High-temperature alloy round-heaven square-earth thin-wall cylindrical guide pipe forming die and forming method

A high-temperature alloy, the technology of the sky is round and the place is applied in the field of mechanical processing, which can solve the problems of unretrieved, difficult to guarantee quality, and difficult to load and unload parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

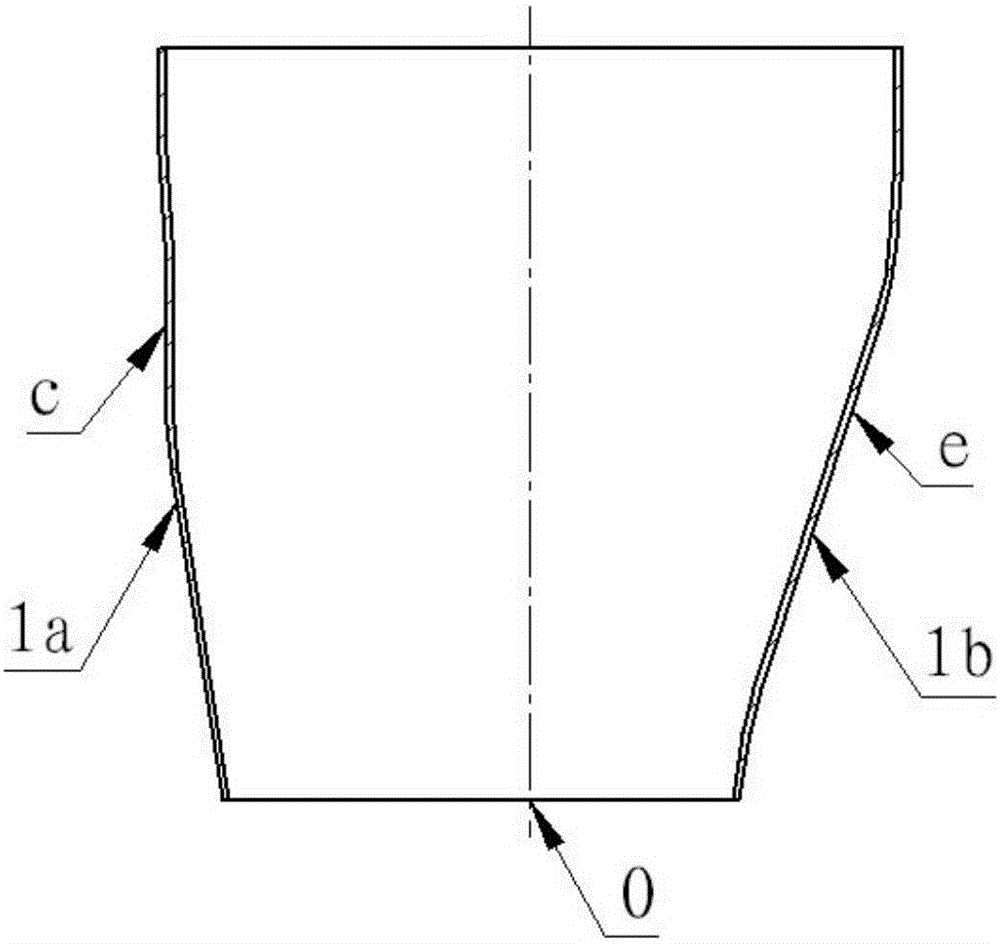

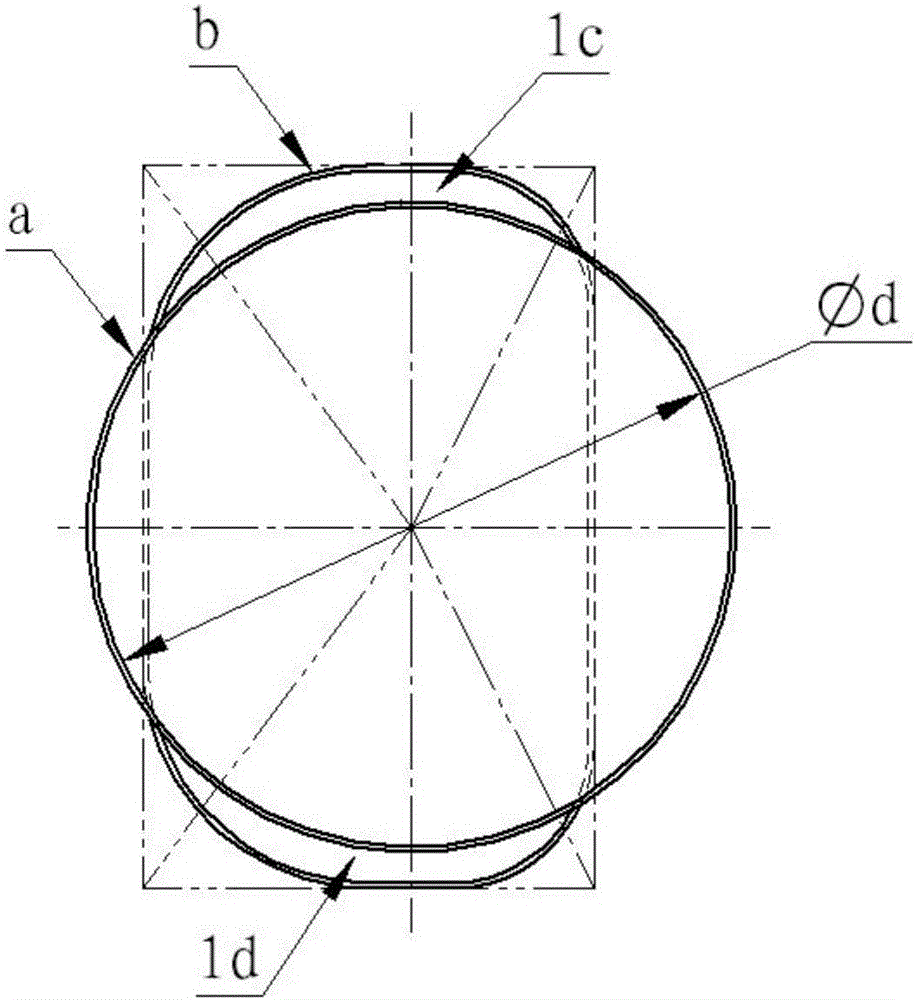

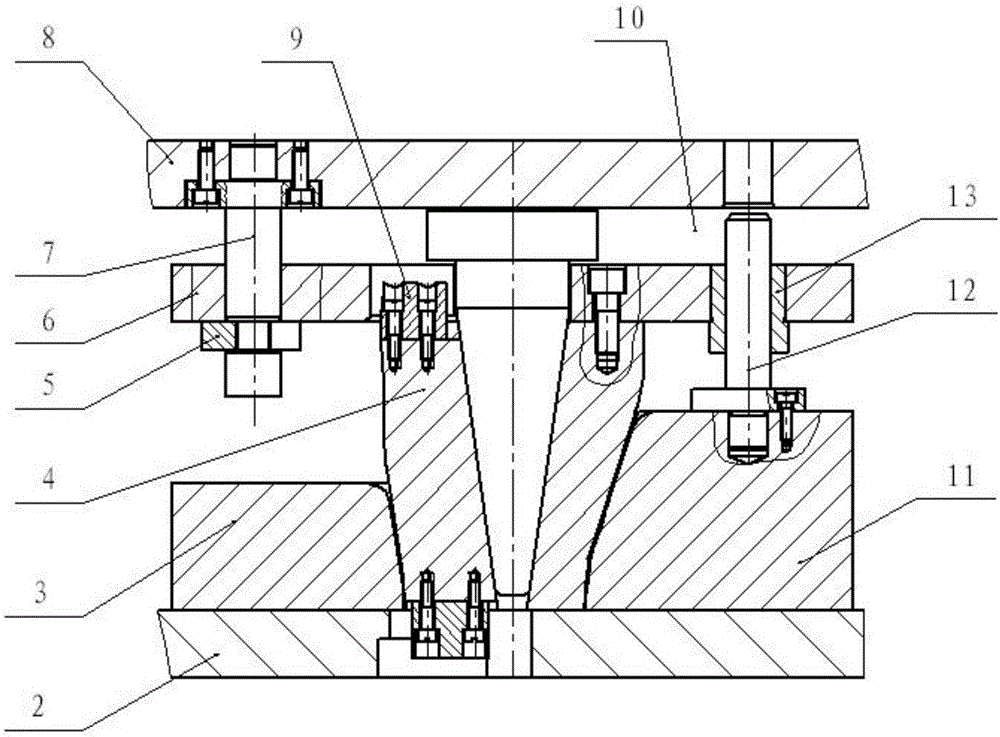

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 with figure 2The conduit to be formed and processed is a thin-walled cylindrical part made of a high-temperature alloy material with a round shape and a square shape. Its upper end surface is a circular section line a with a diameter of φ140mm. , the width is 156mm, the distance from the left straight side of the rectangular section line b to the point O is 58mm, and the distance from the right side straight side to the O point is 30mm, the four corners of the rectangular section line b are rounded, and the center of φd is at the lower end surface of the transverse section The projection point is point O, and in the longitudinal section passing through the center of φd and the width center line of the rectangular section line b, there are left guide line c and right guide line e with convex and concave shapes, left guide line c and right guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com