Forklift truck loading and unloading adaptive lightweight compartment floor structure

A lightweight, floor technology, applied in the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve the problem that deep corrugated boards cannot adapt to manual forklift loading and unloading operations, do not conform to the trend of lightweight, and the floor structure is heavy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

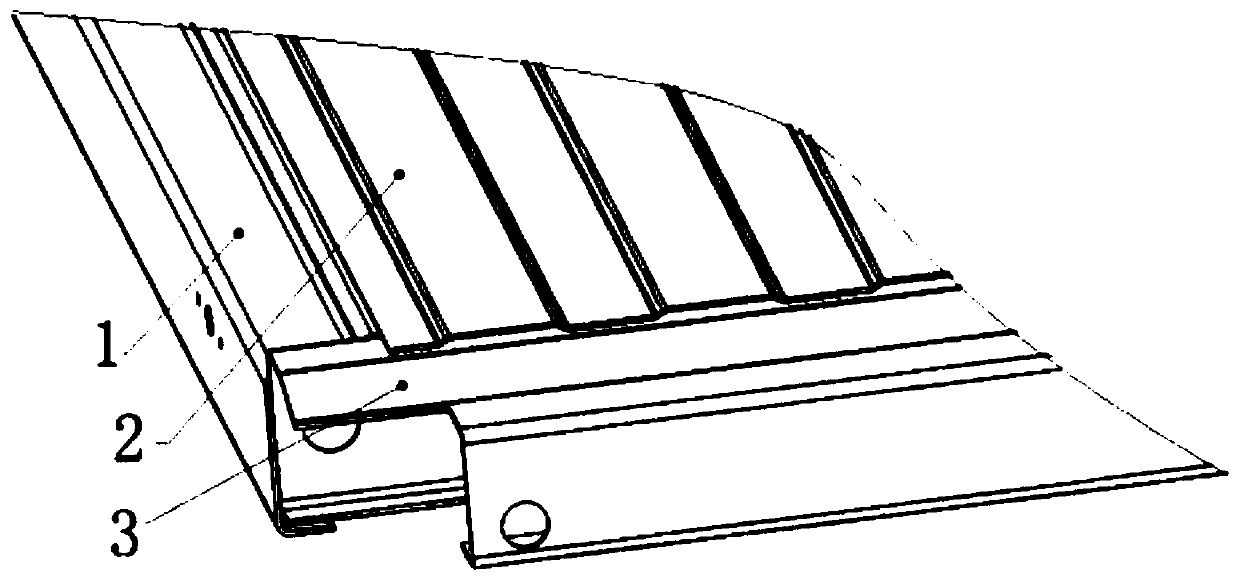

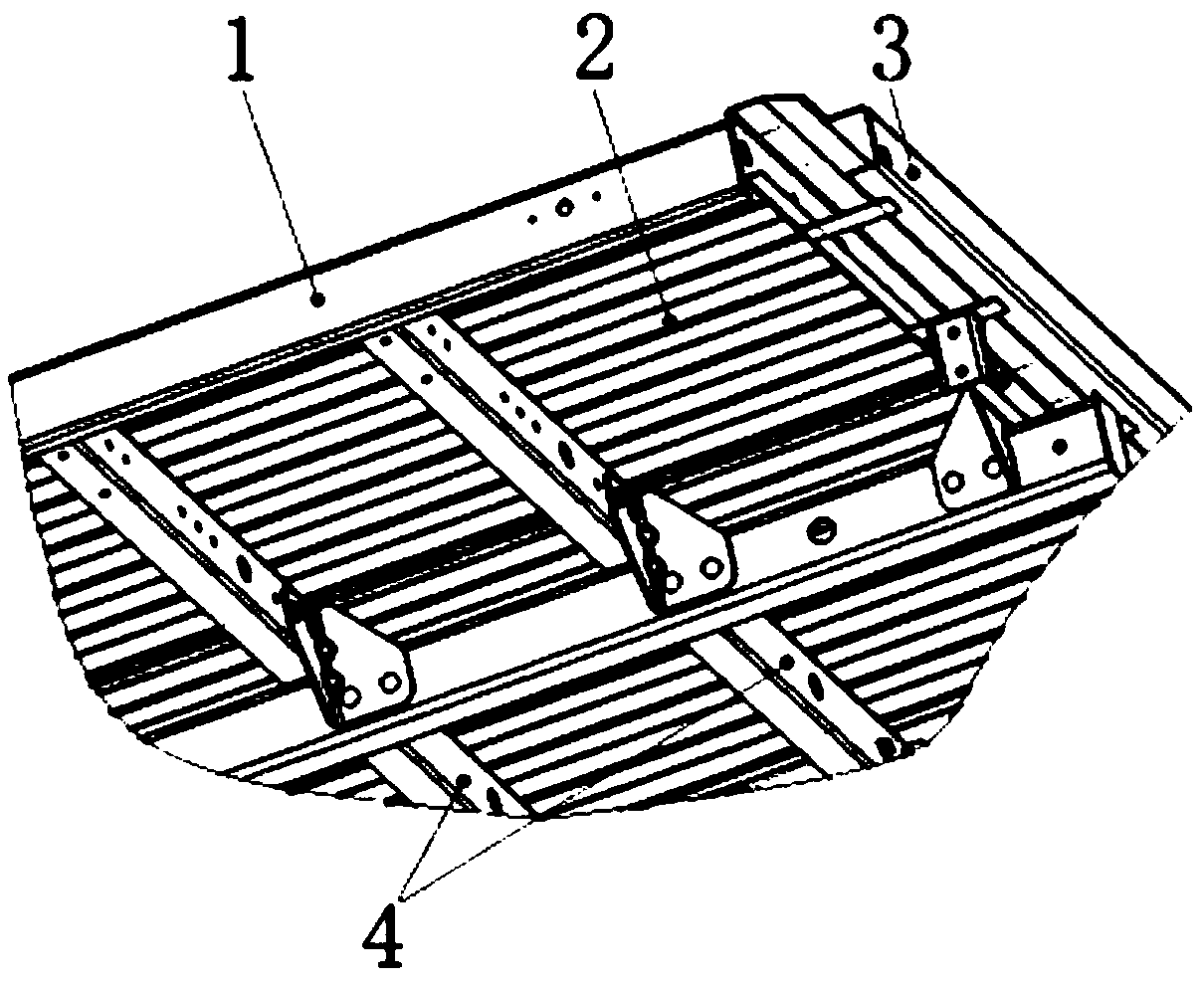

[0023] see Figure 1-3 , in an embodiment of the present invention, a lightweight car floor structure suitable for forklift loading and unloading, including a floor frame 1, a rear beam 3 and a middle beam 4, one end of the floor frame 1 is installed with a rear beam 3, and the floor frame 1 is installed There is a micro-corrugated floor 2, the underside of the micro-corrugated floor 2 is also provided with several middle beams 4, and the upper side of the middle beam 4 is connected and fixed with the micro-corrugated floor 2, and the two ends of the middle beam 4 are connected to the The bottom plate frame 1 is connected and fixed.

Embodiment 2

[0025] see Figure 1-3 , the difference between this embodiment and embodiment 1 is:

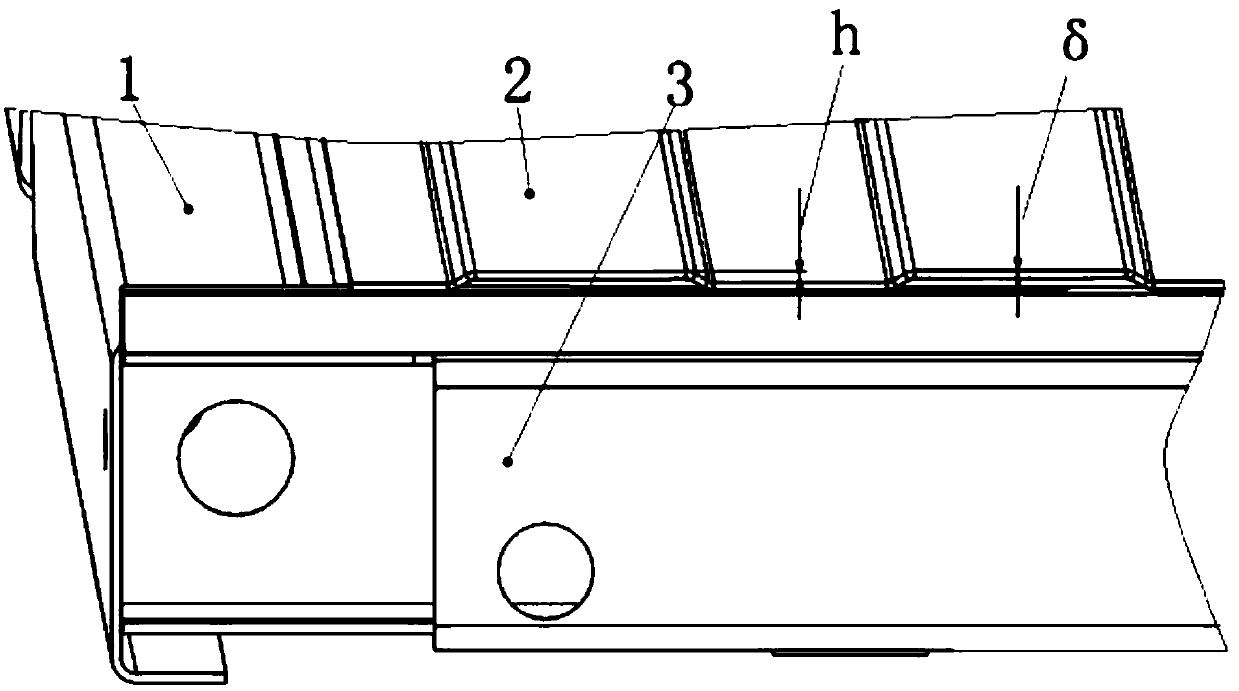

[0026] In this embodiment, the micro-corrugated floor 2 is made of high-strength steel plates, and the groove depth (h) rolled on the micro-corrugated floor 2 is twice the material thickness (δ).

[0027] In this embodiment, several middle beams 4 are evenly arranged on the lower side of the micro-corrugated floor 2, and the distance between two adjacent middle beams 4 is 350-500 mm.

[0028] The lightweight car floor structure adapted to loading and unloading by forklifts is a low-cost, lightweight floor structure, and simultaneously solves the loading and unloading problems of electric forklifts and manual hand forklifts.

[0029] High-strength steel plates are used, rolled into a micro-corrugated floor 2 with a ratio of groove depth (h) to material thickness (δ) of 2, and a reasonable choice of beam spacing of 350-500mm to accommodate forklifts of different tonnages and types for loading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com