Feeding and discharging mechanical arm for pipe forming machine

A forming machine and manipulator technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of danger, manual loading and unloading, low efficiency, etc., to achieve easy operation, solve loading and unloading, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

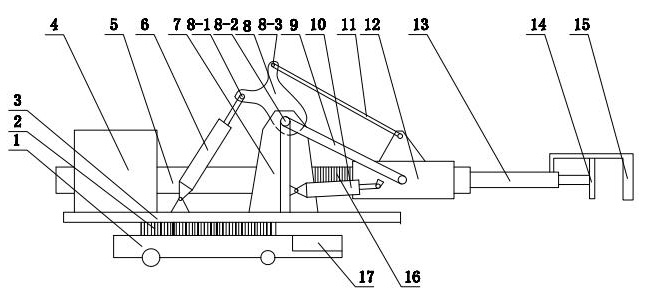

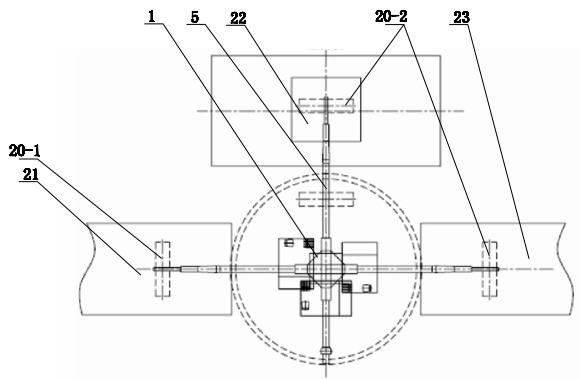

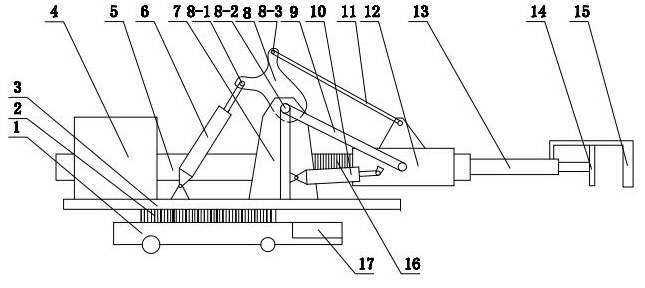

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, the present invention includes a mobile trolley 1 provided with rollers at the bottom, which can be pushed on the ground. The front of the mobile trolley 1 is connected to a rotary platform 3 through a rotary gear 2, and the rotary gear 2 is driven by a motor 17, so that the rotary platform 3 can be made 360-degree omnidirectional rotation; a hydraulic control system 4 is provided at the front and rear of the rotating platform 3 for hydraulic control and driving of each hydraulic cylinder; There is a fulcrum 8-2 of the trident connecting arm 8, the fulcrum 8-1 of the connecting arm 8 is pivotally connected to the piston rod of the pitch-down hydraulic cylinder 6, and the cylinder body of the pitch-down hydraulic cylinder 6 is pivotally connected to the rotating platform 3; the connecting arm Another fulcr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com