Device and method for installing and detaching large mirror for ion beam polisher for large-caliber optical parts

A technology of optical parts and loading and unloading devices, which is applied in the field of ion beam polishing, can solve the problems of poor operability and conveying efficiency of ion beam polishing machines, difficulty in ensuring the docking accuracy of inner and outer rolling guide rails, and inability to guarantee the processing accuracy of internal rolling guide rails. Achieve the effect of improving operability and convenience, convenient separation and connection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

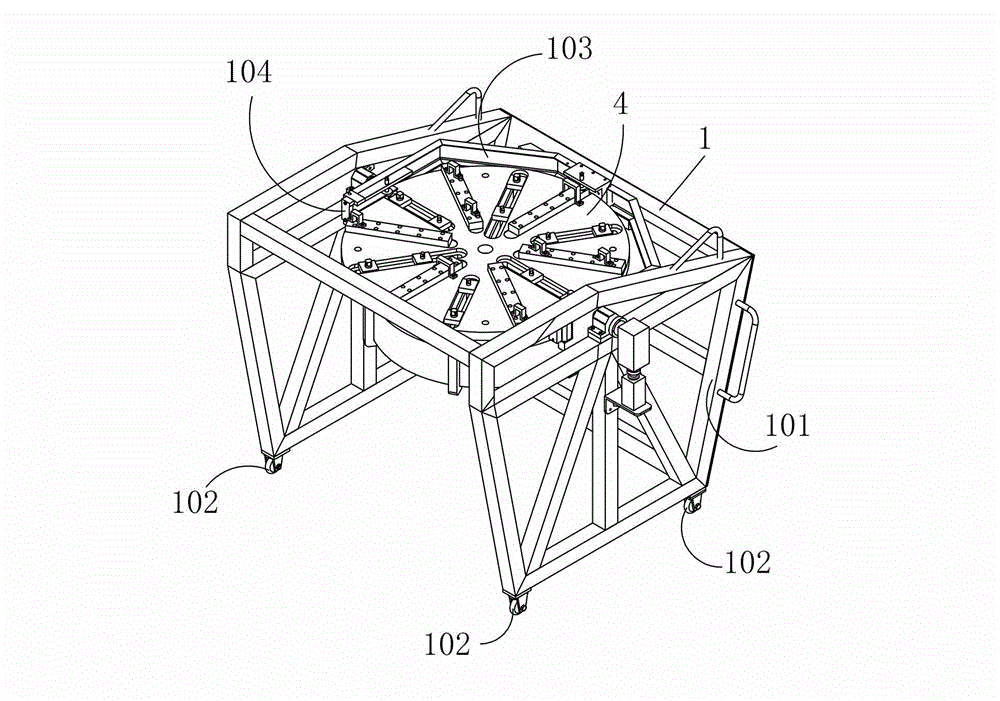

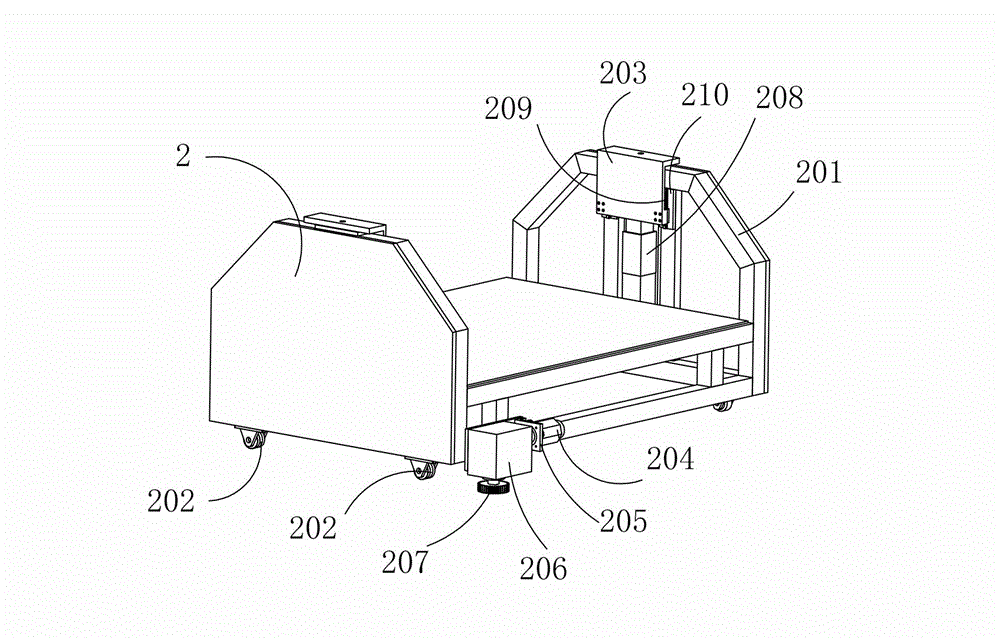

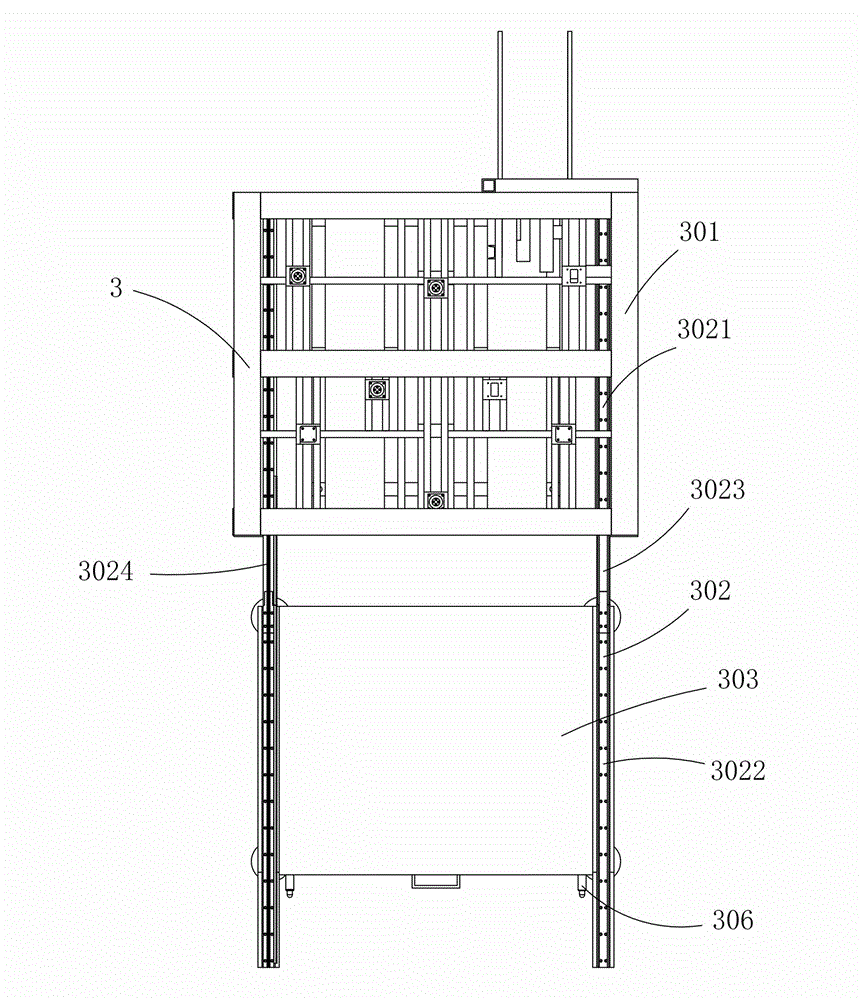

[0045] Figure 1 to Figure 7 An embodiment of a large mirror loading and unloading device for a large-diameter optical part ion beam polishing machine of the present invention is shown, the device includes a carrier device 3, used to transport the workpiece after measurement, and make the workpiece The turning device 1 whose surface to be processed is kept downward and is used to accept the workpiece transported by the turning device 1 and deliver the workpiece to the delivery device 2 in the ion beam polishing vacuum chamber of the polishing machine. The inner frame 301 in the beam polishing vacuum chamber is used to accept the workpieces conveyed by the conveying device 2 . The conveying device 2 is arranged on the guide rail 302 and moves along the guide rail 302 . The present invention adopts the combination of turning device 1, conveying device 2 and bearing device 3 to solve the loading and unloading problem of large-diameter optical parts, no longer rely on cranes to ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com