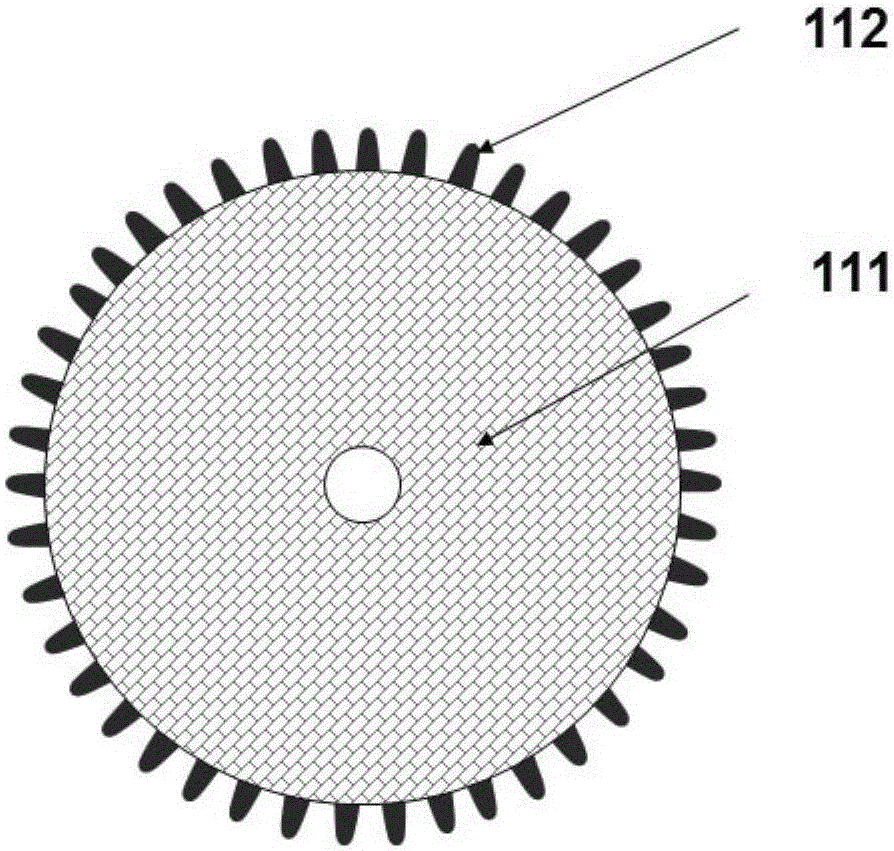

Needle-free electrostatic spinning equipment

The invention relates to needle-free electrostatic spinning equipment which is characterized by comprising a spinning box, a feeding system, a reception counter electrode, a high-voltage power source and a drive system. The feeding system is connected with the spinning box. The reception counter electrode is located above the spinning box and grounded. A positive electrode of the high-voltage power source is connected with the spinning box, and a negative electrode of the high-voltage power source is grounded. The drive system is arranged at one end of the spinning box. The equipment solves the problems of needle blocking, electric field repellence among needle heads and low spinning efficiency of a needle type spinning nozzle, the situation that due to the fact that environmental temperature changes, viscosity of feed liquid changes is avoided by means of a storage tank and a constant-temperature tank of the storage tank, the spinning nozzle is simple in structure, independent, detachable and easy to disassemble, assemble and clean, the problem of inconvenience of assembling, disassembling and cleaning a large number of spinning needle heads is solved, maintenance and repair cost is reduced, spinning efficiency is improved, large-scale production is facilitated, and the requirement of practical application can be well met.

Owner:烟台森森环保科技有限公司 +1

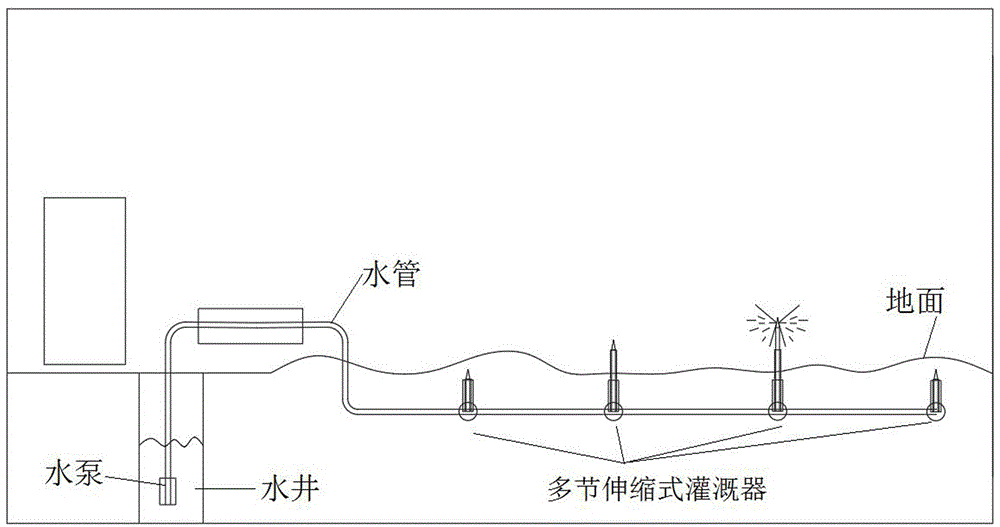

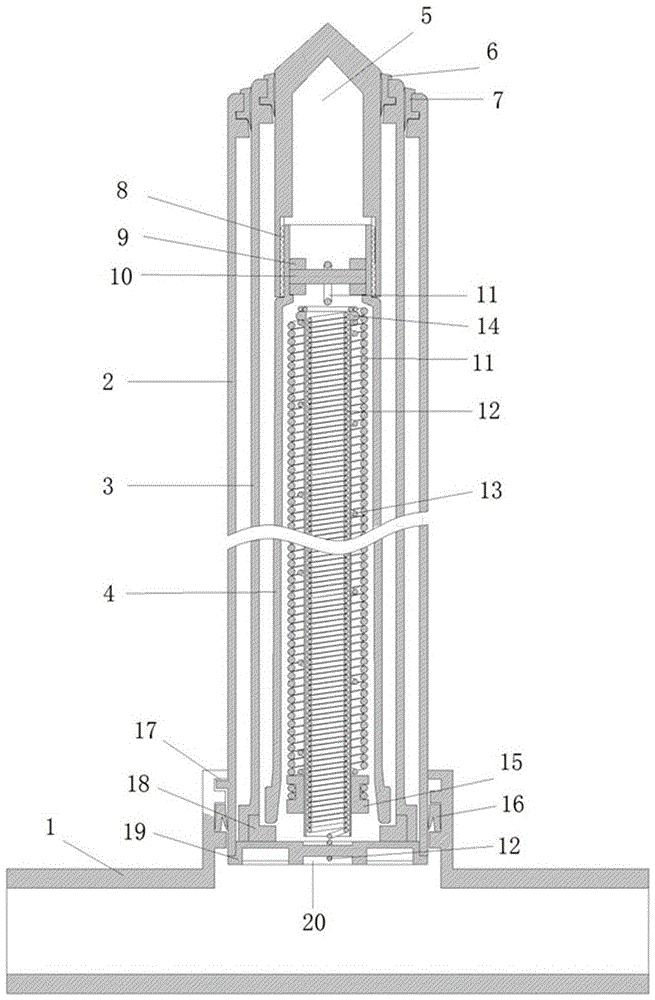

Multi-section telescopic irrigator

InactiveCN106069617ARealize intelligenceSolve frequent installationWatering devicesCultivating equipmentsEngineeringWater irrigation

The application discloses a multi-section telescopic irrigator. A spring device is arranged inside an inner tube; the spring device comprises a first tension spring, a spring, a second tension spring, an orientated isolation tube and spring pull sleeves. When used, the multi-section telescopic irrigator can be automatically lifted up by virtue of water pressure, after irrigation is completed and pressure is not supplied any more, the irrigator can be automatically withdrawn into the ground under the action of the spring device, and then field cultivation is not affected. Meanwhile, the tediousness that an upright rod, a bracket and an ejector of a conventional fixed and half-fixed sprinkling irrigation system are frequently mounted and dismounted is avoided, intellectualization and automation of irrigation and fertilization are completely achieved, and the labor can be saved by not less than 90%. As multiple sections are overlapped, not only can inconvenience of transportation, loading and unloading and storage be solved, but also the construction and mounting cost can be greatly reduced. Meanwhile, the multi-section telescopic irrigator can be matched with intelligent control equipment, and automation of the whole irrigation process can be achieved.

Owner:SHIJIAZHUANG DILONG PLASTIC

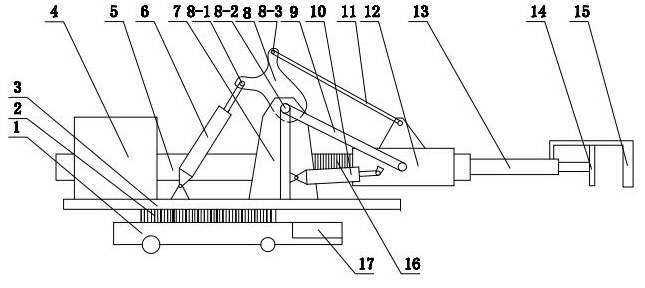

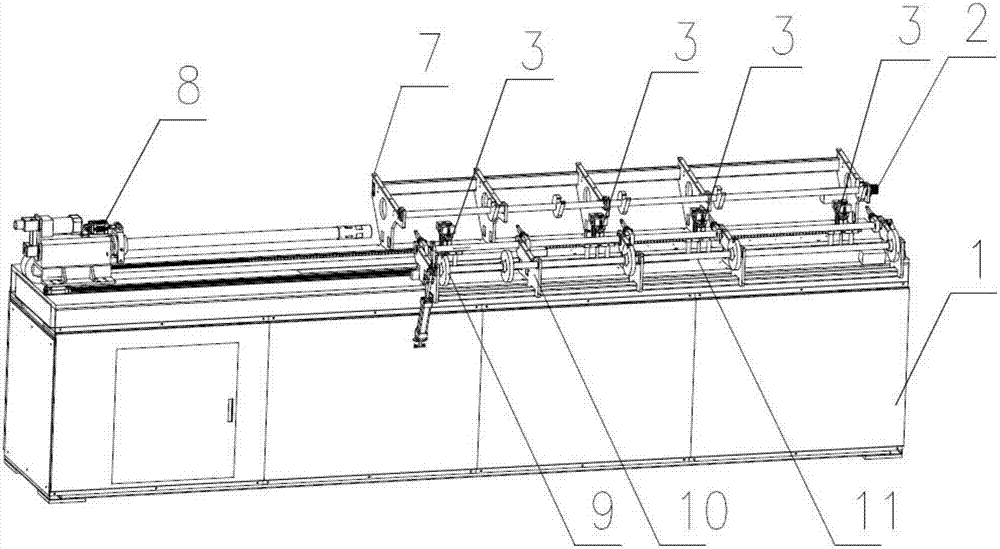

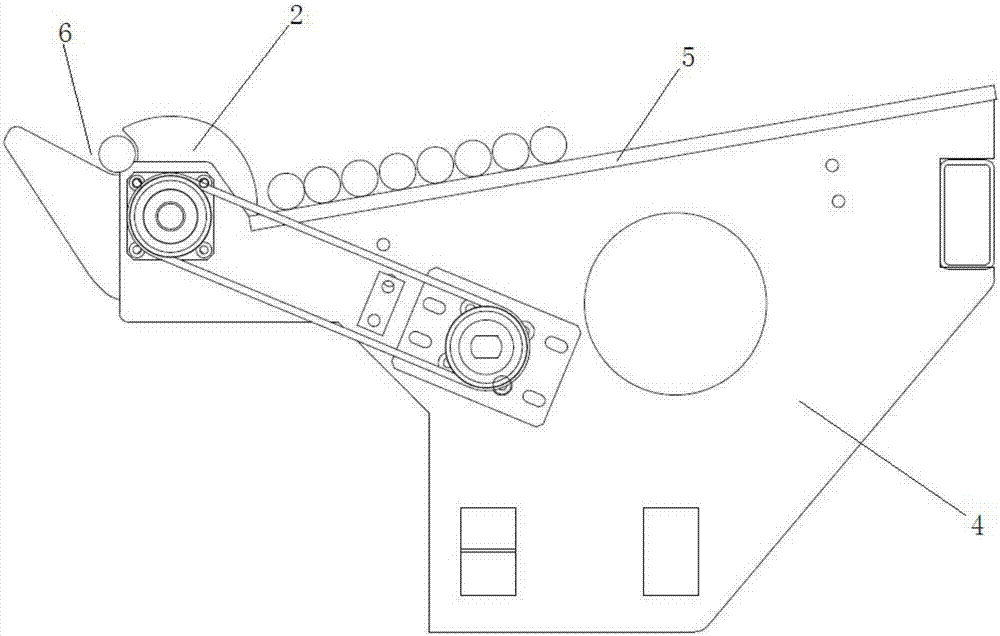

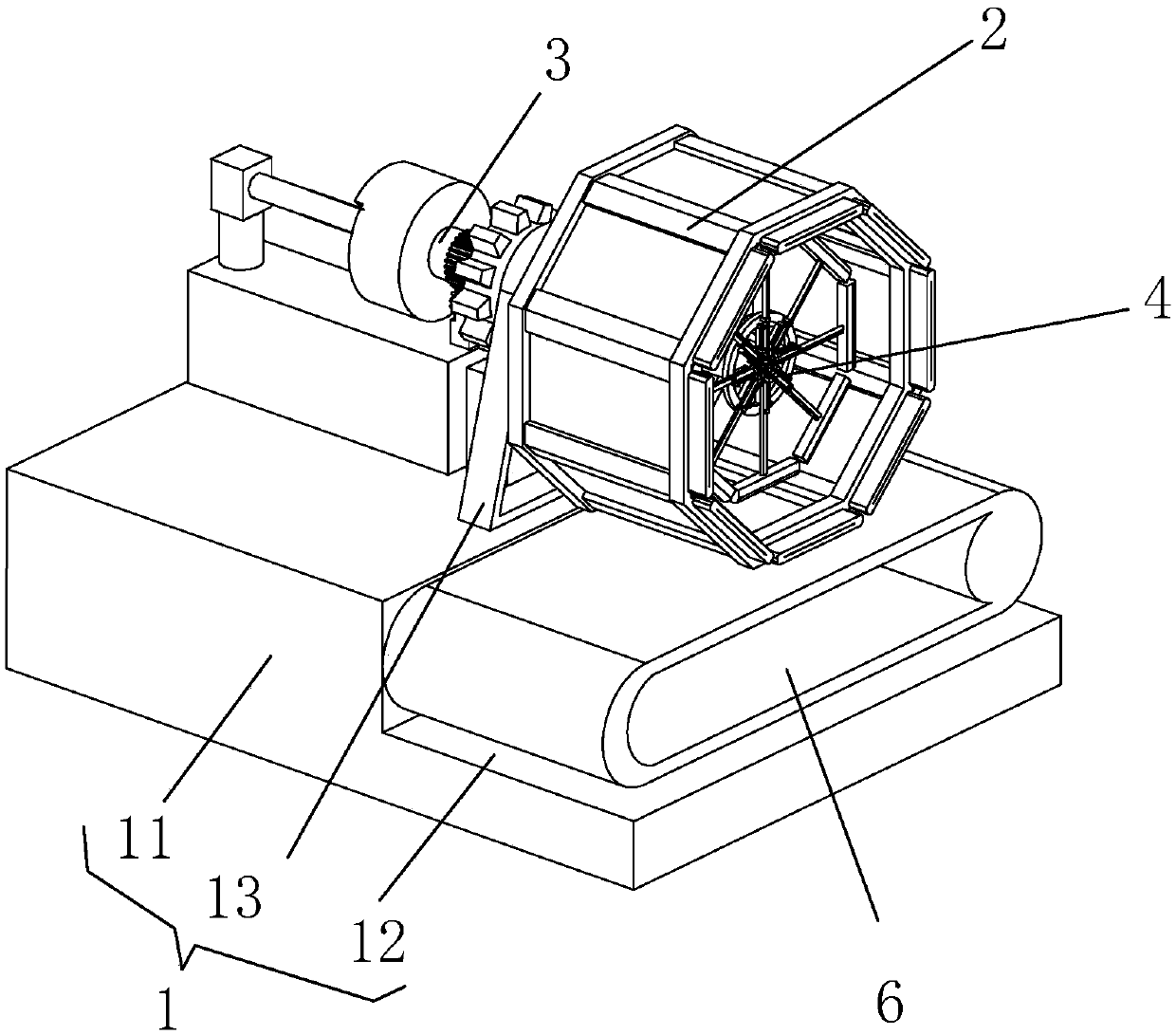

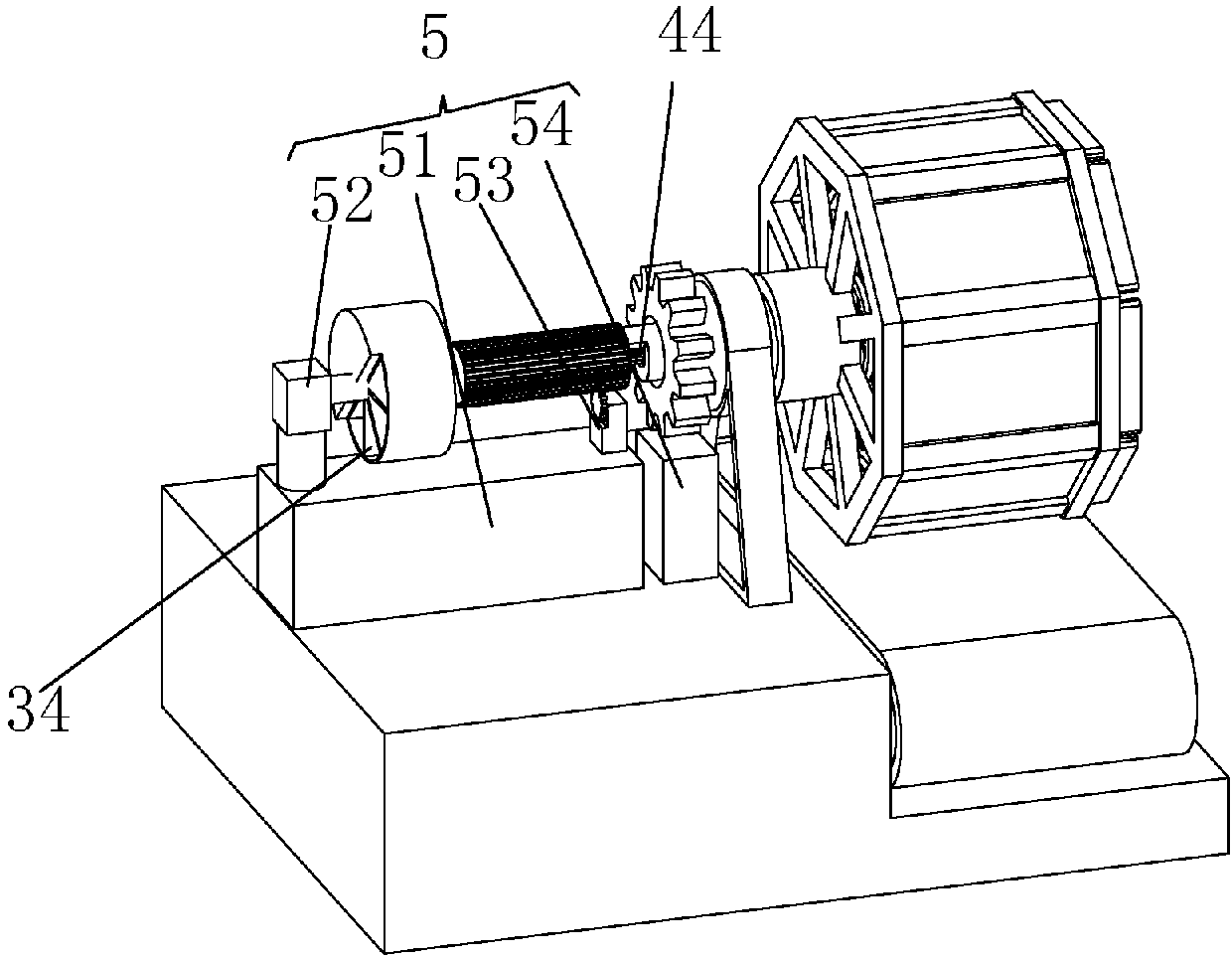

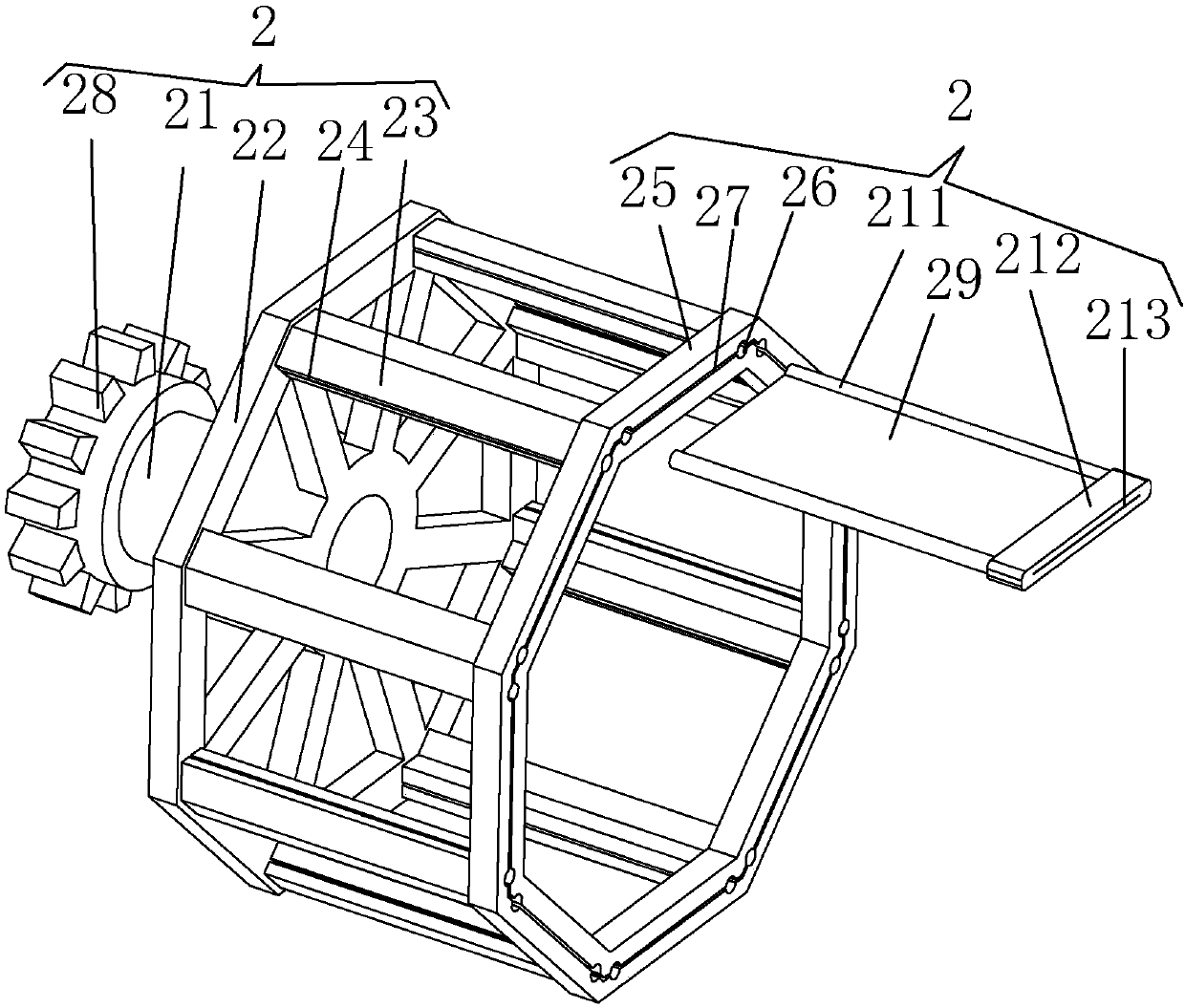

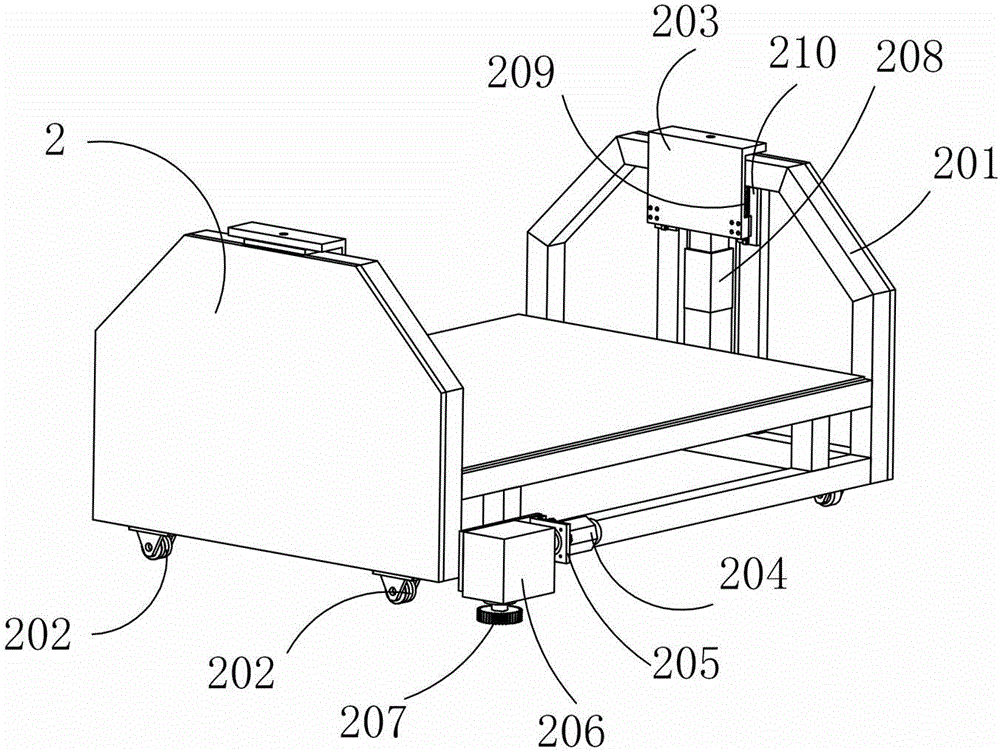

Automatic feeding device and method for machining lead screw parts

PendingCN106862991ASolve loading and unloadingHigh degree of automationMetal working apparatusMachine toolAutomation

The invention discloses an automatic feeding device and method for machining lead screw parts. The automatic feeding device comprises a feeding workbench; the feeding workbench is provided with a distributing and charging assembly, a plurality of supporting cylinder assemblies, a charging bracket assembly, a feeding trolley assembly, a distributing and discharging assembly, a discharging bracket assembly and a discharging assembly; the charging bracket assembly and the discharging bracket assembly are respectively arranged at two sides of the feeding workbench; the feeding trolley assembly is mounted on a sliding rail of the feeding workbench and is used for clamping to-be-machined or machined lead screw parts and feeding the to-be-machined or machined lead screw parts into a machine tool for machining and taking the to-be-machined or machined lead screw parts out of the machine tool; the plurality of supporting cylinder assemblies are mounted at the lower part of the charging bracket assembly; the distributing and charging assembly is mounted at the upper part of the charging bracket assembly; the discharging assembly is mounted on the discharging bracket assembly; and the distributing and discharging assembly is mounted on the discharging bracket assembly; The automatic feeding device is relatively high in automation degree, high in machining efficiency and favorable in application prospect and is used for solving the problem of manual charging and discharging of the lead screw parts and reducing the manual labor intensity.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

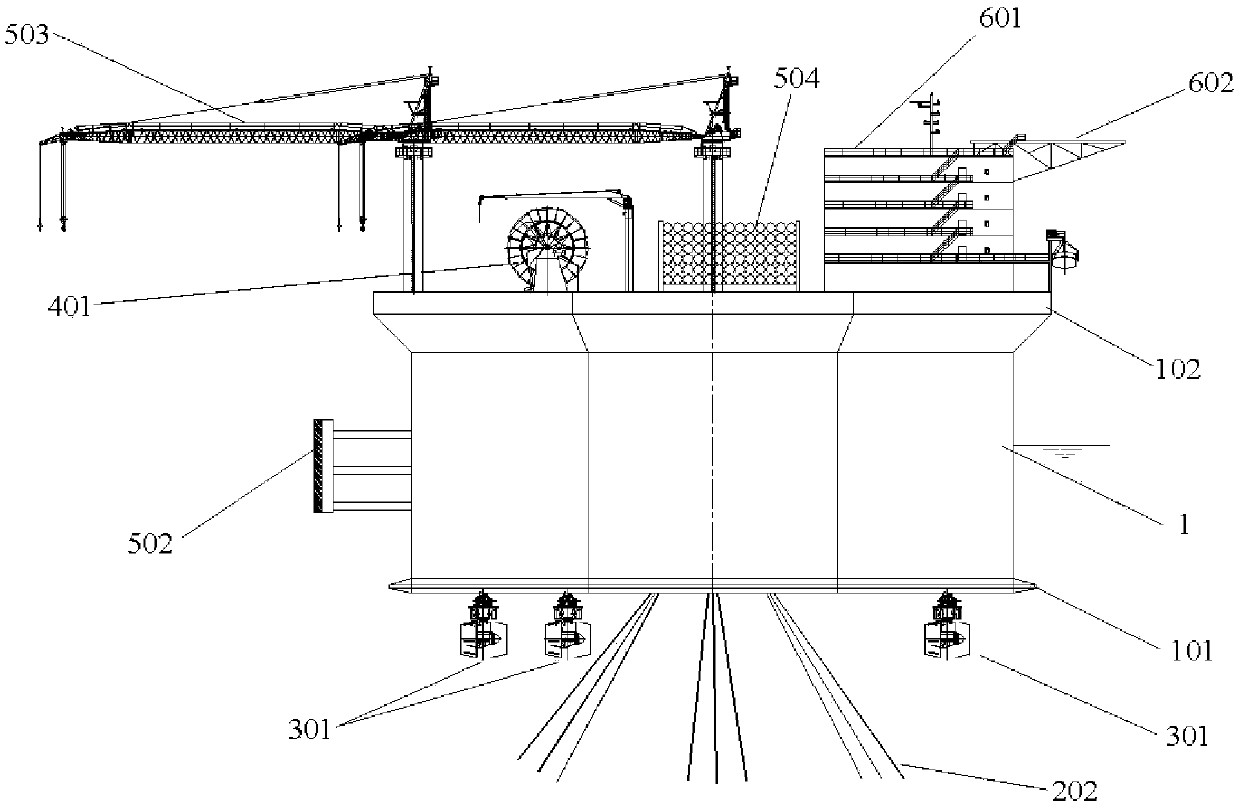

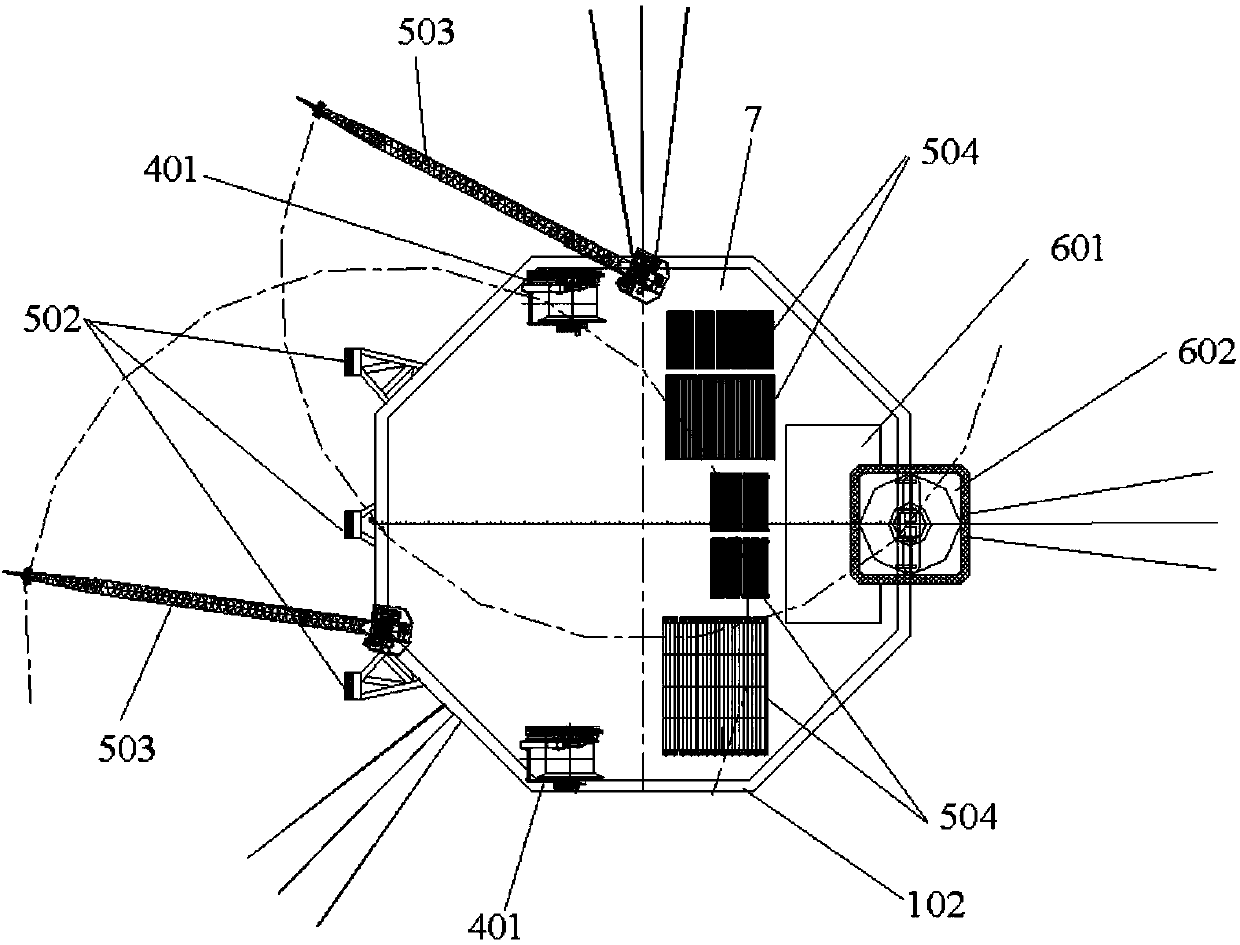

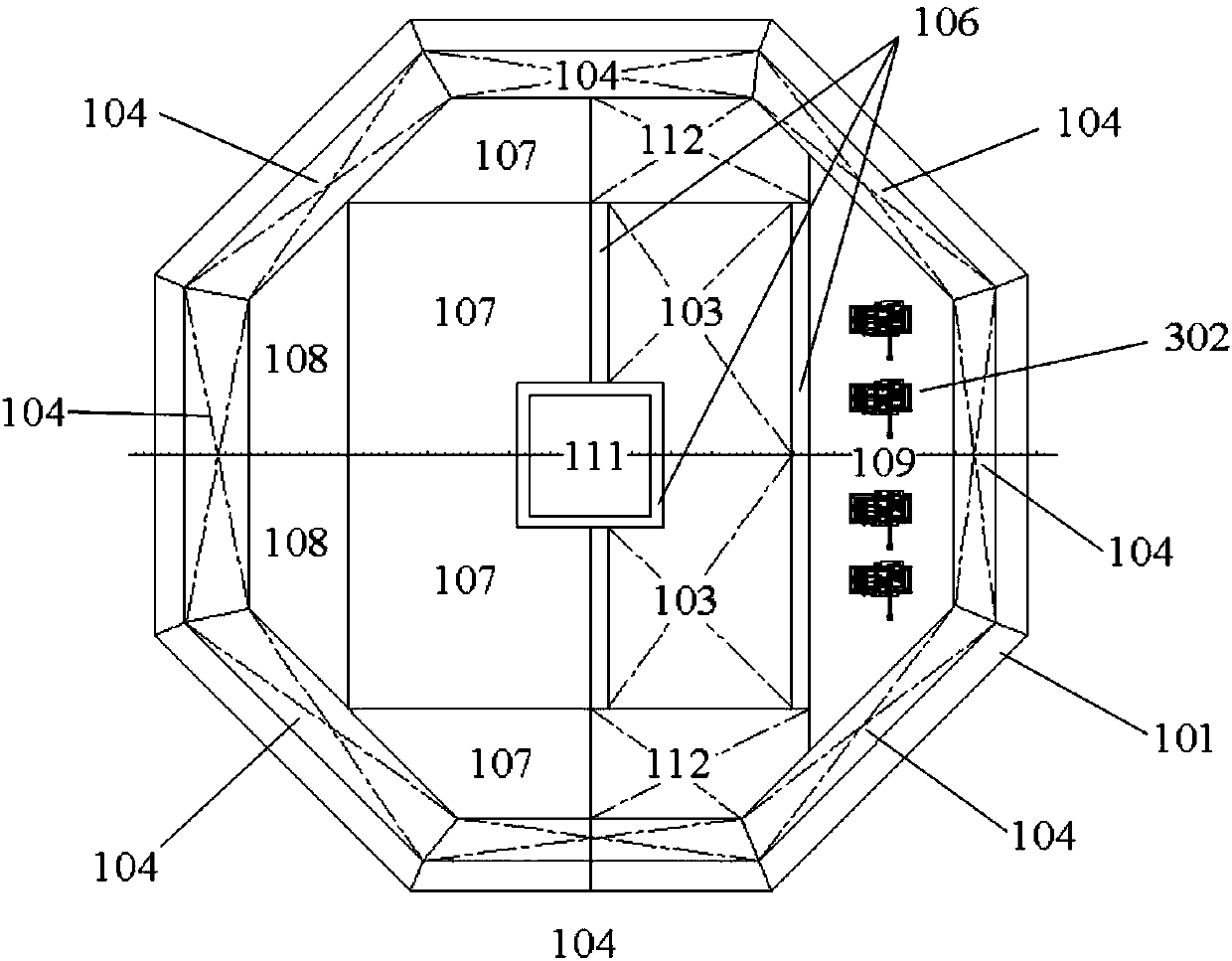

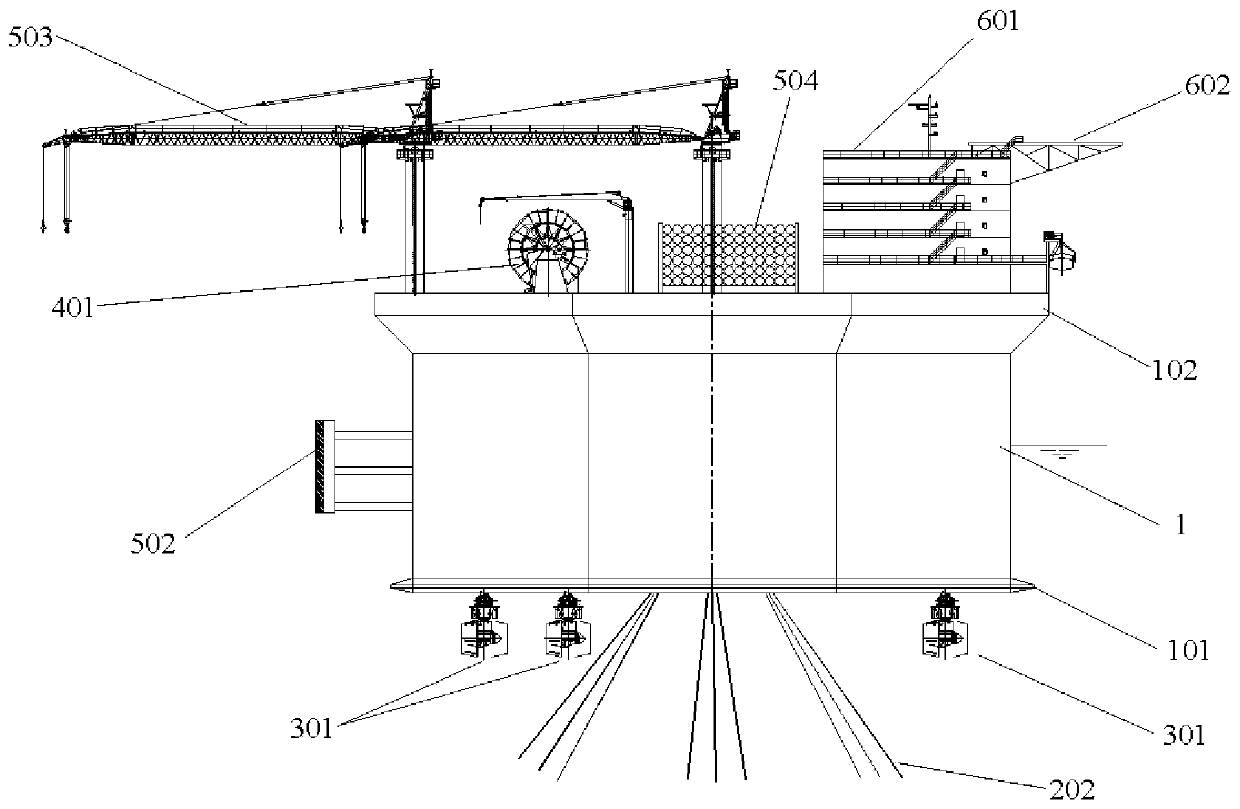

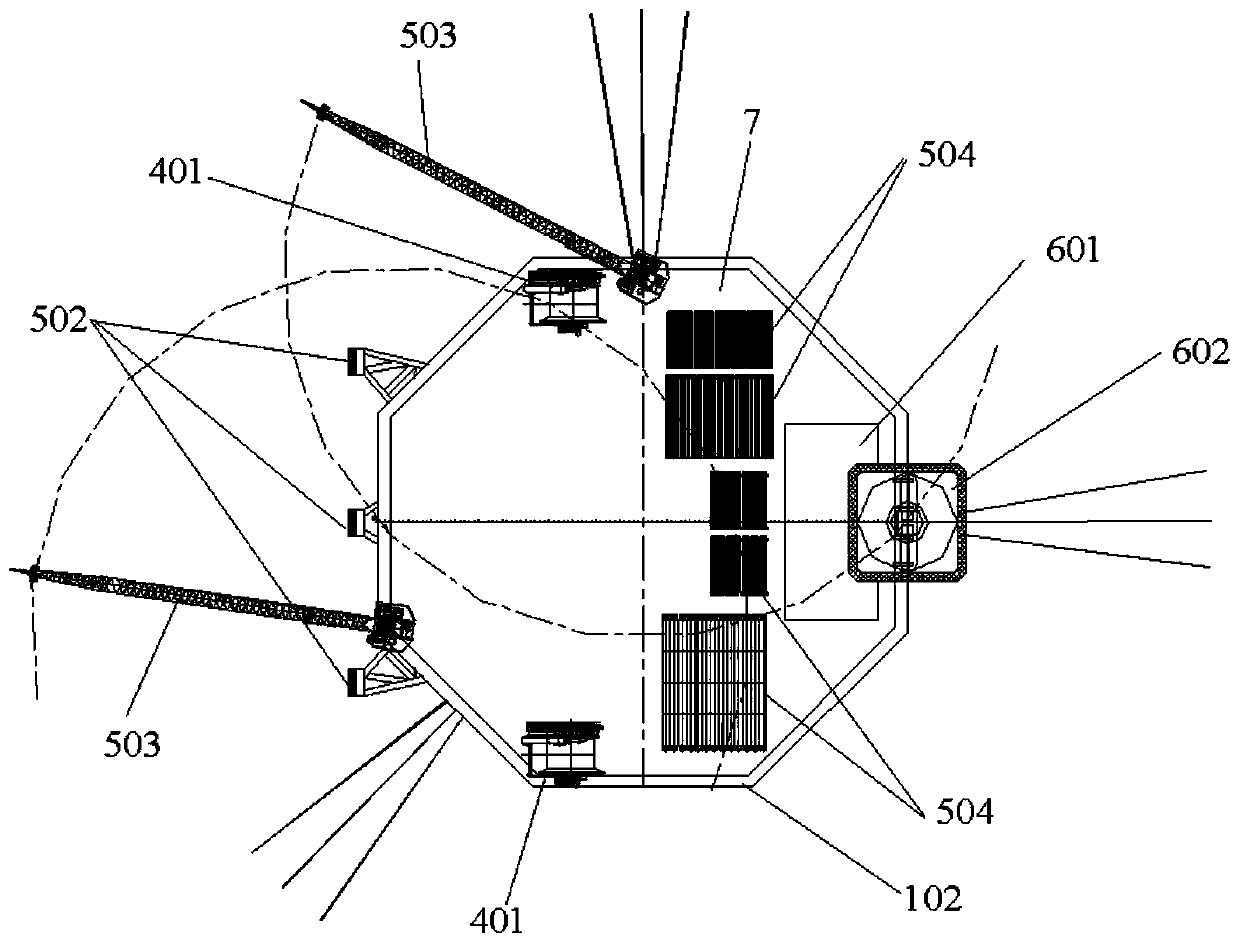

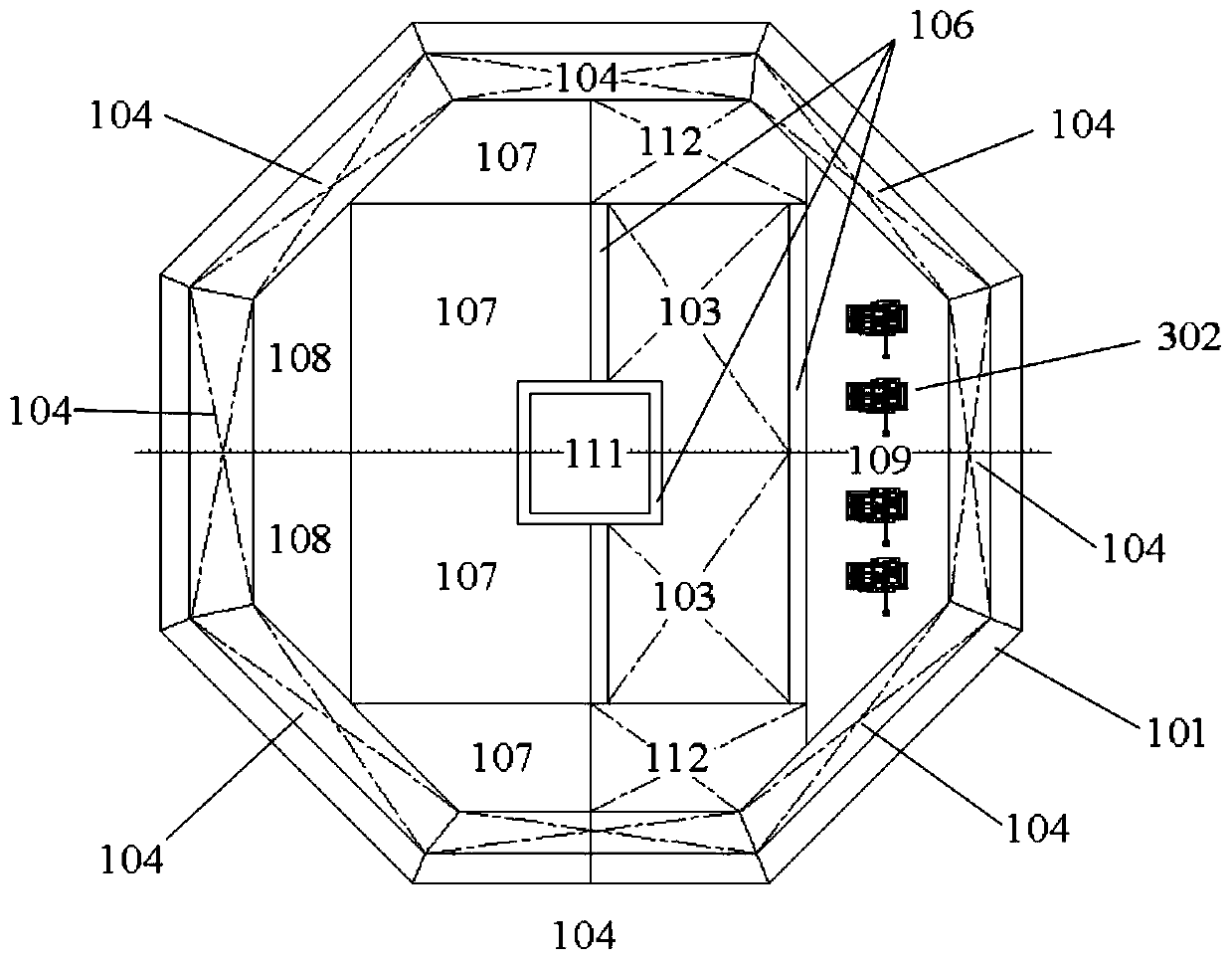

Deep sea oil-gas field development drilling supply storage transfer floating type platform

ActiveCN107640296AReduce difficultyImprove economyFloating buildingsAnchoring arrangementsFuel tankSupply Storage

The invention relates to a deep sea oil-gas field development drilling supply storage transfer floating type platform. The platform is characterized by comprising a nearly circular floating body and adeck arranged on the top of the nearly circular floating body, the nearly circular floating body is internally provided with a fuel oil tank, a ballast water tank, a pump room, a cofferdam, a dry bulk tank, a production waste tank, a cabin, a thruster room, a single point cabin, a fresh water tank and a drilling water tank; a single point mooring system is arranged in the single point cabin; a telescopic all-rotation propeller system is arranged in the thruster room; an electric generator is arranged in the cabin; a liquid cargo handling and tandem mooring system is arranged on the deck; a side by side mooring system is arranged on the side face of the nearly circular floating body; the deck is provided with a crane, a drilling supply stacking area, a living building and a helicopter platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

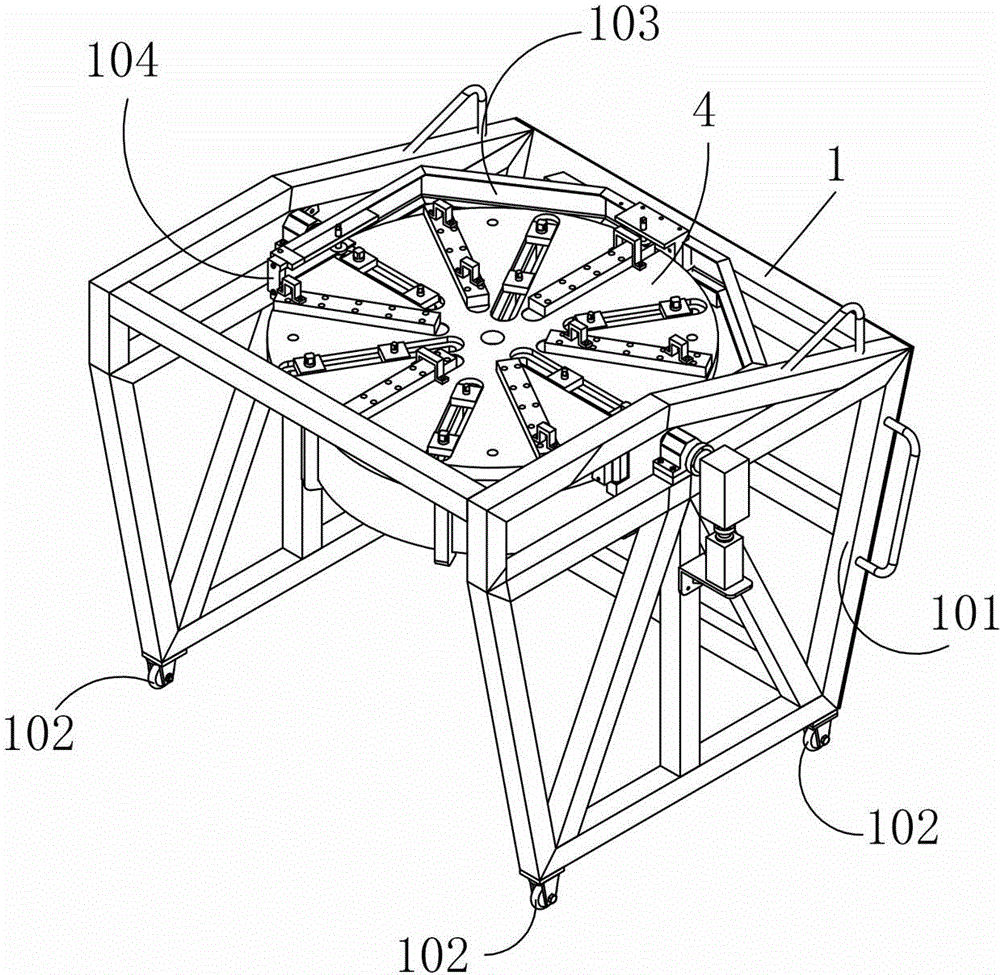

Device and method for installing and detaching large mirror for ion beam polisher for large-caliber optical parts

The invention discloses a device for installing and detaching a large mirror for an ion beam polisher for large-caliber optical parts. The device comprises a bearing device, a turning device for transporting measured workpieces and enabling workpiece faces to be machined to be kept downward in the transportation process and a conveying device for carrying the workpieces transported by the turning device and conveying the workpieces to an ion beam polishing vacuum chamber of the polisher. The bearing device comprises a guide trail and an inner frame arranged in the ion beam polishing vacuum chamber and used for carrying the workpieces conveyed by the conveying device. The conveying device is arranged on the guide rail and moves along the guide rail. The device is simple in structure, convenient to operate and control and capable of guaranteeing cleanness of working environment of the ion beam polisher, improves machining precision and machining efficiency of the ion beam polisher, and prolongs the service life of the device. The invention further discloses a method for installing and detaching the large mirror for the ion beam polisher for the large-caliber optical parts.

Owner:NAT UNIV OF DEFENSE TECH

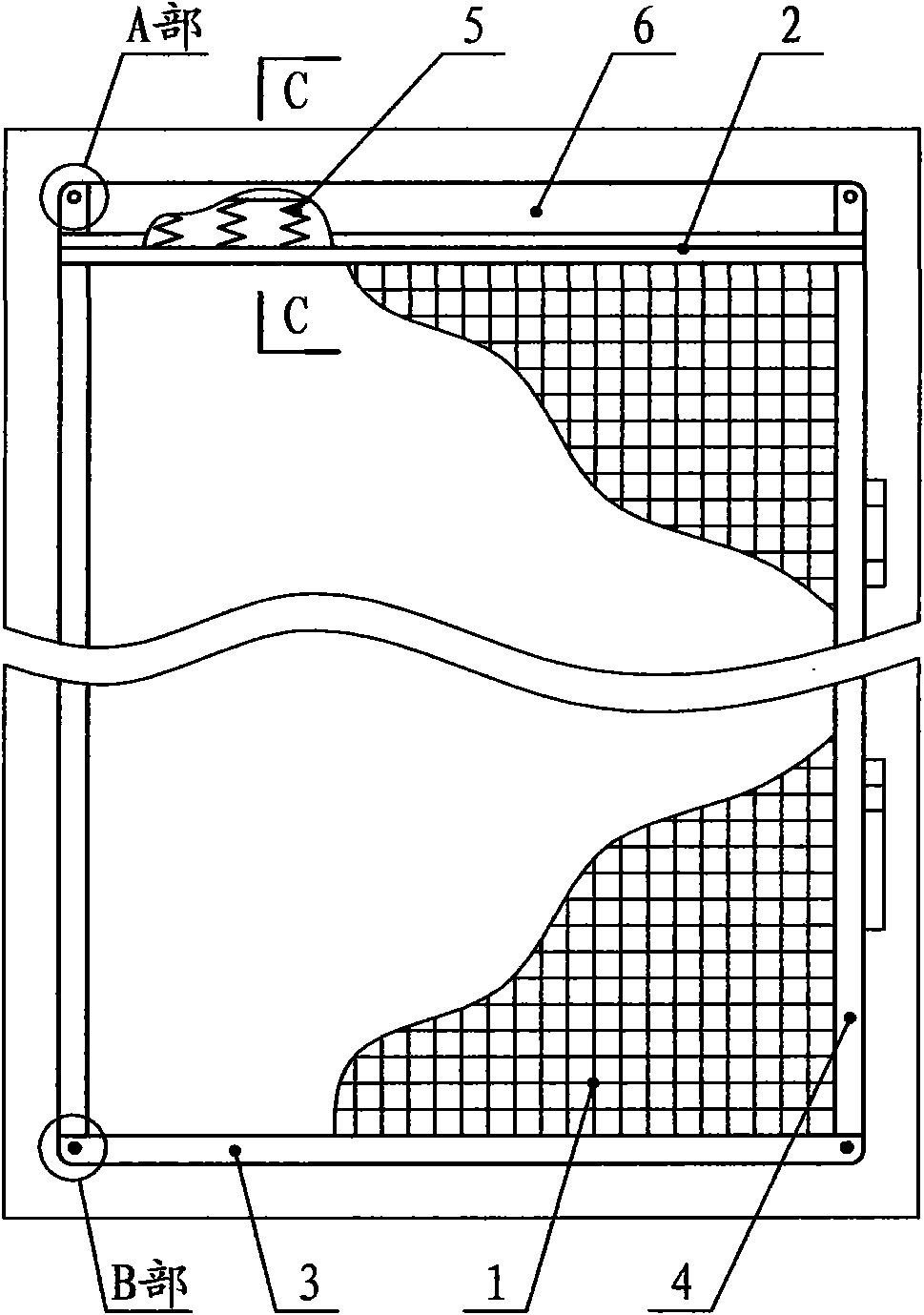

Elastic force tensioned window screen

InactiveCN101806190AEasy to switchLoading and unloadingInsect protectionWing framesSlab windowSash window

The invention relates to an elastic force tensioned window screen which belongs to the field of anti-mosquito devices for windows in buildings and aims at solving the problem of poor combination property commonly existing in the traditional window screens. The invention has the technical scheme that an elastic force assembly is arranged above the bottom face of the upper frame of the window screen or / and under the top face of the lower frame of the window screen, and generally, the elastic force assembly is provided with a secondary frame and is provided with a baffle part if necessary. When the window screen is in a working state, the side frame of the window screen reaches the tension intensity of the set wind resistance through vertical tension generated by pull force in the perpendicular direction. The position limiting function can also ensure no oversize seam of the side frame of the window screen in storm wind. The side frame of the window screen can be coiled so that the window in a building can be opened and closed after collecting or lifting the window screen. Connecting parts for assembly are generally hanging type, sleeve type and inserting type fittings, which are easy to install and disassemble and are prevented from falling. The invention is suitable for out-opening windows, sash windows and the like in buildings.

Owner:郭波

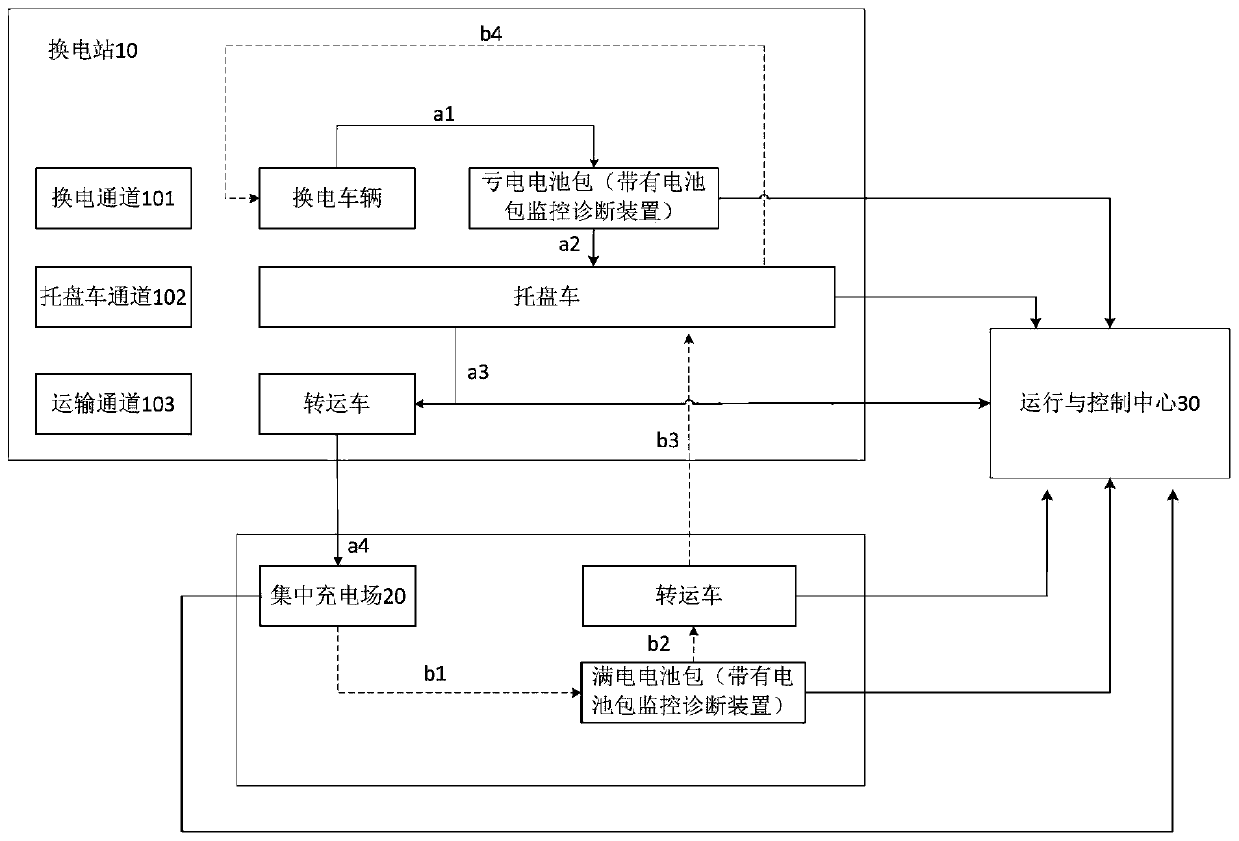

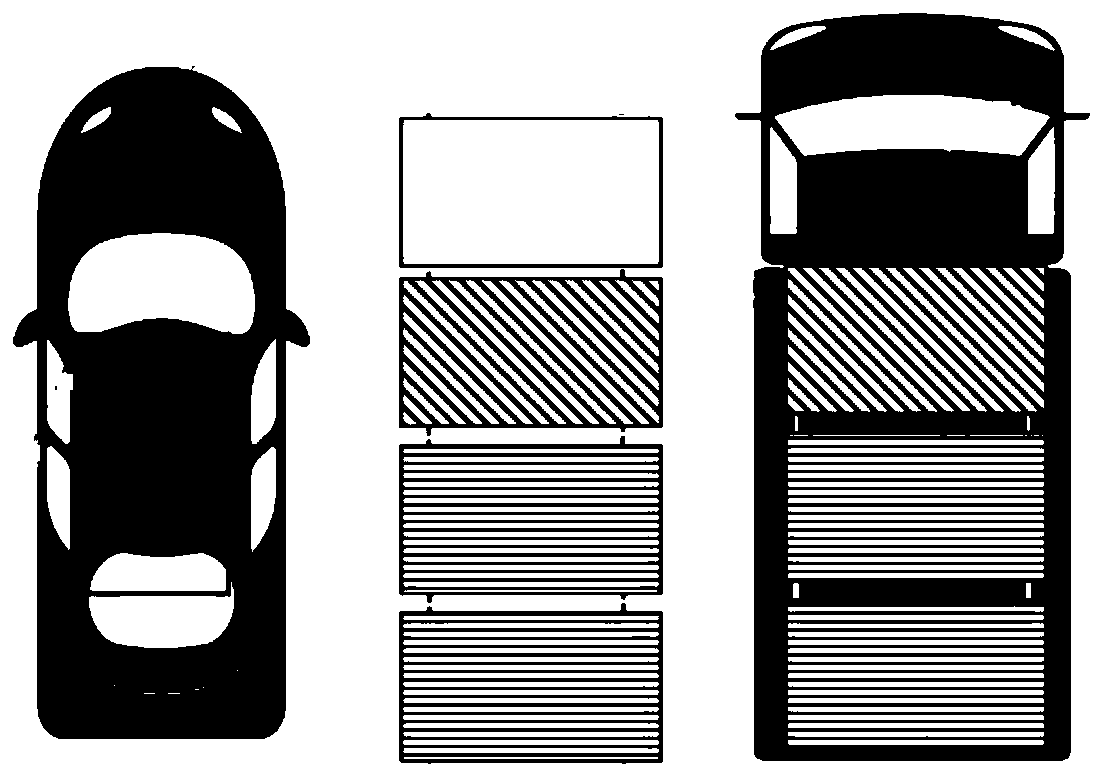

Electric vehicle battery replacing system and method in charging and replacing separation mode

ActiveCN111452664ASolve loading and unloadingSolve shipping problemsCharging stationsElectric vehicle charging technologyElectric-vehicle batteryElectrical battery

The invention relates to an electric vehicle battery replacing system and a method which are in a charging and replacing separation mode. The system comprises a battery replacing station, a centralized charging field, a battery pack data management system and an operation and control center. The battery replacing station is provided with a battery replacing channel, a pallet truck channel and a transportation channel; the pallet truck channel is provided with a pallet truck; the battery replacing channel is arranged to be corresponding to a battery replacing operation area, a power-lack battery pack is unloaded and placed in the pallet truck in the battery replacing operation area, and a full-charge battery pack is loaded to a battery replacing vehicle; and the transportation channel is arranged to be corresponding to a transportation operation area and is used for the pallet truck to transfer the power-lack battery pack and the full-charge battery pack between the battery replacing station and the centralized charging field in the pallet truck. The battery pack data management system comprises a plurality of battery pack monitoring and diagnosing devices, and the operation and control center exchanges data with the battery packs of the battery replacing station, the centralized charging field and the transfer link through a battery pack monitoring and diagnosing device. The system can overcome the defect of charging in a charging and replacing integrated mode, has good practicability and is easy to popularize.

Owner:浙江秦欧控股集团有限公司

Screen printing machine capable of rotating and switching films

The invention discloses a screen printing machine capable of rotating and switching films. The screen printing machine comprises a base, and is characterized in that the upper side of the base is provided with a circuit assembly, the front side of the base is provided with a conveying belt used for conveying screen printing plates, the upper side of the conveying belt is provided with a film switching device, a rotating device is arranged in the film switching device, and one side of the rotating device is provided with a scraper blade device. According to the screen printing machine, the structure is simple, using is convenient, the problem that the films cannot be automatically loaded, unloaded and switched through an existing screen printing machine can be solved, the needed films can be loaded at a time, after printing of one film on a printed product is completed, the used film can be directly replaced with another film, the working procedure is quite automatic, and the screen printing machine is quite convenient when being applied to industrial multi-batch production.

Owner:MEIBAN TECH ZHONGSHAN CO LTD

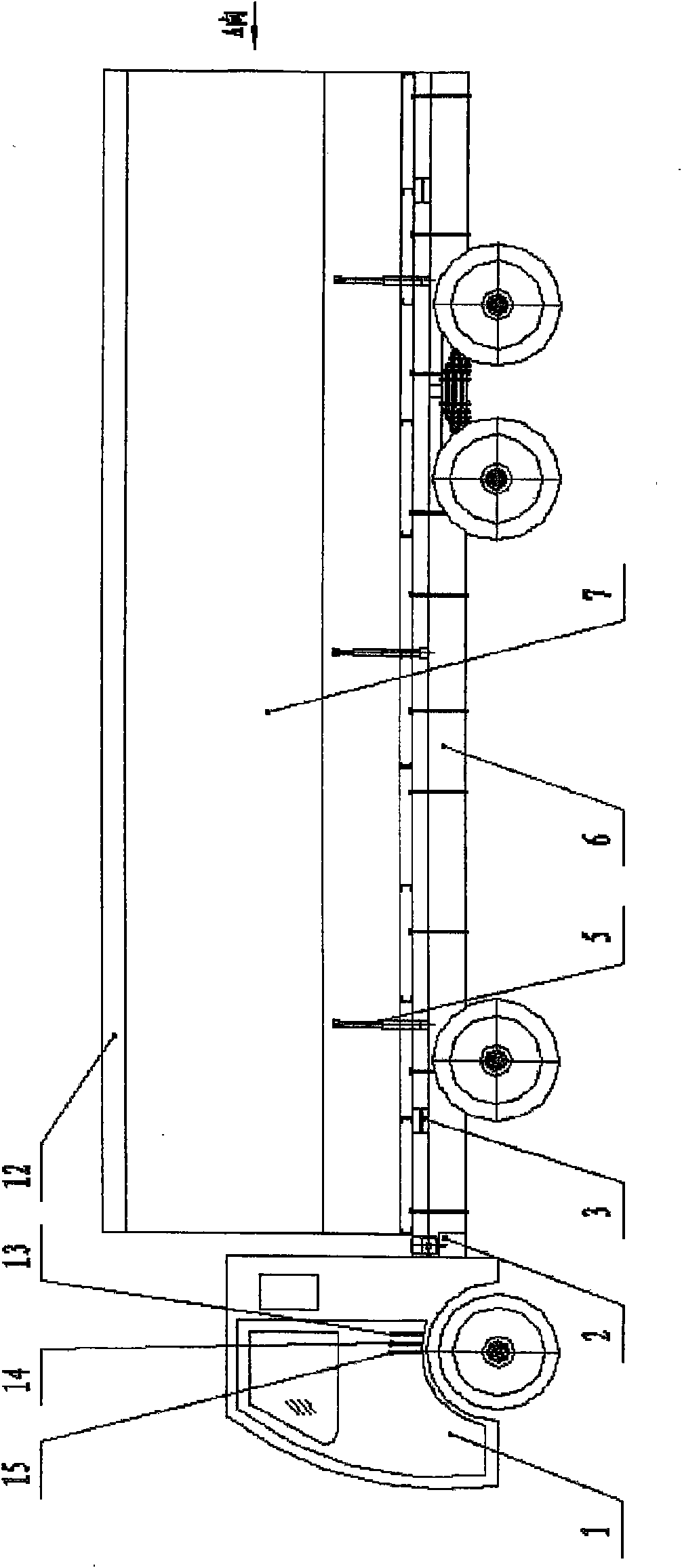

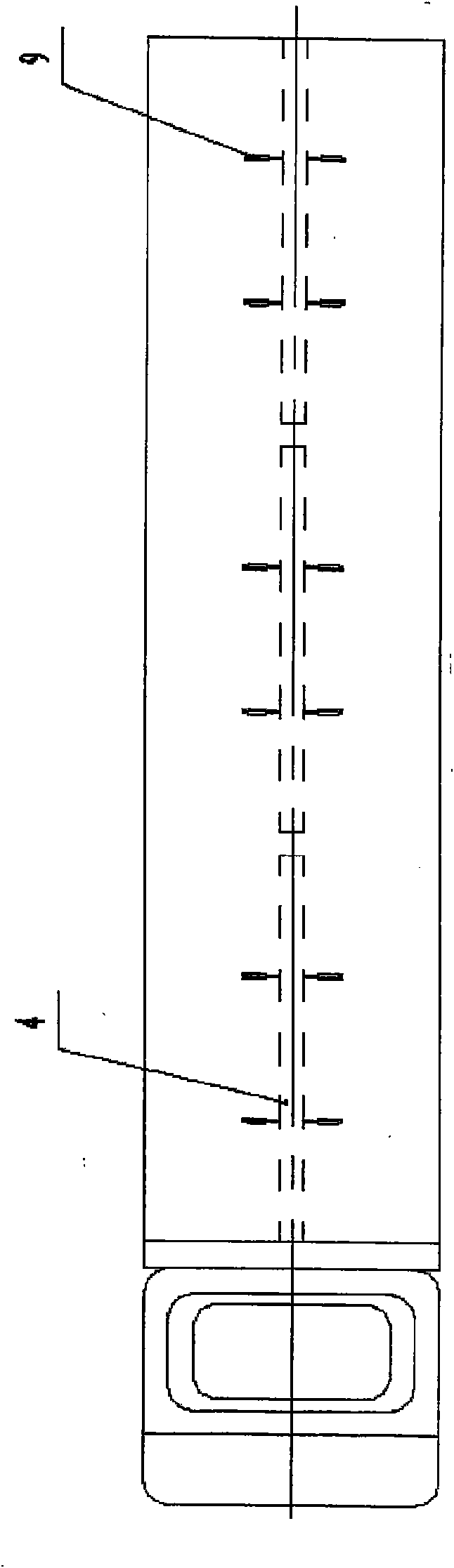

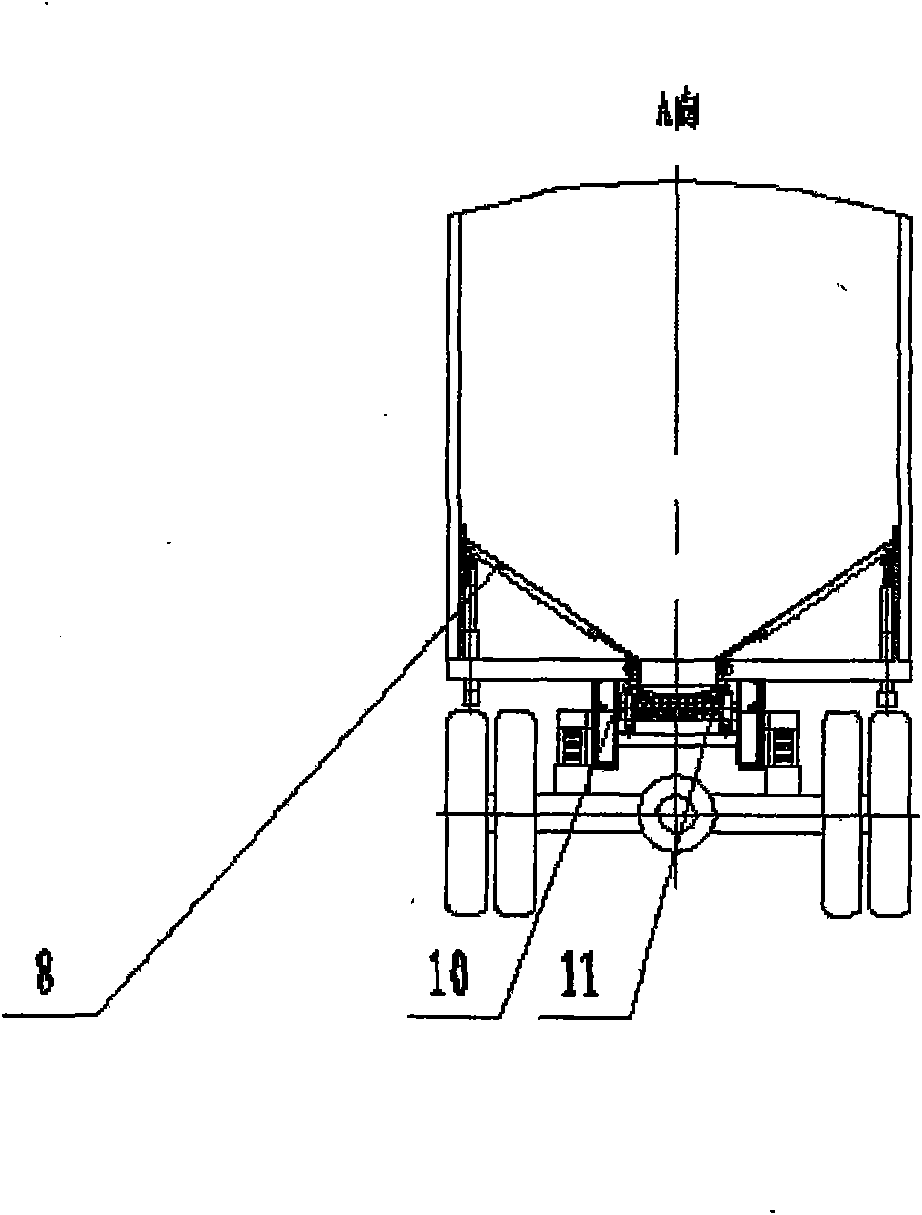

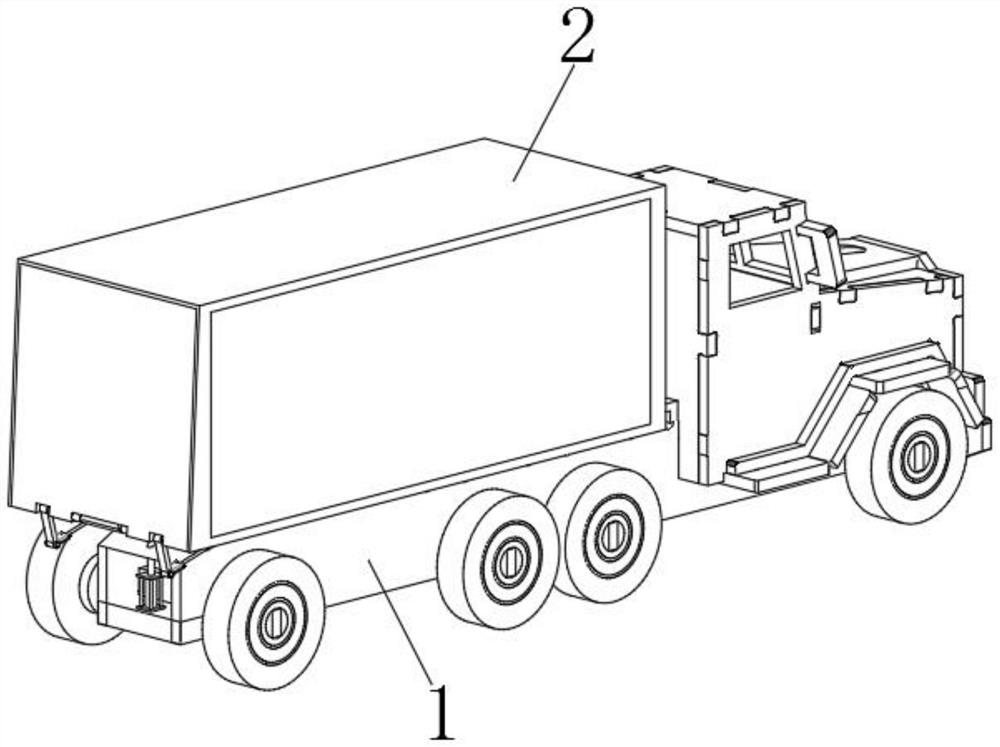

Novel multi-use bulk grain transport automobile

InactiveCN101570152ALow costSolve loading and unloadingItem transportation vehiclesVehicle with screw conveyorsVehicle frameEngineering

At present, most food grain is packed and loaded on the automobile for transportation in the food grain circulation, so that a great deal of labor force is needed, the working efficiency is low, and the cost for moving the food grain is increased. The invention aims at solving the practical problems in the process of loading, unloading and transporting the bulk grain, so as to lighten the labor intensity, realize rapid loading, unloading and transporting and greatly save the cost for moving the food grain. A novel multi-use bulk grain transport automobile mainly comprises two parts: a finished automobile chassis and wagon box and an automatic unloading mechanism; meanwhile, flexible connection is adopted between a wagon box body and a frame bottom beam of the bulk grain automobile, two weighting sensors are arranged at the two sides, and the loading quantity can be directly displayed without being weighed.

Owner:曹全礼

Simple hinge type manual feeding and discharging device for shaft hobbing

ActiveCN105252331AEasy to operateReduce labor intensityAutomatic workpiece supply/removalMetal working apparatusLower limitHobbing

The invention discloses a simple hinge type manual feeding and discharging device for shaft hobbing. The simple hinge type manual feeding and discharging device for shaft hobbing comprises two link rods. The lower ends of the two link rods are fixedly connected with a hinge bracket. The upper ends of the link rods are connected with a machine tool tailstock through transition flanges. A lower limiting bracket is arranged below the hinge bracket, fixed to a machine tool stand column and used for limiting the lower extreme position of the hinge bracket. During machining, the lower end of a workpiece stretches into a clamp body and rotates along with a workbench after being clamped; the machine tool tailstock moves up and down to drive a whole mechanism and the workpiece to move up and down, and thus the workpiece can be placed in and taken out of the clamp body. By designing the simple hinge type feeding and discharging device and fixing the simple hinge type feeding and discharging device onto the machine tool tailstock, the workpiece is taken out of the clamp body by means of the upward movement of the tailstock when a machine tool is loosened; then the workpiece is rotated out of the center of a clamp to reach a position in front of a protective door through a hinge type rotary mechanism, and discharging operation is conducted by a worker. The feeding action is conducted in the sequence opposite to the discharging action.

Owner:SHAANXI FAST GEAR CO

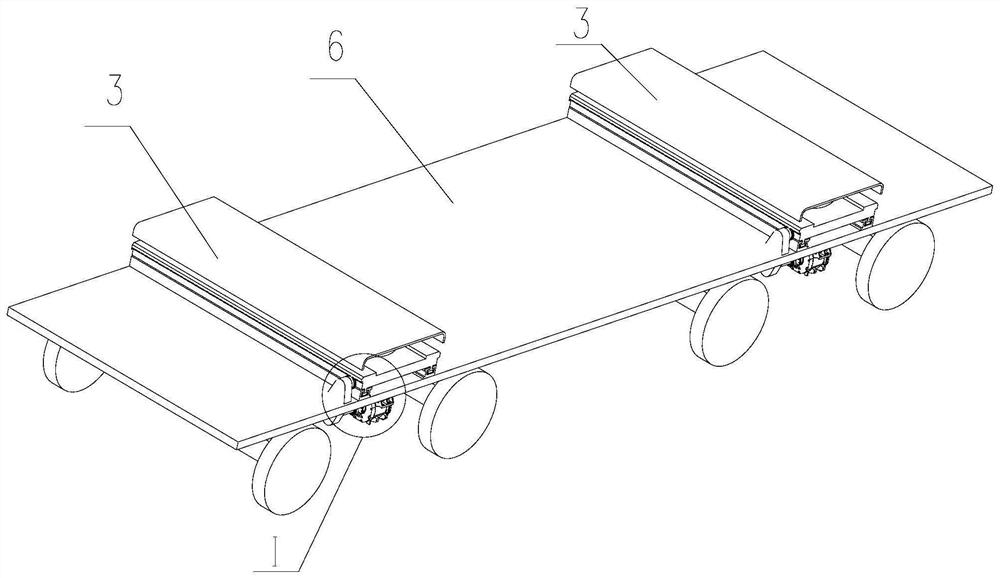

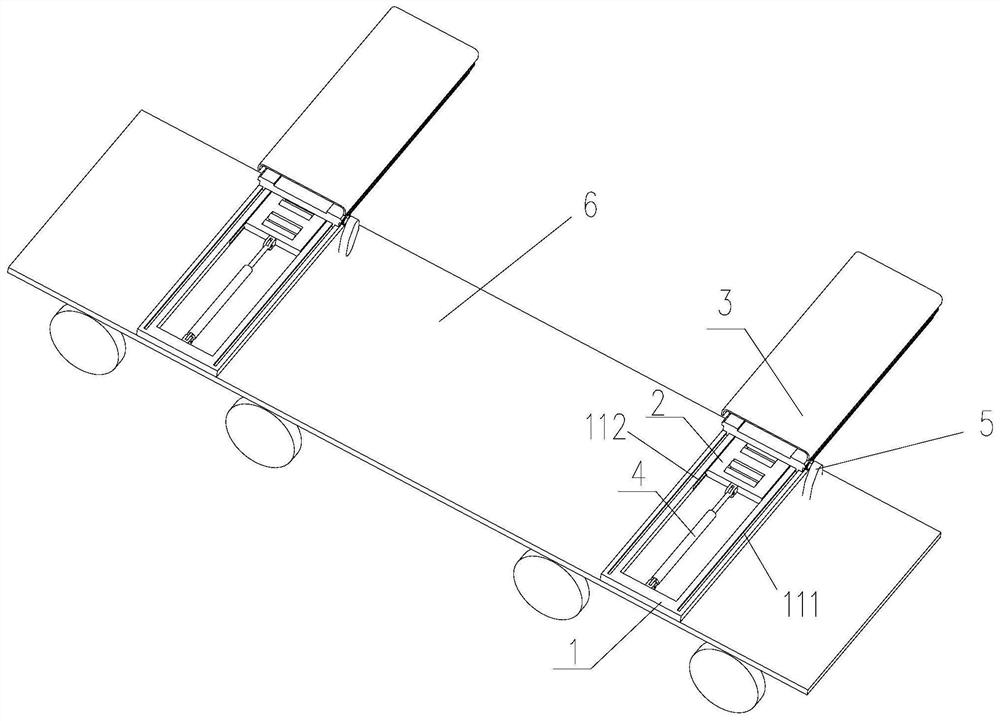

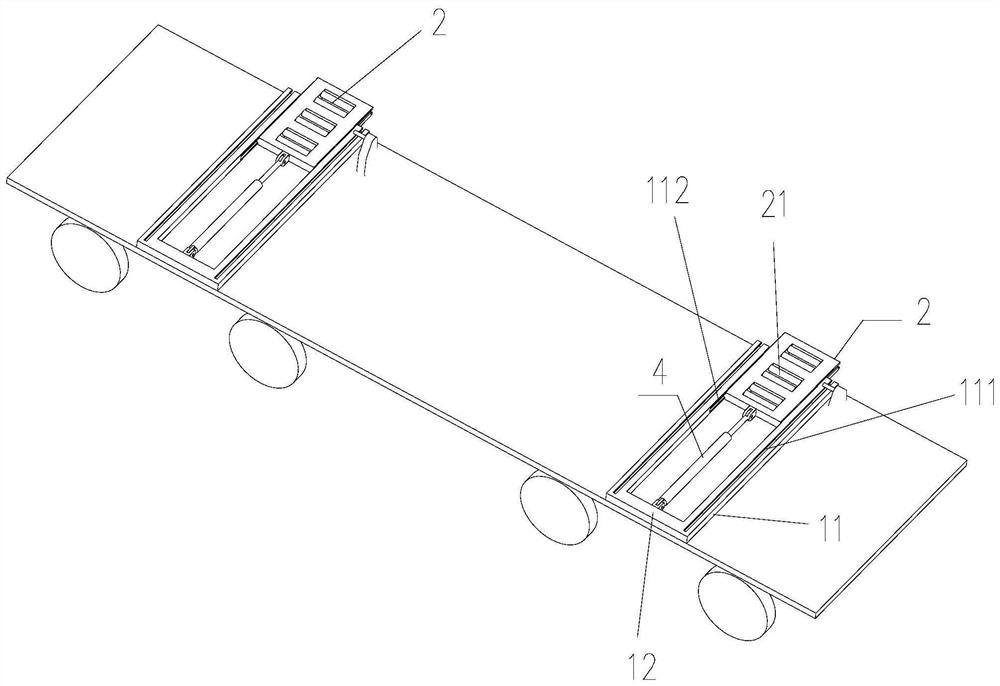

Cargo loading and unloading device for rail vehicle, and rail vehicle

ActiveCN112193266ASolve loading and unloadingRailway device loading/unloadingRailway transportMarine engineeringStructural engineering

The invention discloses a cargo loading and unloading device for a rail vehicle. The cargo loading and unloading device comprises a fixing frame and a transferring mechanism, the fixing frame is usedfor being installed at the top of a railway vehicle body, and the transferring mechanism is arranged on the fixing frame in a sliding mode and can move in the left-right direction of the railway vehicle relative to the fixing frame; one end of the transfer mechanism extends below a goods shelf at the top of another rail vehicle or platform; the transferring mechanism comprises a bracket arranged on the fixing frame in a sliding mode, a cover plate arranged above the bracket and a lifting mechanism connected between the bracket and the cover plate, and the lifting mechanism is used for drivingthe cover plate to ascend and descend relative to the bracket. By means of the structure, goods on the transfer vehicle or the platform on one side of the rail vehicle in the left-right direction canbe transferred to the rail vehicle, or the goods on the rail vehicle can be transferred to the transfer vehicle or the platform on one side of the rail vehicle in the left-right direction; the problemof large cargo loading and unloading in the environment without large hoisting machinery or under the condition that a freight vehicle cannot reach is solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

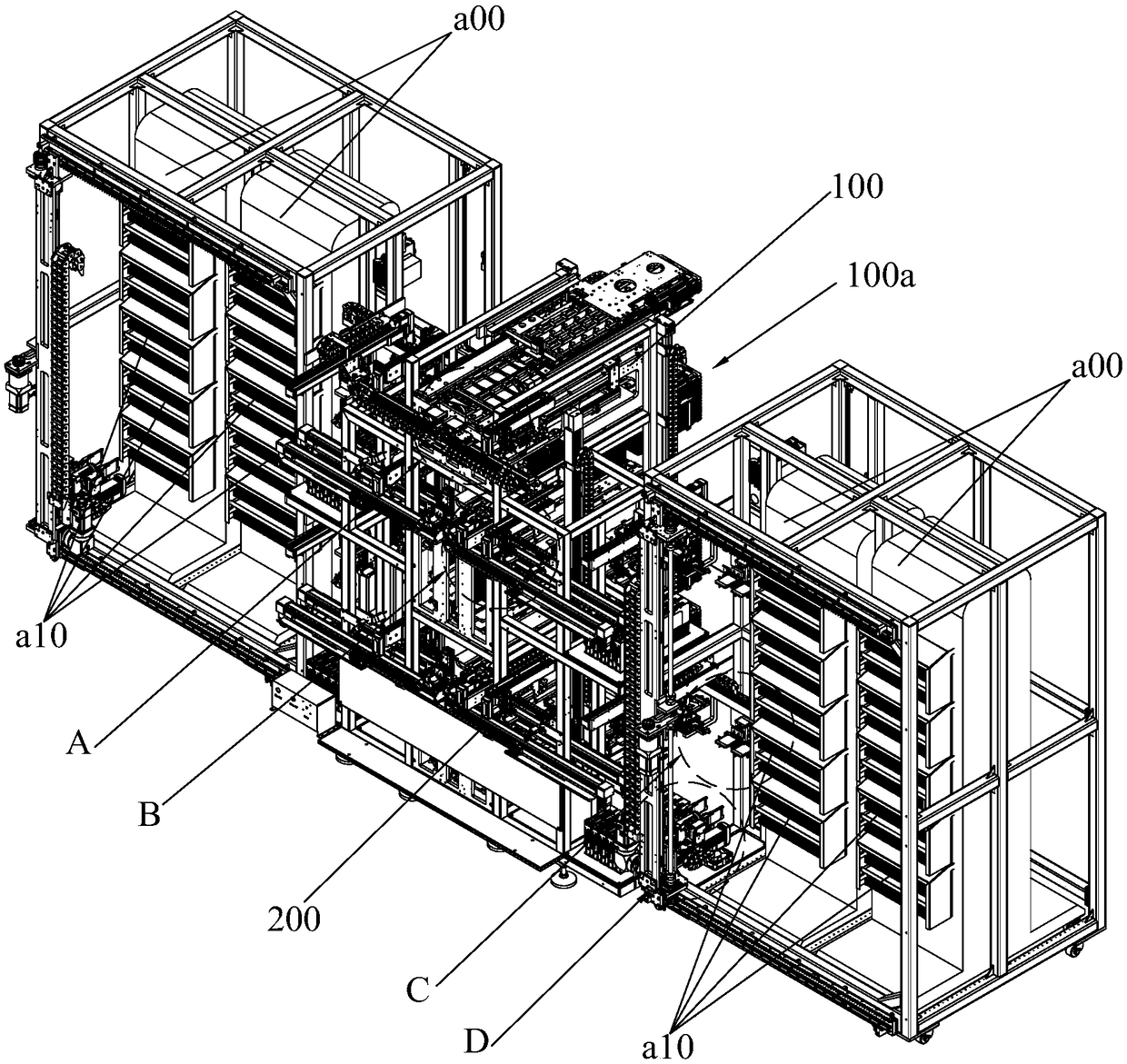

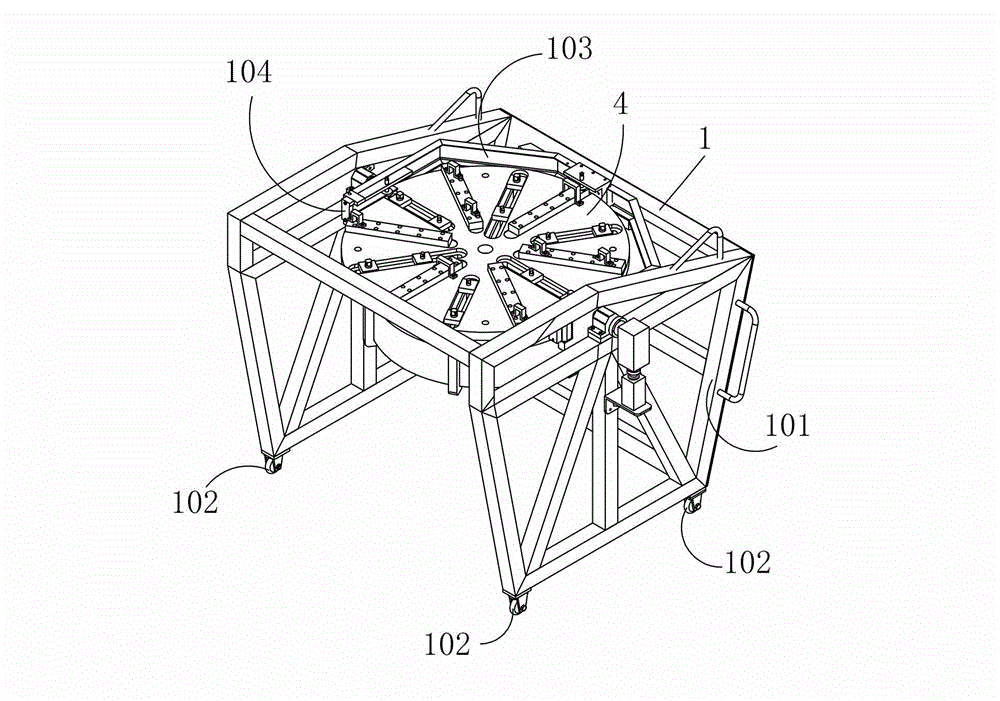

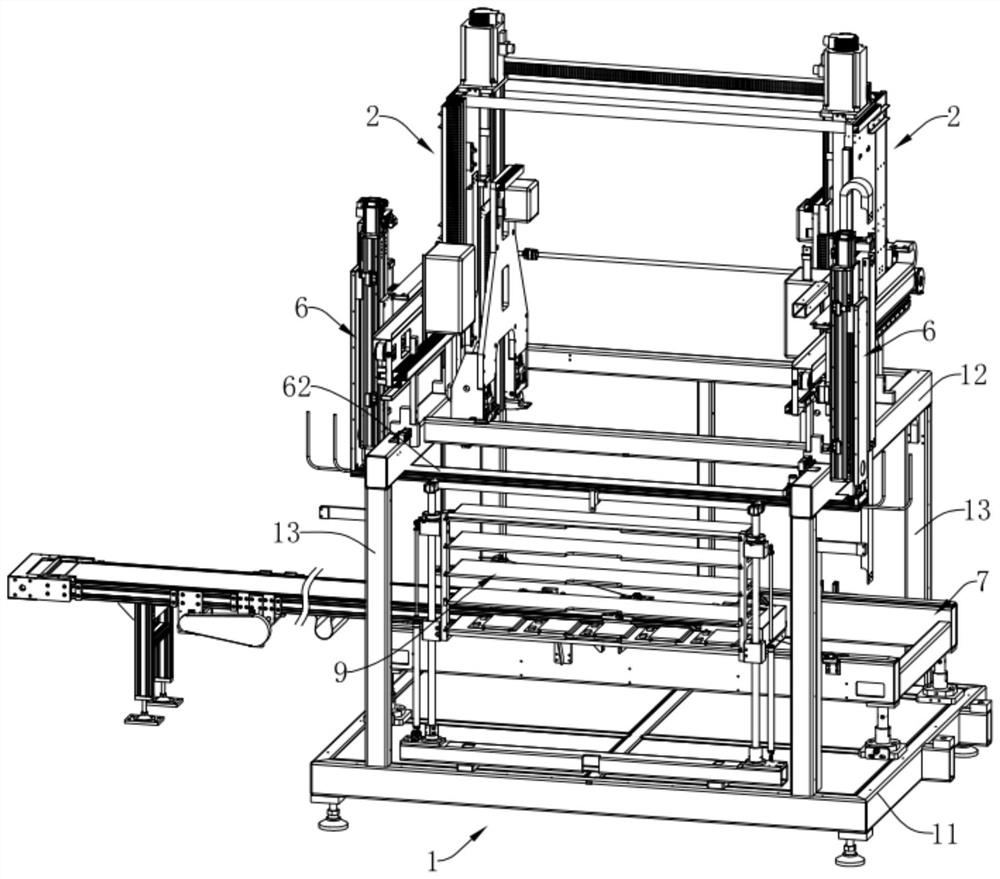

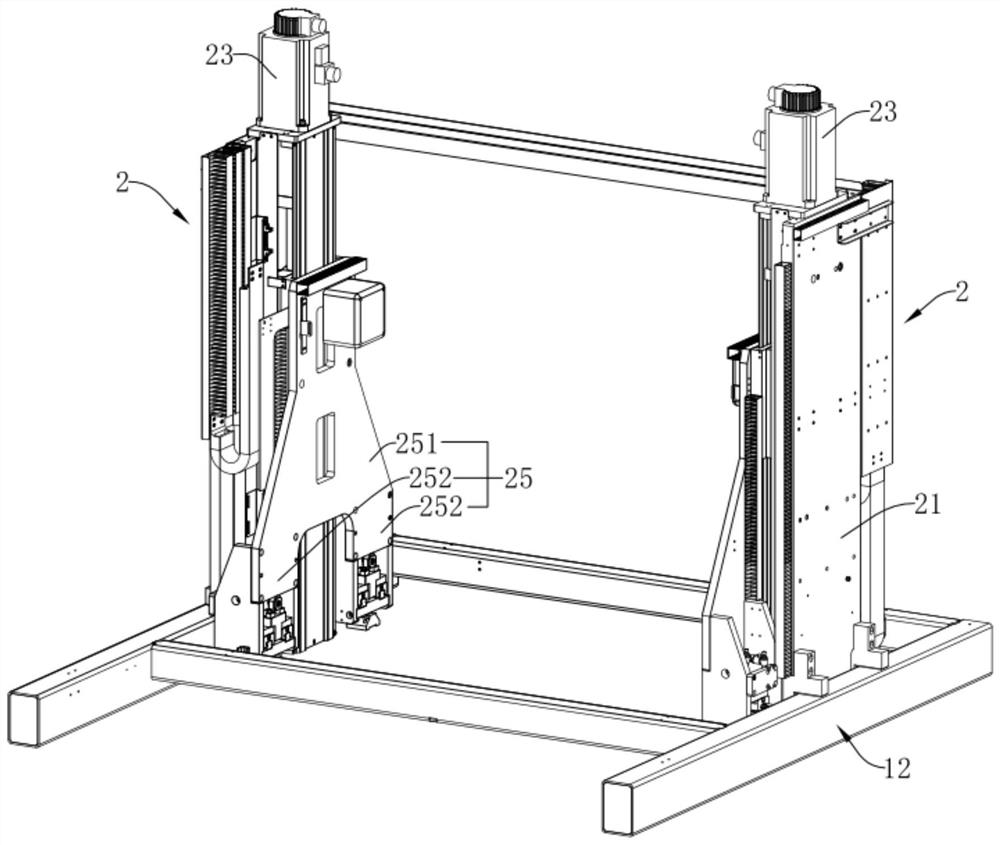

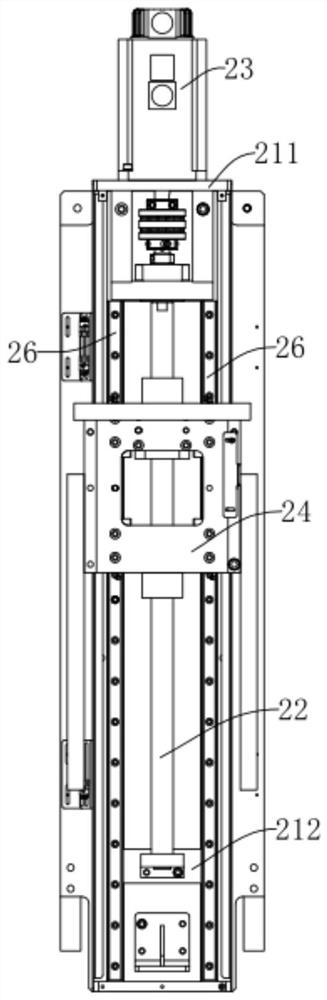

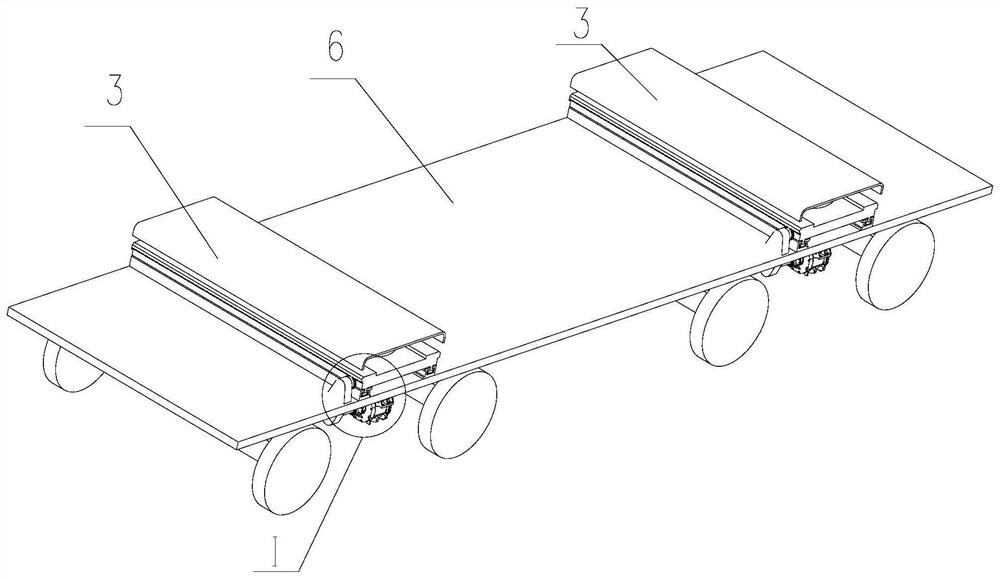

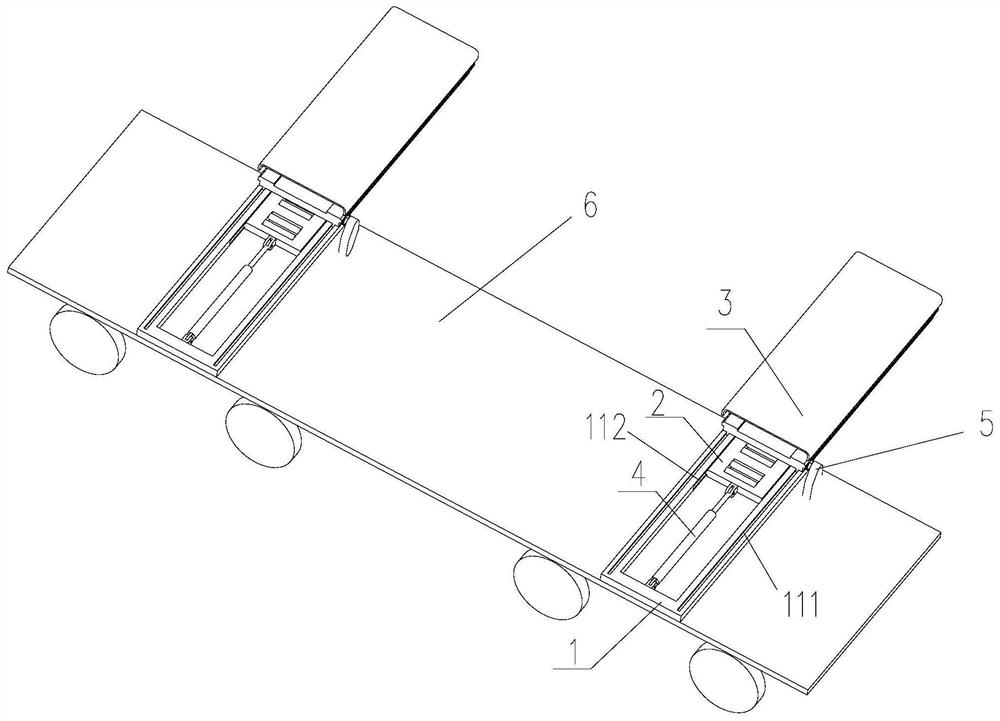

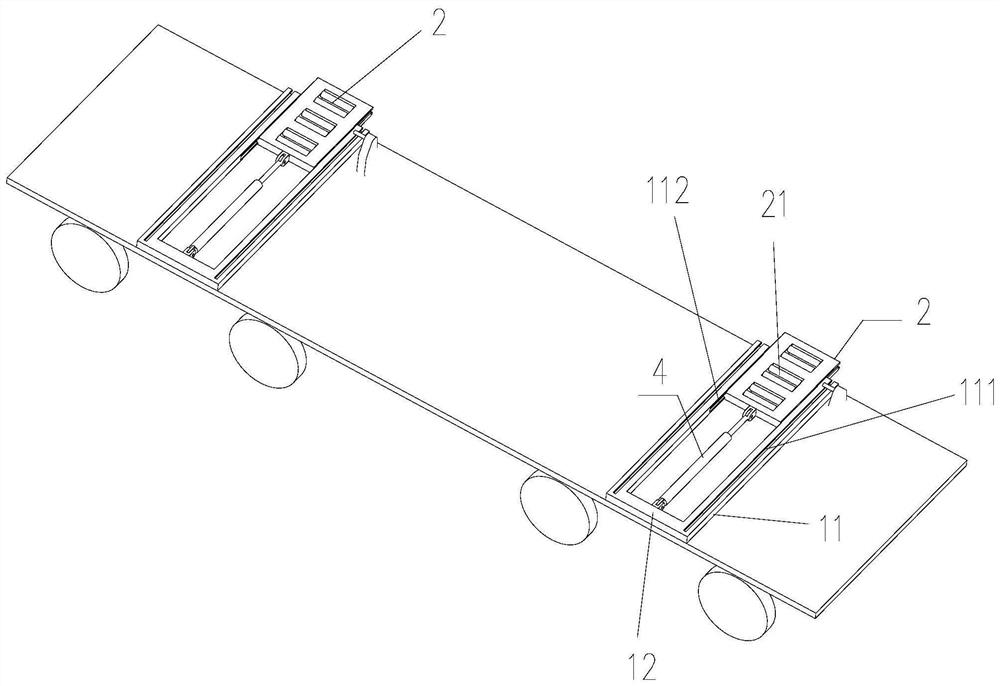

Loading and unloading mechanism for laminated materials

The embodiment of the invention discloses a loading and unloading mechanism for laminated materials, and relates to the technical field of loading and unloading equipment. The invention provides the technical scheme that the loading and unloading mechanism for the laminated materials comprises a support underframe with a rectangular frame structure, a pair of claw lifting modules arranged on the support underframe and arranged oppositely, and a pair of sucker assemblies horizontally and slidably connected onto the pair of claw lifting modules, wherein a guide rail assembly for guiding a material vehicle is further arranged in the middle of the support underframe. The loading and unloading mechanism for the laminated materials aims at solving the problem of low production efficiency causedby manual loading and unloading in the prior art.

Owner:SHENZHEN DACHENG PRECISION EQUIP CO LTD

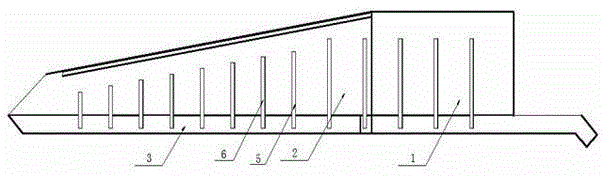

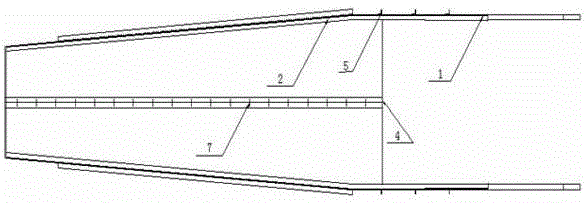

Mine waste rock-turning groove

InactiveCN103334760ASolve shipping problemsSolve loading and unloadingShaft equipmentButt jointMachining

The invention discloses a mine waste rock-turning groove. The mine waste rock-turning groove is characterized by comprising two straight chute sides (1), two inclined chute sides (2) and two chute bottom plates (3). The two chute bottom plates (3) are connected through bolts penetrating through threaded holes formed in the chute bottom plates (3) to form a chute base plate (4). The straight chute sides (1) and the inclined chute sides (2) form chute sides which are installed on two sides of the chute base plate (4). Due to the fact that the six pieces are separately machined and assembled, the problems in the process of machining, transportation, loading, unloading and installation are solved, and the machining and the transportation are easier; the butt joint of the chute bottom plates is realized through the threaded holes, positioning grooves are formed in the straight chute sides, the inclined chute sides and the chute bottom plates, therefore, the loading, the unloading and the installation are all easy and convenient, and cost input is not increased either.

Owner:王博

A floating platform for storage and transfer of drilling and production materials for deep-sea oil and gas field development

ActiveCN107640296BReduce difficultyImprove economyFloating buildingsAnchoring arrangementsSupply StorageFuel oil

The invention relates to a deep sea oil-gas field development drilling supply storage transfer floating type platform. The platform is characterized by comprising a nearly circular floating body and adeck arranged on the top of the nearly circular floating body, the nearly circular floating body is internally provided with a fuel oil tank, a ballast water tank, a pump room, a cofferdam, a dry bulk tank, a production waste tank, a cabin, a thruster room, a single point cabin, a fresh water tank and a drilling water tank; a single point mooring system is arranged in the single point cabin; a telescopic all-rotation propeller system is arranged in the thruster room; an electric generator is arranged in the cabin; a liquid cargo handling and tandem mooring system is arranged on the deck; a side by side mooring system is arranged on the side face of the nearly circular floating body; the deck is provided with a crane, a drilling supply stacking area, a living building and a helicopter platform.

Owner:CHINA NAT OFFSHORE OIL CORP +1

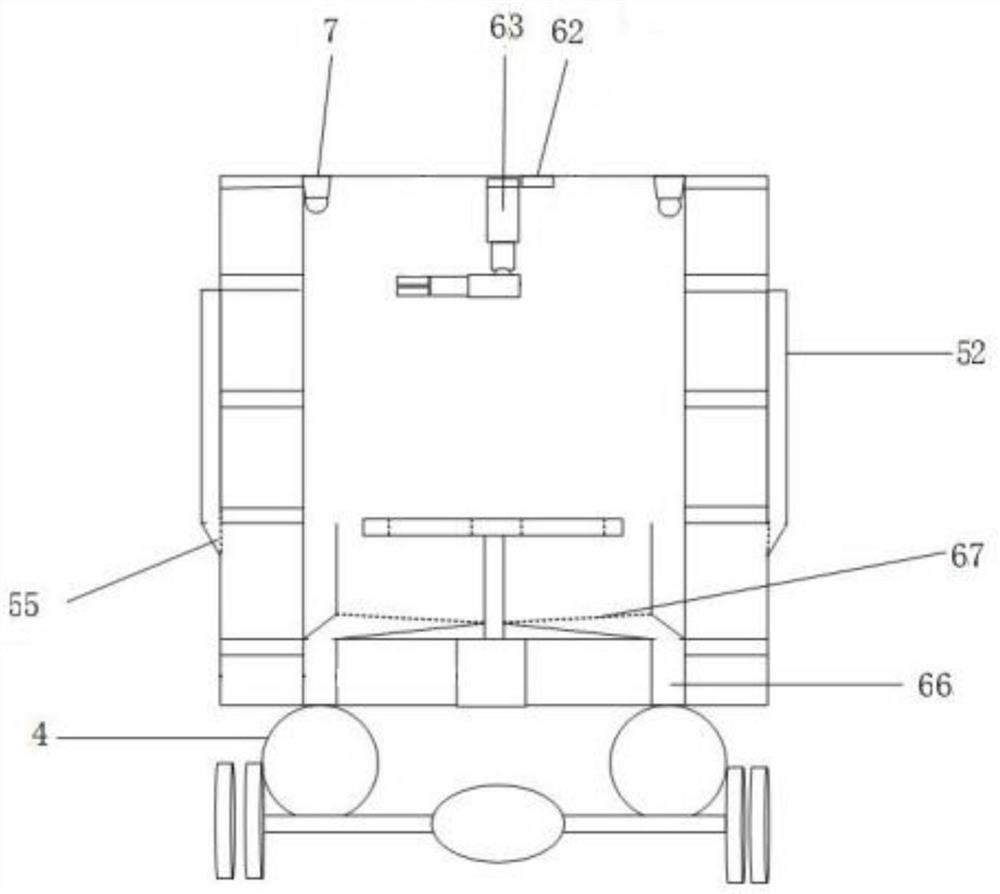

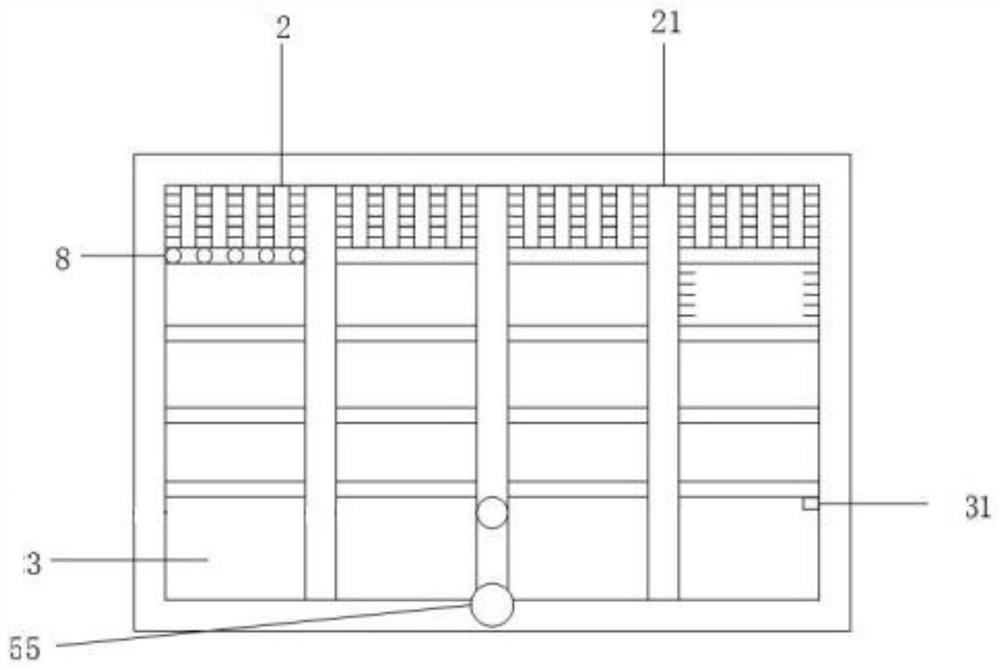

Intelligent integrated beekeeping vehicle

PendingCN112640815ASolve loading and unloadingSave human effortTelevision system detailsMeasurement devicesAgricultural engineeringBeekeeping

The invention discloses an intelligent integrated beekeeping vehicle which comprises a vehicle head, a vehicle body and a carriage. The carriage comprises a pollen collecting device, a honey collecting device, beehives and pollen storage boxes; the pollen collecting device is arranged on the outer side wall of the carriage and is communicated with an inner cavity of the carriage; the beehives and the pollen storage boxes are regularly arranged on the side wall of the inner cavity of the carriage, and the beehives are arranged above the pollen storage boxes; the vehicle body is arranged below the carriage, and a honey storage tank is further mounted at the bottom of the vehicle body; the top of the honey storage tank penetrates through the vehicle body and is communicated with a honey guide pipe of the honey collecting device; the honey collecting device further comprises a mechanical arm device and a honey extracting device; the mechanical arm device is arranged at the top of the inner cavity of the carriage; and the honey extracting device is arranged on the bottom surface of the inner cavity of the carriage. By means of the intelligent integrated beekeeping vehicle, the honey collecting and pollen taking process of bee farmers can be optimized, the production efficiency is improved, and the cost is saved.

Owner:KUNMING UNIV OF SCI & TECH

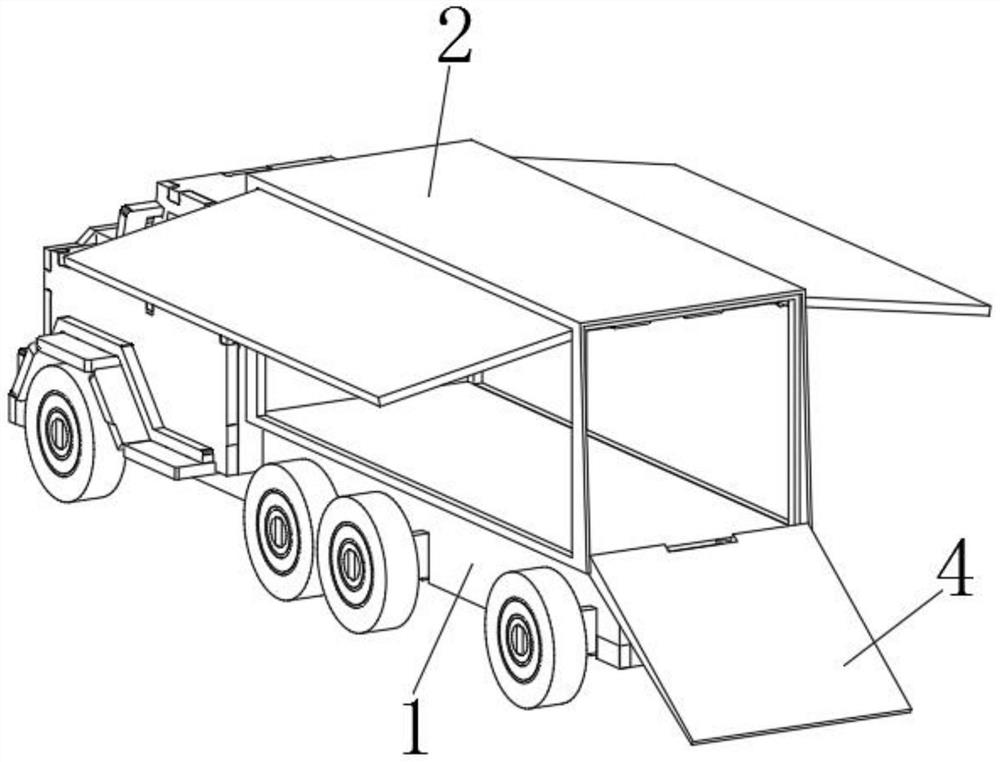

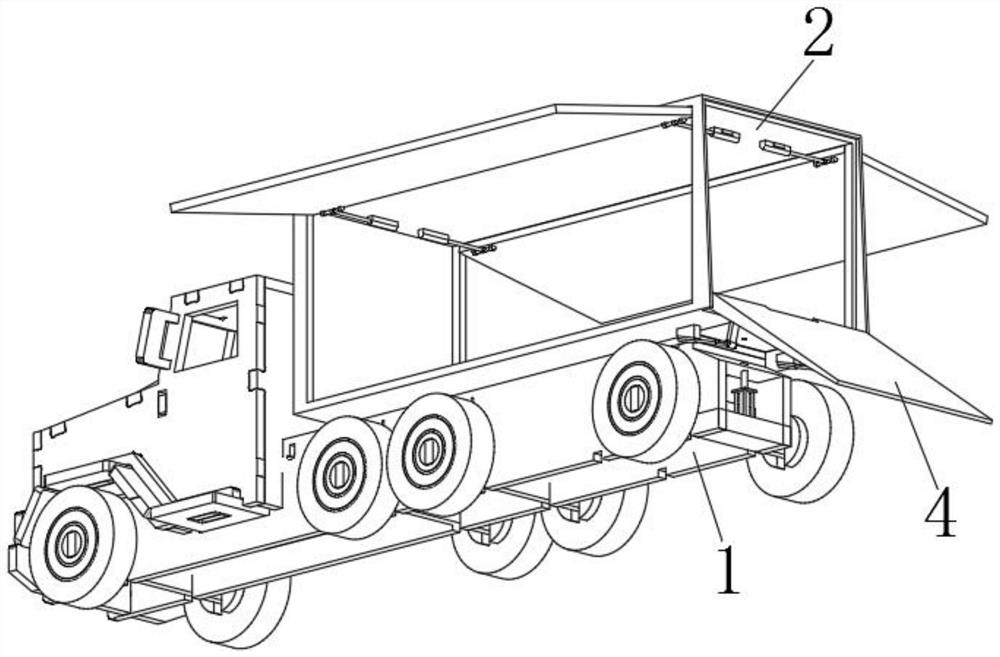

Truck boxboard turnover mechanism

InactiveCN113232493AImprove delivery efficiencyReduce accidentsDoorsVehicle with loading rampVehicle frameButt joint

The invention relates to the technical field of automobile technologies, in particular to a truck boxboard turnover mechanism which comprises a carriage installed on a frame, a rear plate and two side plates, the rear plate and the two side plates are rotationally connected with the carriage, and the carriage can rotate by 360 degrees relative to the frame. The two side plates are arranged in a mirror symmetry mode, rotating shafts of the two side plates are located at the upper end of the compartment, a rotating shaft of the rear plate is located at the bottom end of the compartment, and the rear plate is of a triangular structure and abuts against the horizontal bottom face after rotating by a certain angle. According to the truck boxboard turnover mechanism, the rear plate which can automatically turn over and is in butt joint with the horizontal ground or the storage bin platform is arranged at the tail end of the carriage, so that the butt joint through a butt joint mechanism is avoided, the time is saved, the efficiency is high, the probability of accidents in the butt joint process is reduced, and after the rear plate is in butt joint with the horizontal ground, the rear plate can also be used as an inclined ladder for freight, and the cargo conveying efficiency can be improved conveniently.

Owner:庐江县同创机械制造有限公司

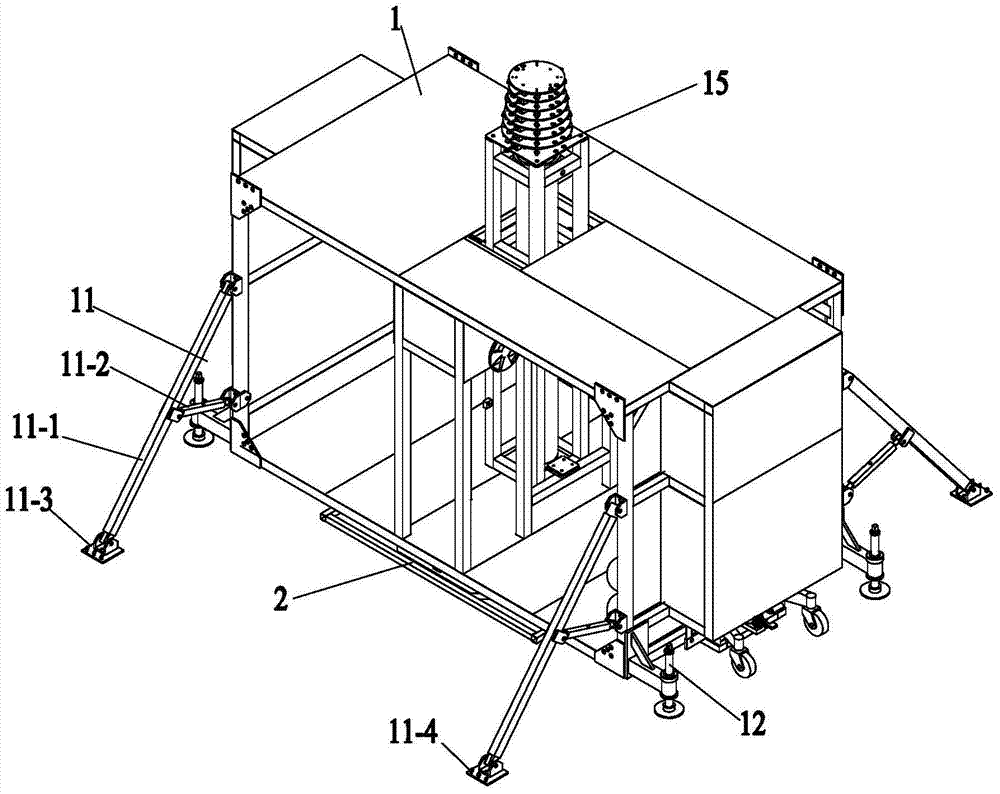

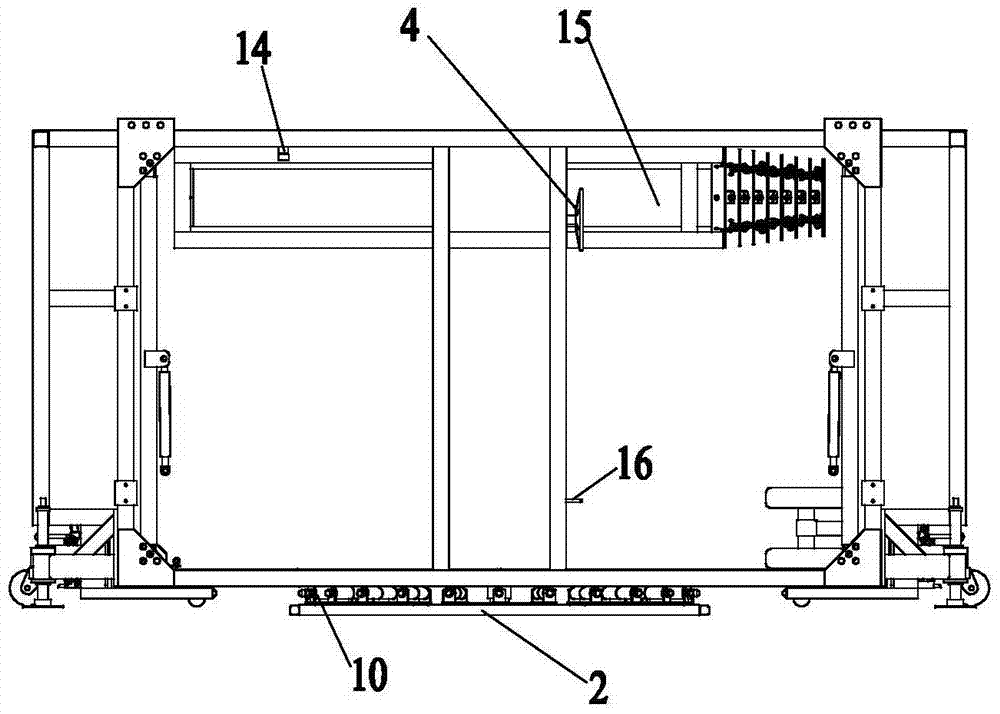

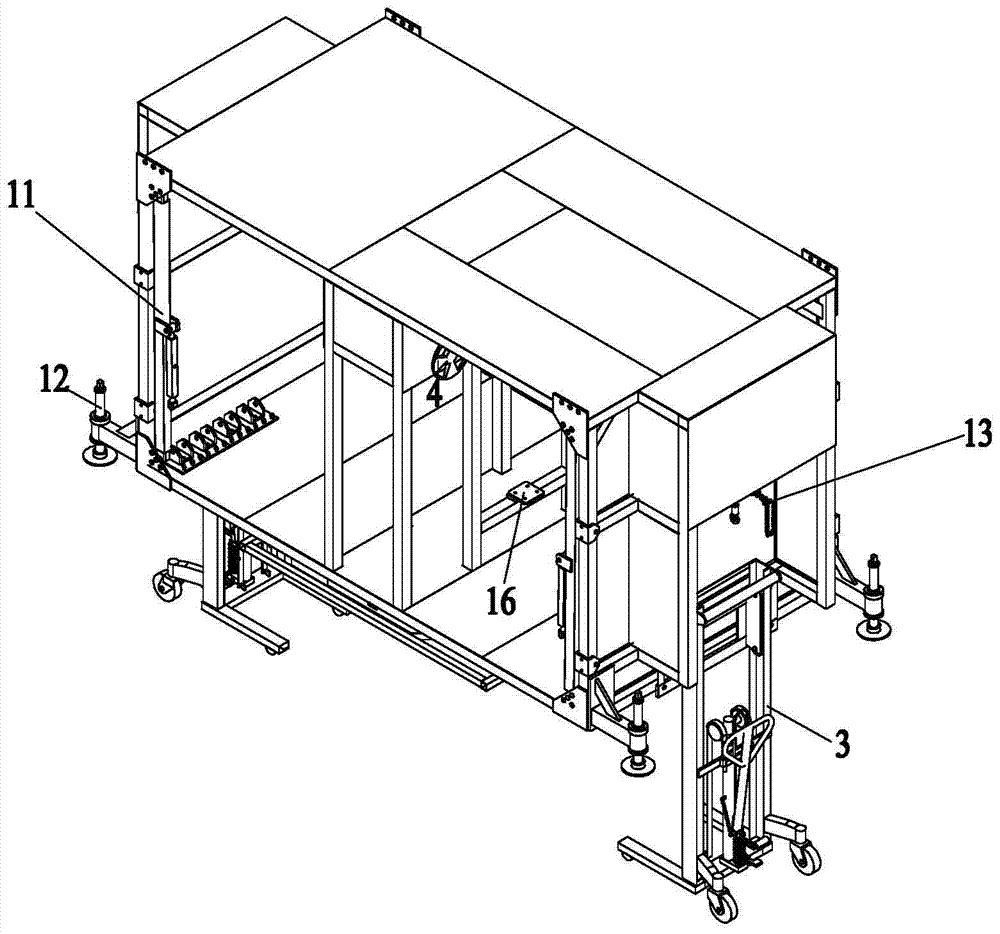

Self-unloading cabin type pneumatic lifting tower

InactiveCN105019712BSolve loading and unloadingImprove wind resistanceTowersEffective solutionMaterial resources

The invention belongs to the technical field of communication equipment, and relates to a mobile base station, in particular to a self-unloading cabin type pneumatic lifting tower, which includes a chassis and a cabin body rotatably arranged on the chassis; the two ends of the cabin body along the length direction are respectively Set up a hydraulic lift car, the cabin body is fixedly connected with the lifting plate of the hydraulic lift car, and a chain block for lifting the hydraulic lift car is installed at both ends of the cabin body; the rotating device on the inner frame of the cabin body There are pneumatic lift towers. The product of the present invention does not need external hoisting equipment to complete the operation during the transfer operation, which greatly saves manpower and material resources. The cabin of the product of the present invention can be lifted and rotated, effectively solving the problem of ultra-wide when the product is loaded and transported .

Owner:无锡市华鹰移动照明有限公司

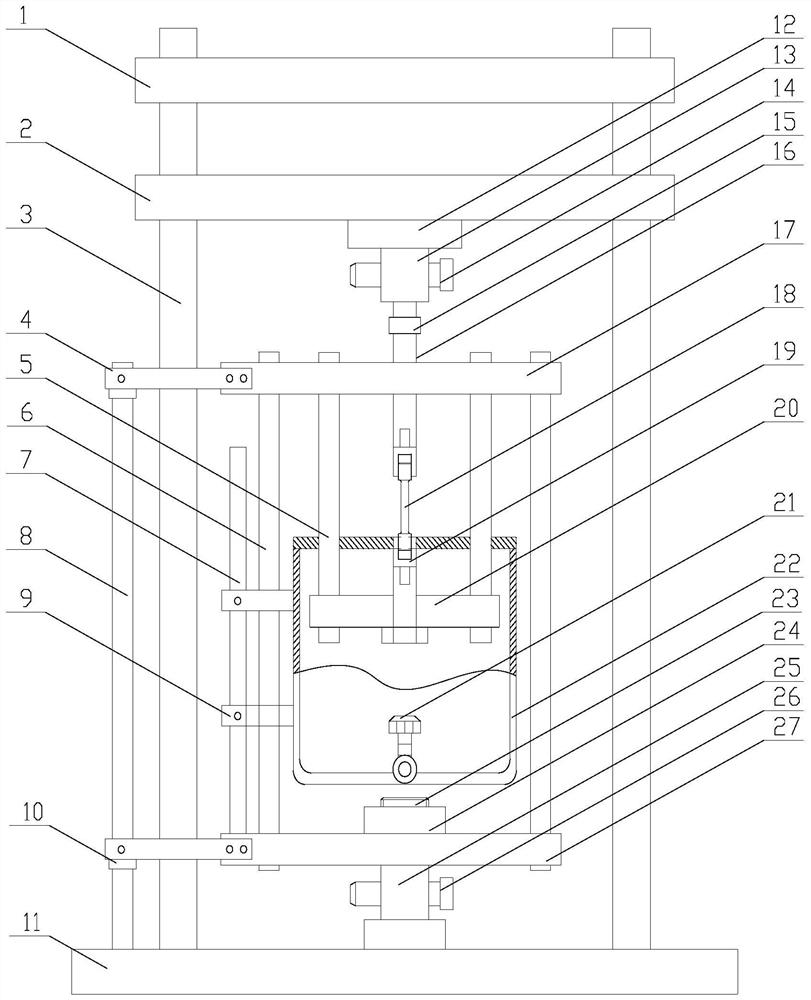

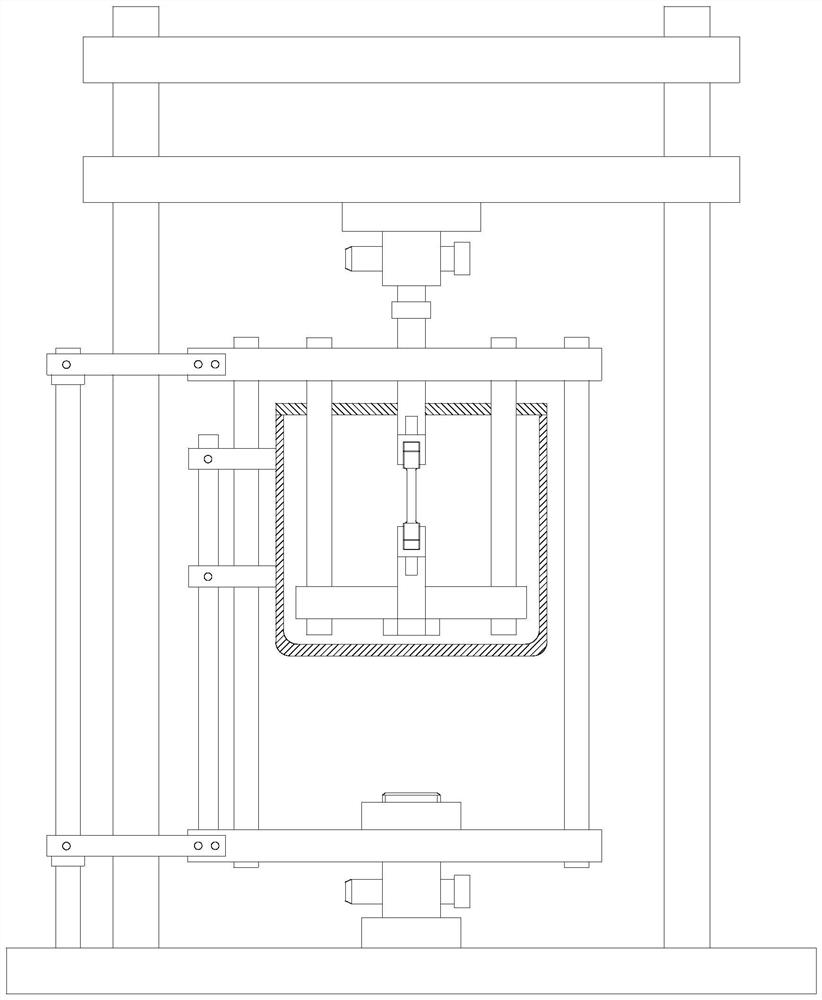

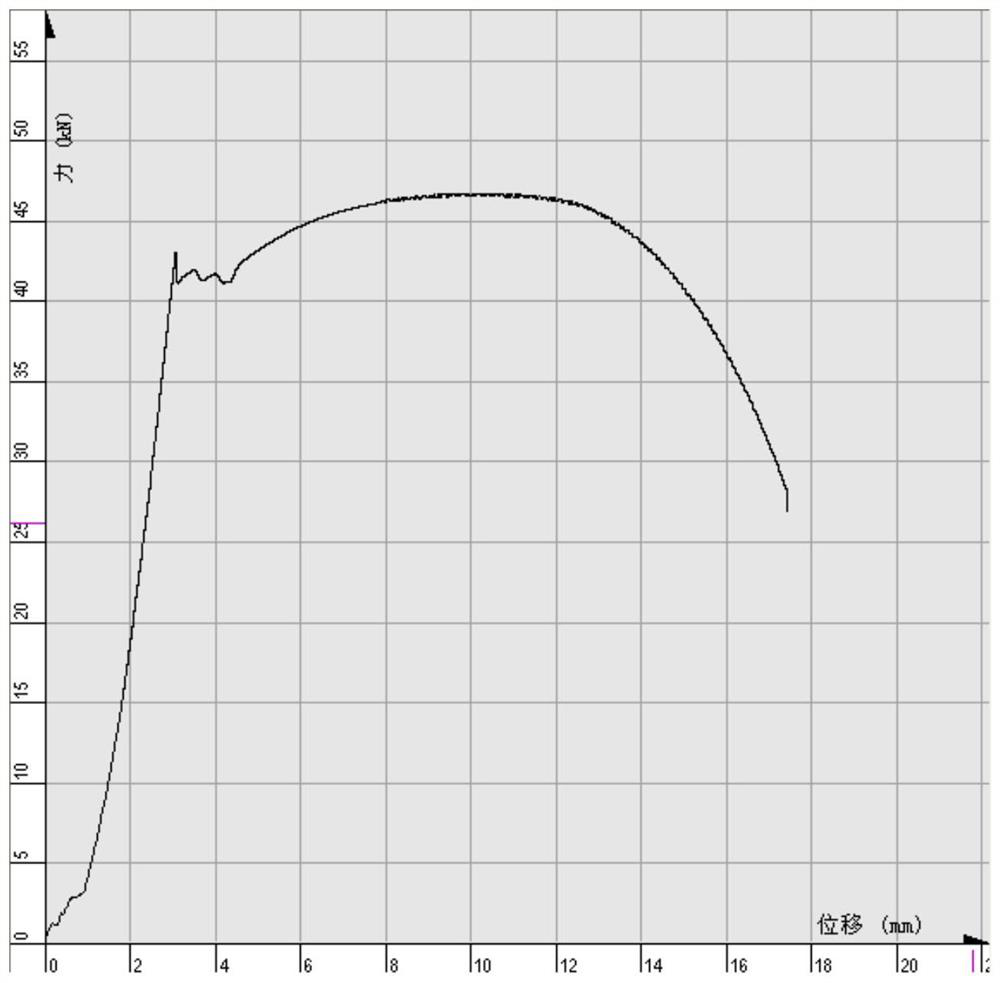

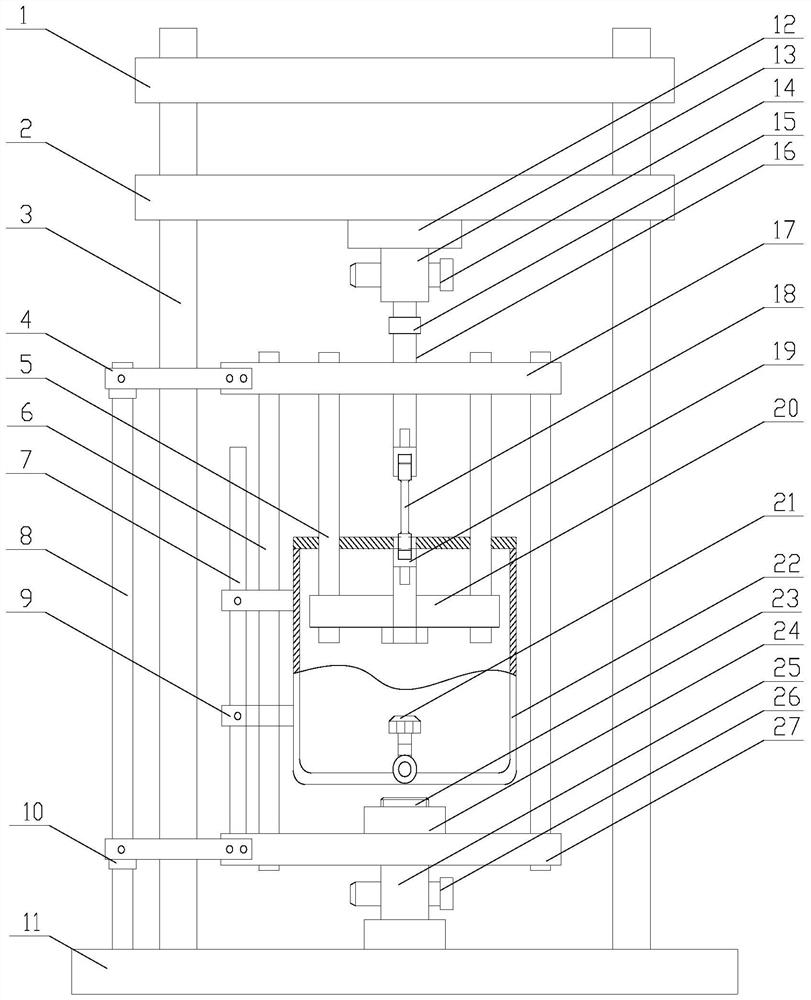

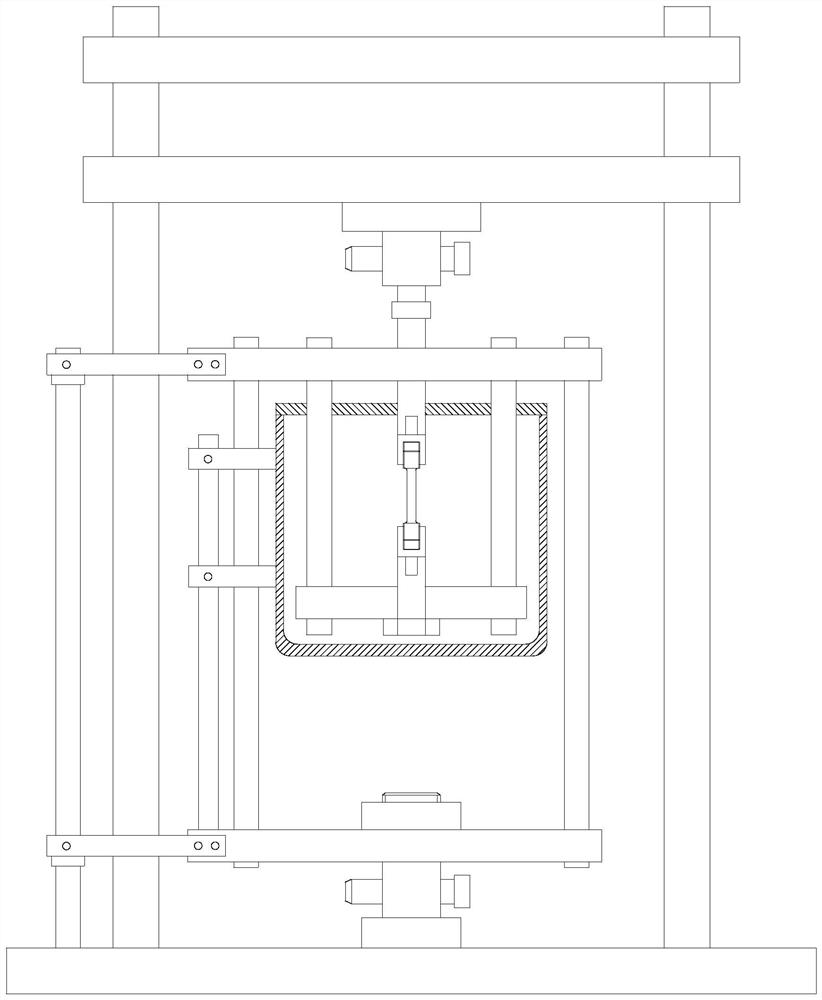

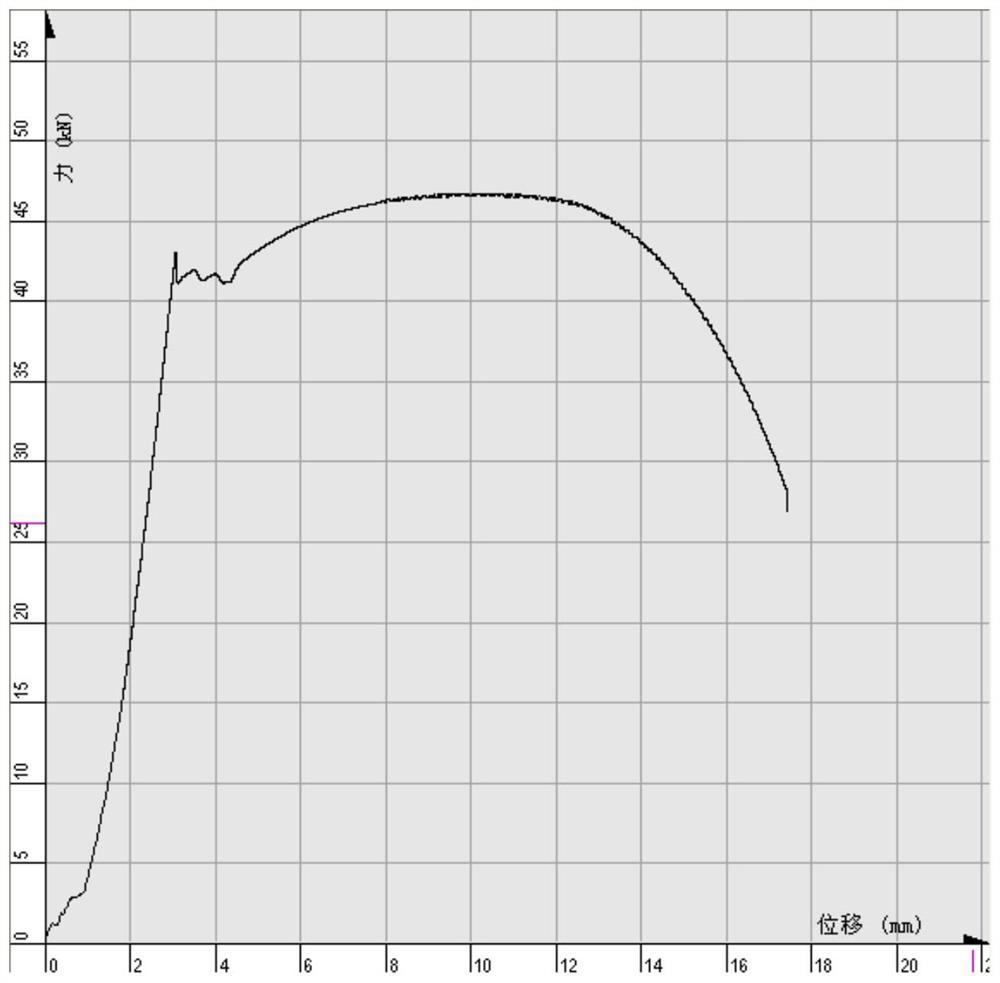

Ultralow-temperature tensile test device and method for ship material

PendingCN114136802APrecision Tensile TestQuick Tensile TestMaterial strength using tensile/compressive forcesMarine engineeringTest sample

The invention discloses an ultralow-temperature tensile test device and method for ship materials, the device comprises a main body frame, a stress mechanism, a storage barrel, an upper connecting sleeve and a lower connecting sleeve, the upper connecting sleeve is arranged on the main body frame, the lower connecting sleeve is mounted on the stress mechanism, and the stress mechanism is arranged on the storage barrel. A to-be-tested sample is mounted between the upper connecting sleeve and the lower connecting sleeve, is provided with a low-temperature extensometer, and is immersed into a storage barrel. According to the invention, the tensile test can be accurately and quickly carried out on the ultralow-temperature material, and the real mechanical properties such as ultralow-temperature yield strength, tensile strength, percentage elongation after fracture, percentage reduction of area and the like of the ultralow-temperature material are reflected, so that the strength and toughness of the ultralow-temperature material in an ultralow-temperature environment are verified and are used as a basis for checking and accepting the ultralow-temperature material; the material use reliability is ensured, and the ship building quality is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Intelligent transport pallet capable of automatically rising and dropping to transport articles

InactiveCN109606908ASolve loading and unloadingLoading and unloadingRigid containersTransport engineeringIntelligent transport

The invention discloses an intelligent transport pallet capable of automatically rising and dropping to transport articles and relates to the technical field of intelligent transport pallets. The intelligent transport pallet capable of automatically rising and dropping to transport the articles comprises a transport pallet body. The two sides of the top of the transport pallet body are symmetrically and fixedly connected with supporting columns. The centers of the opposite side faces of the two supporting columns are symmetrically provided with tooth grooves. Track plates are fixedly connectedto groove openings of the tooth grooves. One side face of each supporting column is provided with a bearing column. The center of the side face, close to the corresponding supporting column, of eachbearing column is provided with a first opening. A supporting washer is fixedly connected to each first opening. The center of the other side face of each bearing column is provided with a second opening. A limiting washer is fixedly connected to each second opening. The intelligent transport pallet capable of automatically rising and dropping to transport the articles can achieve the effect of stably lifting the articles to ascend and descend and provides convenience for loading and unloading of the articles. The problems that when articles on an existing intelligent transport pallet need tobe loaded or unloaded, loading and unloading need to be completed through manual operation, and the existing intelligent transport pallet does not have the lifting function to complete loading and unloading of the articles are solved.

Owner:杭州大晨显示技术有限公司

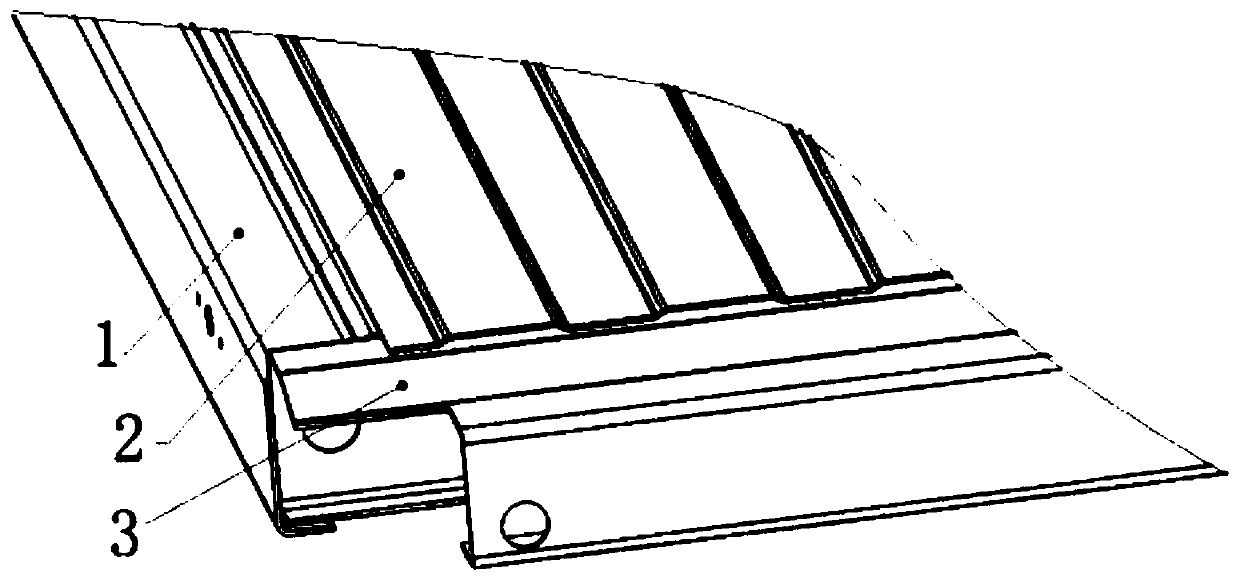

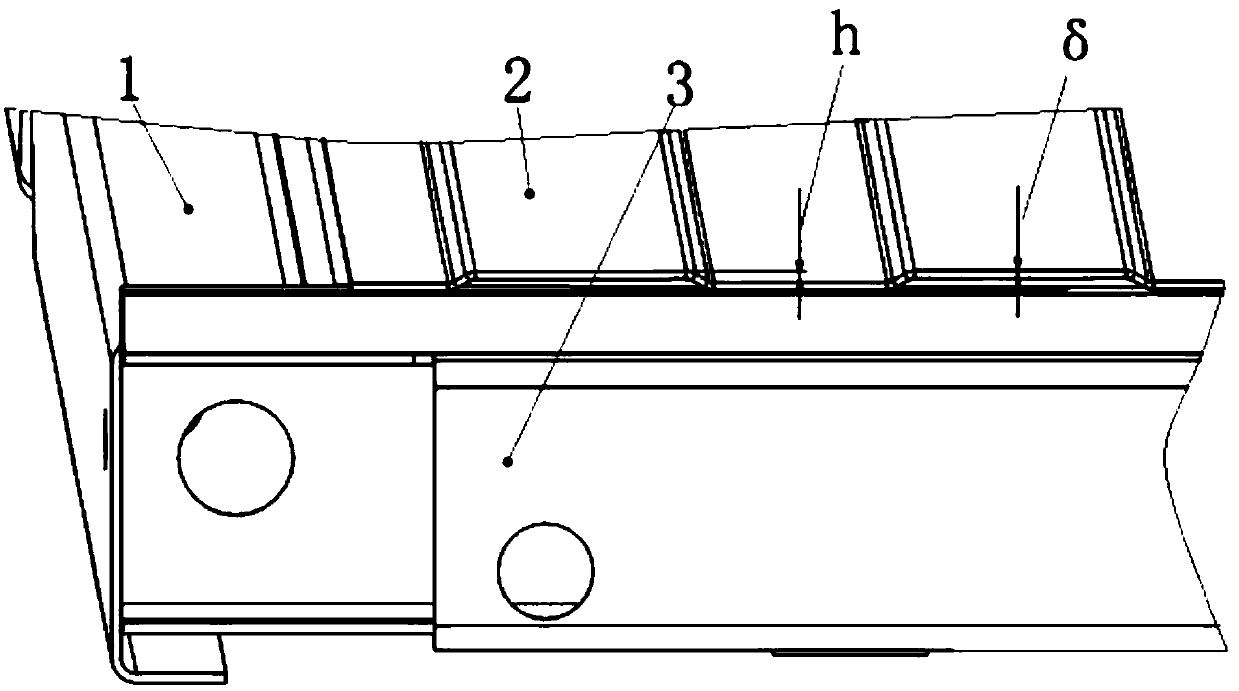

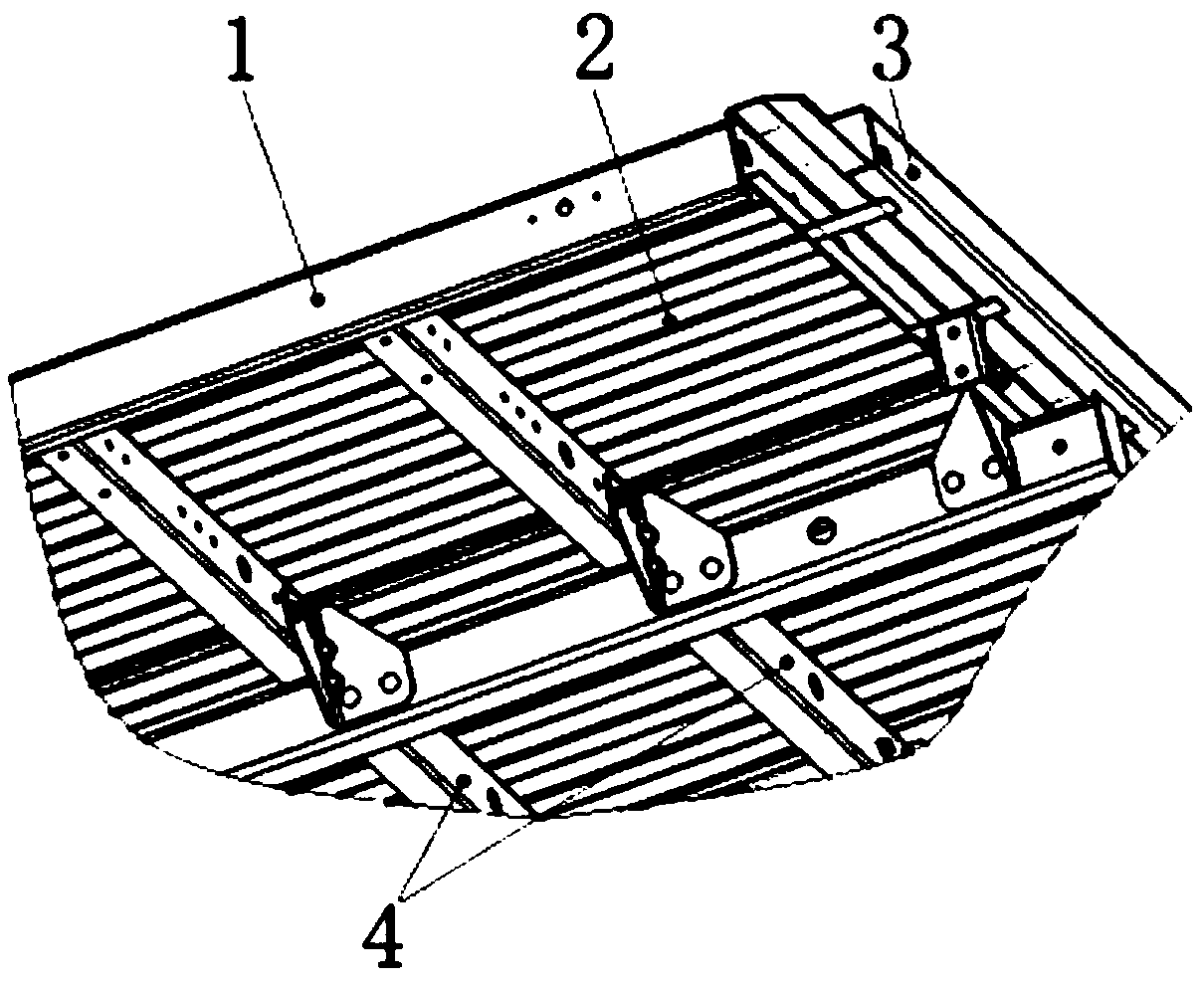

Forklift truck loading and unloading adaptive lightweight compartment floor structure

InactiveCN109649504ASolve loading and unloadingStructure miniaturizationSuperstructure subunitsMechanical engineeringTransverse beam

The invention relates to the field of logistics equipment, in particular to a forklift truck loading and unloading adaptive lightweight compartment floor structure which comprises a bottom plate frame, a rear transverse beam and a plurality of middle transverse beams. The rear transverse beam is mounted at an end of the bottom plate frame, micro-corrugated floors are mounted on the bottom plate frame, and the middle transverse beams are further arranged on the lower sides of the micro-corrugated floors. The forklift truck loading and unloading adaptive lightweight compartment floor structure has the advantages that the forklift truck loading and unloading adaptive lightweight compartment floor structure is a lightweight floor structure with a low cost, and the problems in the aspect of electric forklift truck and manual hand-pull forklift truck loading and unloading can be solved by the aid of the forklift truck loading and unloading adaptive lightweight compartment floor structure; the micro-corrugated floors are made from high-strength steel plates, ratios of rolling grooving depths to material thicknesses of the micro-corrugated floors are 2, the transverse beam distances of 350-550 mm are reasonably selected according to different types of forklift trucks with different degrees of tonnage, accordingly, the forklift truck loading and unloading adaptive lightweight compartment floor structure is adaptive to loading and unloading operation in compartments, and the dead weights of bottom plate structures with the densely arranged transverse beams and thick steel plates canbe reduced by approximately 200-300 kg; operation can be carried out by manual hand-pull forklift trucks without influence of corrugated shapes and depths.

Owner:DONGFENG SPECIAL PURPOSE VEHICLE

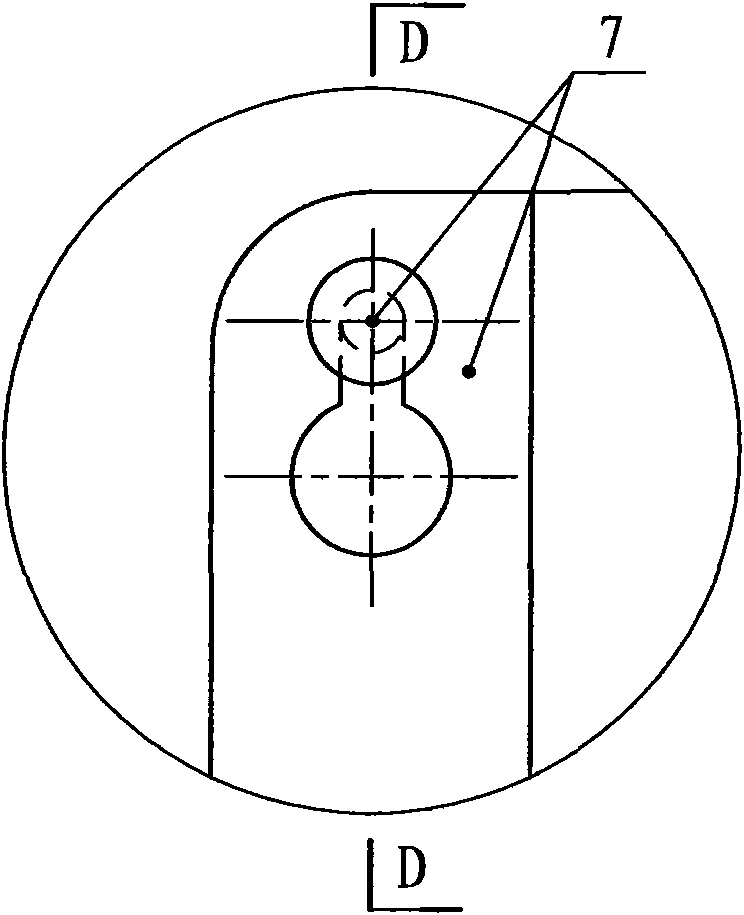

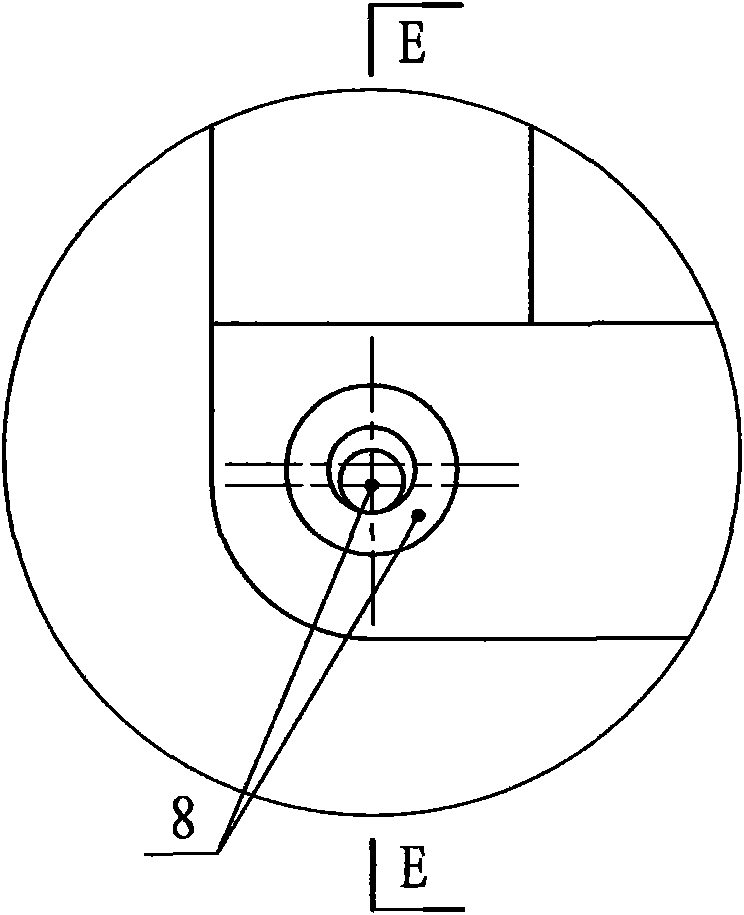

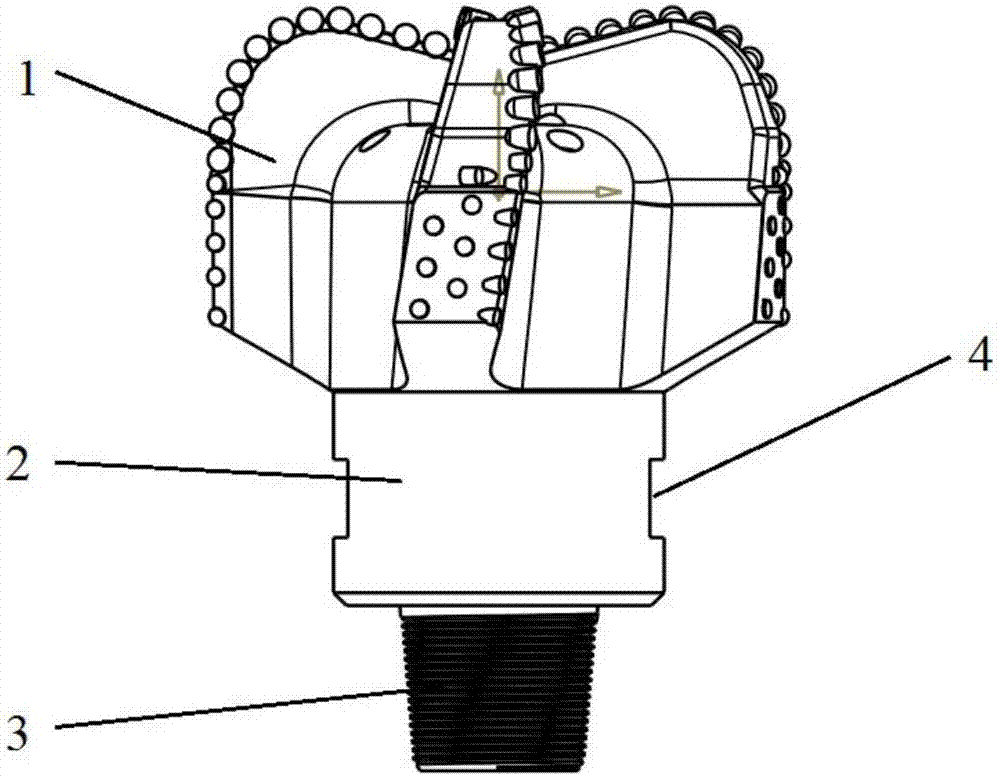

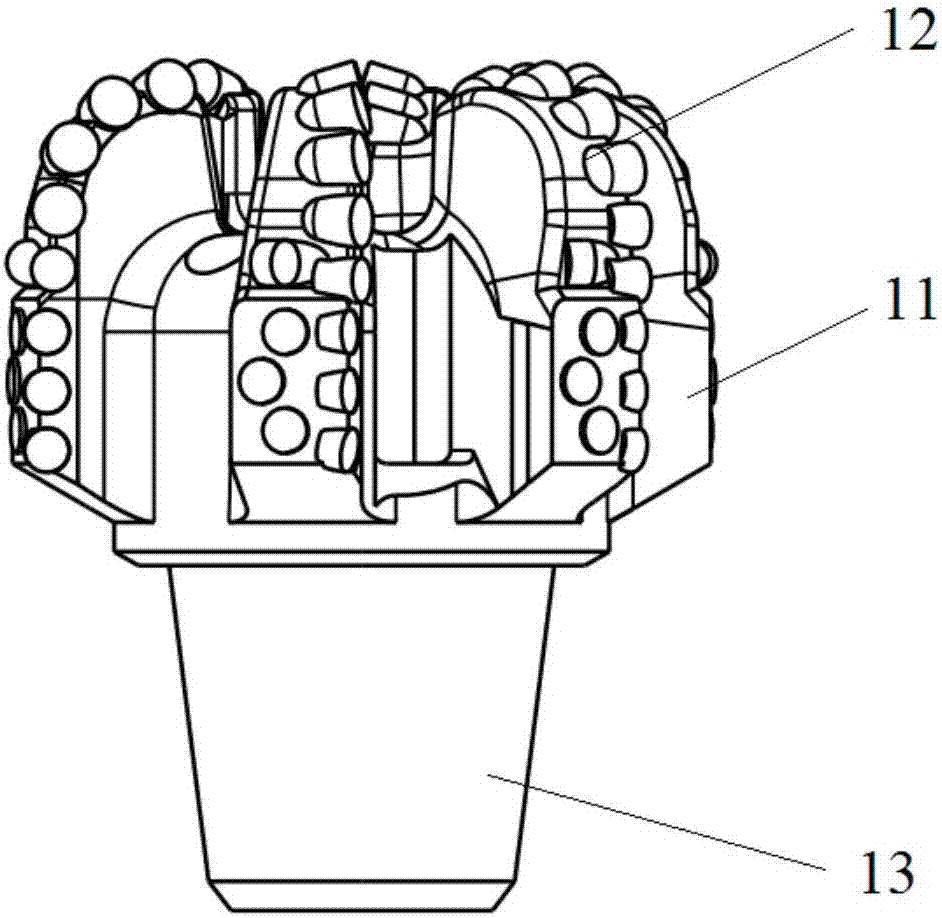

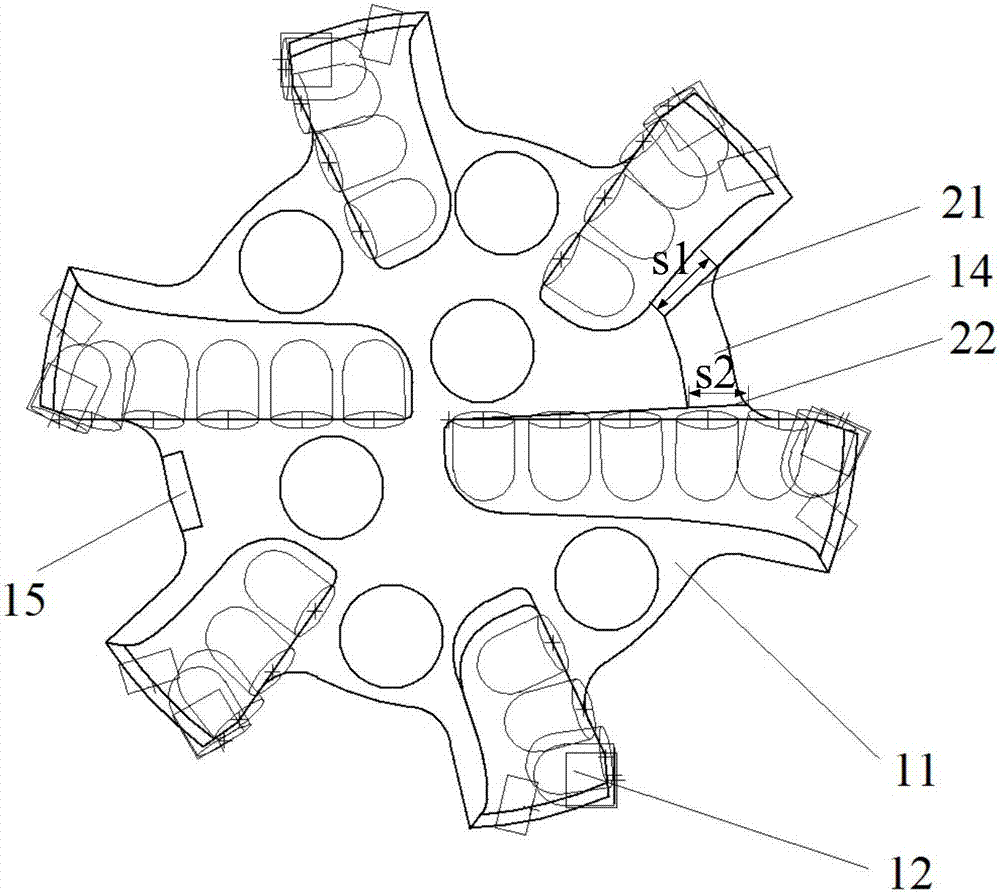

shortened pdc drill bit and its loader

The invention relates to a shortened PDC bit and an assembling and disassembling device for the shortened PDC bit. The shortened PDC bit comprises a crown body (11) and a thread connection part (13), wherein the crown body (11) is provided with a plurality of cutting edges (12); an assembling and disassembling groove (14) is formed between every two adjacent cutting edges (12); each assembling and disassembling groove (14) is sunken inwards from the edge of the upper surface of the crown body (11) and comprises a disassembling side face (21) and an assembling side face (22) which are opposite; the assembling and disassembling grooves (14) are asymmetric grooves; the length s1 of each disassembling side face (21) is greater than the length s2 of each assembling side face (22); and the thread connection part (13) is connected to the lower portion of the crown body (11), and the periphery of the thread connection part (13) is provided with a thread. According to the shortened PDC bit, a bit sub part of a traditional PDC bit is removed, so that the overall length of the PDC bit is greatly shortened.

Owner:LANGFANG DINGXIN LIANTUO IND & COMMERCE

A cargo handling device for rail vehicle and rail vehicle

ActiveCN112193266BSolve loading and unloadingRailway transportRailway device loading/unloadingTransfer mechanismControl theory

The invention discloses a cargo loading and unloading device for rail vehicles, comprising a fixed frame and a transfer mechanism, the fixed frame is used to be installed on the top of the rail vehicle body, the transfer mechanism is slidably arranged on the fixed frame, and the transfer mechanism can be relative to the fixed frame along the edge The rail vehicle moves in the left and right directions until one end of the transfer mechanism extends under the cargo rack on the top of another rail vehicle or platform; the transfer mechanism includes a bracket slidably arranged on the fixed frame, a cover plate arranged above the bracket, and a connecting The lifting mechanism between the bracket and the cover plate is used to drive the cover plate to move up and down relative to the bracket. With the above structure, the goods on the transfer vehicle or the platform on the left and right side of the rail vehicle can be transferred to the rail vehicle, or the goods on the rail vehicle can be transferred to the transfer vehicle or the platform on the left and right side of the rail vehicle, so that the Solve the problem of loading and unloading large cargo in an environment without large hoisting machinery or when freight vehicles cannot reach it.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

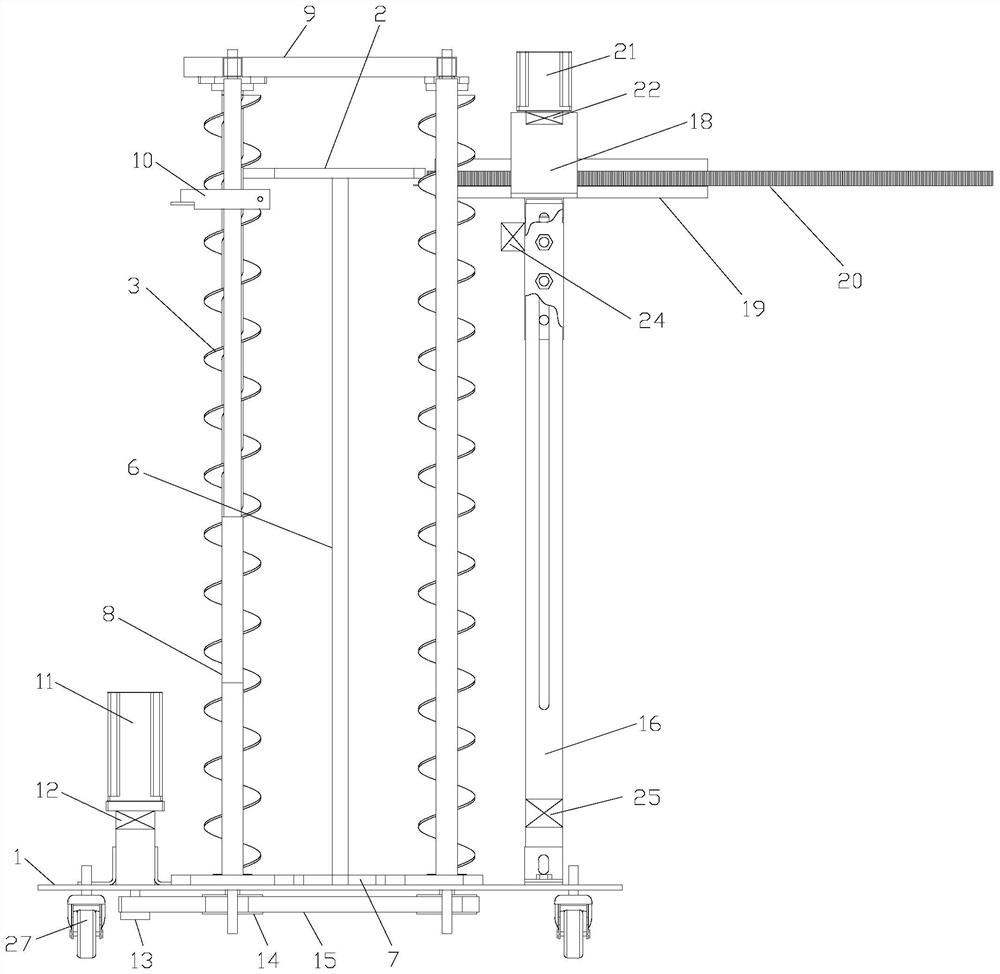

Automatic loading and unloading device

ActiveCN106865271BRealize the unloading operationSolve loading and unloadingLoading/unloadingMicrocontrollerSpiral blade

The invention discloses an automatic loading and unloading device, comprising a base, a loading device, a pushing device, a control device, and a sensor assembly; the loading device includes a loading tray, a spiral blade shaft, a driving mechanism I, a main support frame, and a loading tray It is connected with the screw blade shaft by screw transmission, and the lower end of the screw blade shaft passes through the base and is connected with the drive mechanism I. The drive mechanism I is set on the base; the pushing device includes a lifting bracket, a push rod assembly and a driving mechanism II, and the lifting bracket is fixed on the base. , and the lifting bracket and the driving mechanism I are respectively located on both sides of the main support frame; the control device includes a single-chip controller and a power switch, and the power switch, the driving mechanism I, the driving mechanism II, and the sensor assembly are electrically connected to the single-chip controller. The invention has the advantages of strong power saving capability, high continuous working efficiency, flexible cargo loading and unloading, zero emission, and low cost, and can effectively solve complex vertical cargo loading and unloading problems.

Owner:营口铁源物流股份有限公司

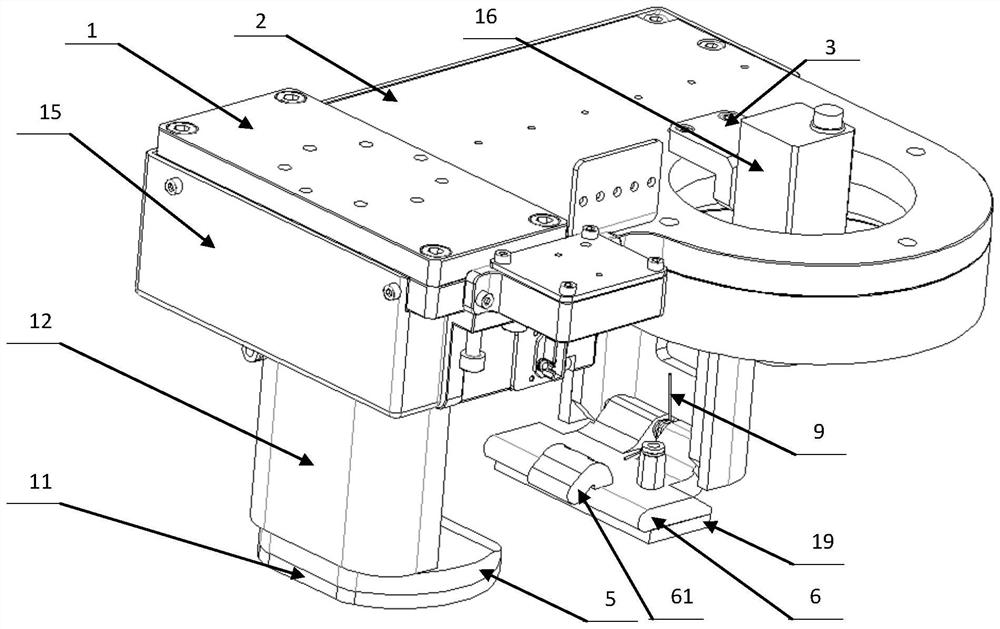

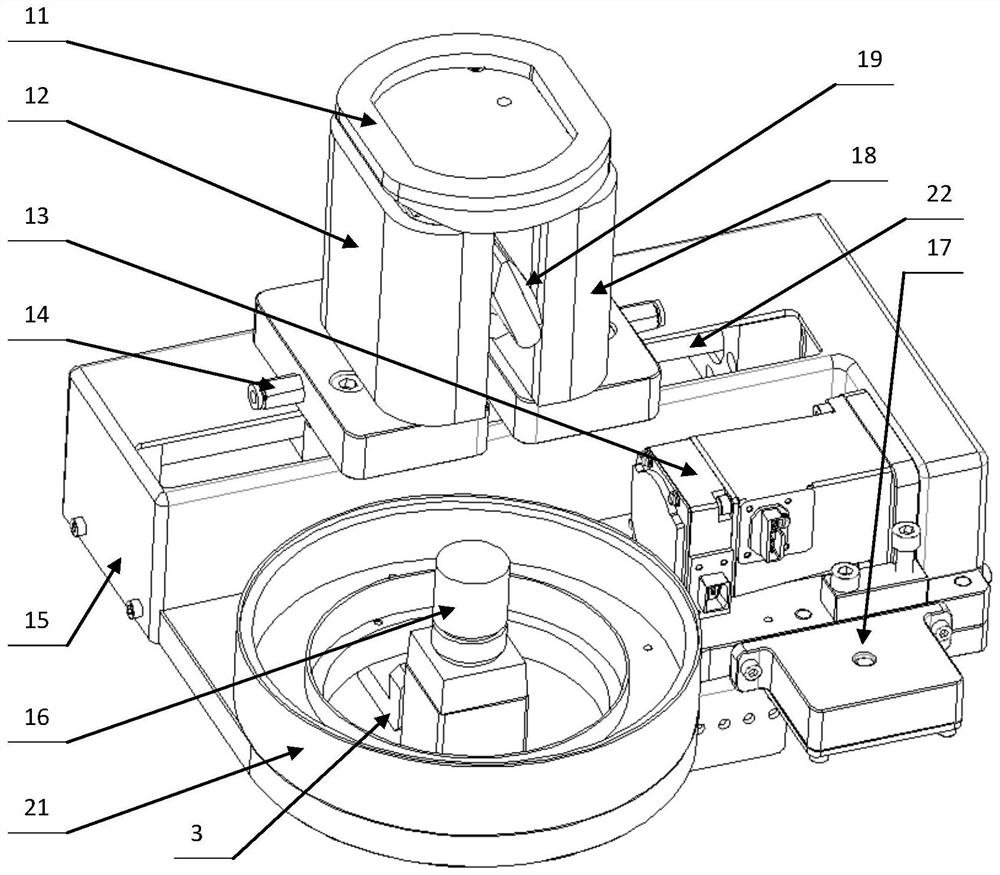

Multifunctional gripper capable of taking and placing yarns and separating plate

PendingCN111618900ASolve the problem of loading and unloadingSolve loading and unloadingGripping headsPhysicsCollaborative robotics

The invention discloses a multifunctional gripper capable of taking and placing yarns and a separating plate. The multifunctional gripper comprises a motor, a belt drive, a lead screw nut pair, a guide rail sliding block, a visual system, a distance measuring sensor module, yarn grabbing fingers and sponge suction cups, the motor transmits motion to a lead screw through a belt wheel, the lead screw rotates to achieve nut movement, and therefore opening and closing of the fingers are achieved; each finger is provided with one sponge suction cup, the suction cups can be folded into the two fingers along with combination of the fingers, and the yarn grabbing process is not affected; when the separating plate is grabbed, the fingers are opened to the maximum stroke, and the two sponge suctioncups suck up the separating plate through negative pressure; the stroke of the gripper is 100 mm, the inner diameter of a bobbin capable of grabbing cheese ranges from 92 mm to 130 mm, and the weightof the bobbin depends on the load (smaller than 20 kg) of the tail end of a cooperative robot; and the separating plate between the yarns can be grabbed, by means of the function, the number of the yarns conveyed by an AGV can be greatly increased, the grabbing problem of the separating plate does not need to be considered any more, and the automation efficiency is also improved.

Owner:TIANJIN YANGTIAN TECH CO LTD

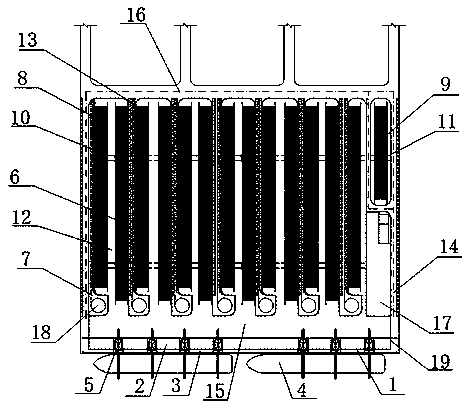

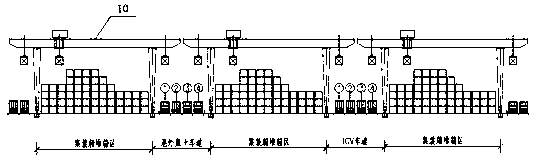

High-speed rail freight loading, unloading and carrying system and method based on roller way

PendingCN113526003AImprove system stabilityReduce weightLoading/unloadingRoller-waysRoll pass designAutomotive engineering

The invention discloses a high-speed rail freight loading, unloading and carrying system and method based on a roller way. The loading, unloading and carrying system comprises a special platform for a high-speed rail freight motor train unit, a platform carrying roller way, a universal wheel platform, a universal roller floor in the high-speed rail freight motor train unit, an equipment channel, a safety shielding door, a personnel sideway, an equipment ramp and a high-speed rail freight transfer center. The high-efficiency automatic loading and unloading requirement of the high-speed rail freight motor train unit can be met, and a double-roller-way design guarantee system has high stability.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

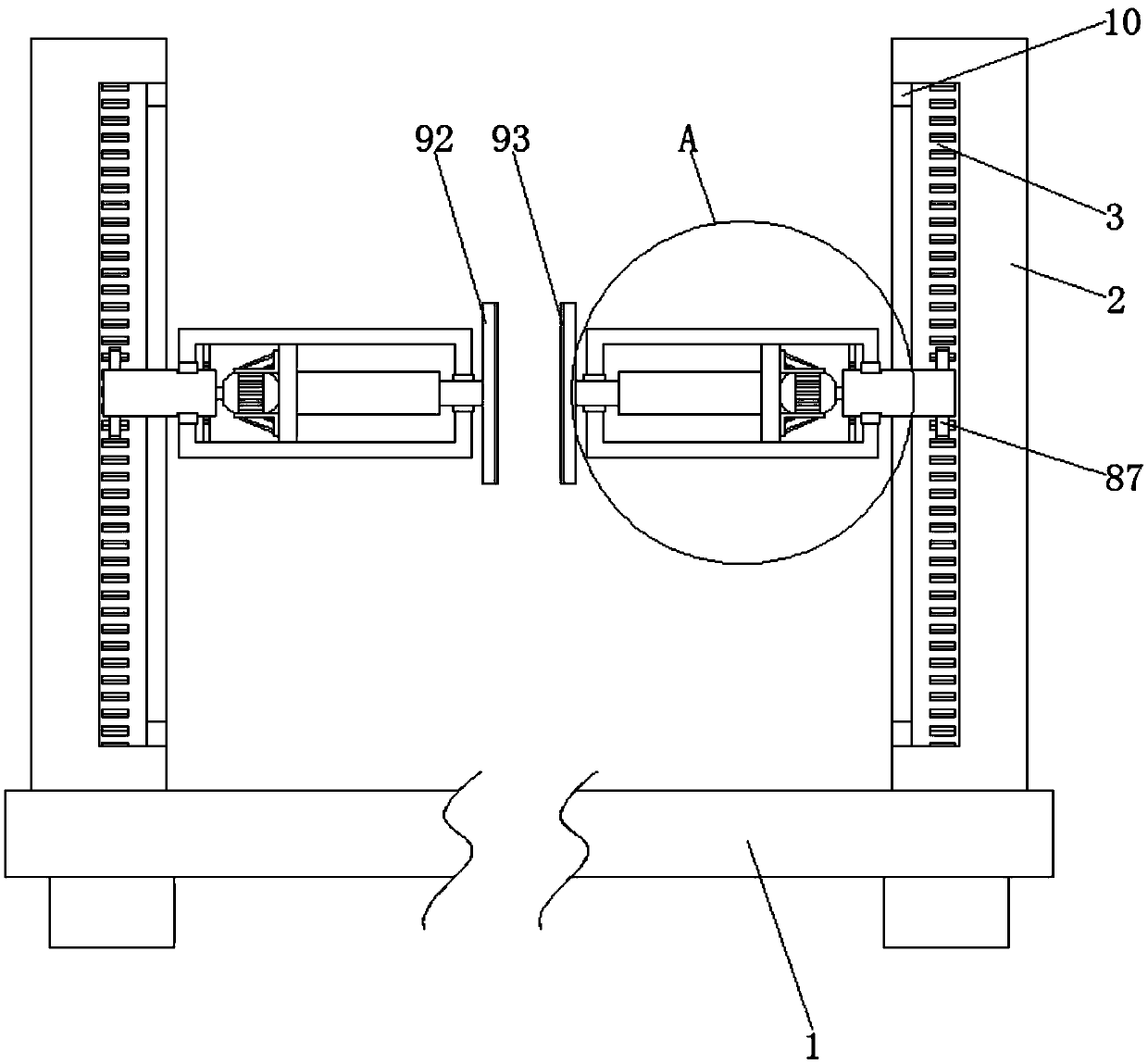

Multi-purpose ultralow-temperature tensile test device for ship material

PendingCN114136803APrecision Tensile TestQuick Tensile TestMaterial strength using tensile/compressive forcesMarine engineeringTest sample

The invention discloses a multipurpose ship material ultralow-temperature tensile test device which comprises a main body frame, a stress mechanism, a storage barrel, an upper connecting sleeve and a lower connecting sleeve, the upper connecting sleeve is arranged on the main body frame, and the lower connecting sleeve is mounted on the stress mechanism; a to-be-tested sample is mounted between the upper connecting sleeve and the lower connecting sleeve, is provided with a low-temperature extensometer, and is immersed into a storage barrel. According to the invention, the tensile test can be accurately and quickly carried out on the ultralow-temperature material, and the real mechanical properties such as ultralow-temperature yield strength, tensile strength, percentage elongation after fracture, percentage reduction of area and the like of the ultralow-temperature material are reflected, so that the strength and toughness of the ultralow-temperature material in an ultralow-temperature environment are verified and are used as a basis for checking and accepting the ultralow-temperature material; the material use reliability is ensured, and the ship building quality is improved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Device and method for installing and detaching large mirror for ion beam polisher for large-caliber optical parts

The invention discloses a device for installing and detaching a large mirror for an ion beam polisher for large-caliber optical parts. The device comprises a bearing device, a turning device for transporting measured workpieces and enabling workpiece faces to be machined to be kept downward in the transportation process and a conveying device for carrying the workpieces transported by the turning device and conveying the workpieces to an ion beam polishing vacuum chamber of the polisher. The bearing device comprises a guide trail and an inner frame arranged in the ion beam polishing vacuum chamber and used for carrying the workpieces conveyed by the conveying device. The conveying device is arranged on the guide rail and moves along the guide rail. The device is simple in structure, convenient to operate and control and capable of guaranteeing cleanness of working environment of the ion beam polisher, improves machining precision and machining efficiency of the ion beam polisher, and prolongs the service life of the device. The invention further discloses a method for installing and detaching the large mirror for the ion beam polisher for the large-caliber optical parts.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com