Ultralow-temperature tensile test device and method for ship material

A tensile test, ultra-low temperature technology, used in measuring devices, analyzing materials, and testing the strength of materials by applying stable tension/pressure, to solve the problems of sample loading and unloading and cooling, improve ship construction quality, and ensure reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

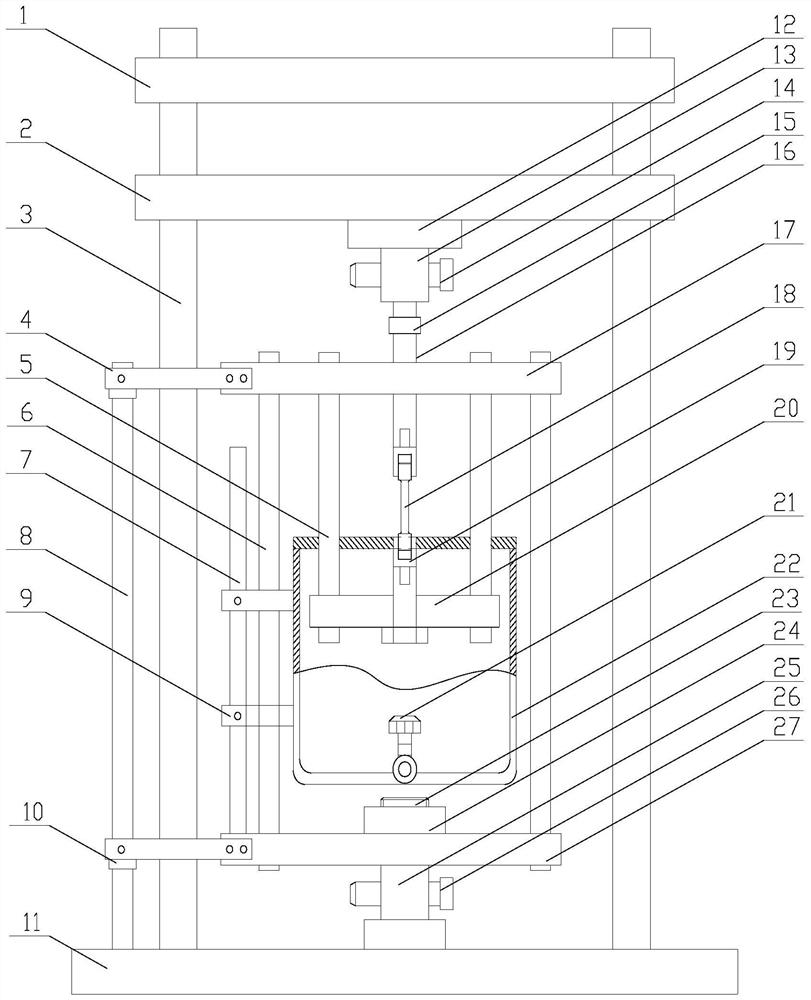

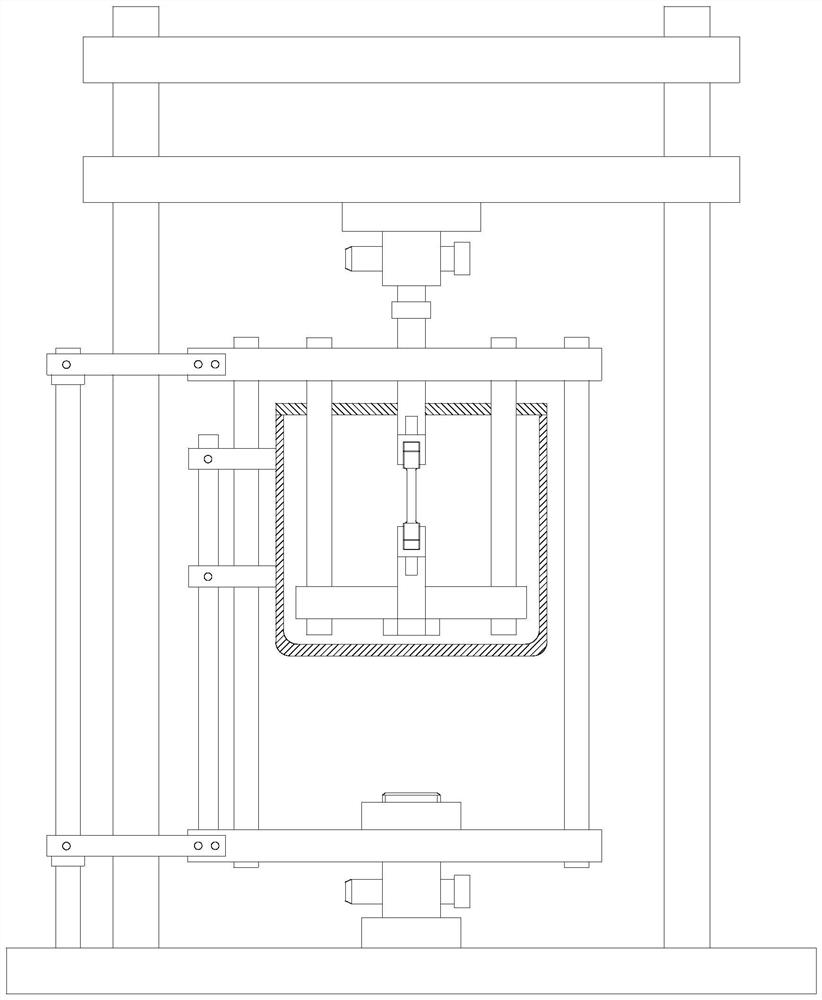

[0046] This embodiment provides an ultra-low temperature tensile test device for ship materials,

[0047] It includes a main body frame, a force receiving mechanism, a storage bucket 22 , an upper connecting sleeve 16 and a lower connecting sleeve 19 .

[0048]Among them, the main frame includes the upper beam 1 of the testing machine, the lower beam 11 of the testing machine, the movable beam 2 and the column 3 of the testing machine, the upper beam 1 of the testing machine and the lower beam 11 of the testing machine are fixed structures, and the upper end of the column 3 of the testing machine passes through the upper beam of the testing machine 1. The lower end of the column 3 of the testing machine passes through the lower beam 11 of the testing machine. The moving beam 2 is located between the upper beam 1 of the testing machine and the lower beam 11 of the testing machine and can move up and down along the column 3 of the testing machine. The column 3 of the testing mach...

Embodiment 2

[0053] This embodiment provides a method for ultra-low temperature tensile testing of ship materials, comprising the following steps:

[0054] Step 1. Install the force-bearing mechanism on the force-bearing installation shaft 8 through the force-bearing connecting piece 4. There is a force-bearing turntable 10 between the force-bearing connecting piece 4 and the force-bearing installation shaft 8. Turn the force-bearing mechanism in or out as required. Out of the test space of the testing machine and installed firmly; the force-bearing mechanism can be transferred into the test space of the testing machine when the ultra-low temperature test is required, and transferred out of the test space of the testing machine when the ultra-low temperature test is not required, without affecting the testing machine for other tests;

[0055] Step 2, install the storage on the force bearing mechanism through the barrel connector 9;

[0056] Step 3. Connect one end of the upper connecting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com