Simple hinge type manual feeding and discharging device for shaft hobbing

A hinge type and gear hobbing technology, applied in the direction of automatic in/out of workpieces, metal processing machinery parts, metal processing, etc., can solve the problems of high cost, heavy weight and high labor intensity of old machine tools, and reduce the labor of workers. Strength, low cost, and the effect of avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in further detail below in conjunction with accompanying drawing:

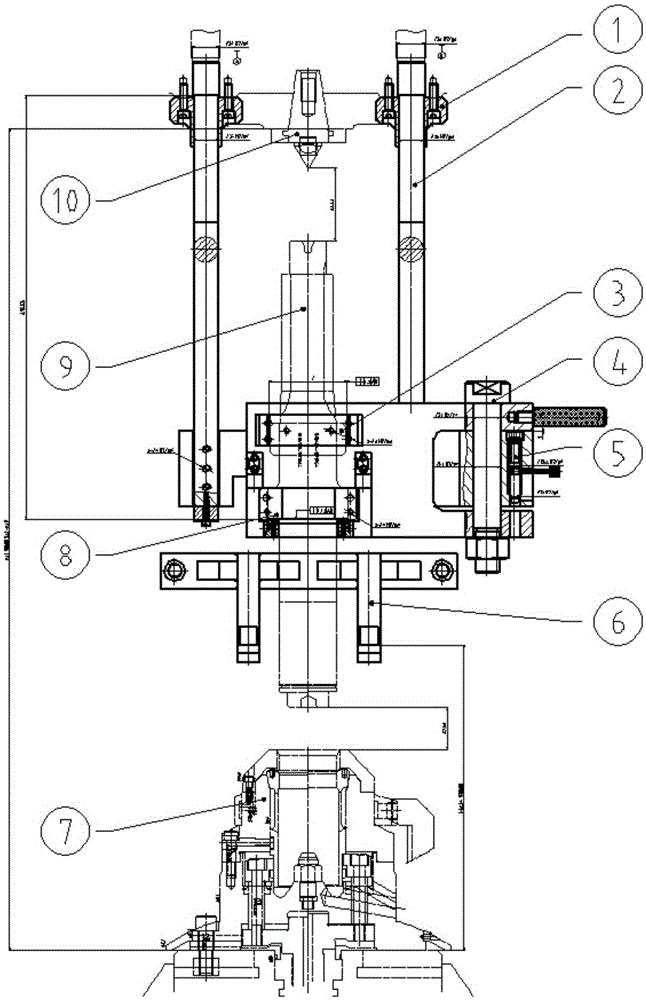

[0019] see figure 1 , the present invention includes a double link 2, the lower end of the double link 2 is fixedly connected to the hinge bracket 4, and the upper end is connected to the machine tool tailstock 10 through a transition flange 1; a lower limit bracket 6 is arranged below the hinge bracket 4 , the lower limit bracket 6 is fixed on the machine tool column, and is used to limit the lower limit position of the hinge bracket 4; during processing, the lower end of the workpiece 9 extends into the clamp body 7, and rotates with the workbench after being clamped; the machine tool The up and down movement of the tailstock 10 drives the whole mechanism and the workpiece 9 to move up and down, so as to realize the loading and extraction of the workpiece 9 in the clamp body 7 . The workpiece 9 is a gear shaft. The upper end of the double link 2 runs through the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com