Multifunctional gripper capable of taking and placing yarns and separating plate

A multi-functional, claw technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of falling, one end of the baffle, and achieve the effect of solving the problem of loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

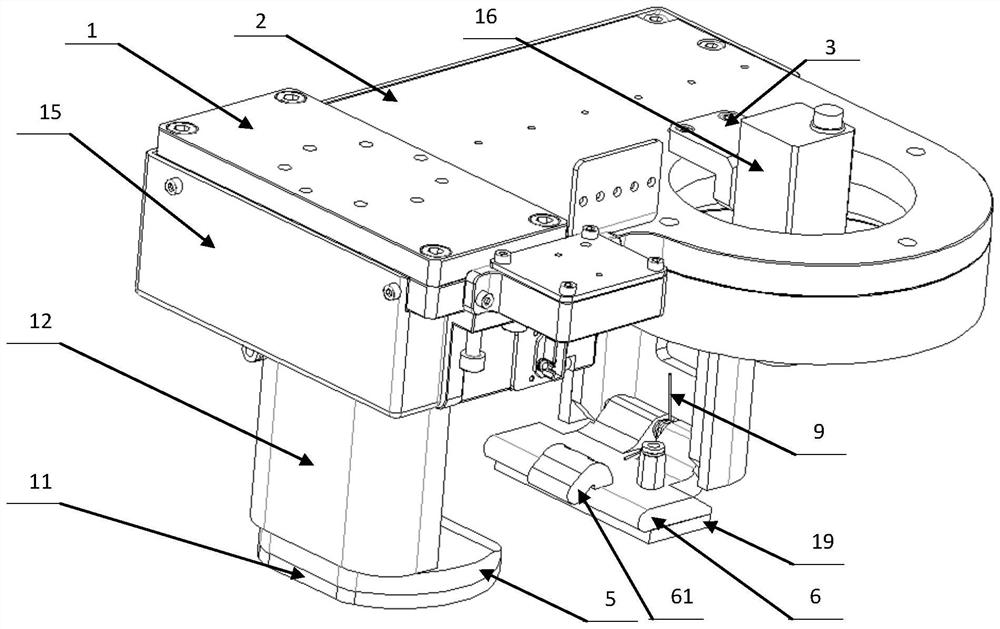

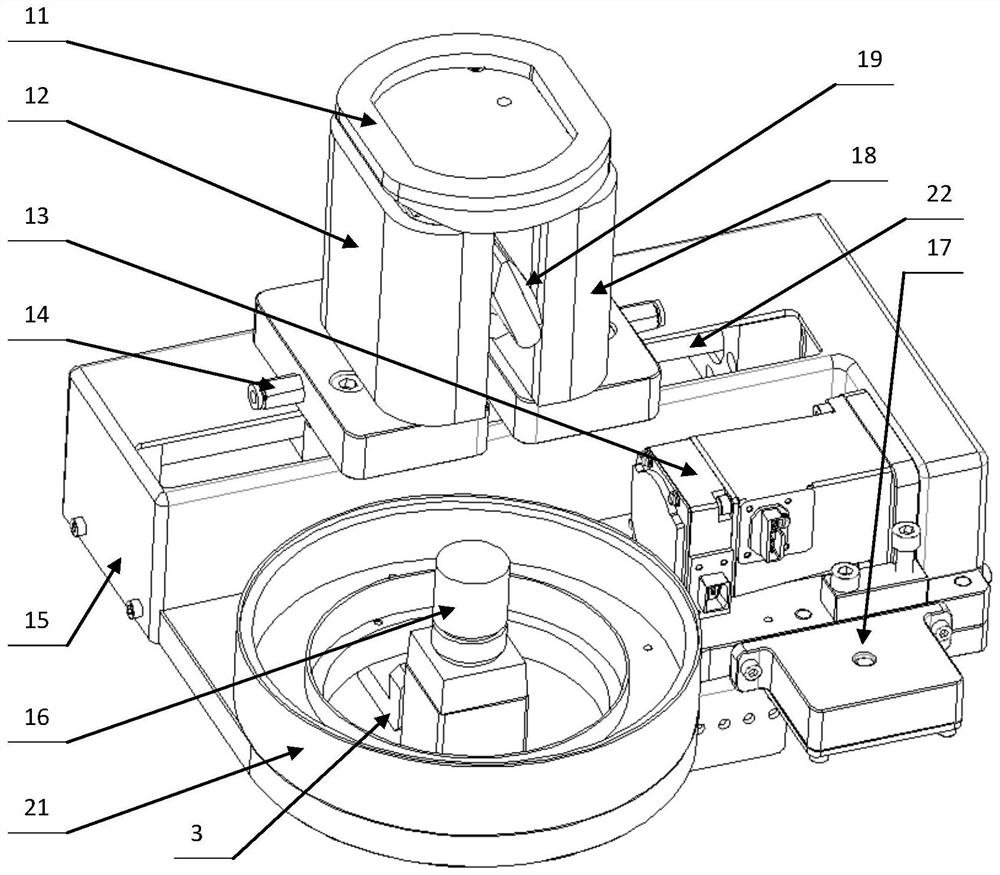

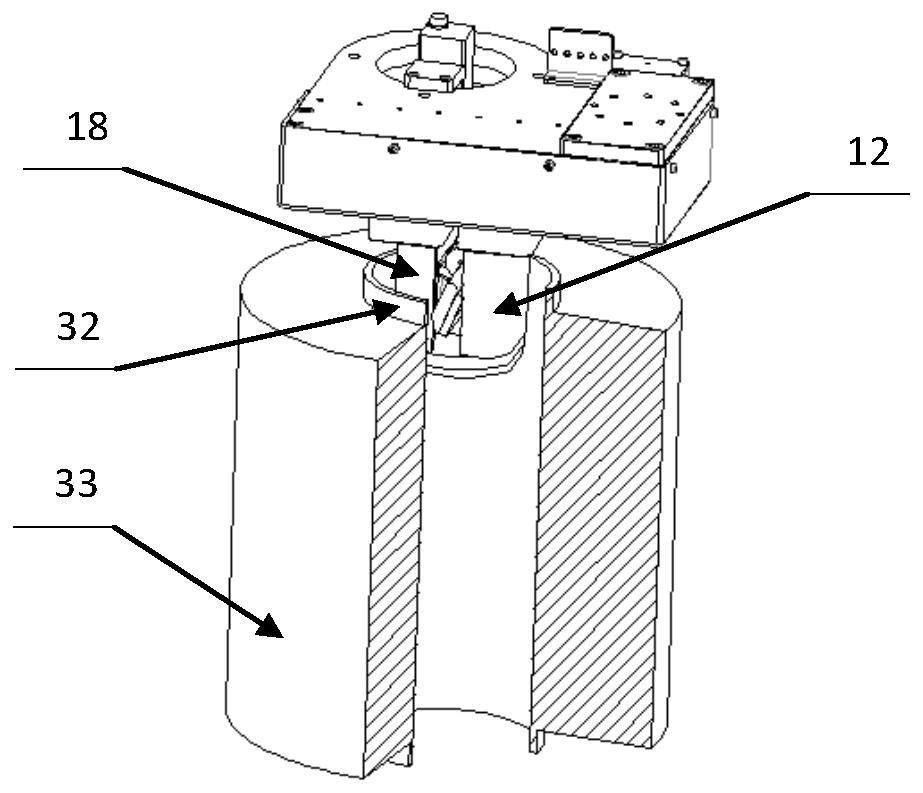

[0037] As shown in the accompanying drawings, a multifunctional gripper capable of taking and placing yarns and partitions of the present invention includes a mounting base plate 2, and a robot transition plate 1 is fixed on the left side of the top wall of the mounting base plate 2. The described The robot transition plate 1 is used for connecting the gripper of the present invention to the six-axis end flange of the robot. A distance measuring sensor 17 is fixed on the left side of the front wall of the housing 15. In front of the installation substrate 2 A camera 16 is fixed on the right side of the wall through the camera mounting plate 3 , and the ring light source 21 of the camera is fixedly connected with the mounting substrate 2 . Described camera is used for collecting yarn 33 and partition 41 (as attached Figure 4) is used for positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com