Mine waste rock-turning groove

A gangue chute and mine shaft technology, which is applied in the field of shaft mine construction and gangue discharge, can solve problems in processing, loading and unloading, and transportation, increase input costs, increase cost input, etc., and achieve increased cost input, simple and convenient loading, unloading, and installation , the effect of simple transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

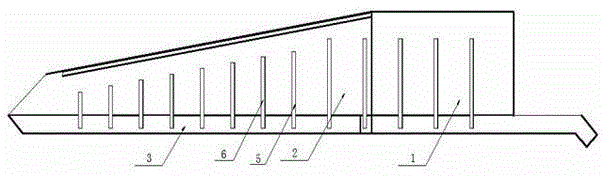

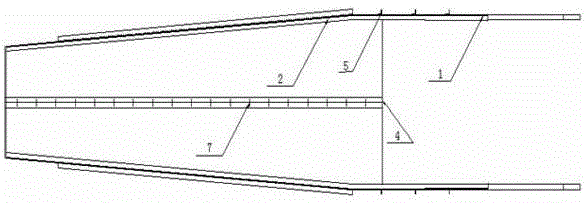

[0012] like figure 1 , 2 The shown one kind of mine gangue turning chute includes two chute straight sides 1, chute inclined sides 2, and chute bottom plate 3 respectively. The chute chassis 4;

[0013] Further, the bottom plate 3 of the chute is provided with a positioning groove 5 on the straight side 1 of the chute and the inclined side 2 of the chute, and the positioning groove 5 is welded and connected by a reinforcing rib 6 .

[0014] By improving the structure of the large-scale mine turning gangue chute, six parts are used for block processing, which is beneficial to shorten the processing period, and at the same time, due to the reduced volume and convenient loading and unloading, it solves the problems in processing, transportation, and loading and unloading. Make processing and transportation easier; the bottom plate of the chute is connected by bolt holes, the straight side of the chute, the inclined side of the chute and the positioning grooves set on the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com