Needle-free electrostatic spinning equipment

An electrospinning, needle-free technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of adverse effects of stable nanofiber quality, electrostatic repulsion interference, rapid solvent volatilization, etc. Avoid the viscosity change of the material liquid, solve the effect of loading and unloading and cleaning, and inhibit the volatilization of the solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

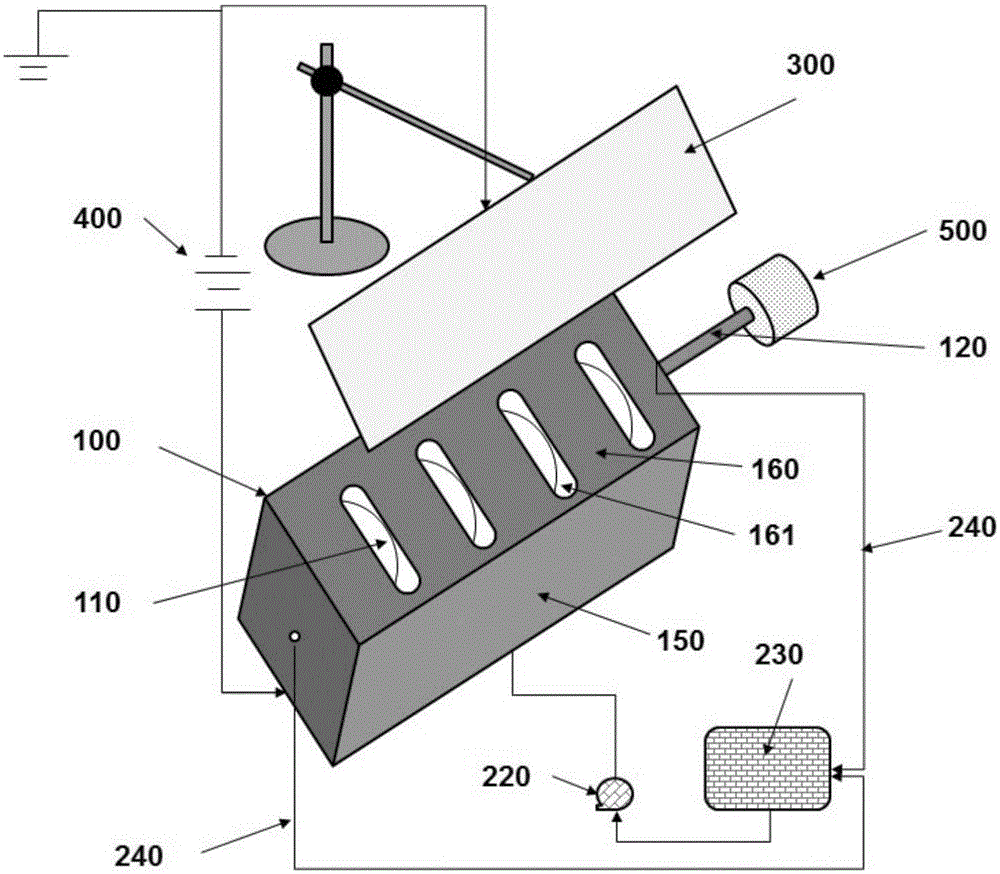

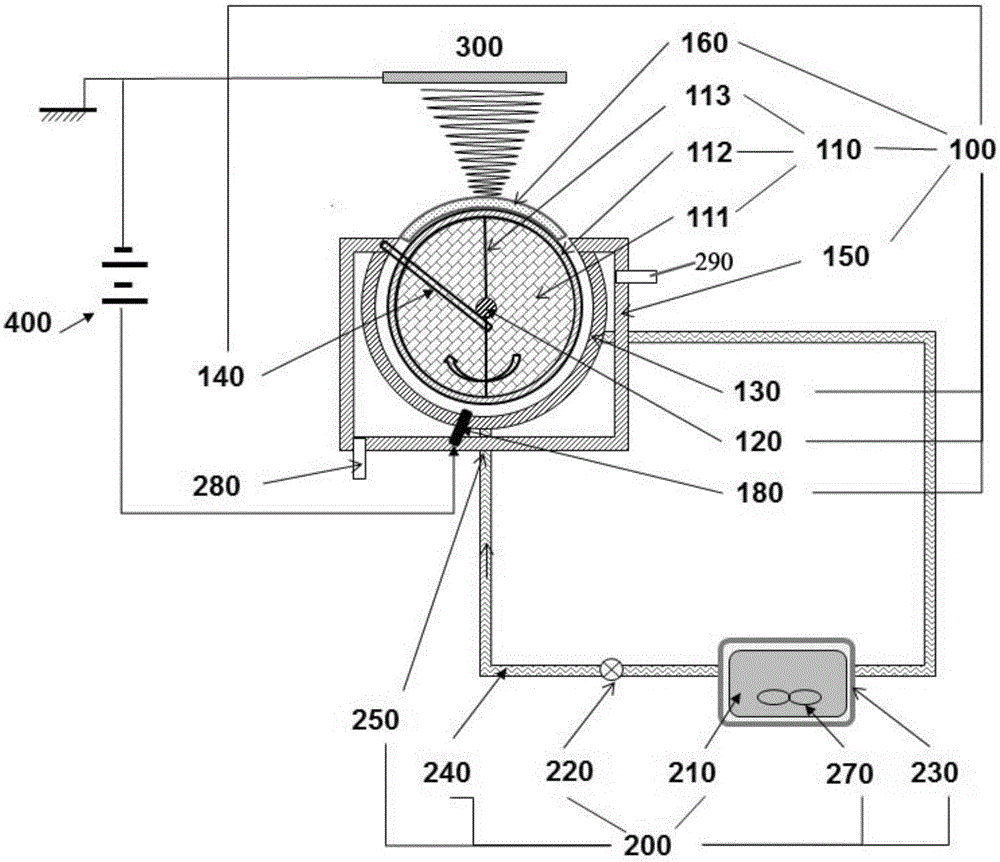

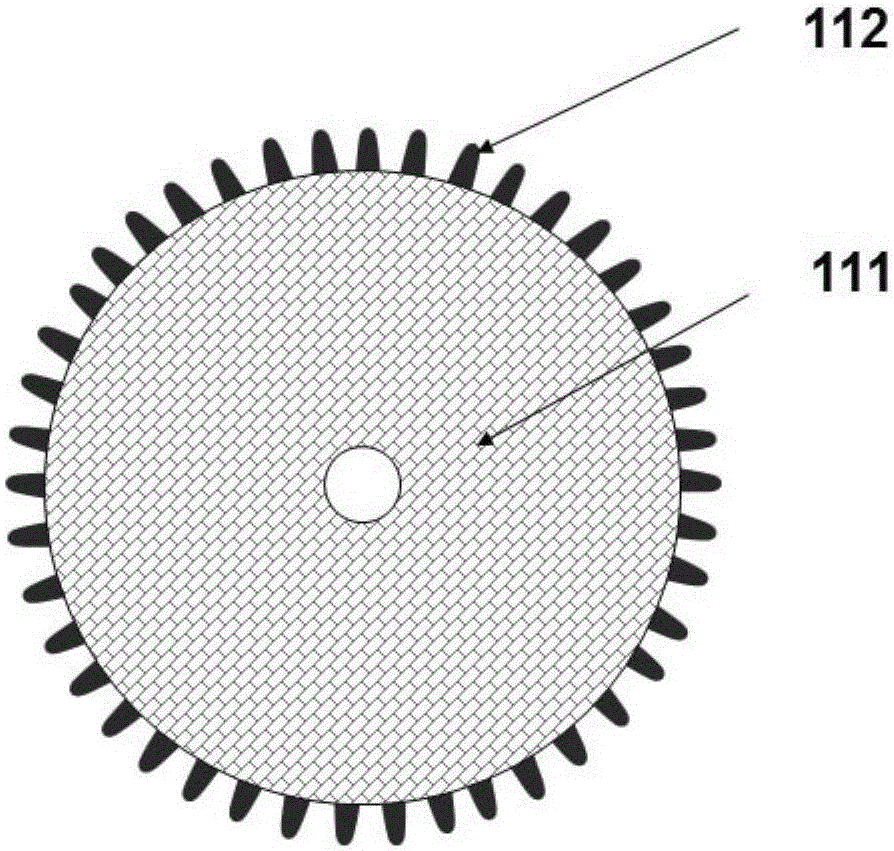

[0037] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a needle-free electrospinning device includes a spinning box 100, a feeding system 200, a receiving counter electrode 300, a high-voltage power supply 400 and a driving system 500, wherein: the spinning box 100 is detachable, Including a spinning nozzle 110, a drive shaft 120, a storage tank 130, a return plate 140, a constant temperature tank A150, a sealing cover 160 and an electrode terminal 180; the feeding system 200 is connected to the spinning box 100; the The receiving counter electrode 300 is located above the spinning cartridge 100 and grounded; the positive electrode of the high-voltage power supply 400 is connected to the lower end of the electrode terminal 180, and its negative electrode is grounded; the driving system 500 is arranged on the At one end of the transmission shaft 120, the driving system 500 is composed of a motor driver and a motor connected to each other...

Embodiment 2

[0046] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a needle-free electrospinning device includes a spinning box 100, a feeding system 200, a receiving counter electrode 300, a high-voltage power supply 400 and a driving system 500, wherein: the spinning box 100 is detachable, Including a spinning nozzle 110, a drive shaft 120, a storage tank 130, a return plate 140, a constant temperature tank A150, a sealing cover 160 and an electrode terminal 180; the feeding system 200 is connected to the spinning box 100; the The receiving counter electrode 300 is located above the spinning cartridge 100 and grounded; the positive electrode of the high-voltage power supply 400 is connected to the lower end of the electrode terminal 180, and its negative electrode is grounded; the driving system 500 is arranged on the At one end of the transmission shaft 120, the driving system 500 is composed of a motor driver and a motor connected to each other...

Embodiment 3

[0055] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6As shown, a needle-free electrospinning device includes a spinning box 100, a feeding system 200, a receiving counter electrode 300, a high-voltage power supply 400 and a driving system 500, wherein: the spinning box 100 is detachable, Including a spinning nozzle 110, a drive shaft 120, a storage tank 130, a return plate 140, a constant temperature tank A150, a sealing cover 160 and an electrode terminal 180; the feeding system 200 is connected to the spinning box 100; the The receiving counter electrode 300 is located above the spinning cartridge 100 and grounded; the positive electrode of the high-voltage power supply 400 is connected to the lower end of the electrode terminal 180, and its negative electrode is grounded; the driving system 500 is arranged on the At one end of the transmission shaft 120, the driving system 500 is composed of a motor driver and a motor connected to each other....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com