Rhodococcus sp., lipopeptid extra-cellular bio-demulsifier, preparation method and application thereof

A rhodococcus and demulsifier technology, applied in the fields of petrochemical and industrial microbiology, can solve the problems of high extraction cost of cell wall-bound products and impact on oil quality, solve the problems of transportation and storage, and solve the high extraction cost , the effect of occupying a small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

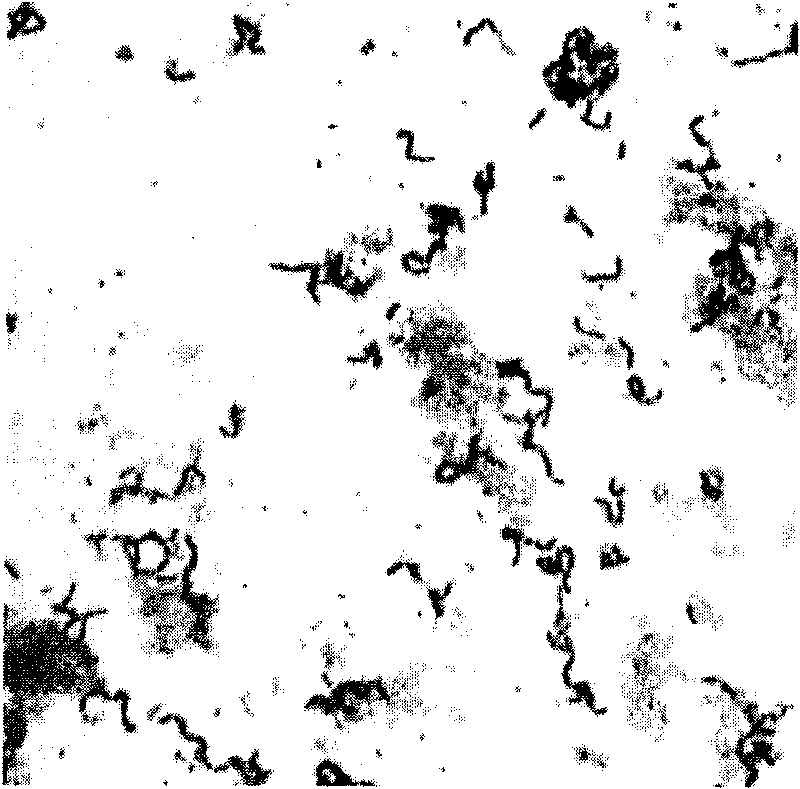

Image

Examples

Embodiment 1

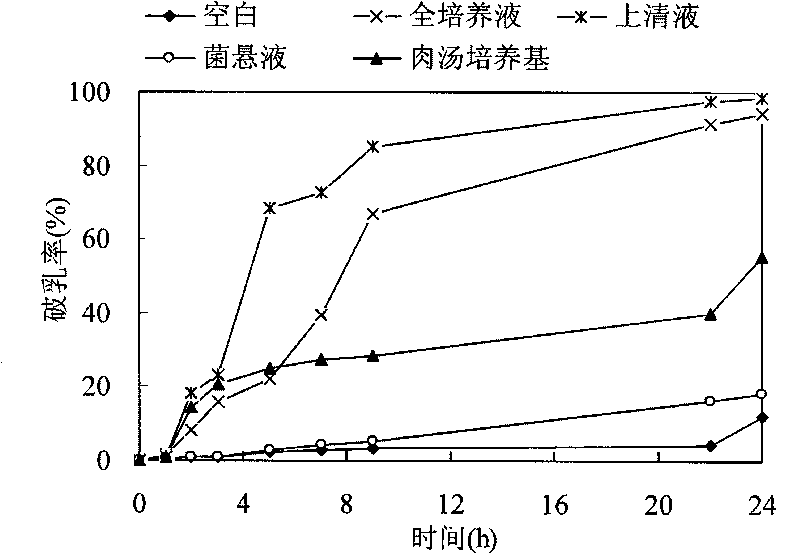

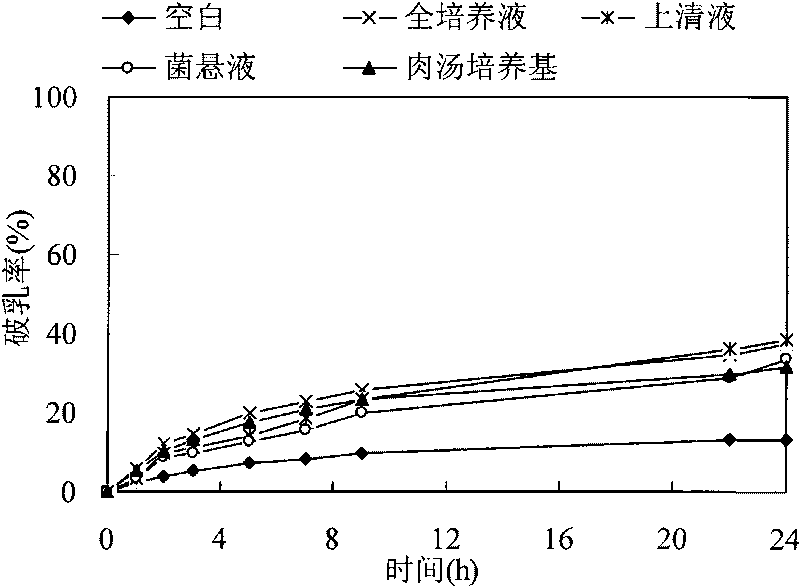

[0037] Demulsification effect of broth culture on kerosene model emulsion:

[0038] The Rhodococcus S-SL-2 obtained by screening was inserted into the broth medium, and cultured in a shaker with a temperature of 35°C and a rotation speed of 140rpm for 3 days, and the whole culture solution was centrifuged at 10000rpm for 20min, and the supernatant was poured out. The centrifuged bacteria were suspended and restored to the original volume with distilled water to make a bacterial suspension, and the whole culture medium, supernatant, and bacterial suspension were respectively added to the W / O and O / W kerosene model emulsions, and the breaking effects of the three were compared. Demulsification effect, and compared with the demulsification effect of no sample and blank broth medium, the temperature of the demulsification test was 35 °C, and the dosage was 10% (V / V). The results are shown in figure 2 , image 3 .

[0039] from figure 2 It can be seen that the demulsification ...

Embodiment 2

[0042] Demulsification effect of paraffin culture on kerosene model emulsion:

[0043] Insert the Rhodococcus S-SL-2 obtained from the screening into paraffin medium, and culture it in a shaker with a temperature of 35°C and a rotation speed of 140rpm for 7 days, and centrifuge the whole culture solution at 10,000rpm for 20min to remove the remaining paraffin in the upper layer and the middle layer. Finally, the centrifuged bacteria were suspended and reduced to the original volume with distilled water to make a bacterial suspension, and the whole culture medium, middle layer liquid, and bacterial suspension were respectively added to the W / O and O / W kerosene model emulsions, and the effects of the three were compared. Demulsification effect, and compared with the demulsification effect without adding any sample, the temperature of the demulsification test is 35 ℃, the dosage is 10% (V / V), the results are shown in Figure 4 , Figure 5 .

[0044] from Figure 4 It can be se...

Embodiment 3

[0047] Demulsification effect of biological demulsifier on W / O kerosene model emulsion:

[0048] The supernatant and middle layer obtained from S-SL-2 in broth medium and paraffin medium were respectively adjusted to pH 2.0 with 6mol / L HCl, stored at 4°C overnight, and then centrifuged at 10,000rpm for 20min , the supernatant was discarded to obtain the primary product in the form of flocculent precipitates, and after 24 hours of freeze-drying, the final biological dry powder demulsifier was obtained. Dissolve the biodemulsifier with a small amount of alkaline solution, adjust the pH to 7.0 with NaOH, and prepare the concentration with distilled water. Test the demulsification effect of biological demulsifiers at different dosages, the results are shown in Image 6 , Figure 7 .

[0049] from Image 6 It can be seen from the figure that the demulsification rate of the W / O kerosene model emulsion is increased with the increase of the dosage of the biological demulsifier ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com