Patents

Literature

173results about "Vehicle with screw conveyors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

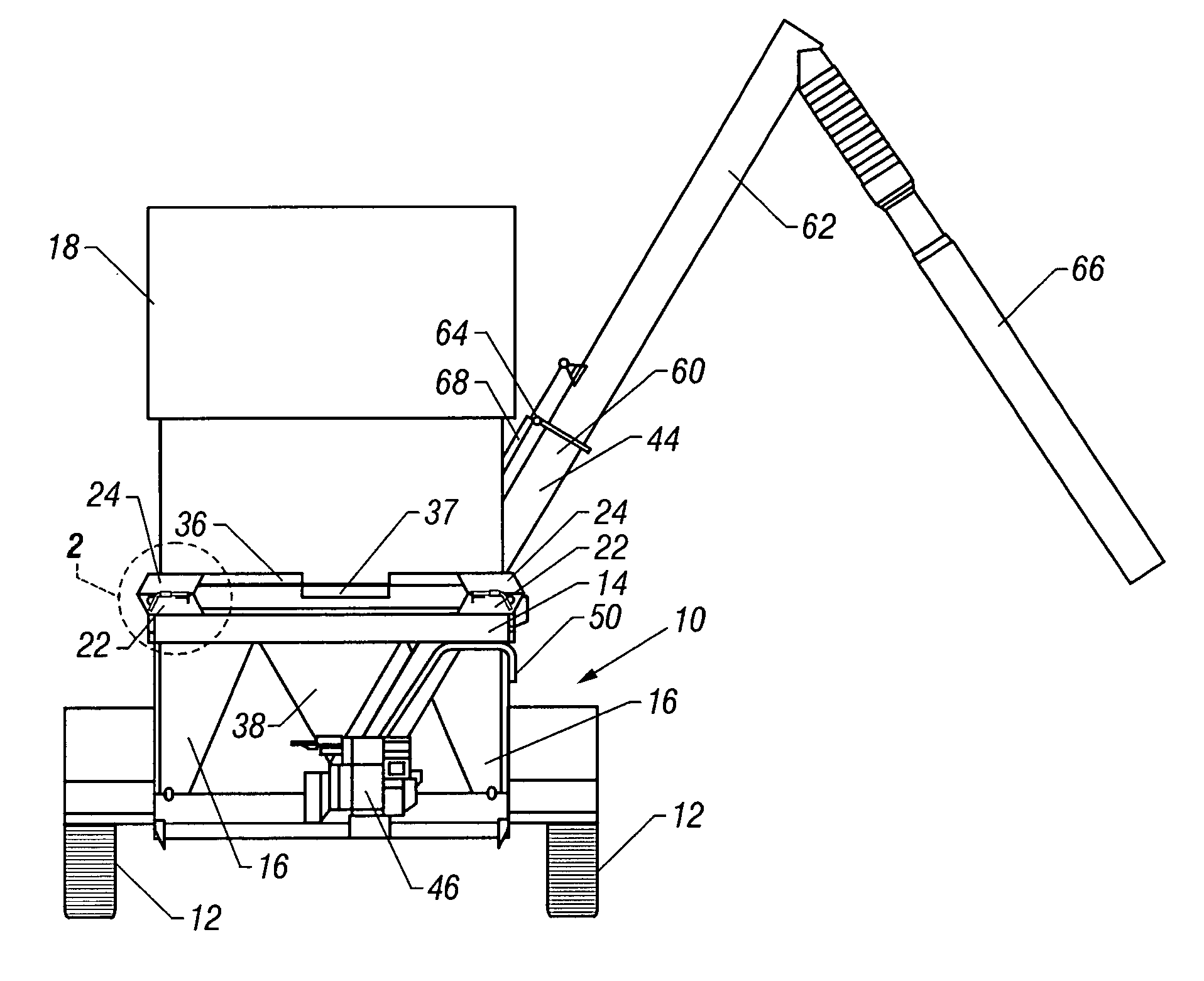

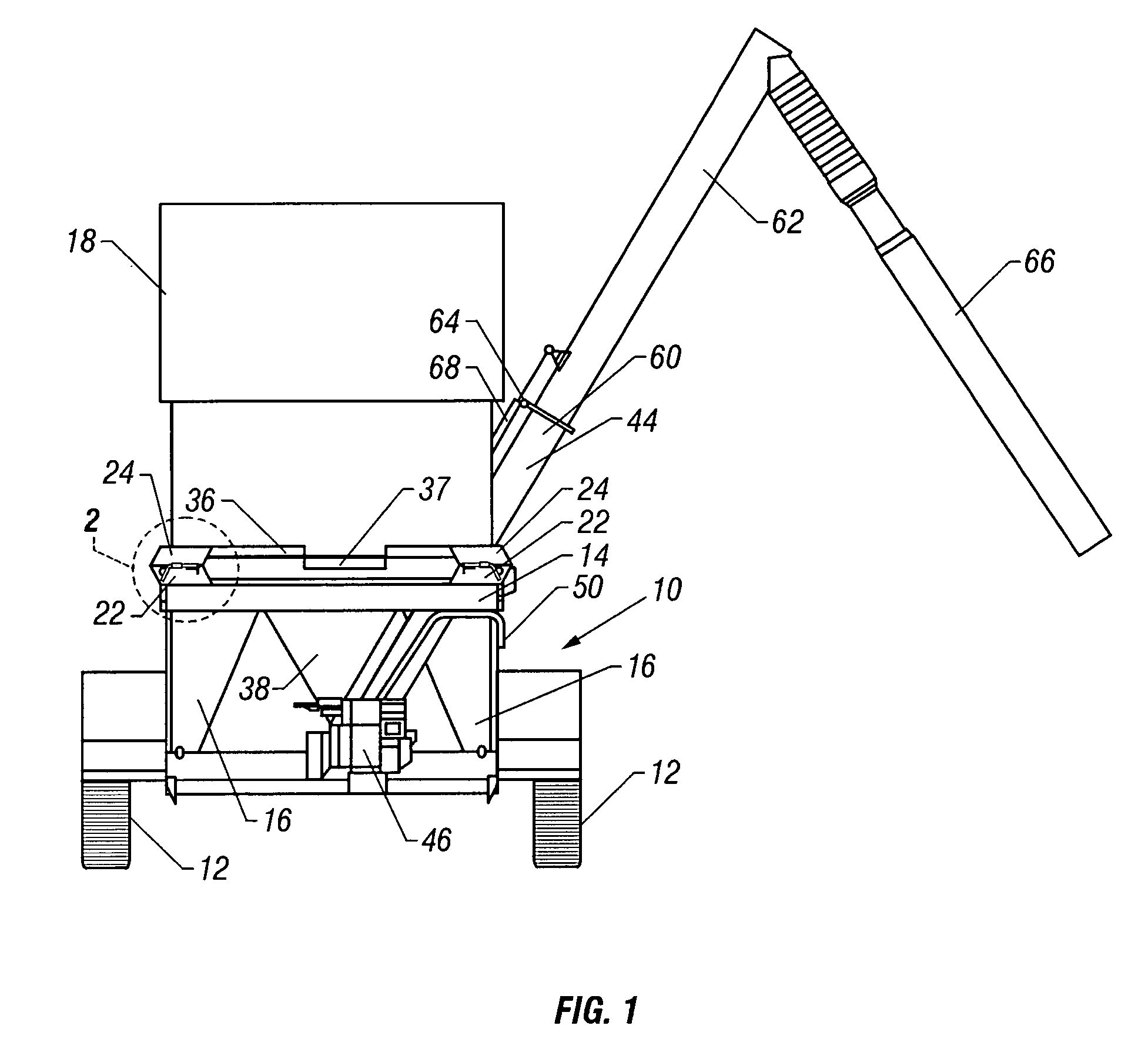

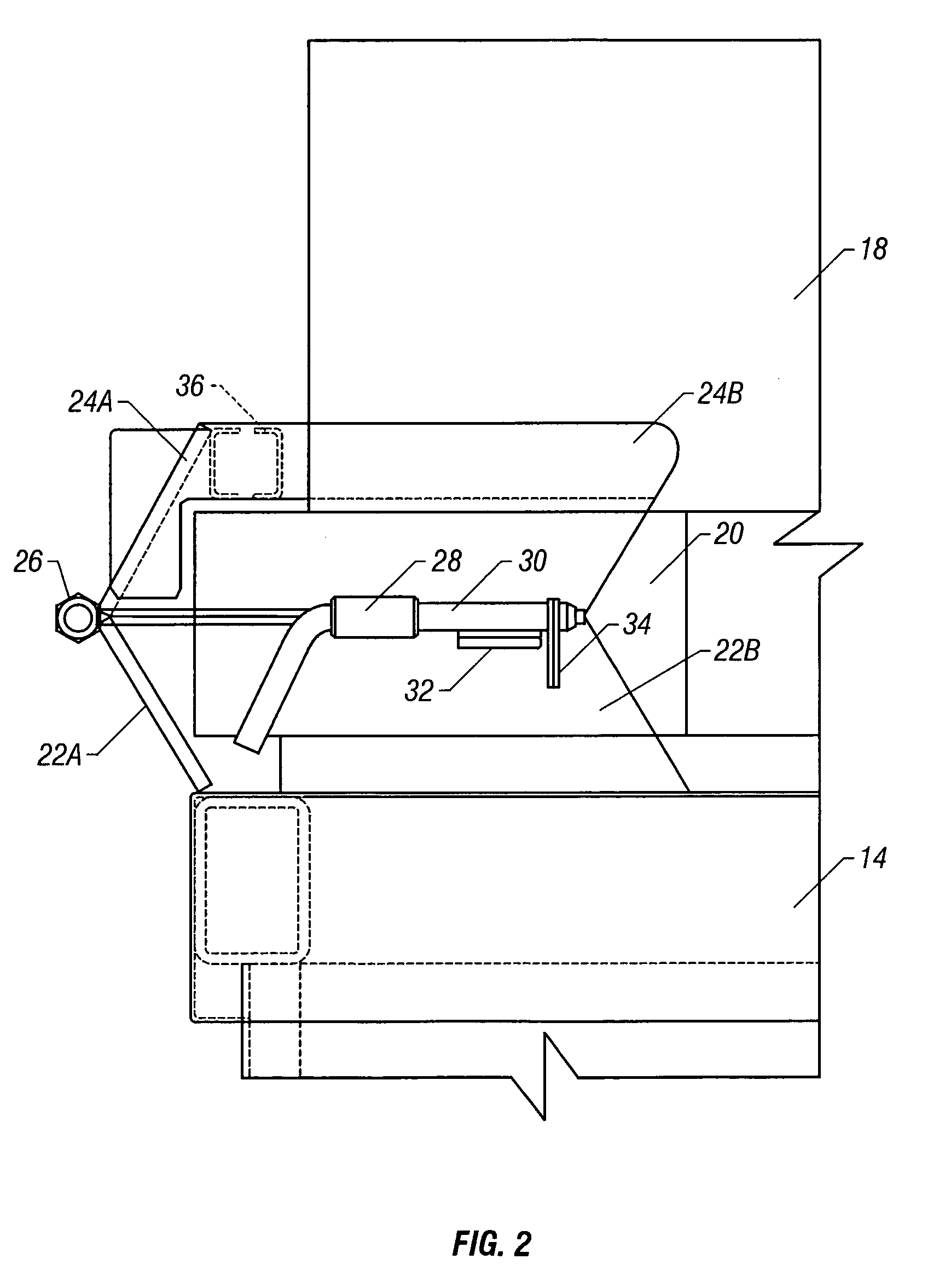

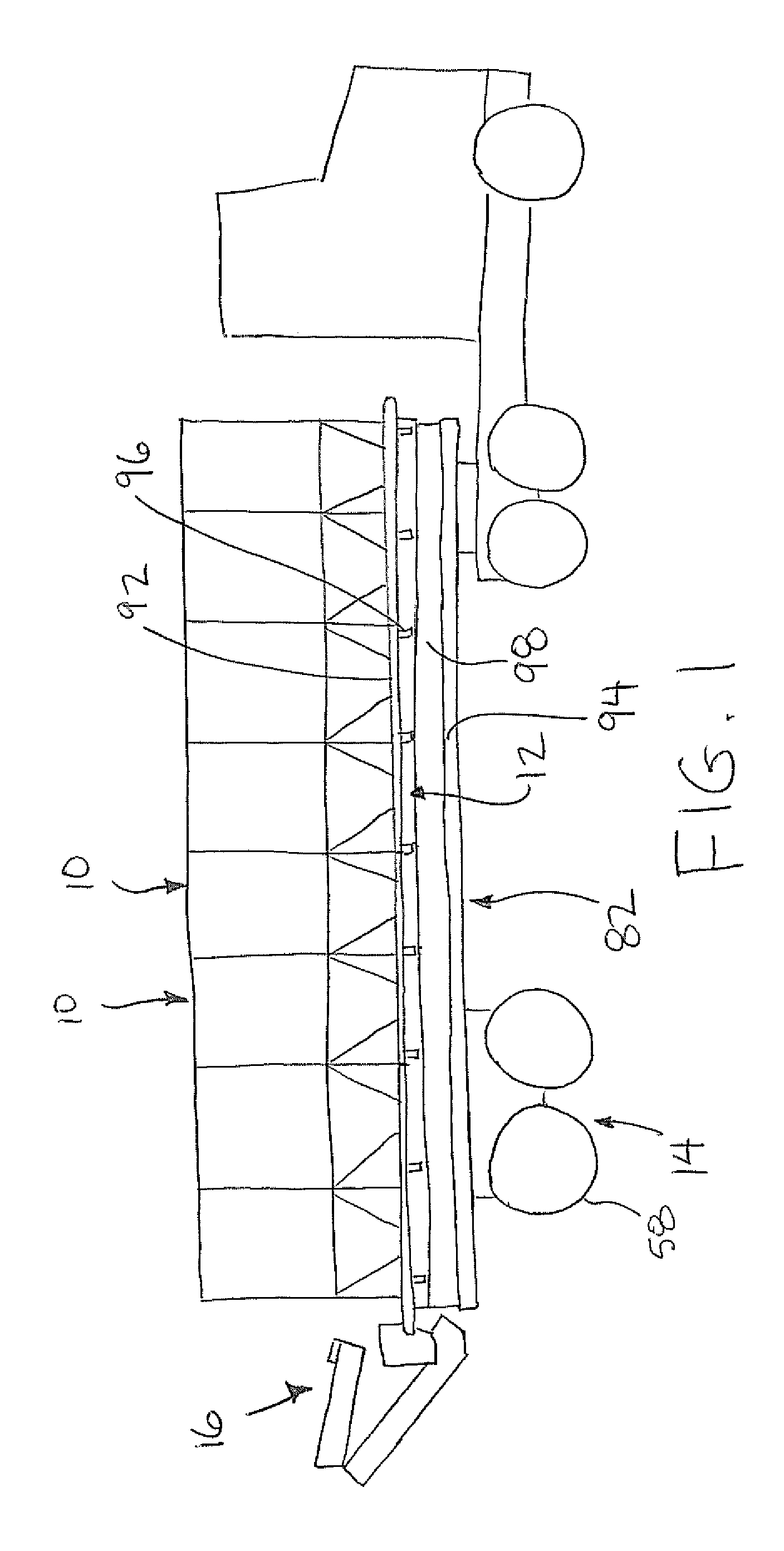

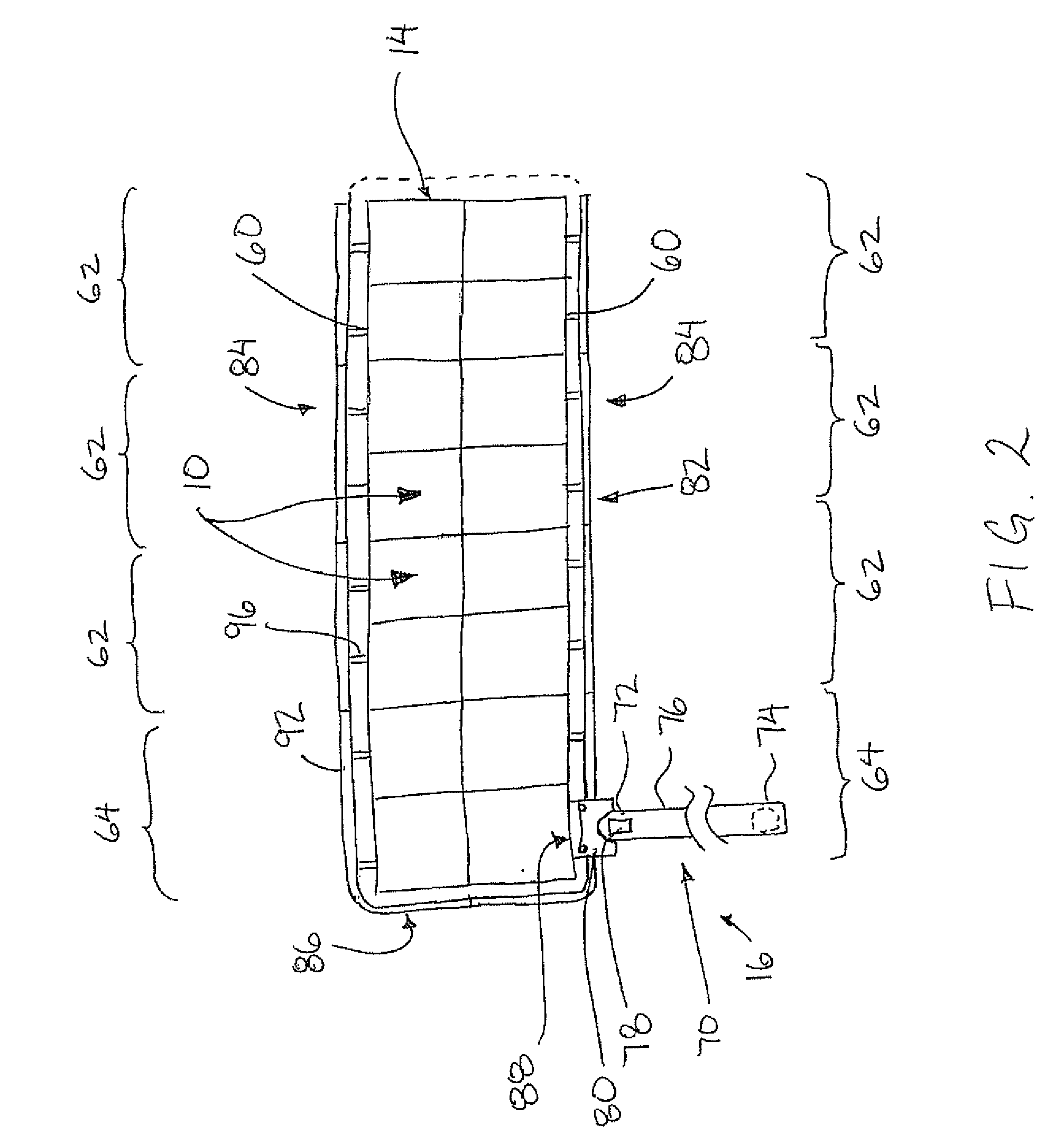

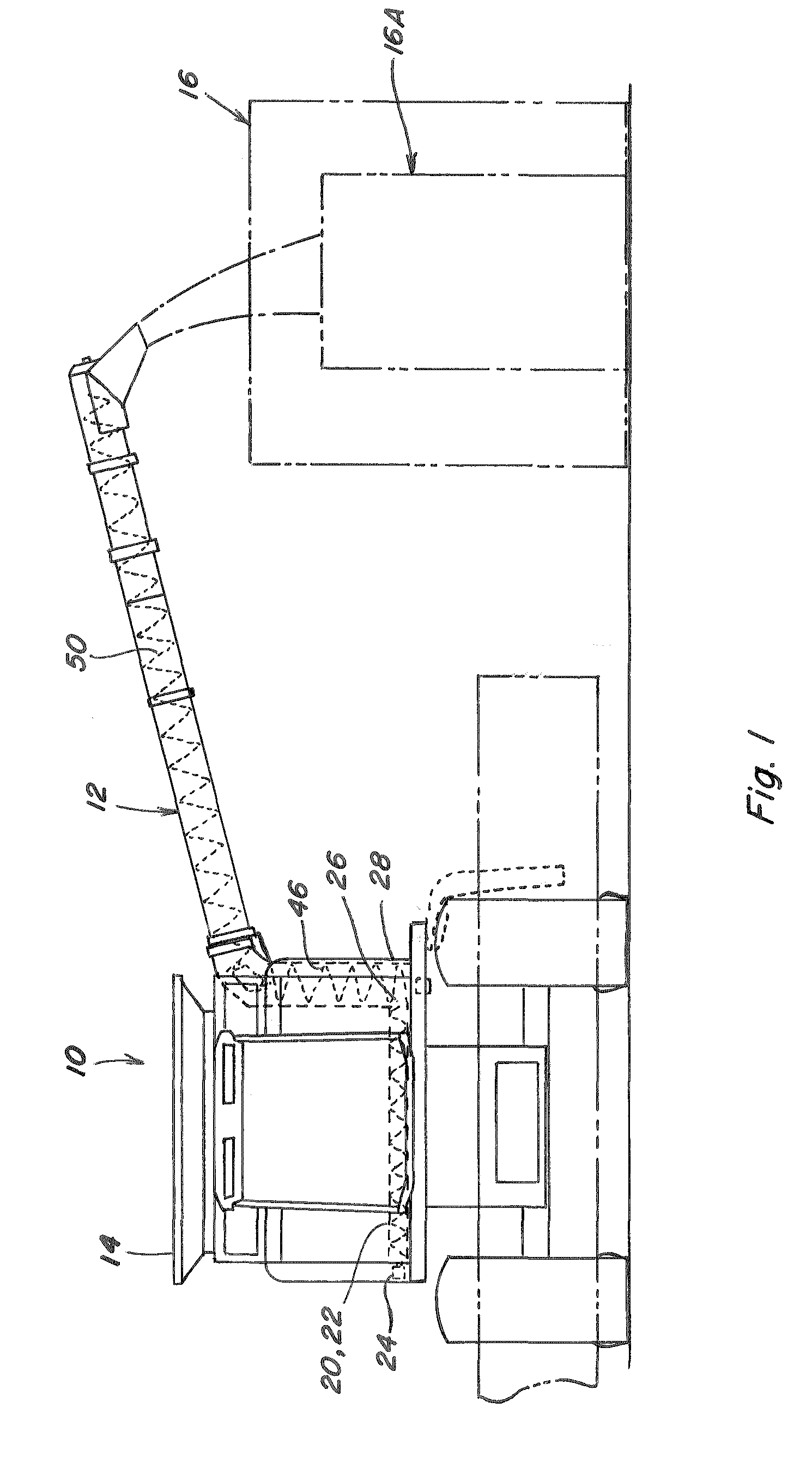

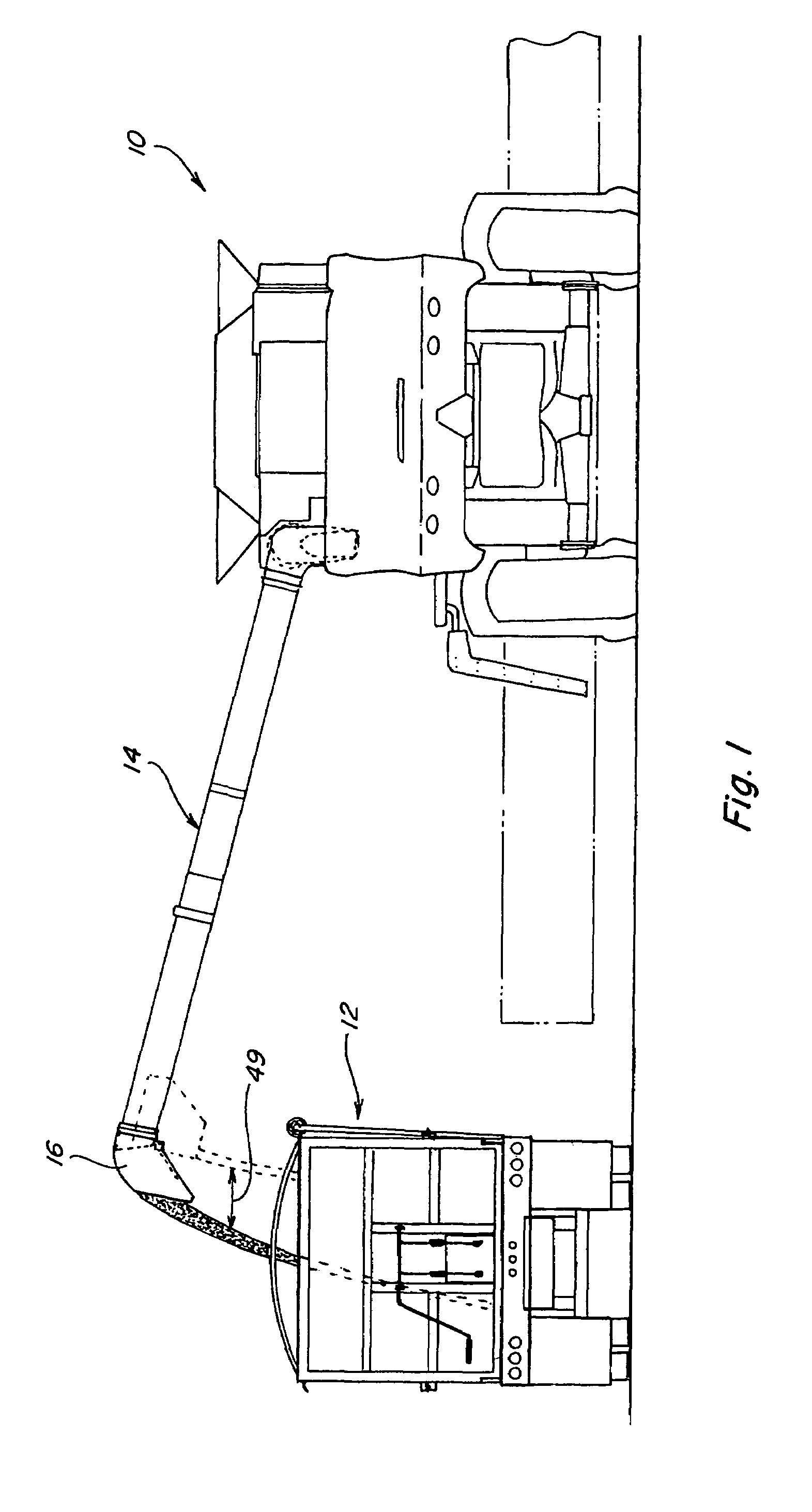

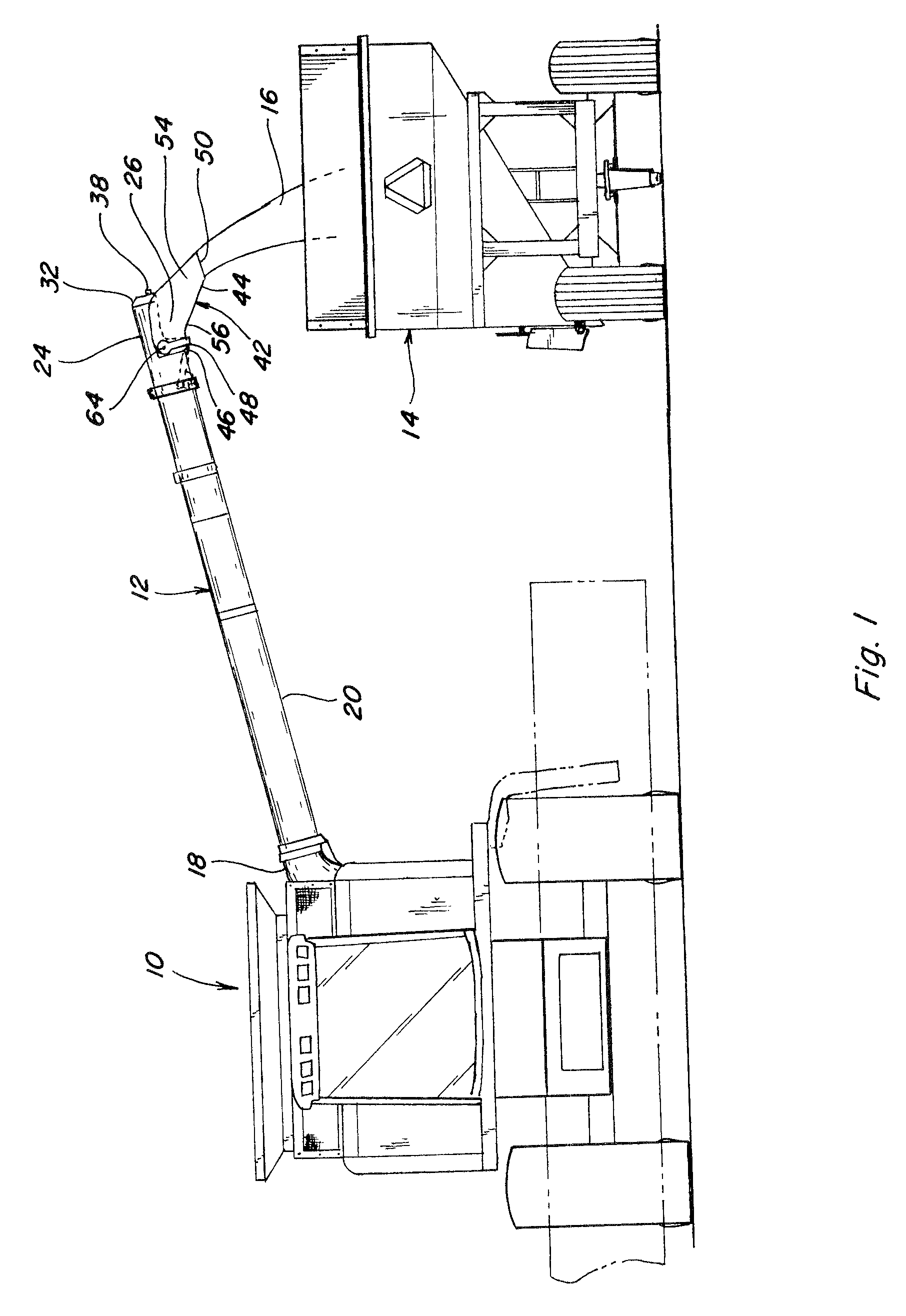

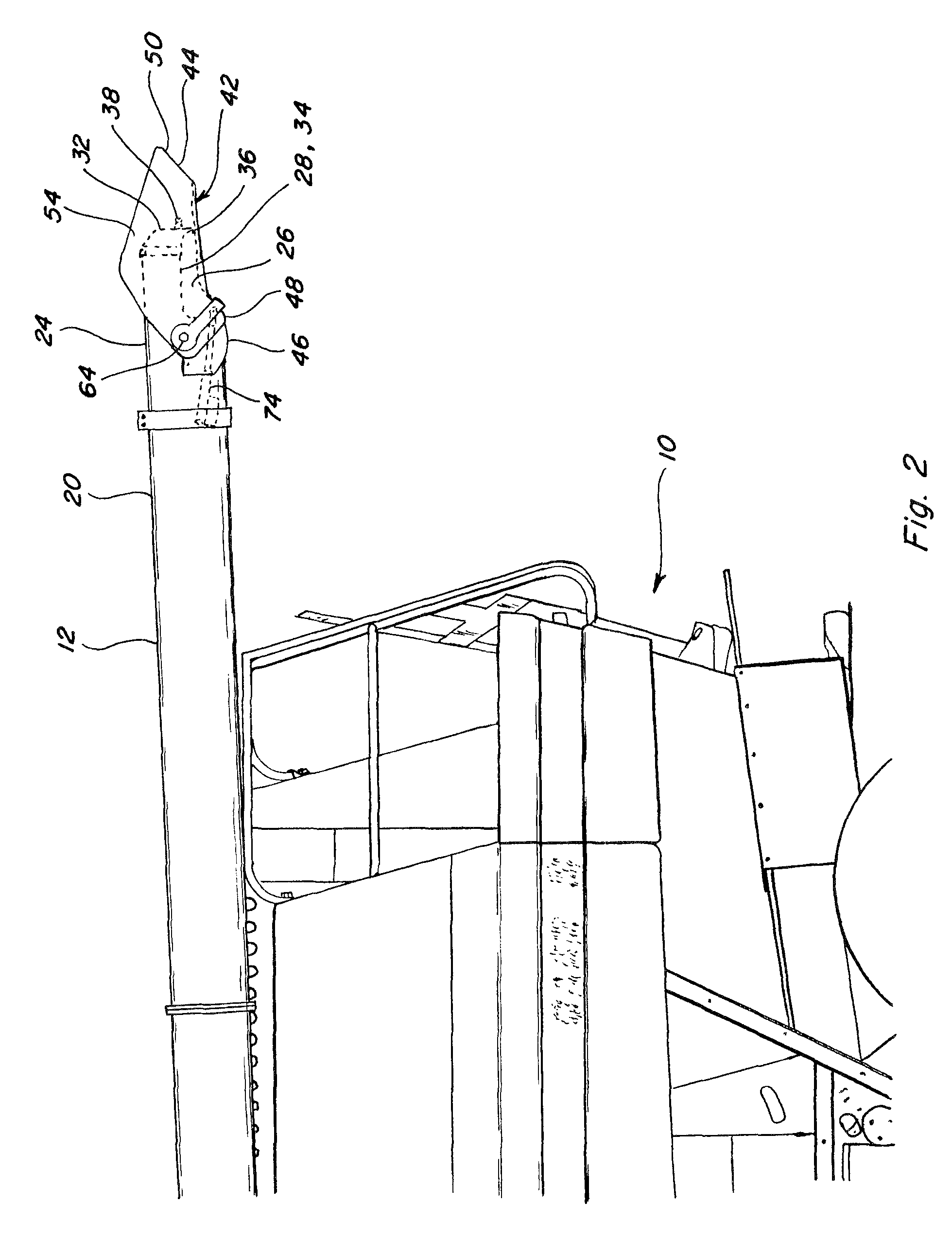

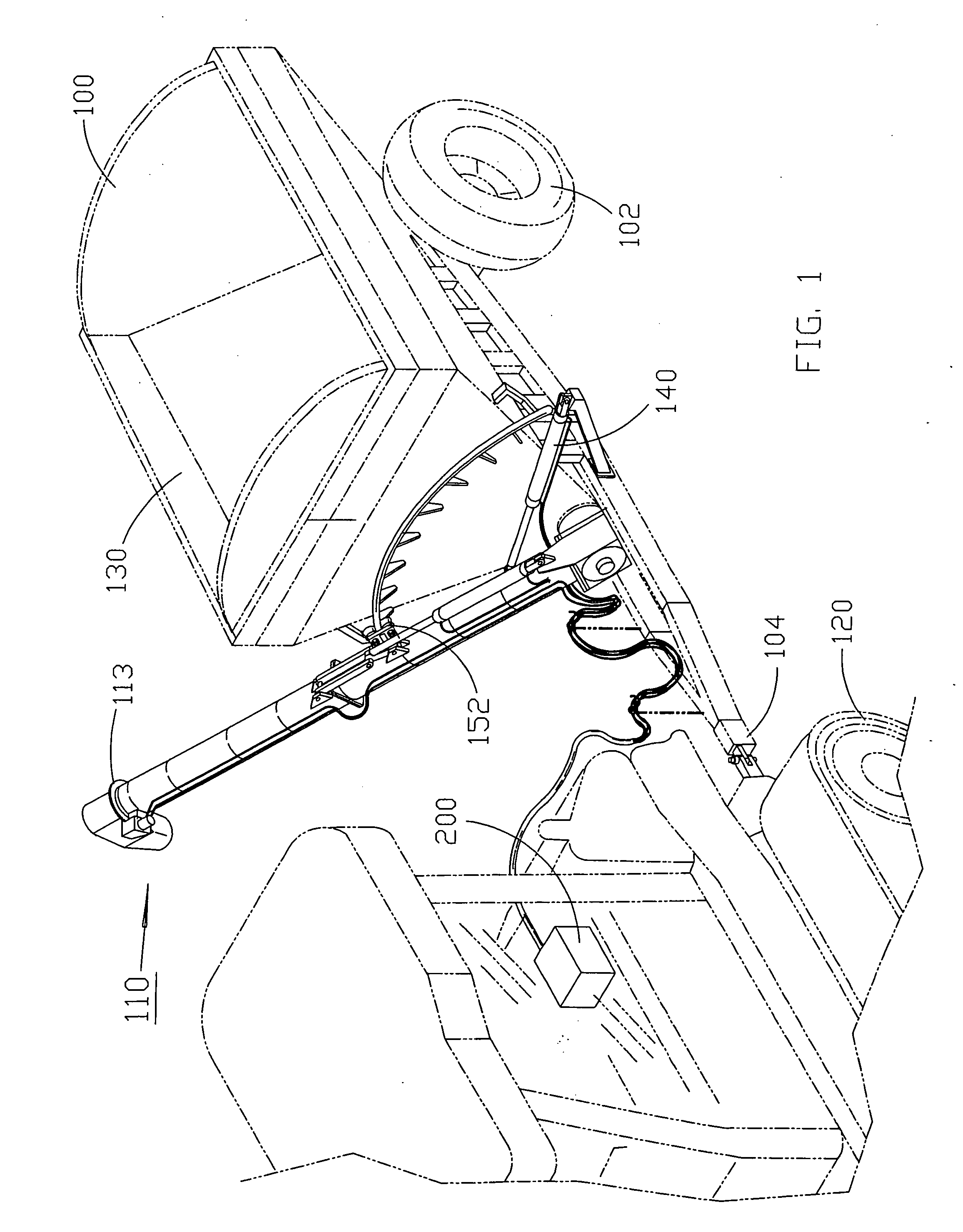

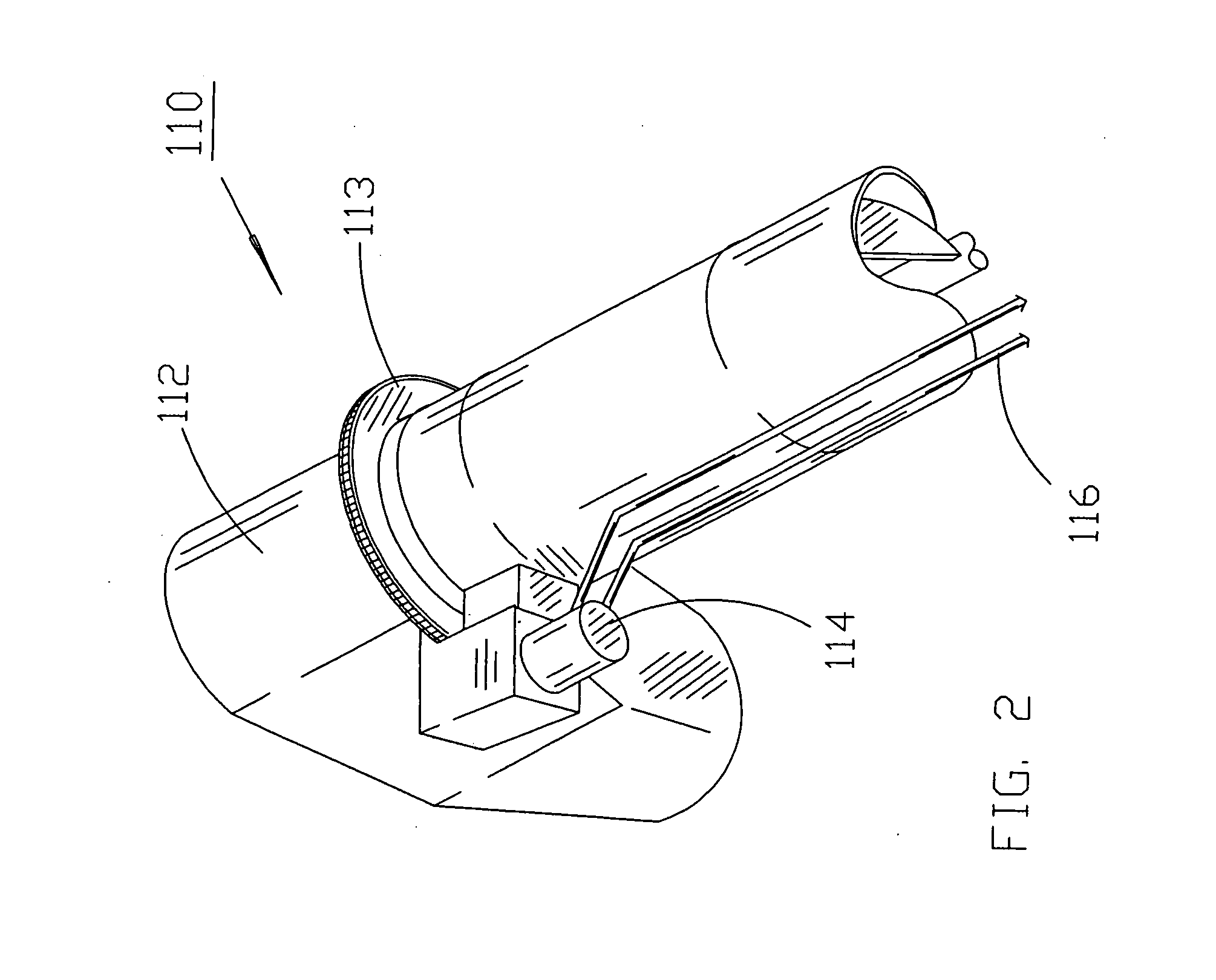

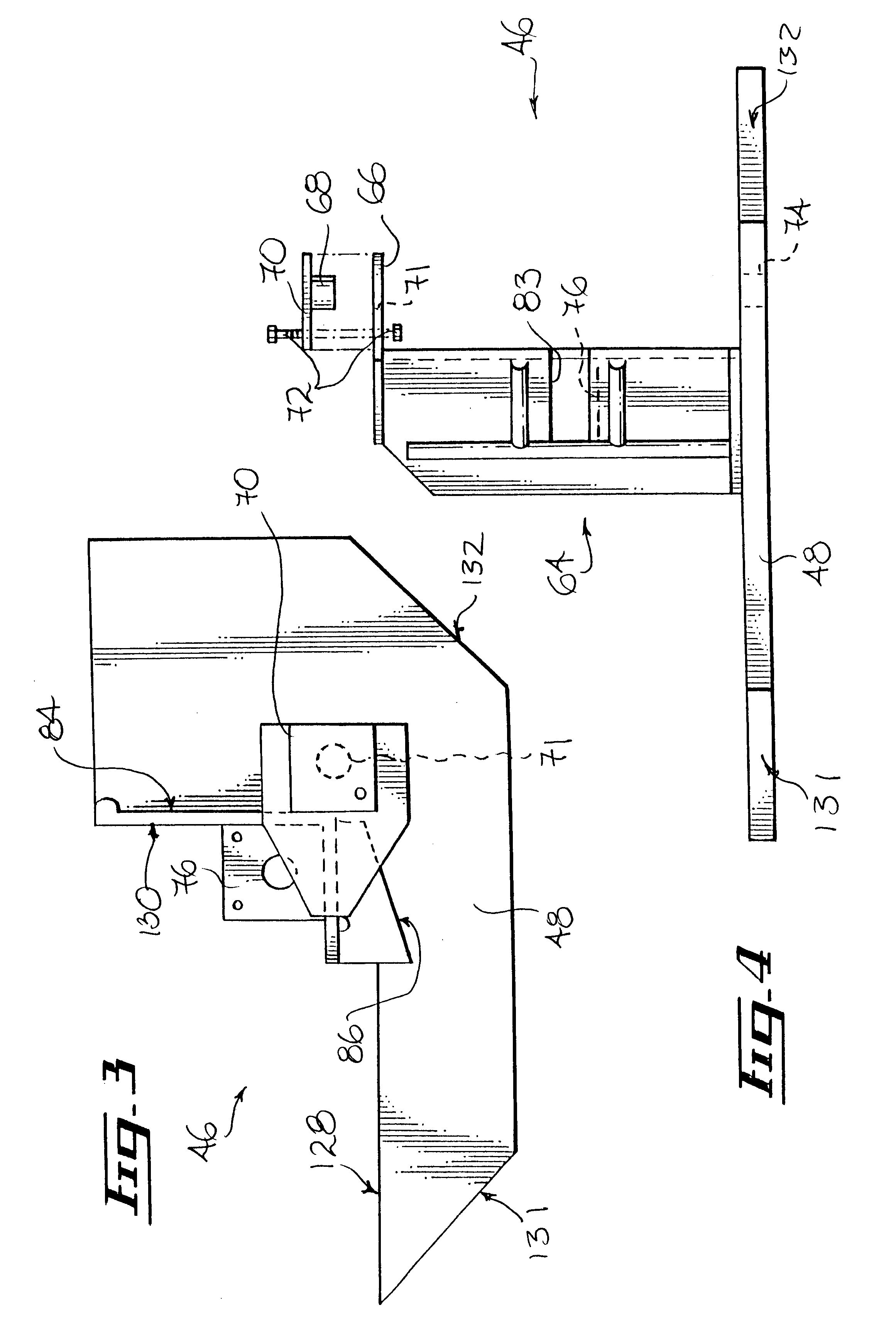

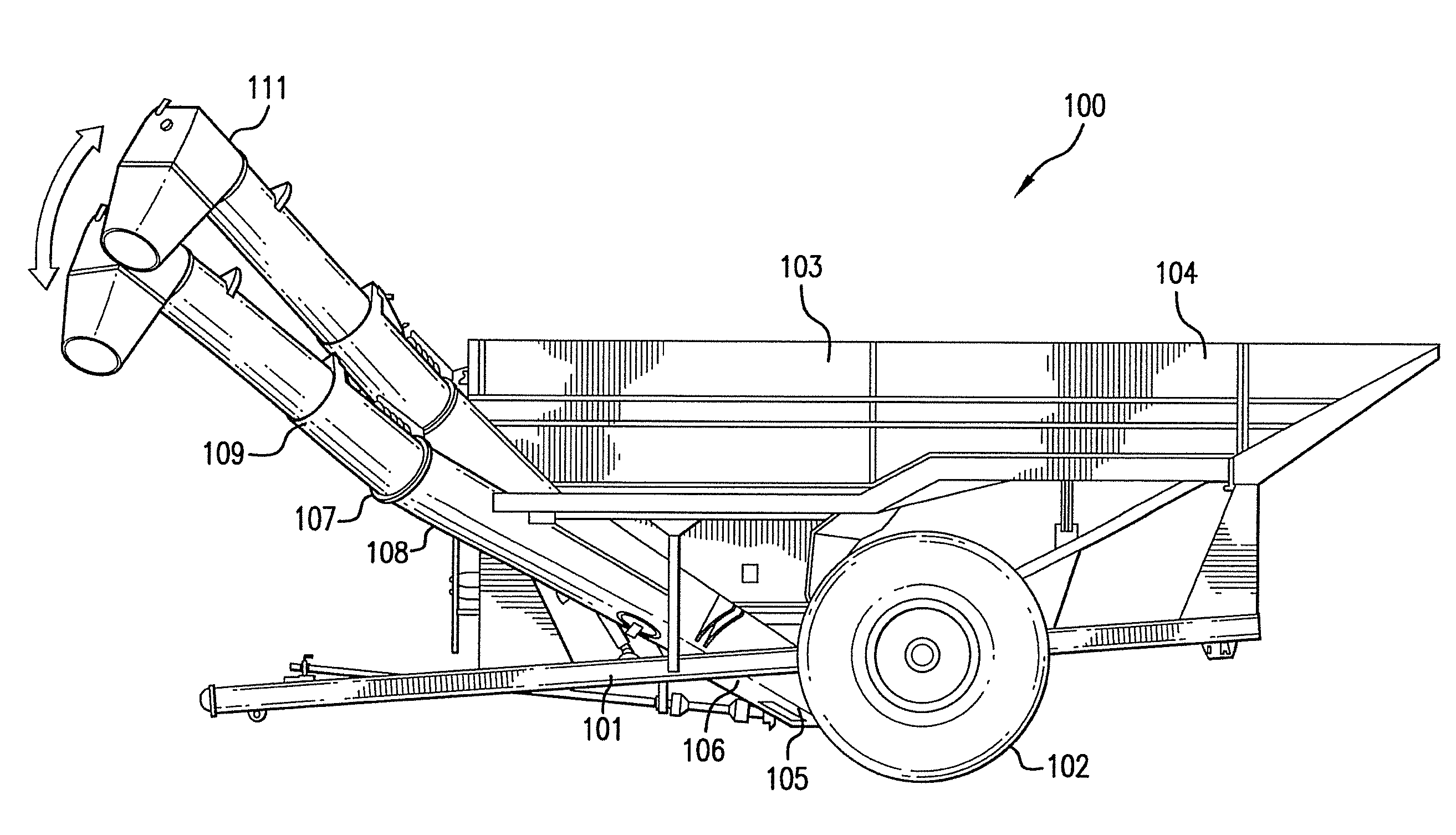

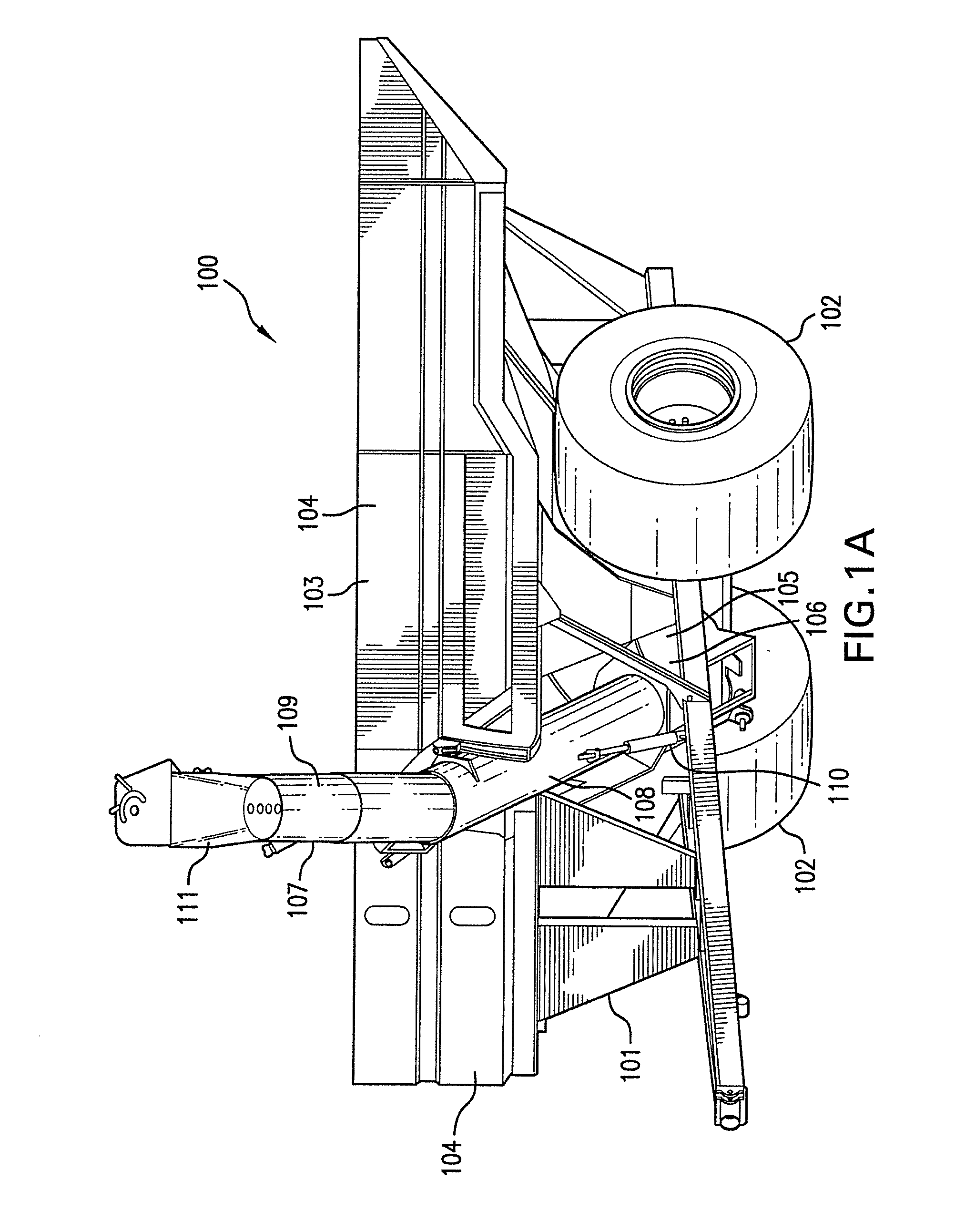

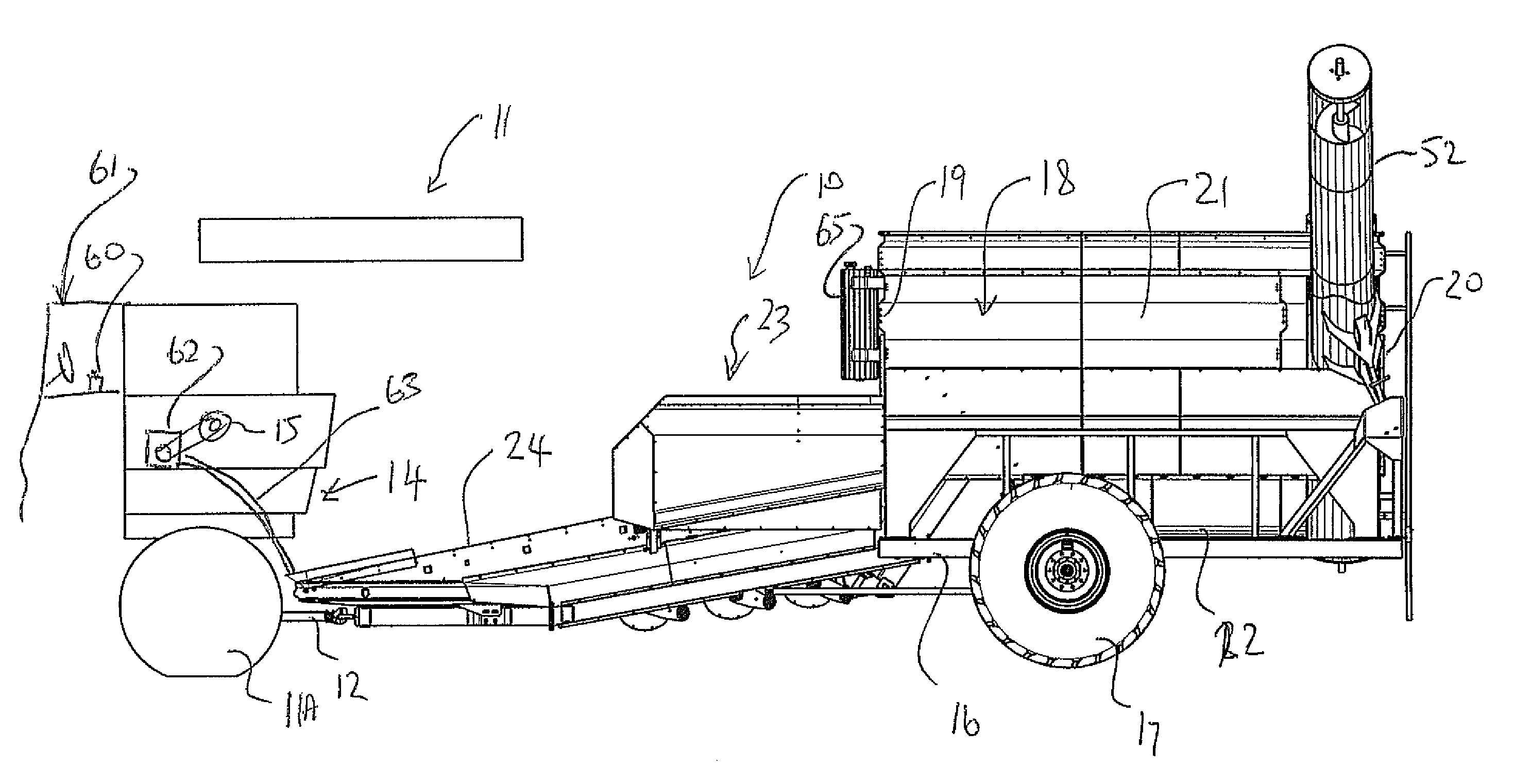

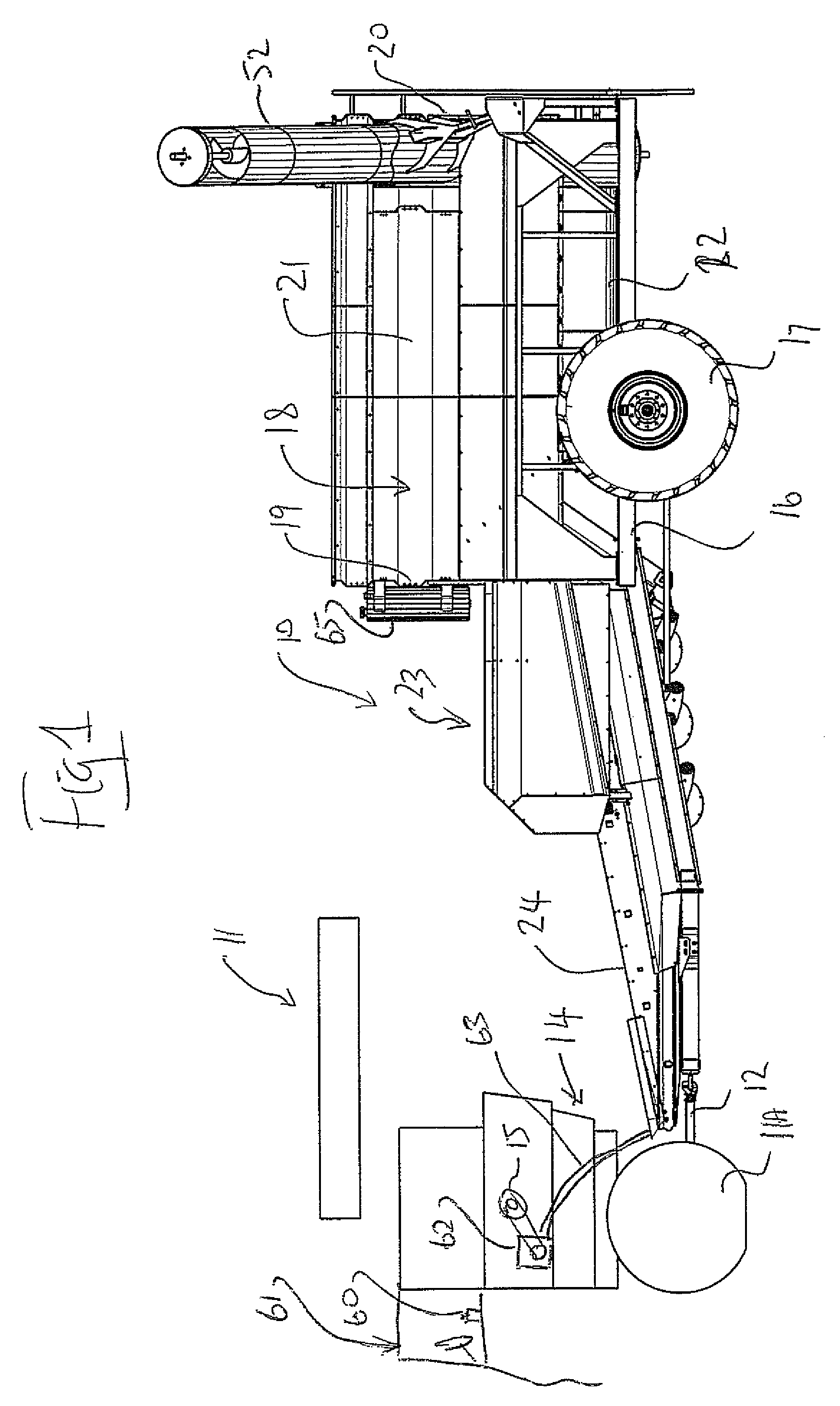

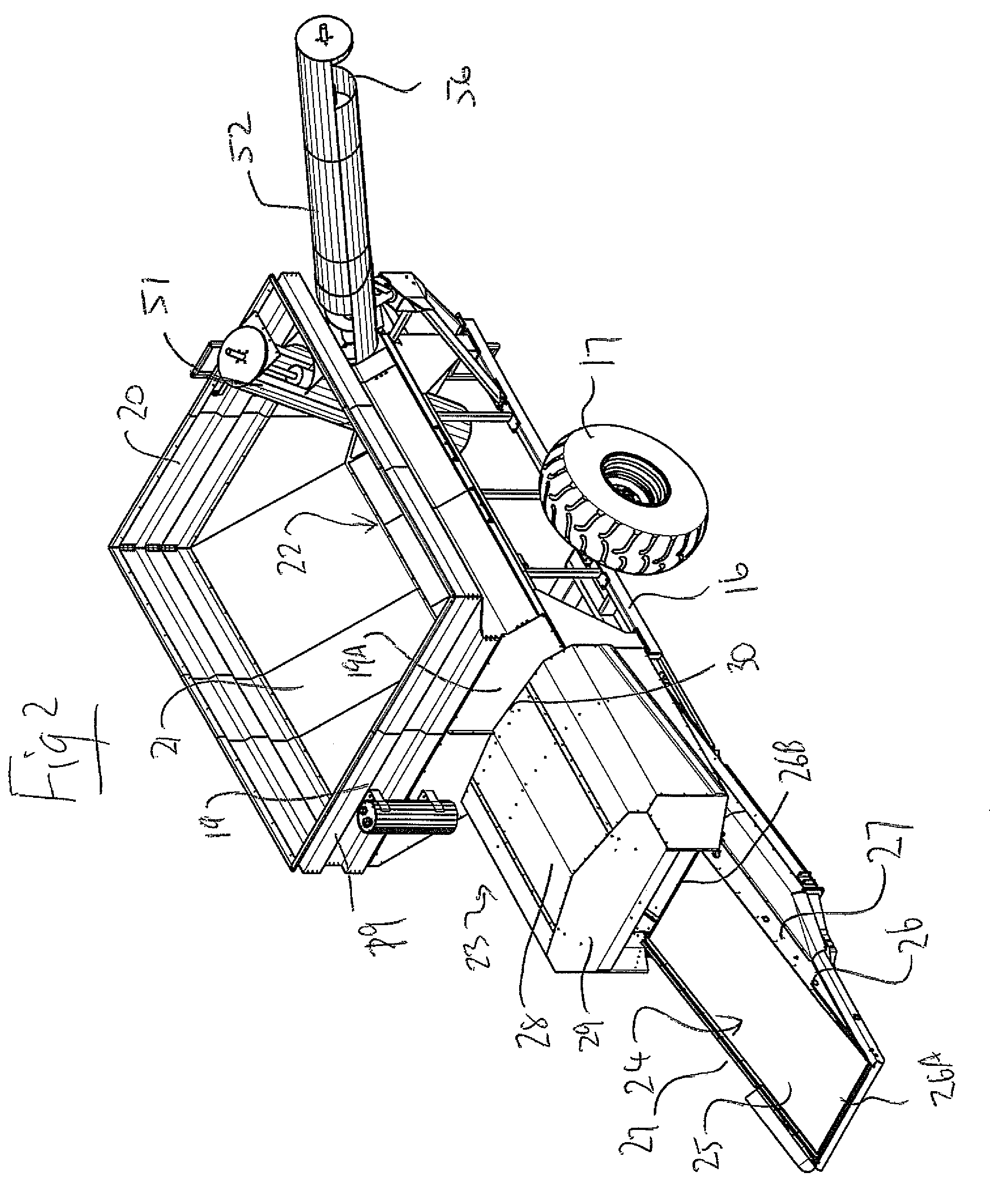

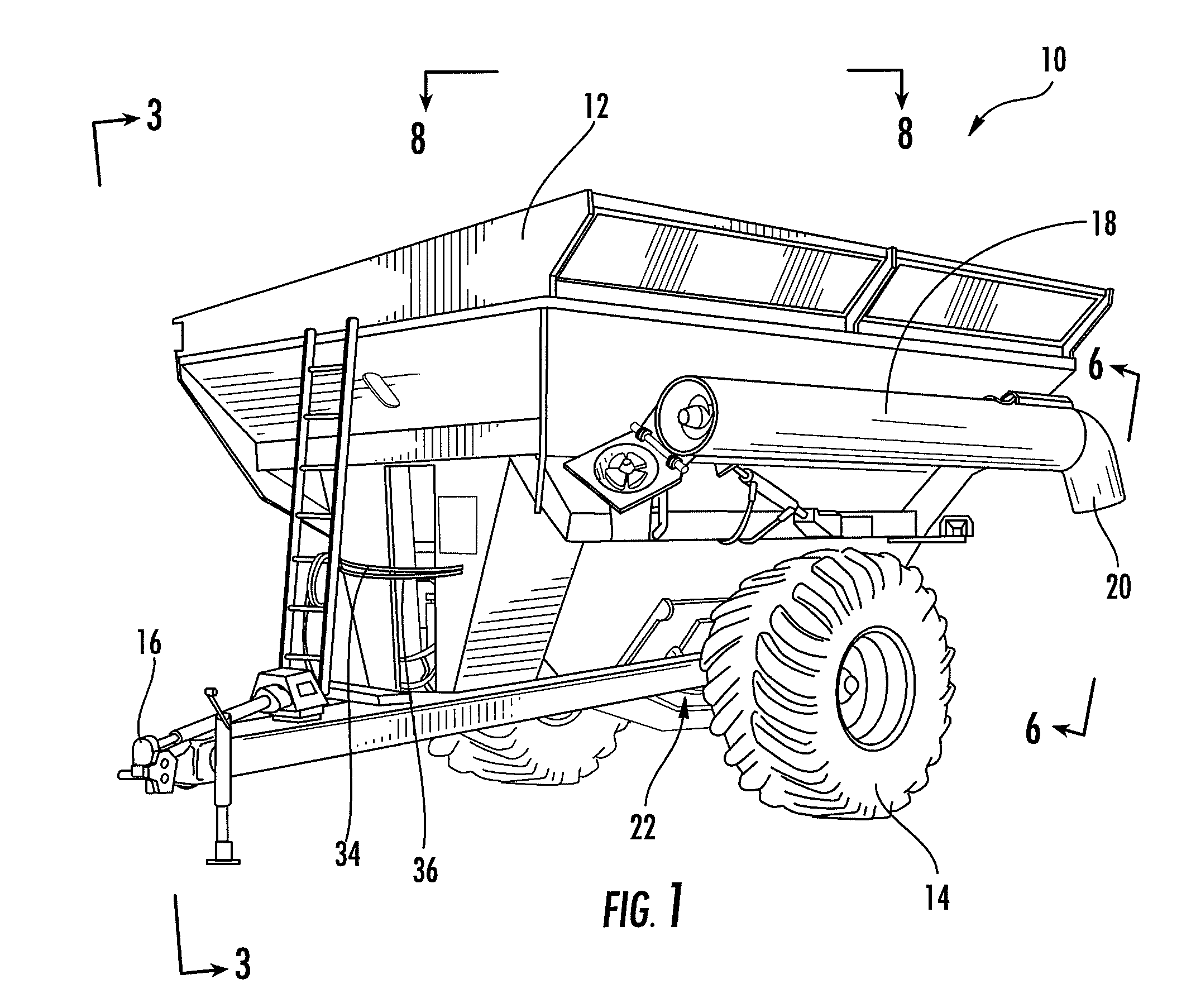

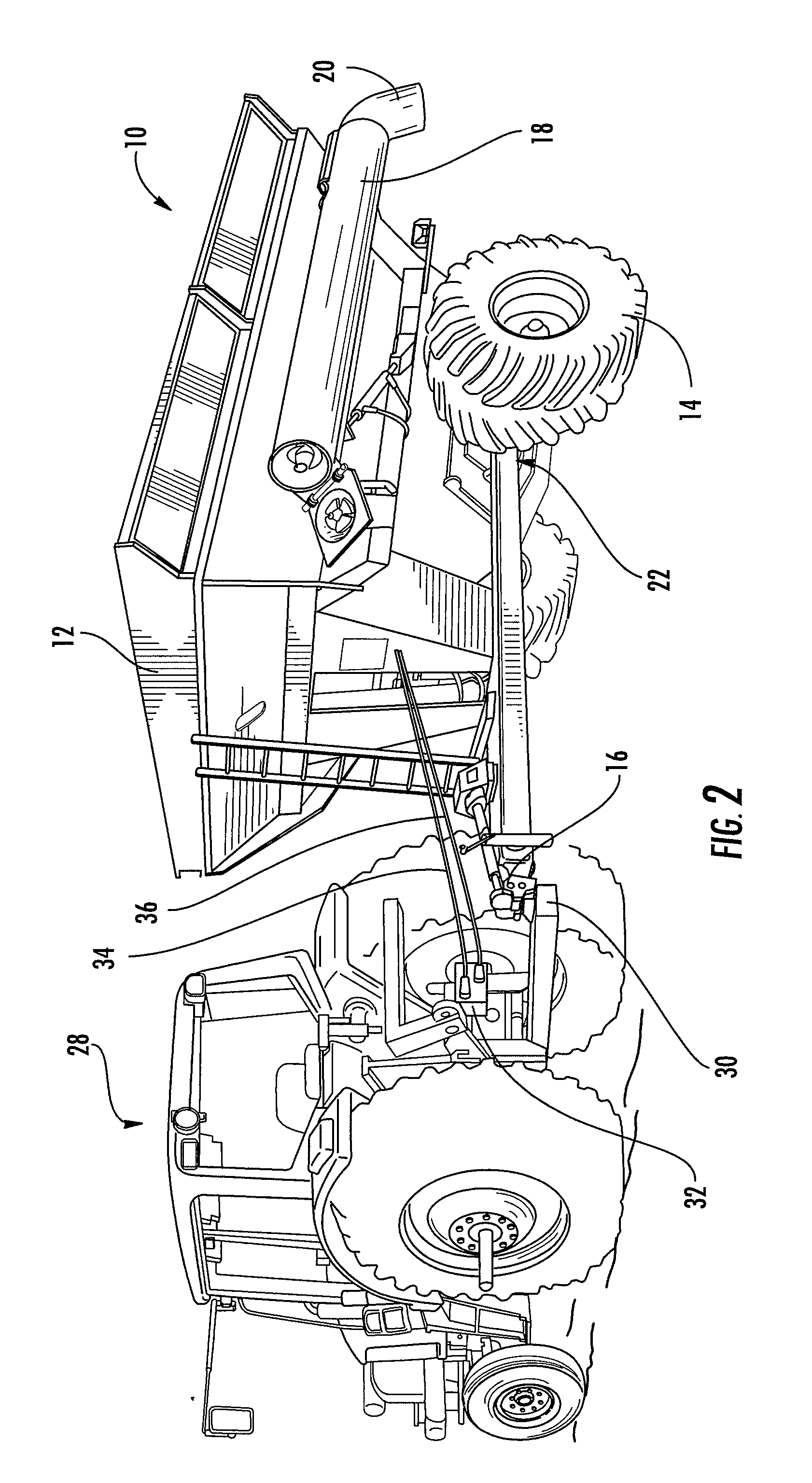

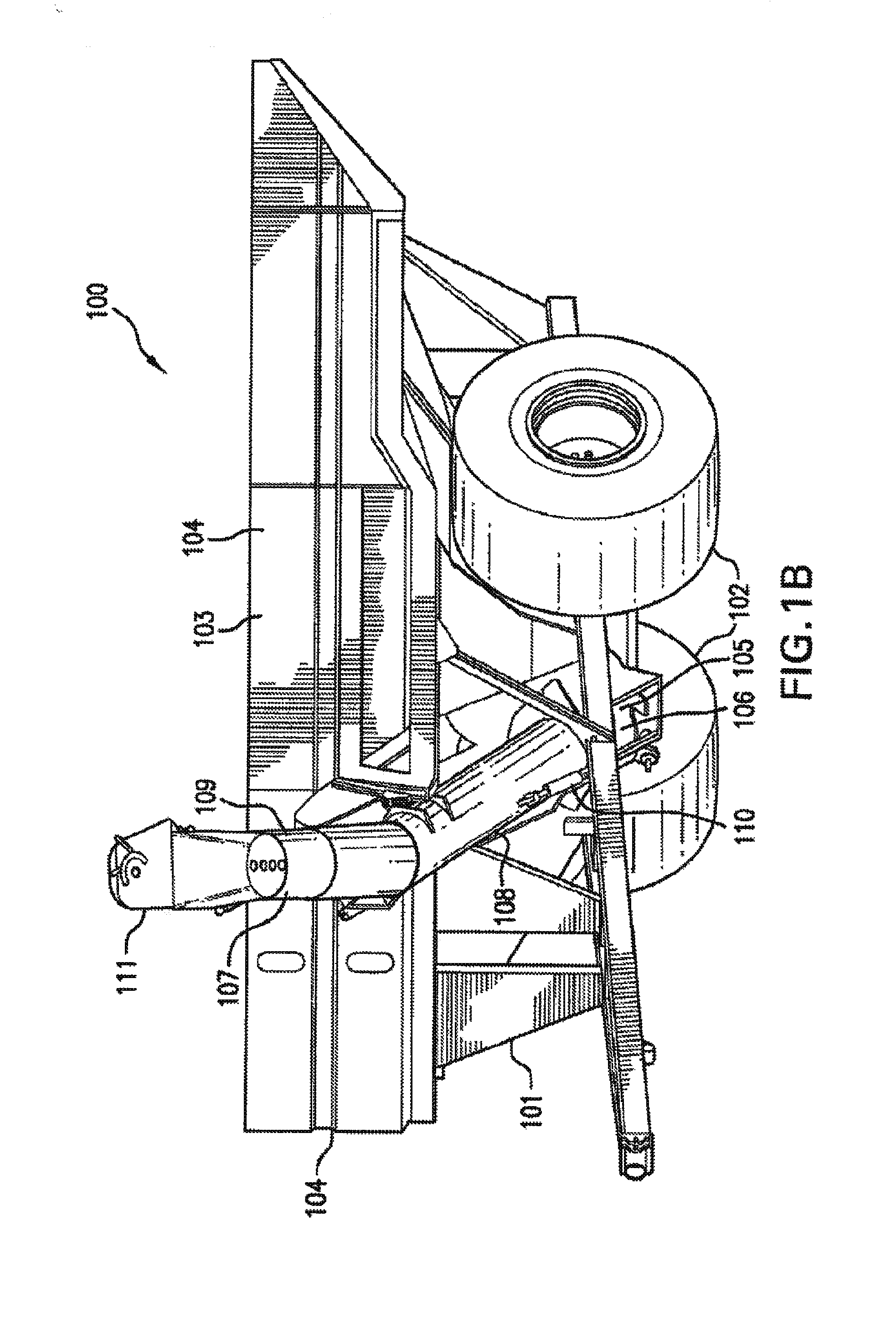

Trailer for transporting bulk seed boxes

InactiveUS6964551B1Promote sportsSecured in quickly and easilyVehicle with removable loadingRefuse receptaclesGas cylinderControl arm

An improved trailer for transporting bulk seed boxes is provided. The trailer includes a bed, a hopper extending below the bed for receiving seed from the bulk seed box, and an auger for unloading seed from the hopper. The bed includes upwardly and outwardly extending guide plates to provide self-centering of the seed box when the box is loaded onto the bed with a forklift truck. The bed includes lock bars moveable between locked and unlocked positions to secure the seed box to the bed. The hopper includes a slide gate with a control arm connected to the gate and extending to the auger side of the trailer for moving the slide gate between open and closed position. The auger includes a foldable upper section which is pivotal between a folded transport position and an extended raised operative position. The folding of the upper auger section is facilitated by a gas cylinder and a lever arm.

Owner:MERIDIAN MFG

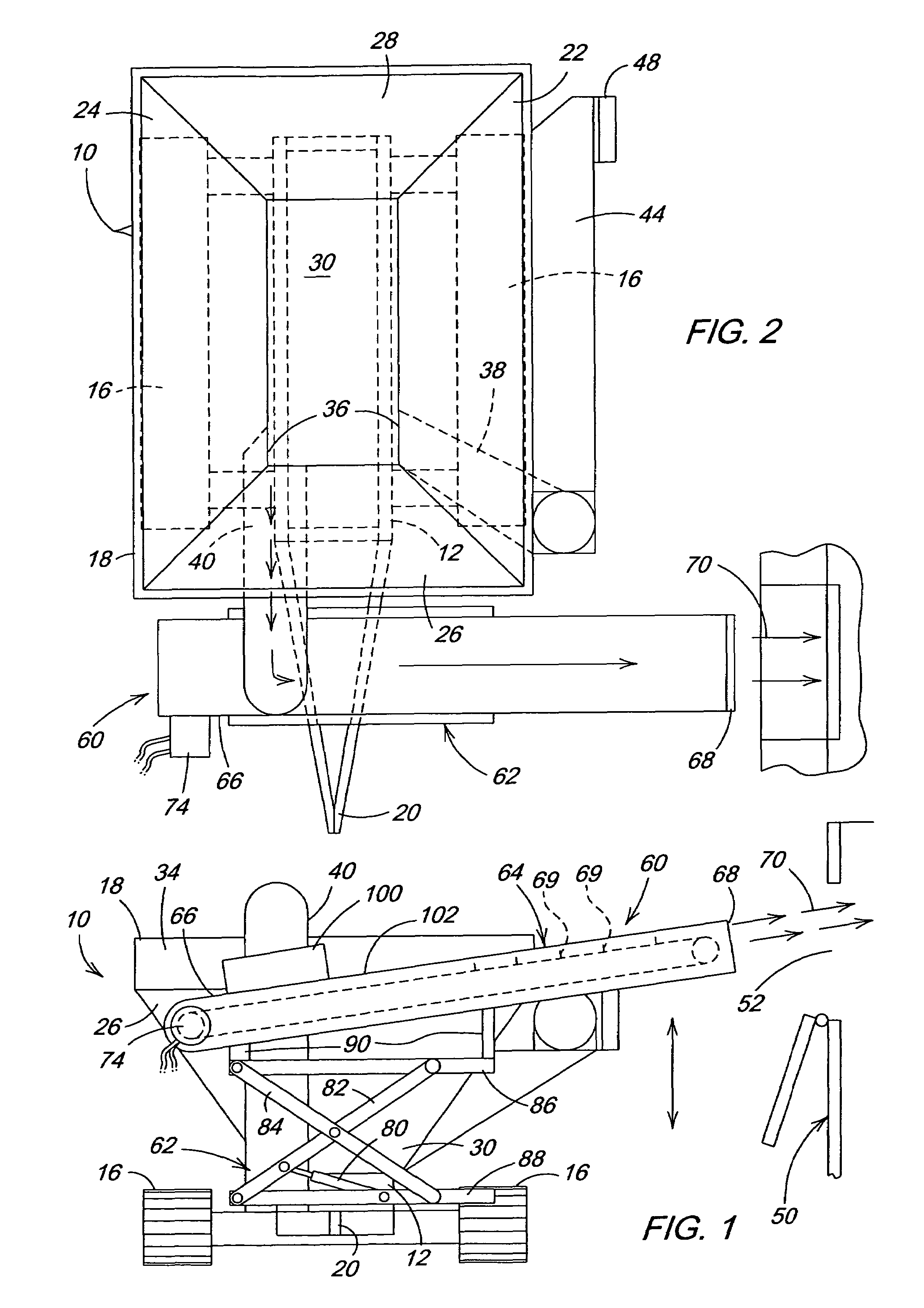

Bulk Material Container and Container Discharging Apparatus

A bulk material container suitable for handling with a pallet mover includes a hopper portion which tapers downwardly to a discharge gate which is in an upright orientation offset to one side of the container. When several containers are supported on a flat deck vehicle or trailer, the gates of all of the containers can be oriented to discharge to the sides of the deck. A discharge apparatus supported on the deck comprises a track supporting a discharge conveyor for displacement along the sides of the deck such that an inlet hopper of the conveyor can be aligned with respective ones of the side discharging gates of the containers supported on the deck.

Owner:REDEKOP JOHAN

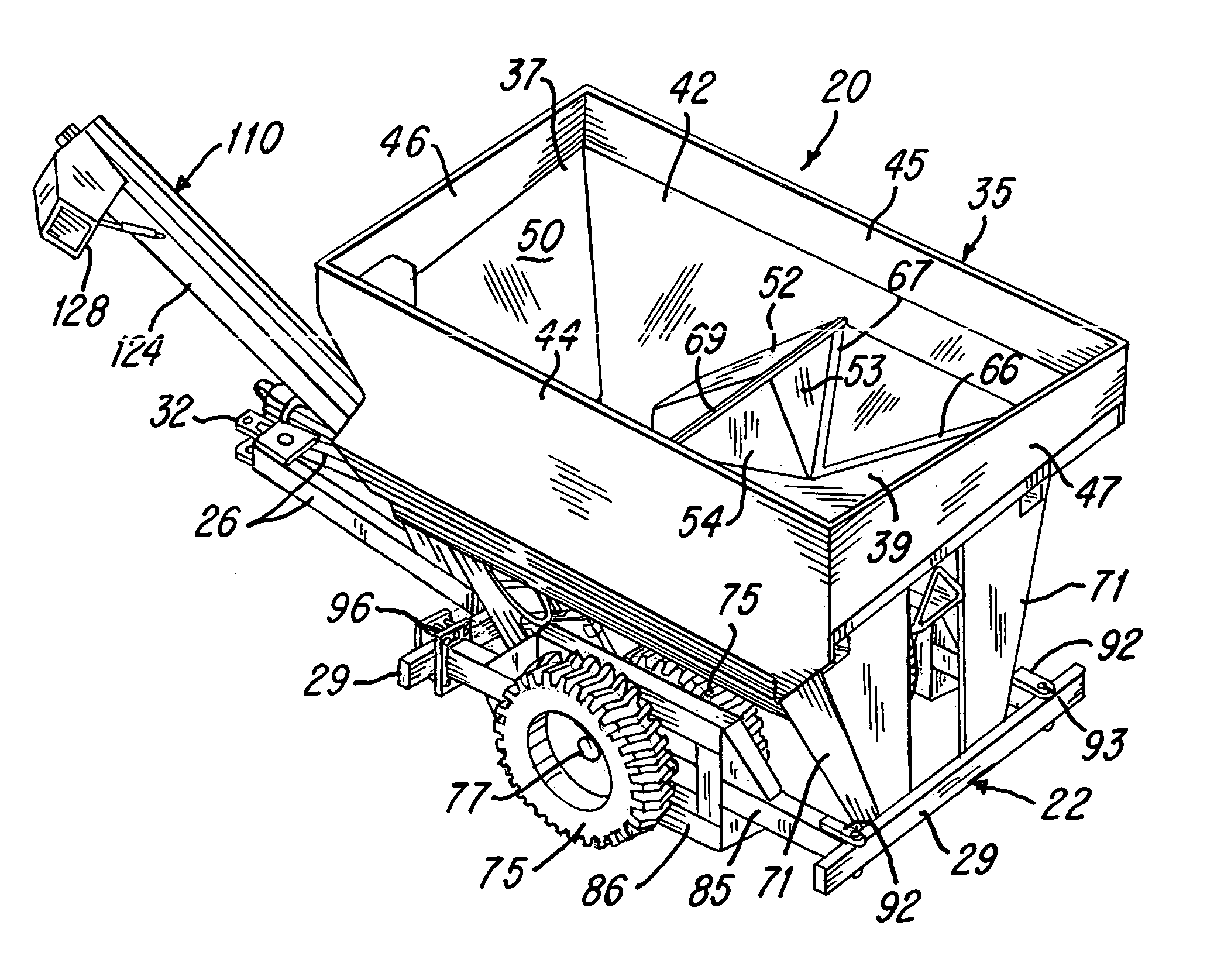

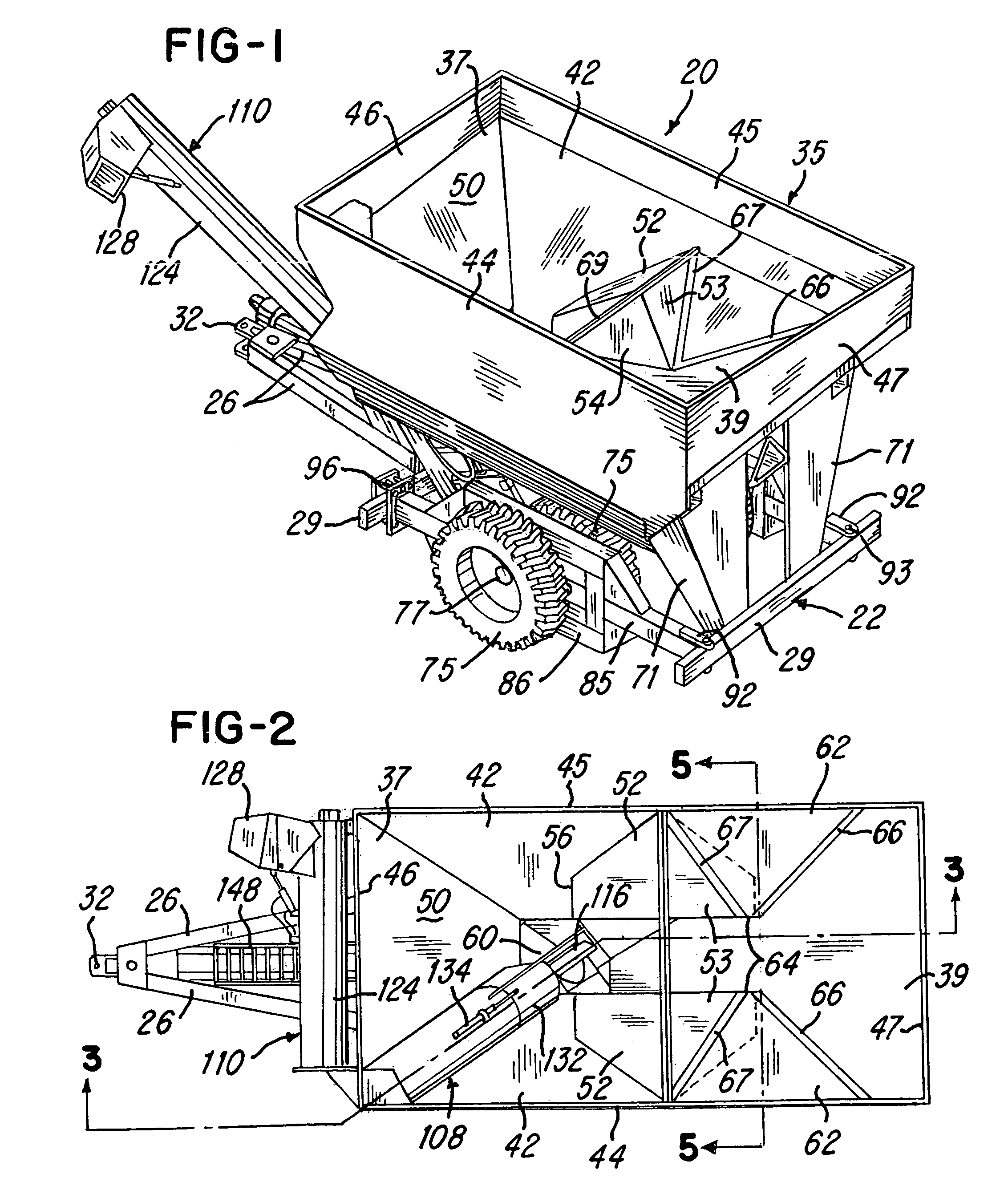

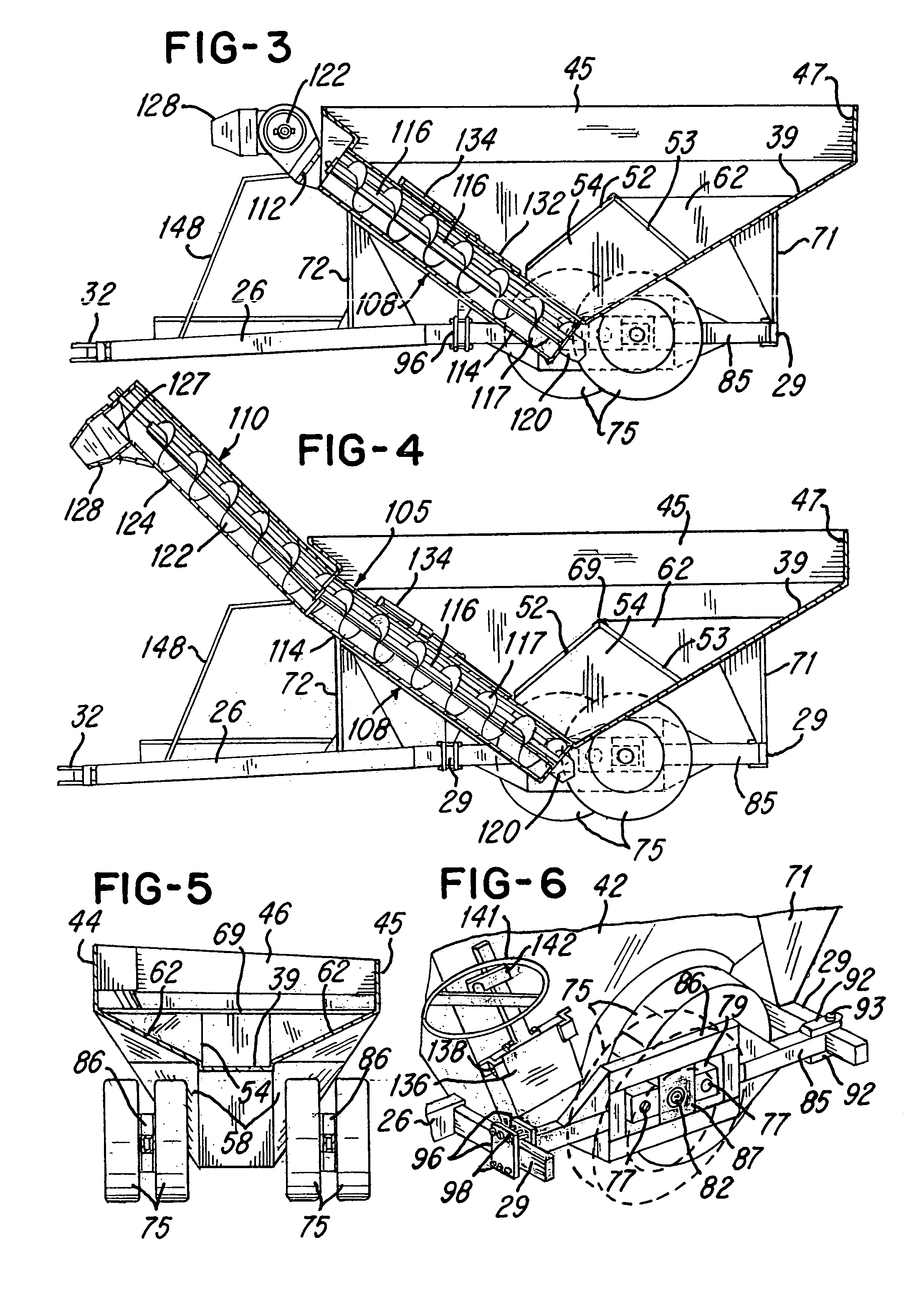

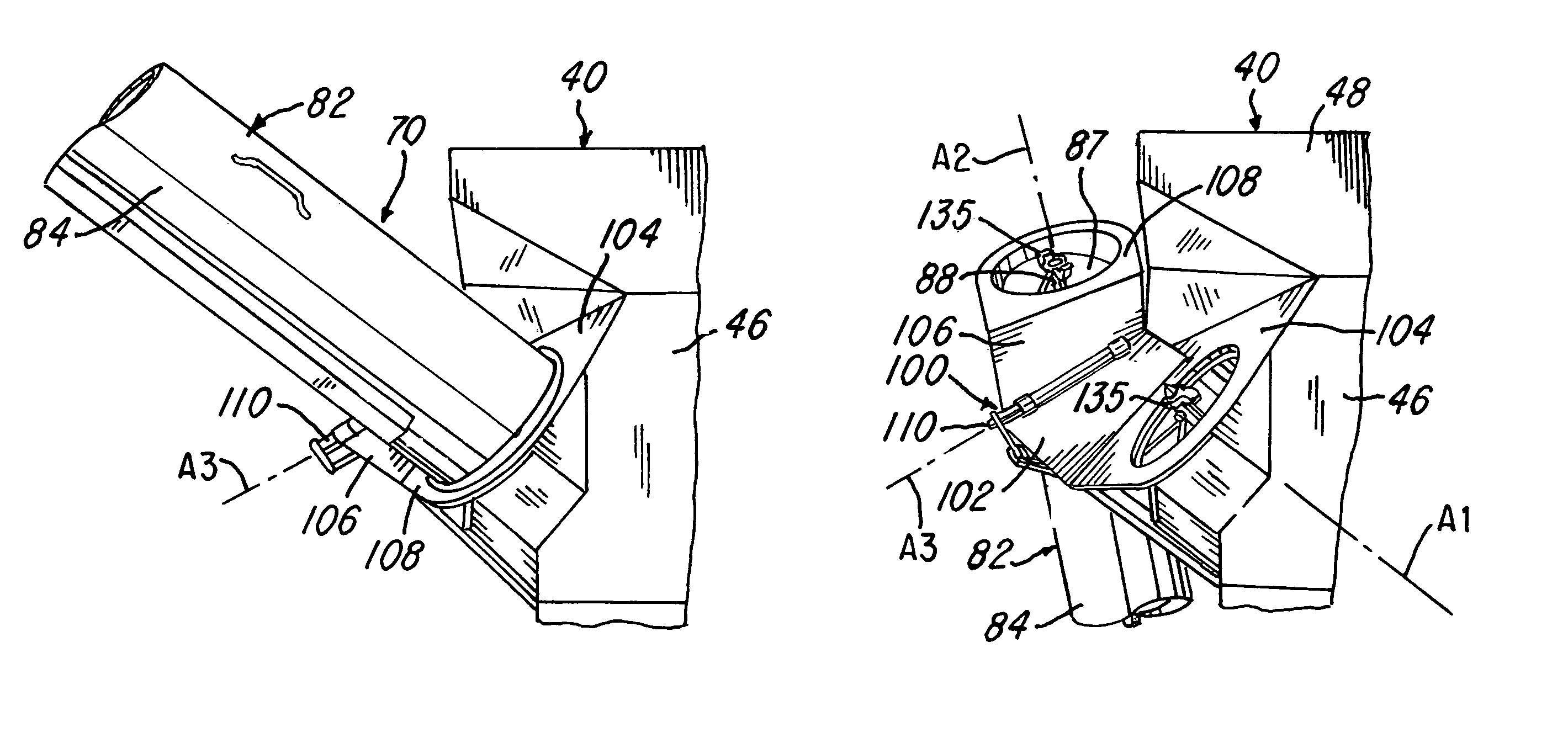

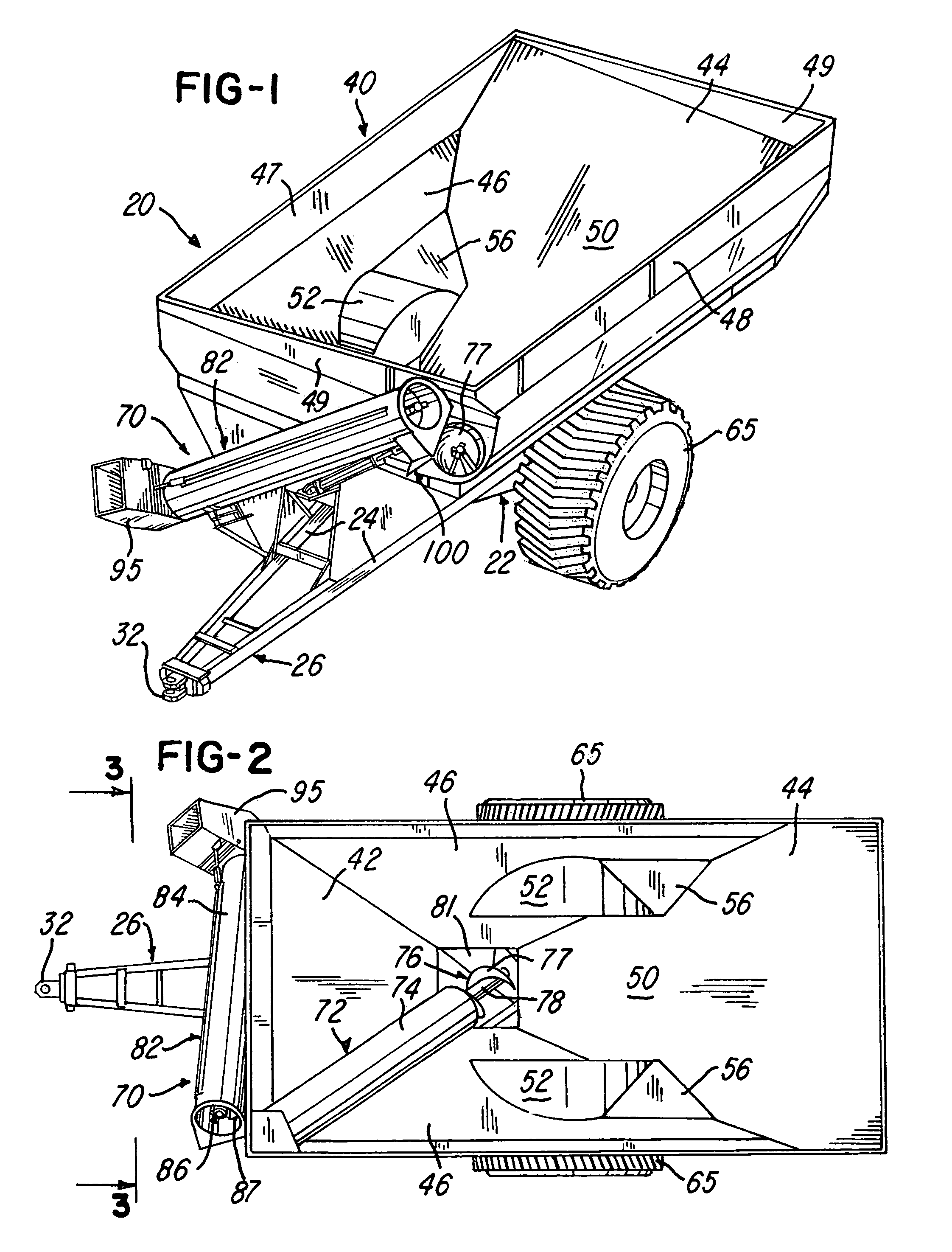

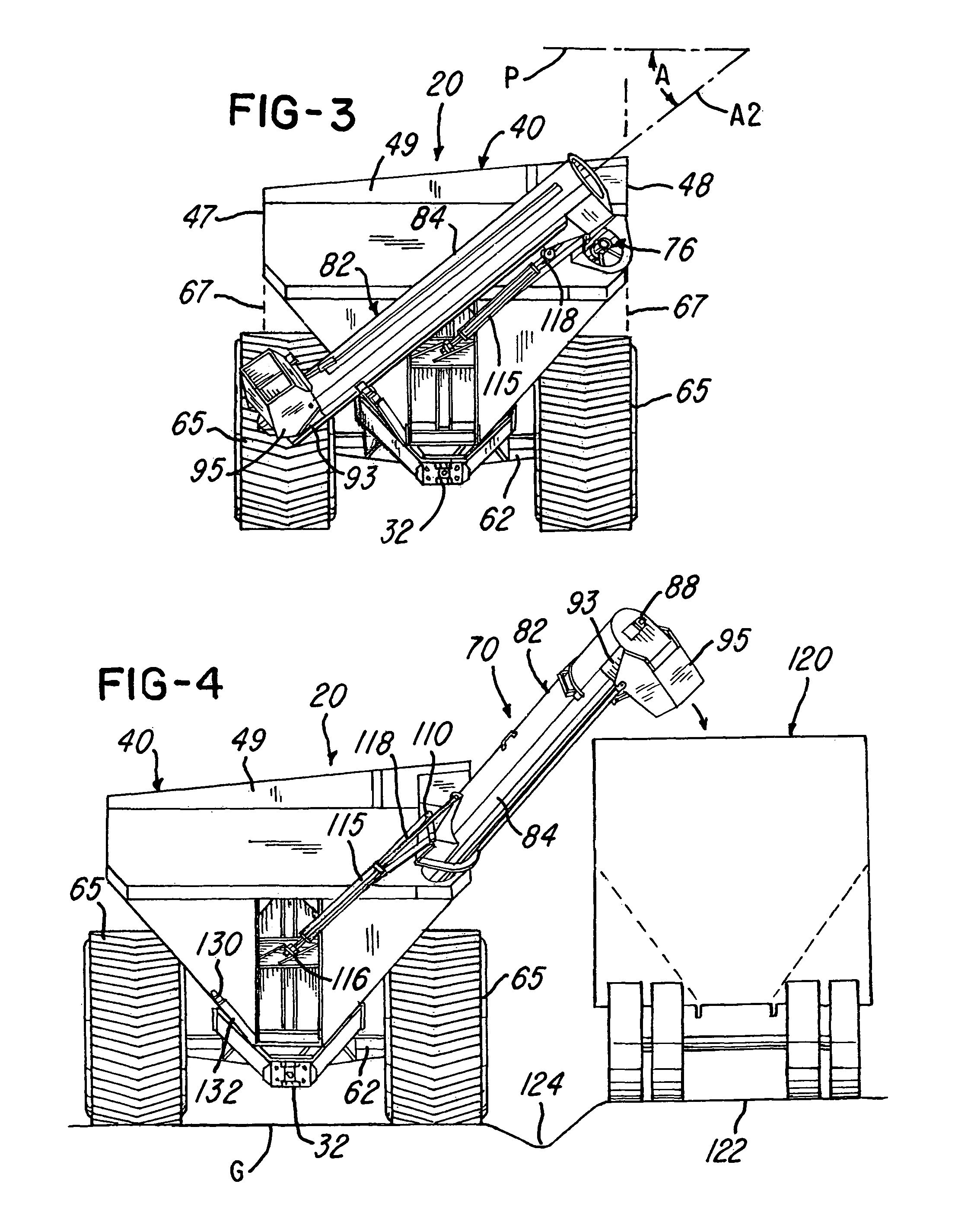

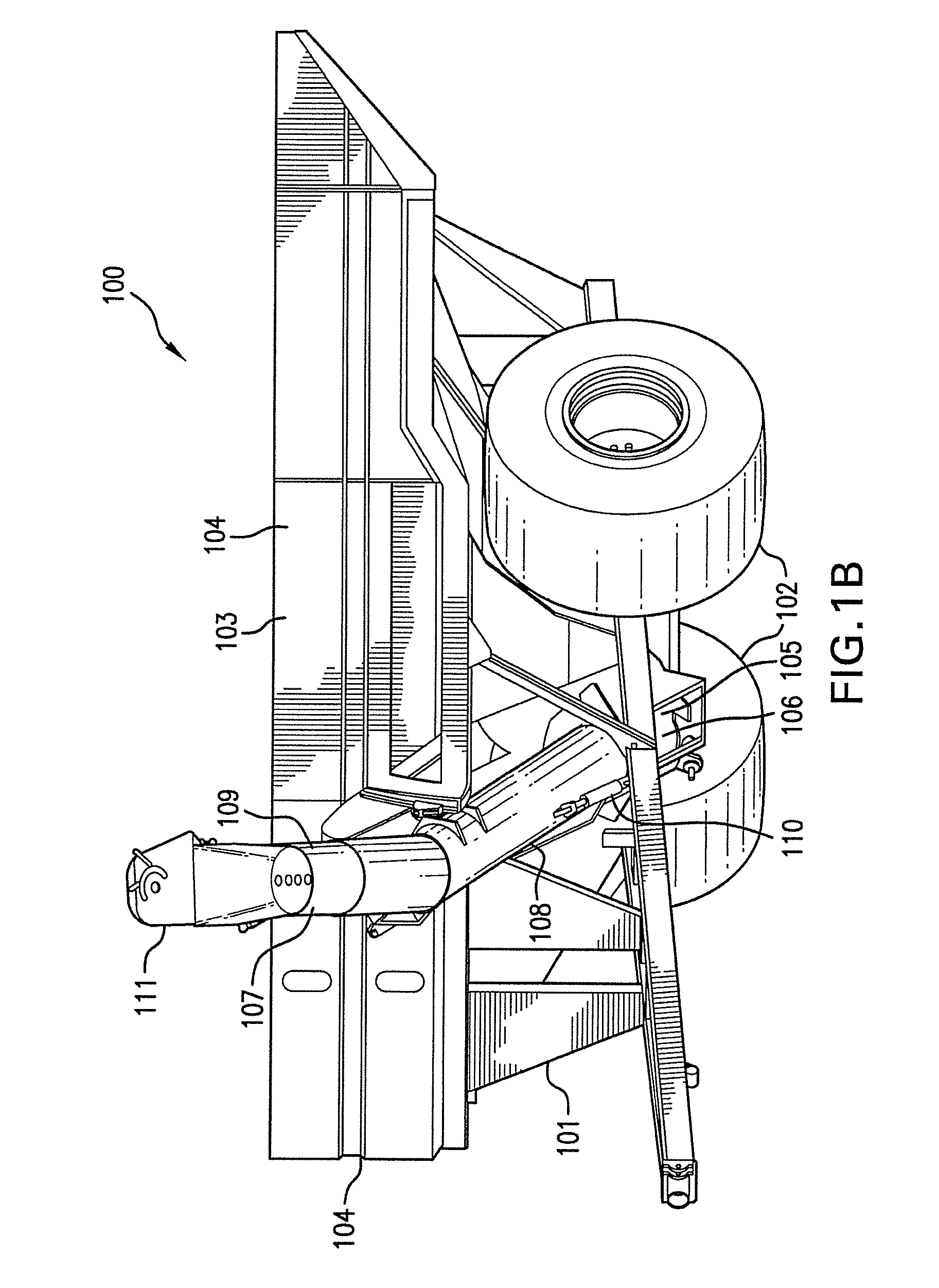

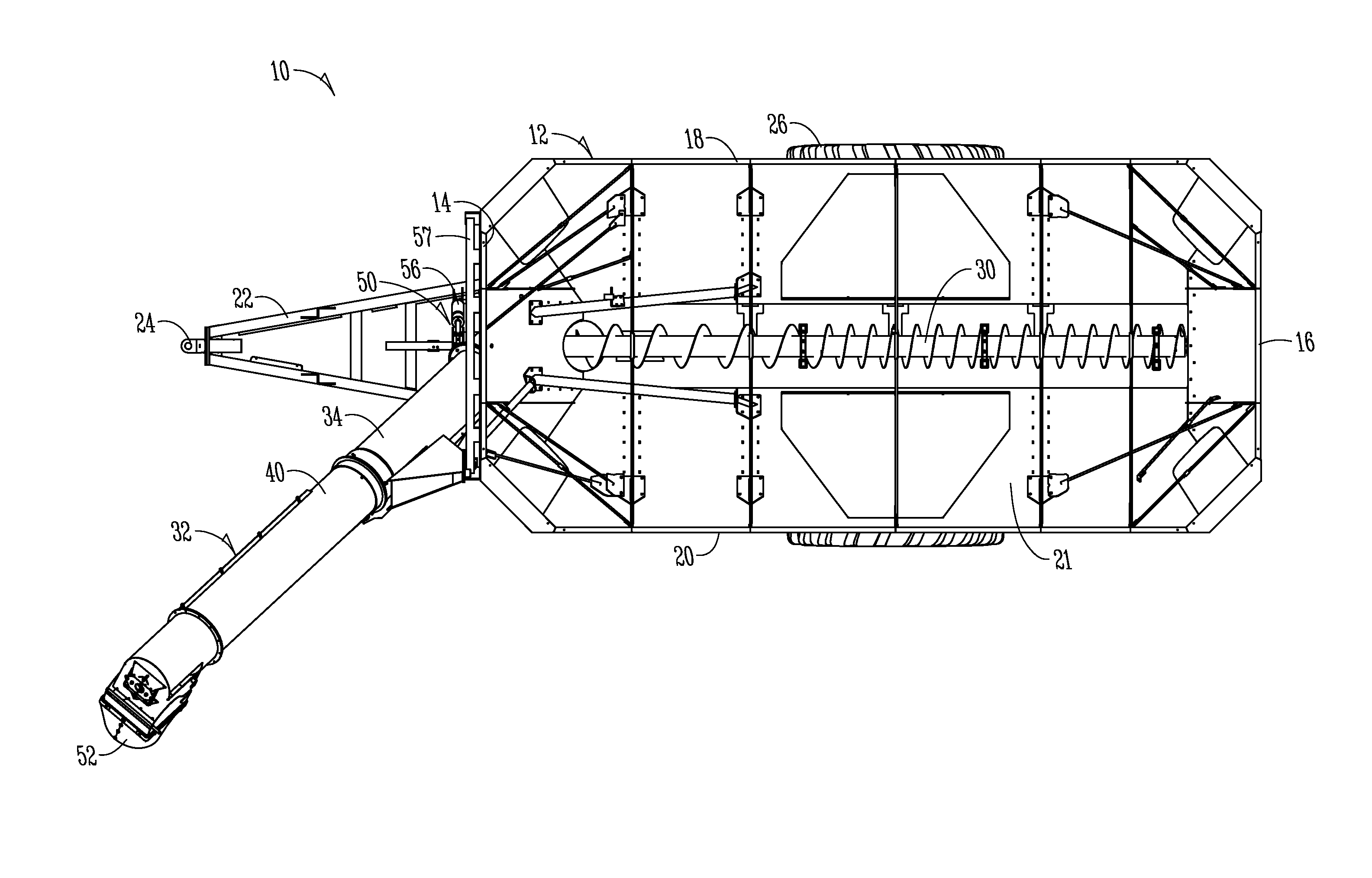

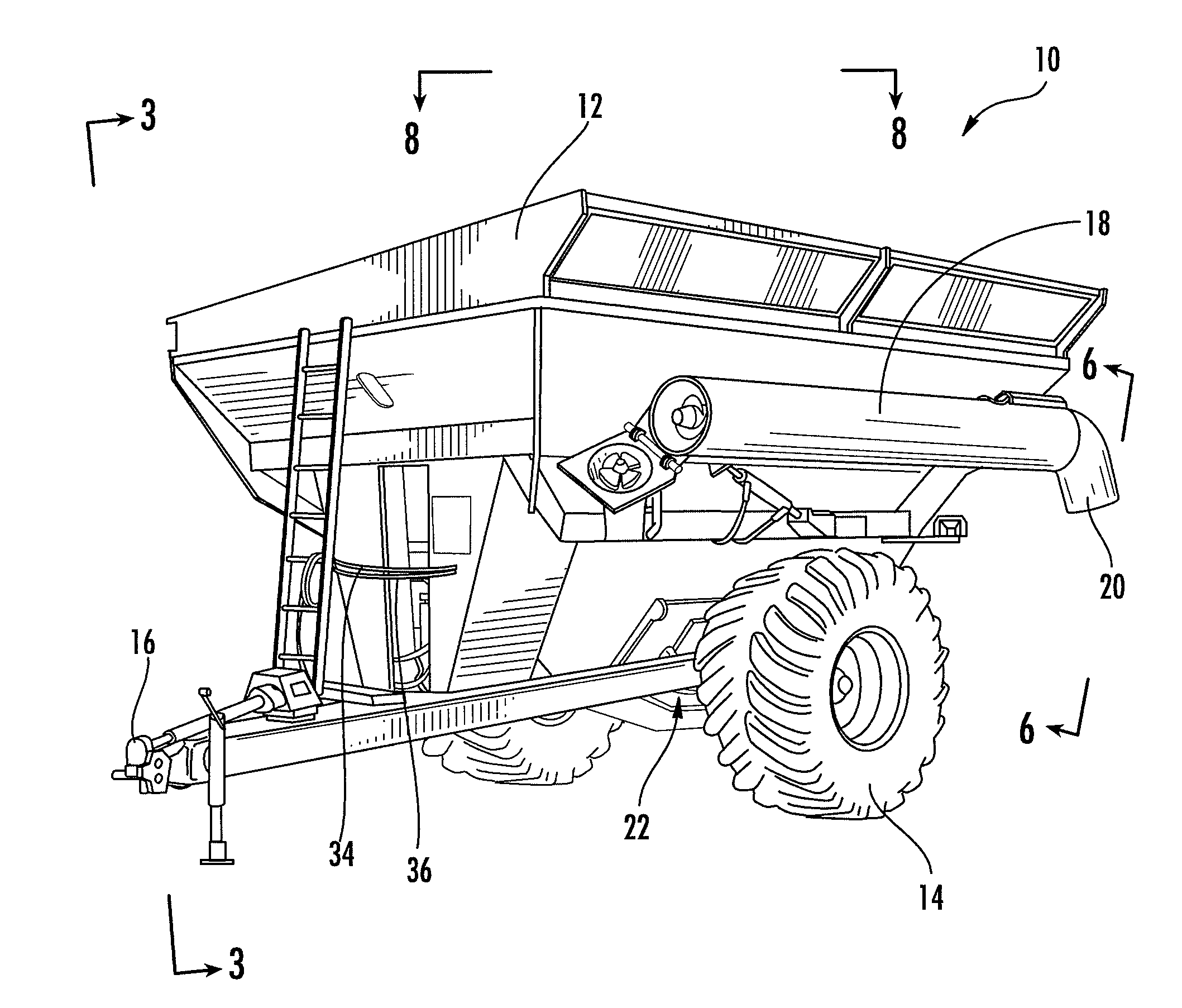

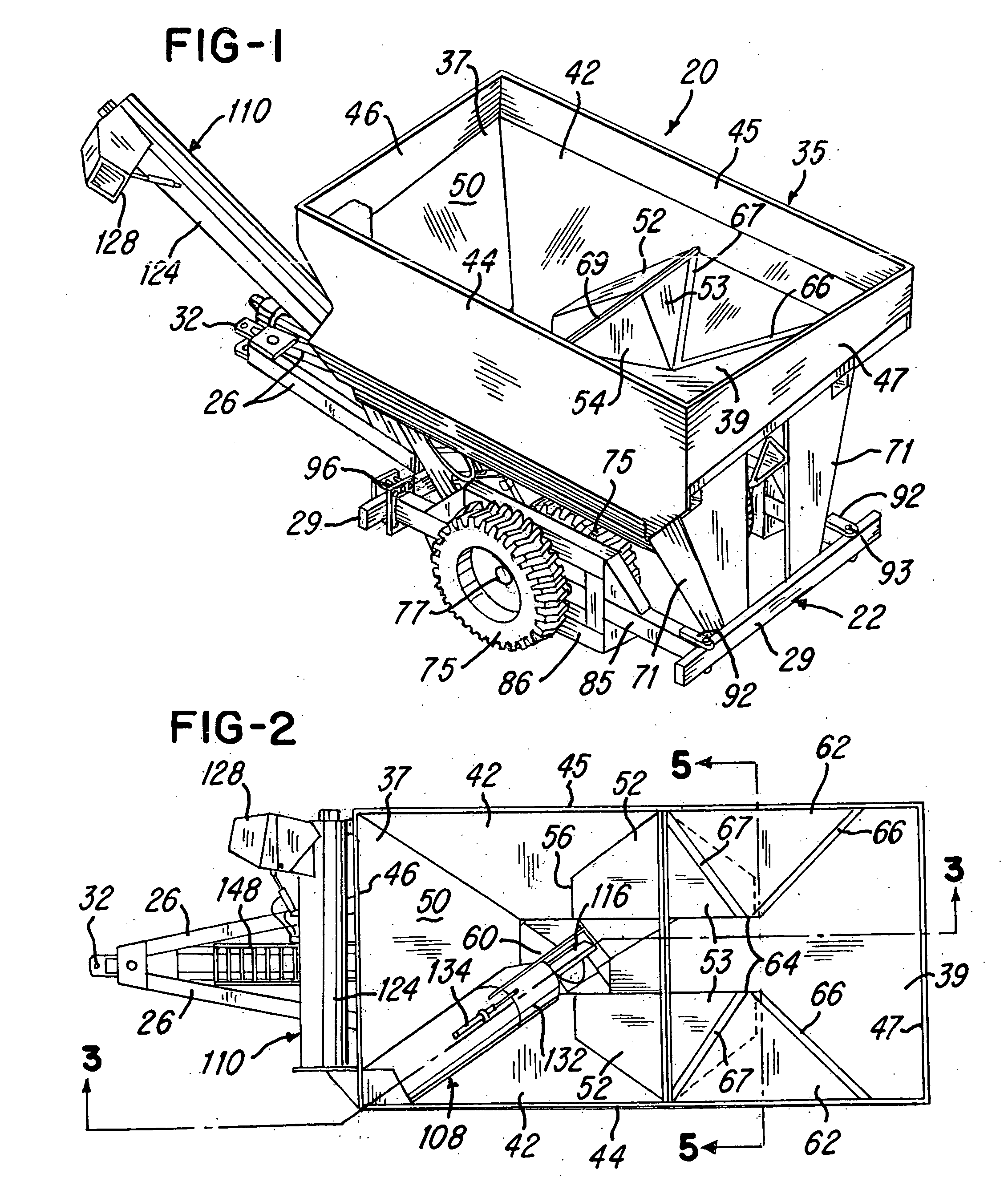

Grain wagon with improved grain container

A grain wagon includes a wheel supported frame supporting a container having inclined front and rear walls connected by opposite inclined side walls. Each side wall has inwardly projecting wall portions defining a wheel well for receiving longitudinally offset dual wheels or extra wide wheels. The rear wall includes a portion sloping between the wheel well wall portions to a forward grain removal zone, and generally triangular diverter walls extend from the rear wall to the wheel well wall portions. A corner discharge auger conveyor extends from the grain removal zone and has an upper portion which pivots to a stored position adjacent the front wall of the container. The dual wheels are positioned within the wheel wells by support members having end portions pivotally connected to the wagon frame and opposite end portions connected to the frame by laterally slidable clamping plates.

Owner:J & M MANUFACTURING CO INC

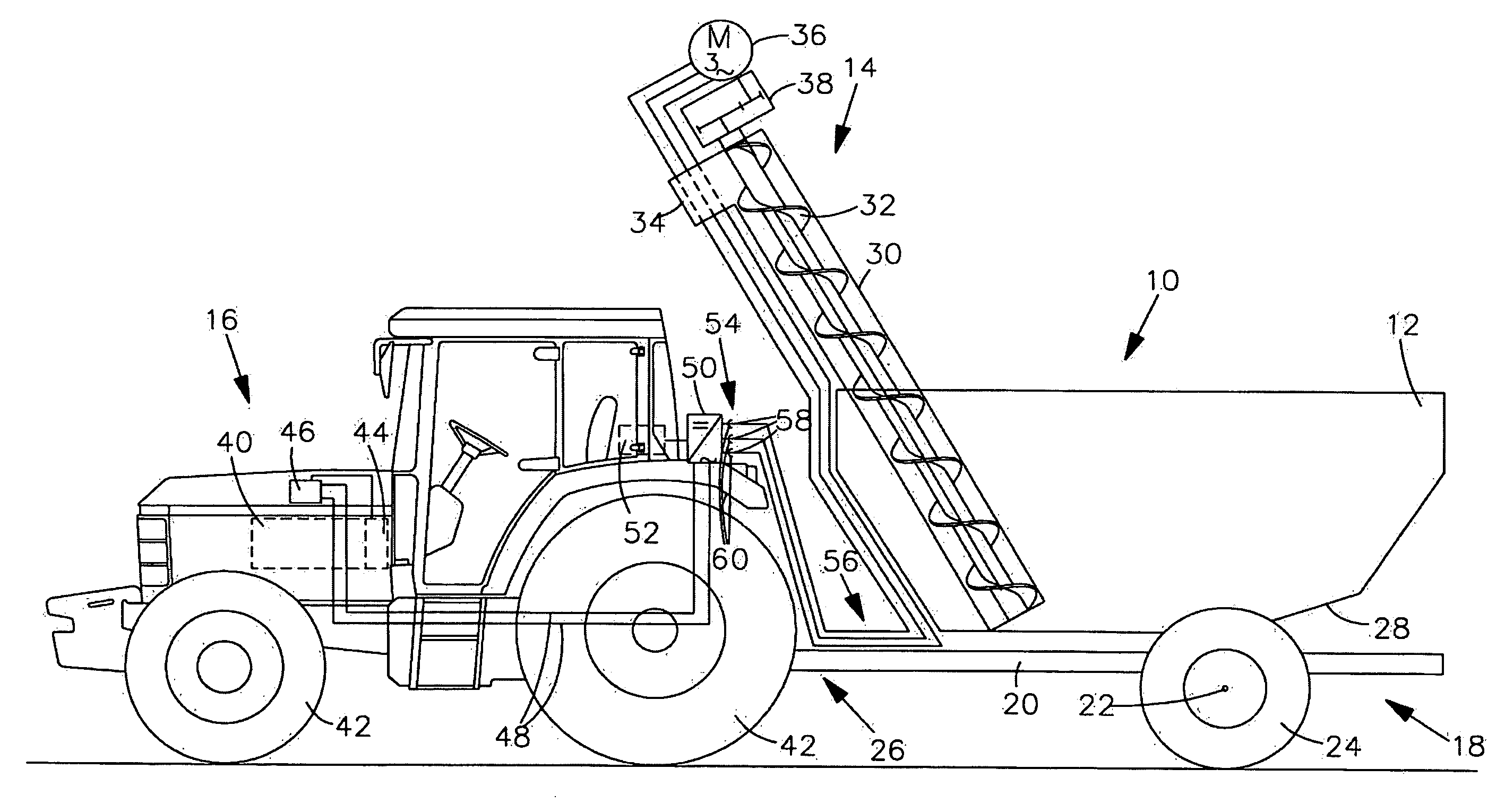

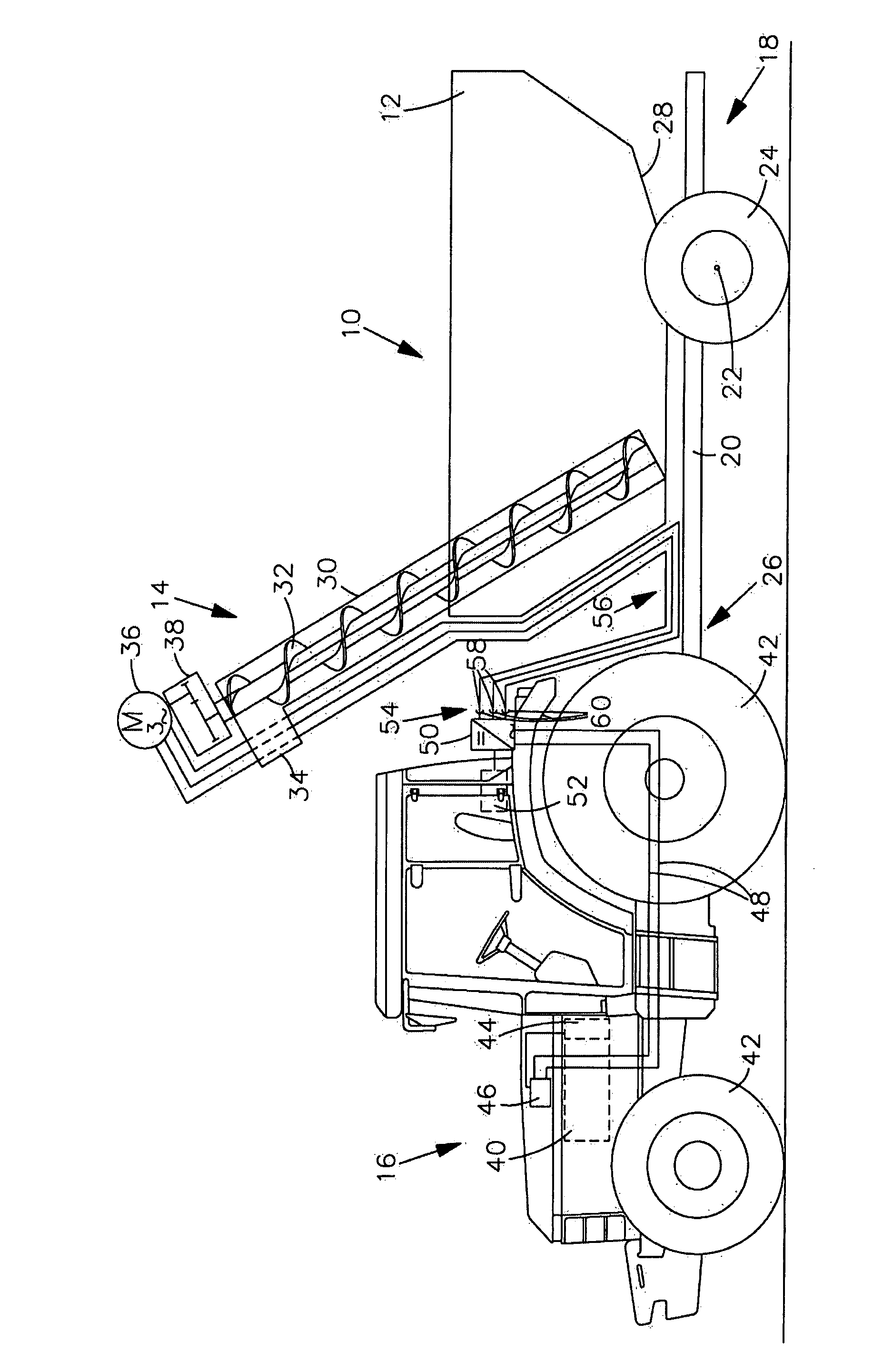

Grain cart with intermodal container loader

InactiveUS7540700B2Easy loadingReduce processingLoadersRefuse receptaclesEngineeringCircular segment

Owner:DEERE & CO

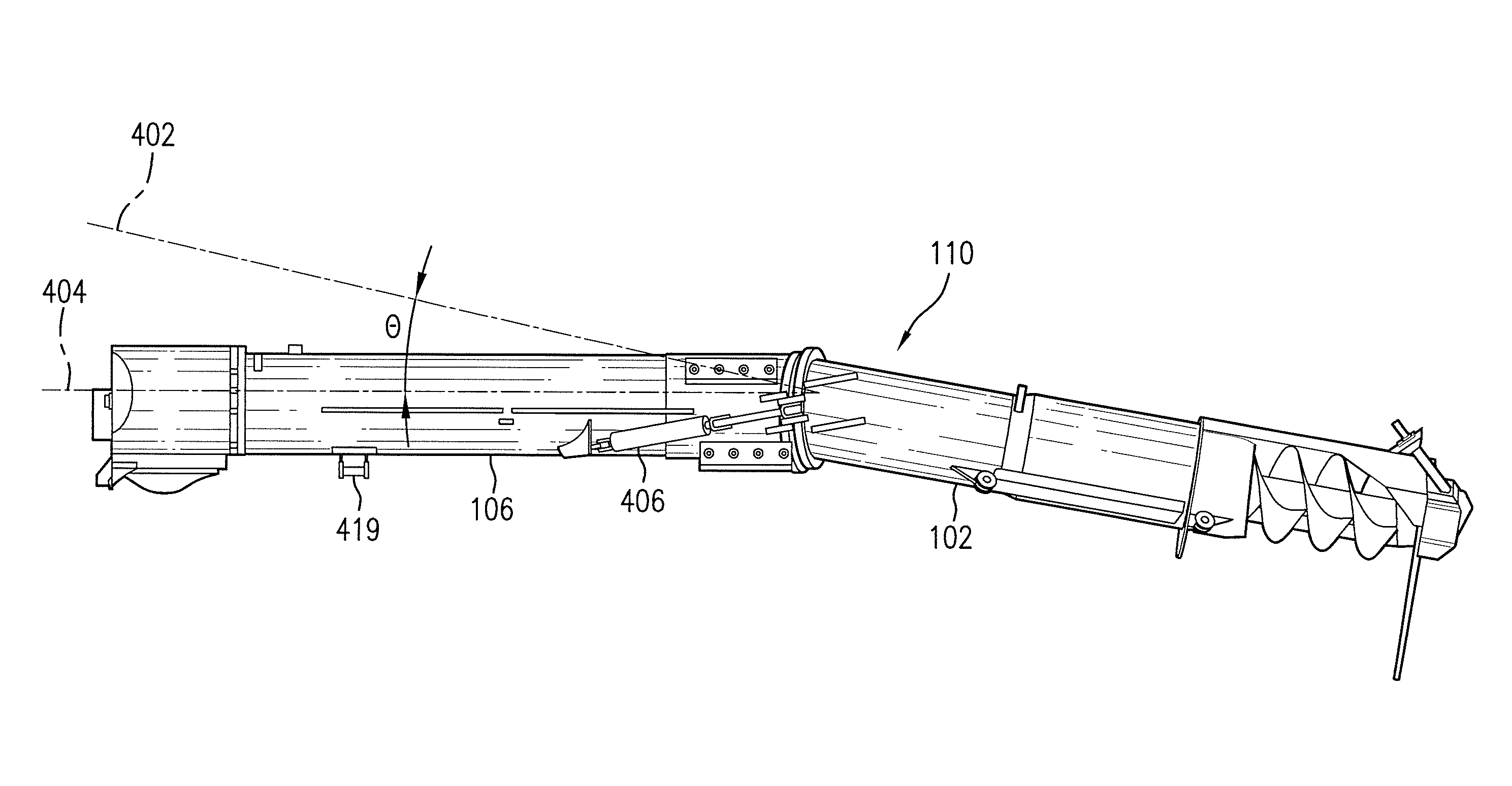

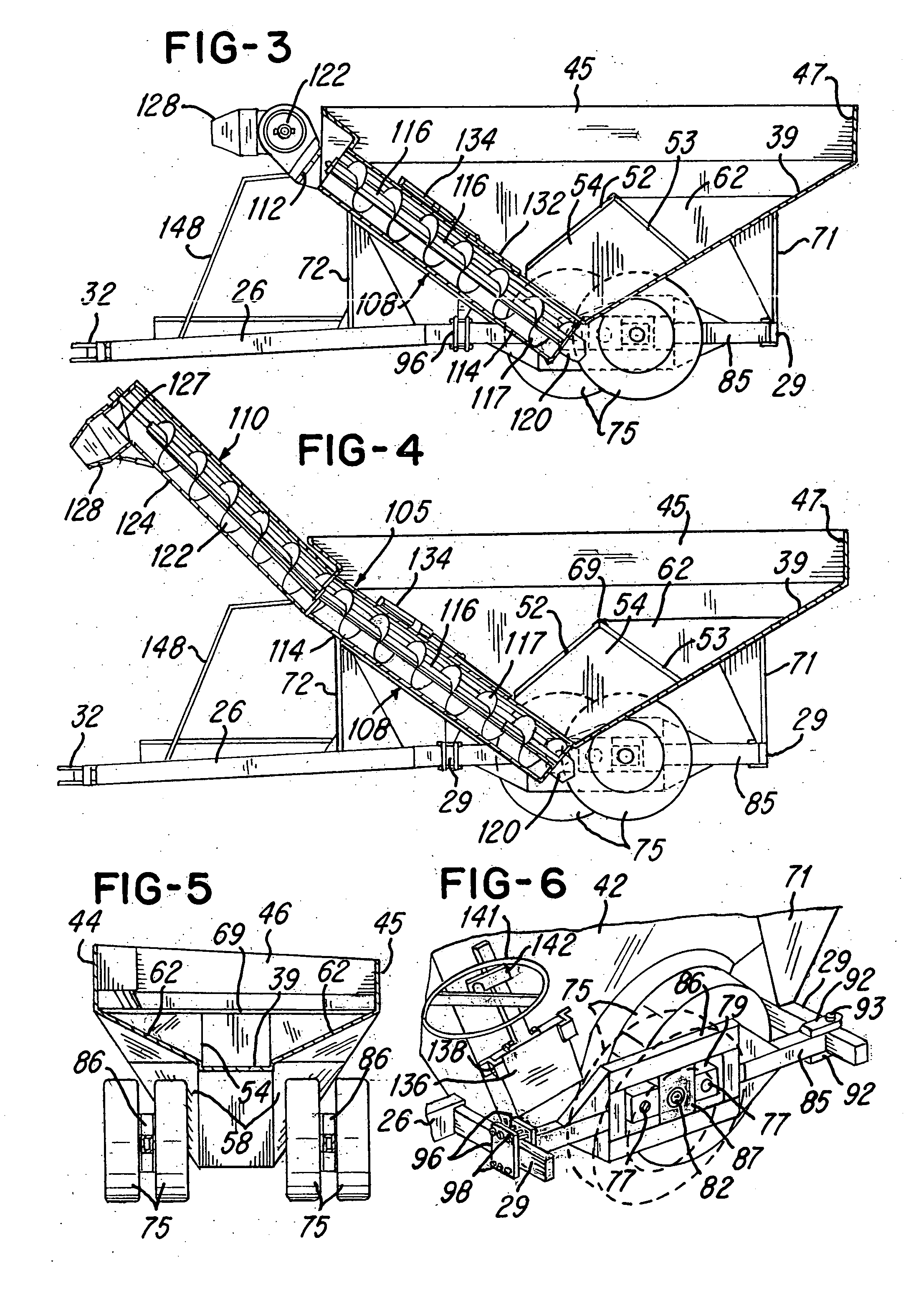

Grain cart having a single auger discharge conveyor

A grain cart has a wheel supported frame on which is mounted an open top container having inclined bottom walls and including a single discharge auger conveyor having a lower section extending from a sump for the container adjacent a front left inclined corner portion of the container. The auger conveyor has an extended upper section supported by a hinge assembly having a pivot axis offset and askewed at an acute angle from the auger axis. The hinge assembly provides for pivoting the upper conveyor section between an inclined grain discharge position projecting upwardly, laterally outwardly and forwardly from the container and a stored position inclined downwardly at a substantial angle from the hinge assembly in front of the container. In the stored position, the grain discharge outlet is located lower than the top surfaces of the wheels and does not project laterally beyond the right side wall of the container.

Owner:J & M MANUFACTURING CO INC

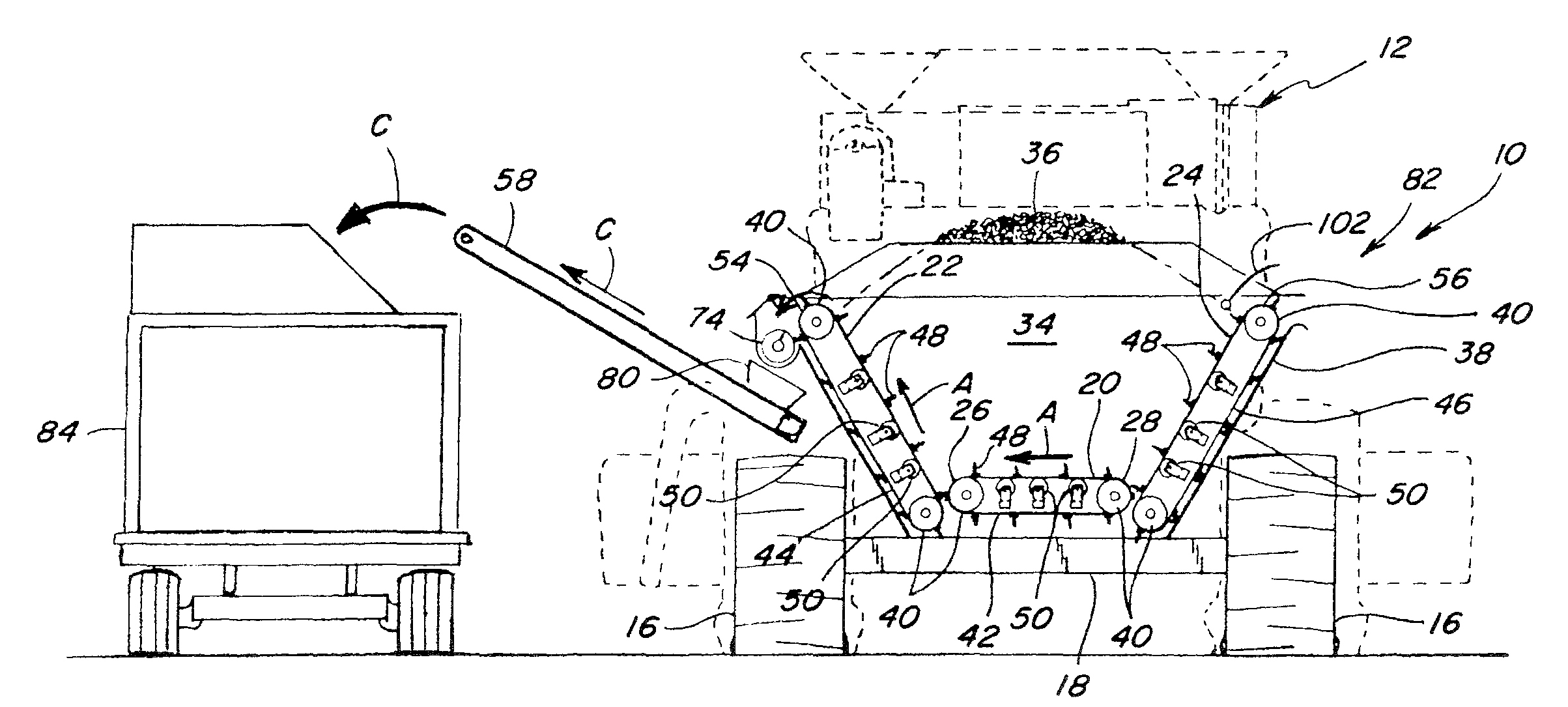

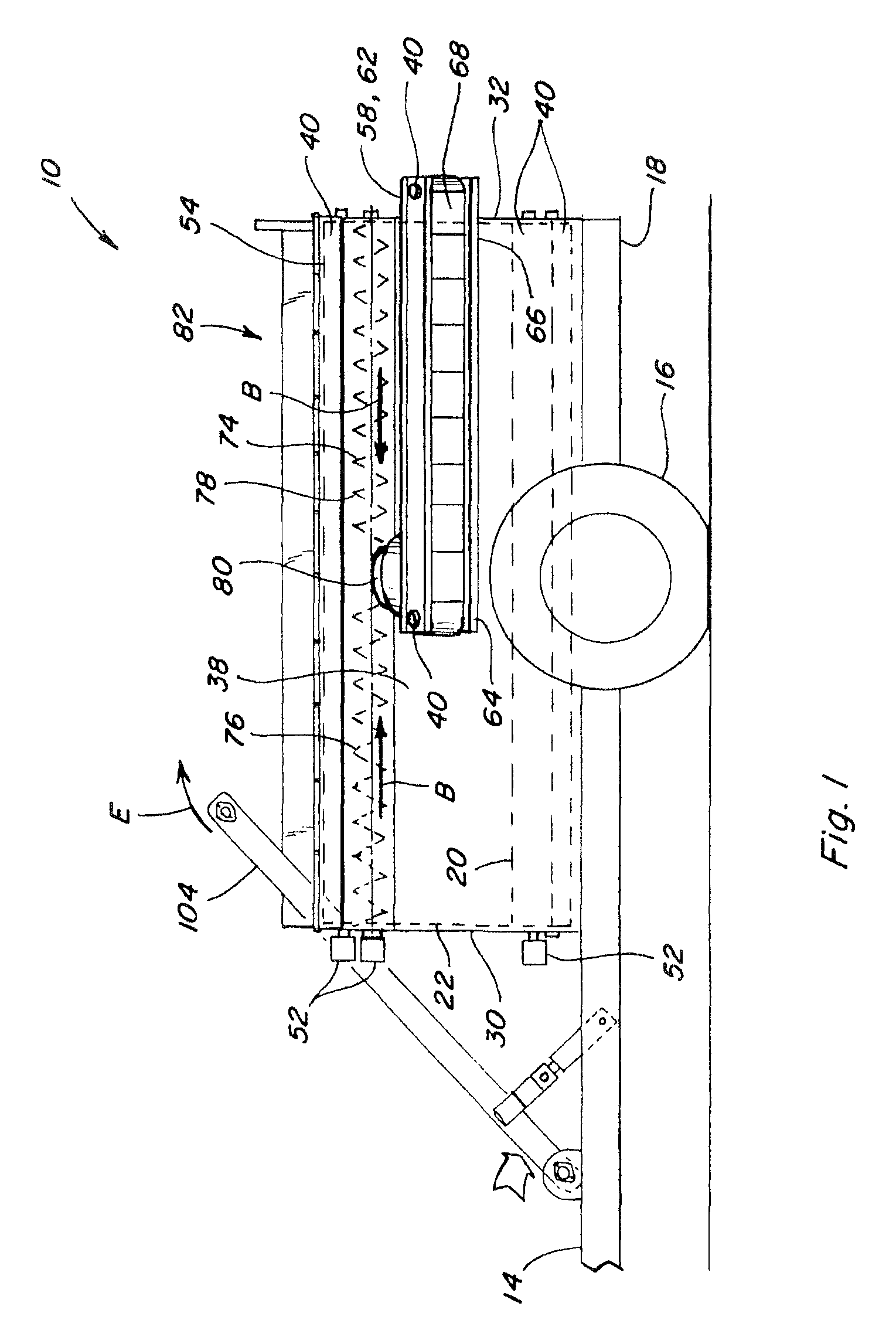

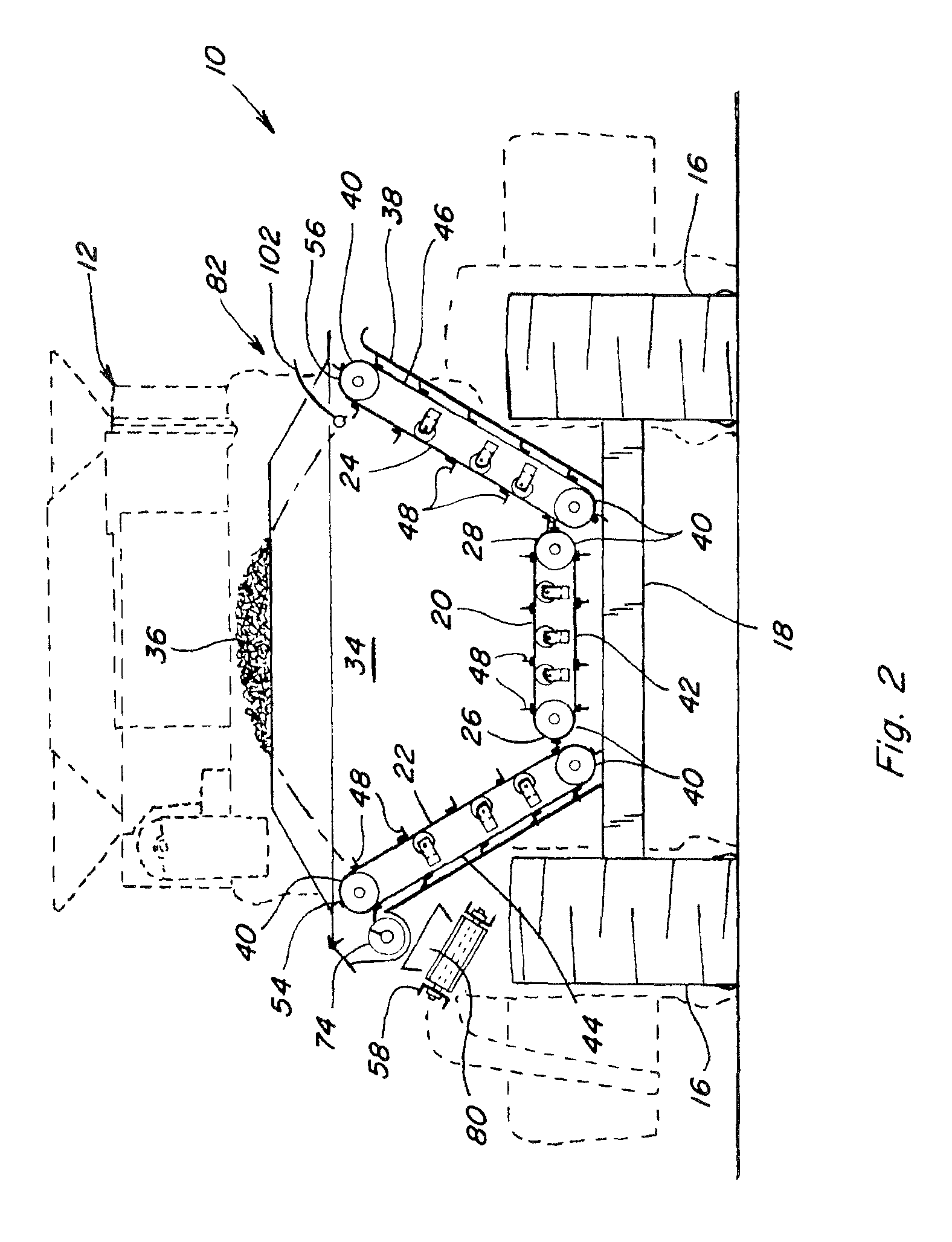

Bulk Materials Cart Having Dual Unload Capability

The bulk materials cart has a dual unload system including at least two inclined belt conveyors bounding an enclosed cavity. A first belt conveyor is operable for conveying bulk materials from the cavity to an unloading conveyor extendable from that side of the cart. A second belt conveyor is operable for conveying bulk materials upwardly and over another side of the cart. The dual unload system is automatically operable in a first mode operating the first belt conveyor and the unloading conveyor for conveying the bulk materials away from the cart, and in a second mode operating the second belt conveyor for conveying the bulk materials over the side of the cart.

Owner:BLUE LEAF I P

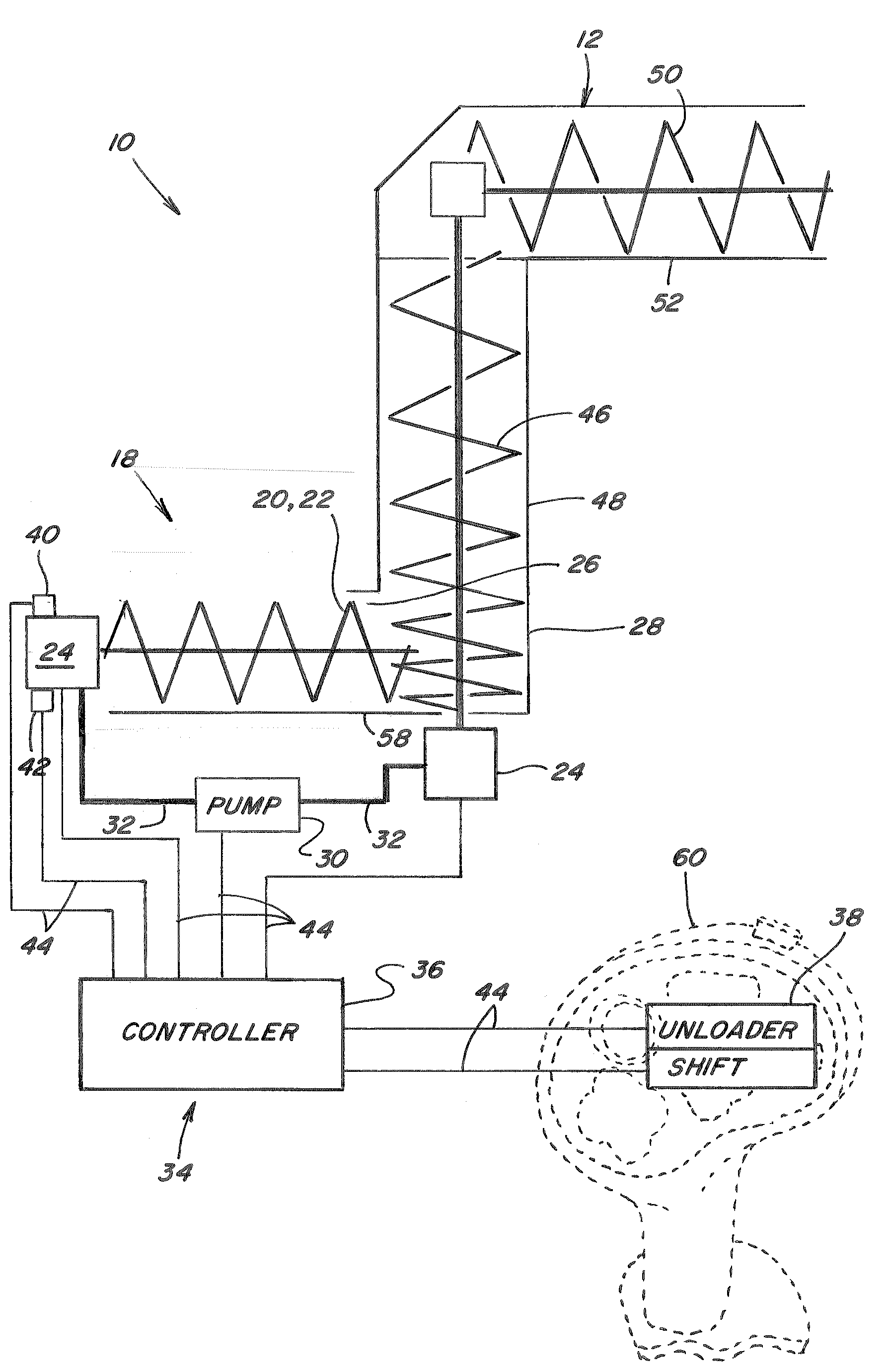

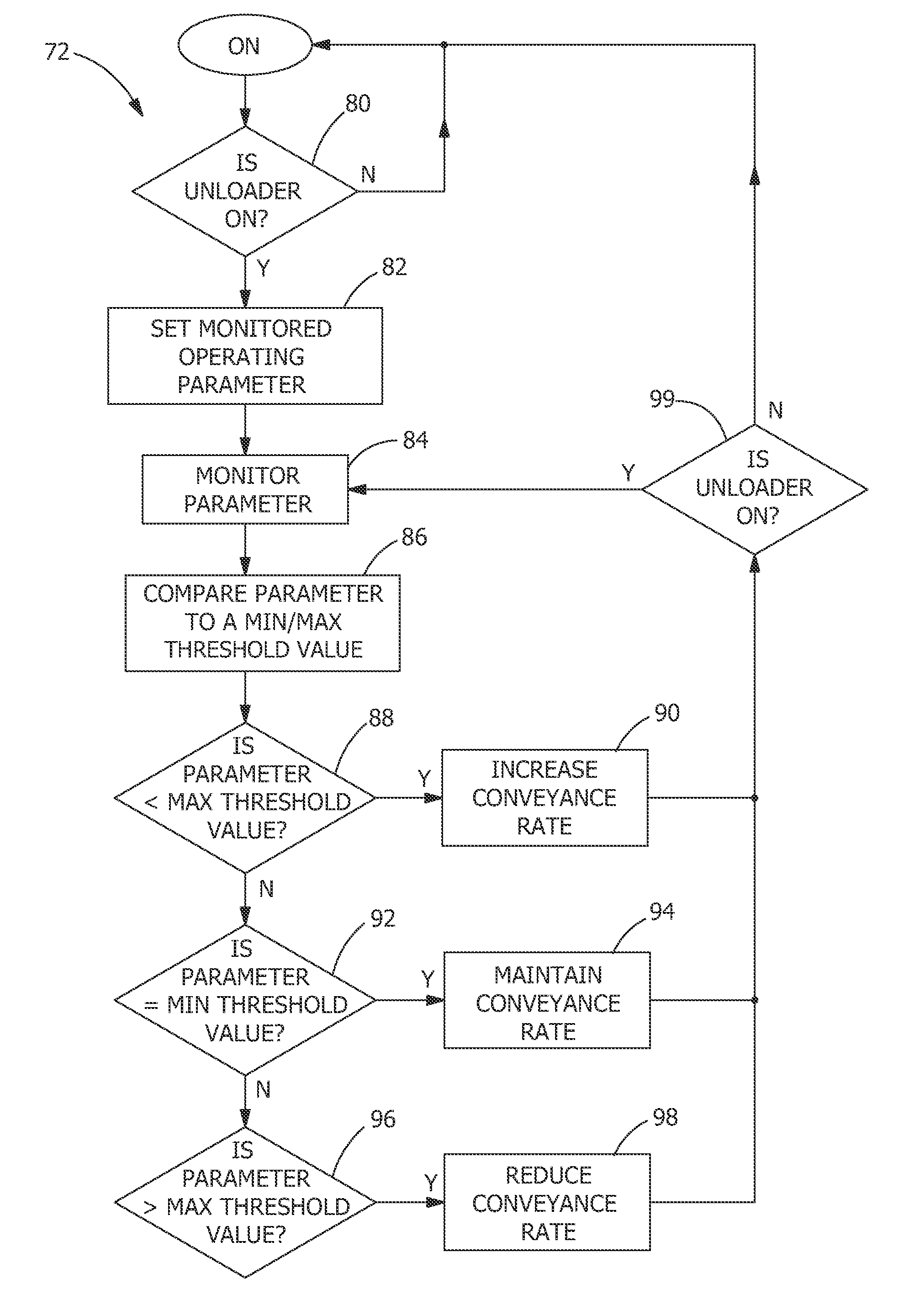

Adaptive rate control for feeding grain to a grain unloader conveyor

ActiveUS20090290970A1Avoid high start up torque spikingLarge capacityConveyorsMowersAutomatic controlEngineering

The control of an apparatus within a grain holding device for feeding grain to an unloader conveyor operable for conveying the grain from the holding device, includes sensing a predetermined condition or conditions representative of capacity of the unloader conveyor for receiving grain, and adaptively controlling the apparatus for feeding grain to the unloader conveyor in advantageous varying manners responsive to the conditions, including to delay initiation of feeding until the receiving capacity is increased, and to match the grain feed to the capacity. The automatic control can be overridden, to allow user control of unloader speed, and can be configured to allow cleanout of the unloader conveyor.

Owner:BLUE LEAF I P INC

Positive operating combine unloader discharge door arrangement

A positive operating combine unloading discharge door which operates independent of the presence of grain in the unloading tube and is attached to the unloading tube to minimize opposition and obstruction to grain flow and completely cover the open end of the unloading tube when the unloading cycle is complete to minimize or eliminate grain loss due to grain dribble.

Owner:BLUE LEAF I P INC

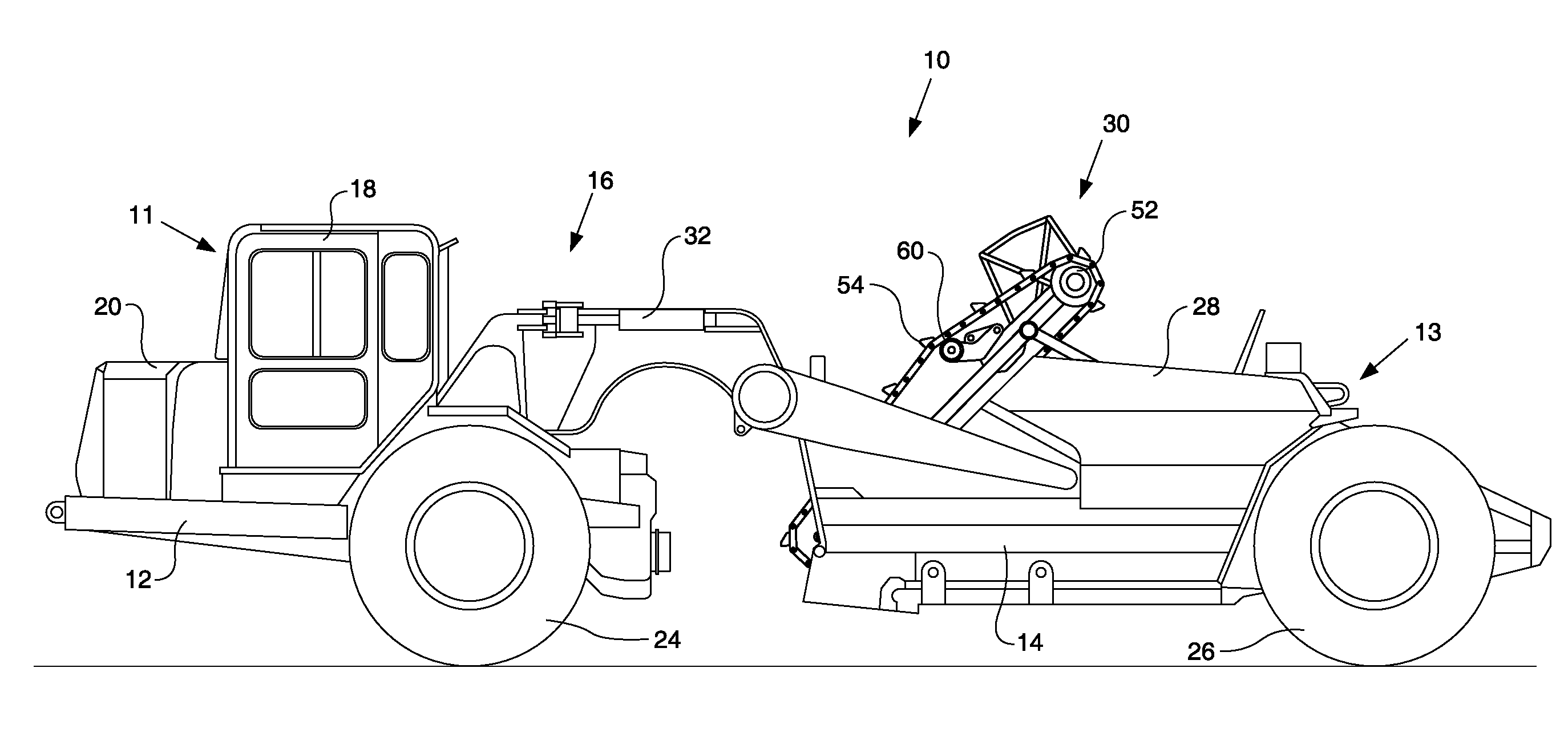

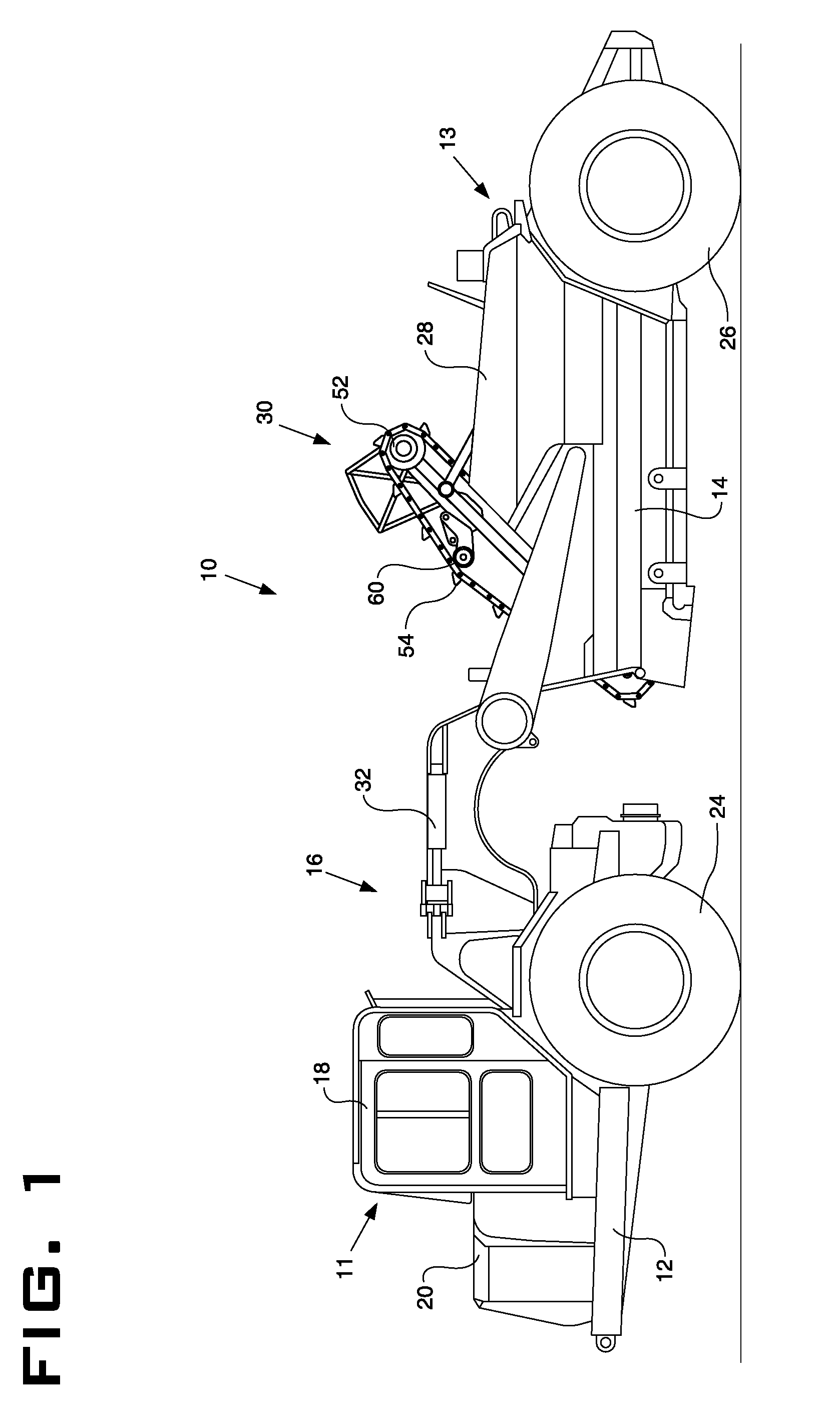

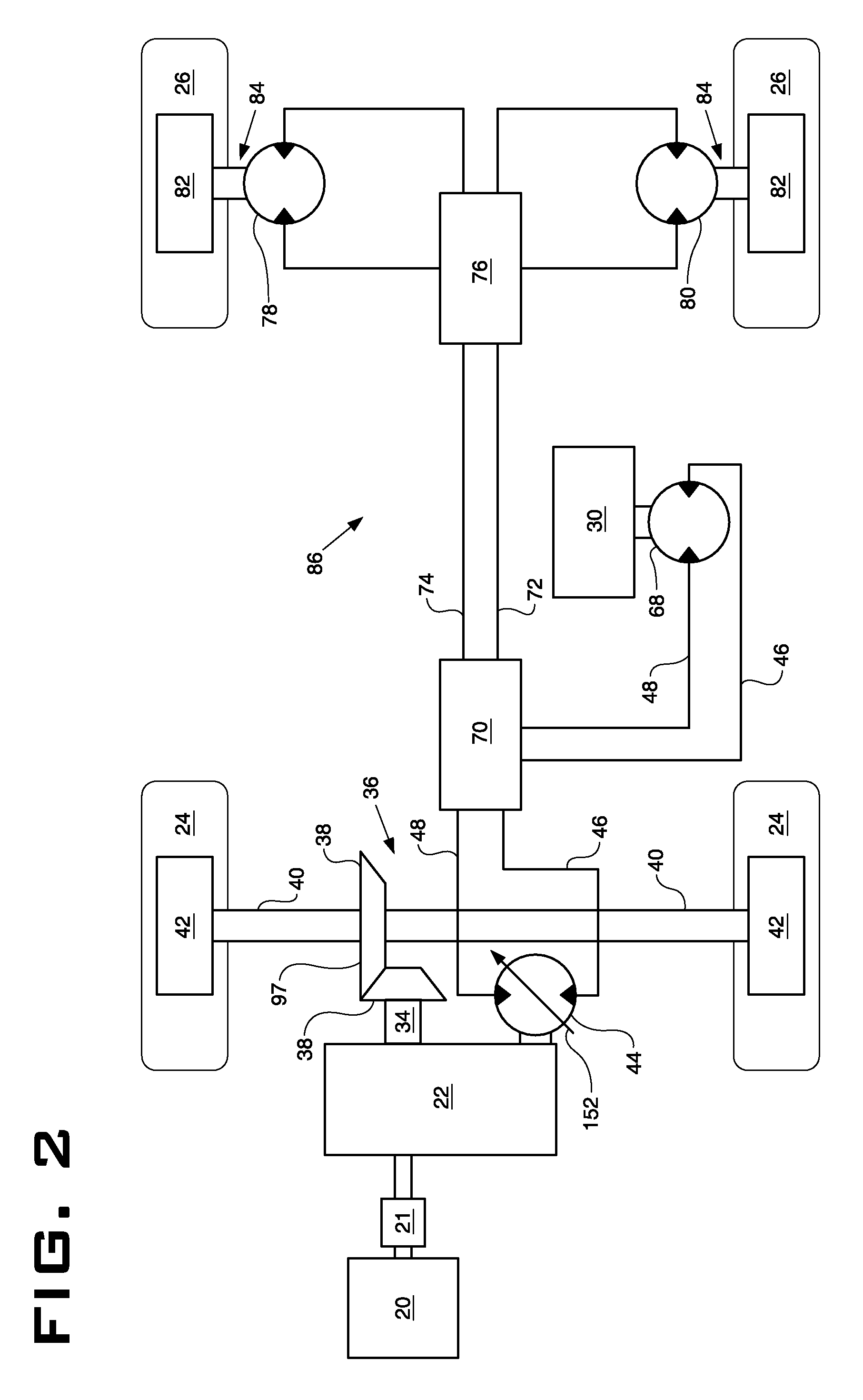

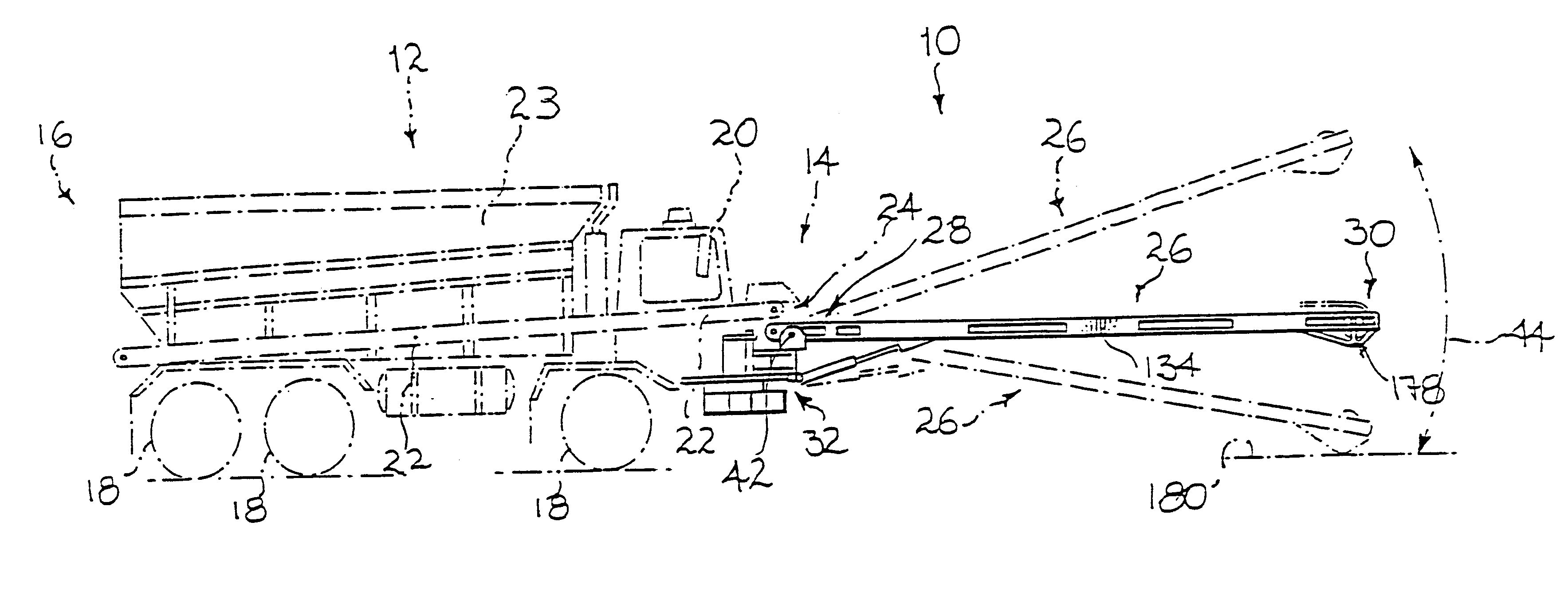

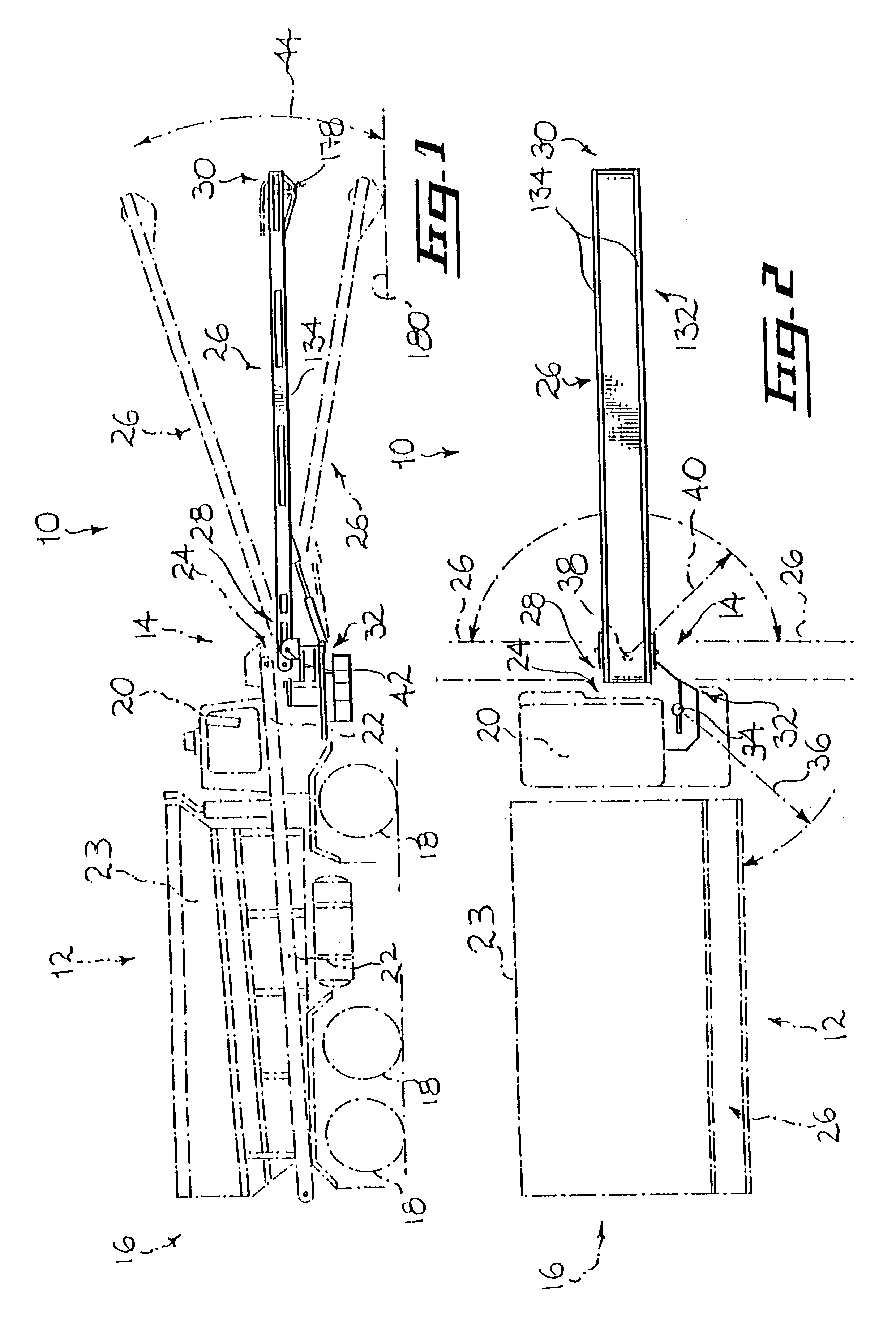

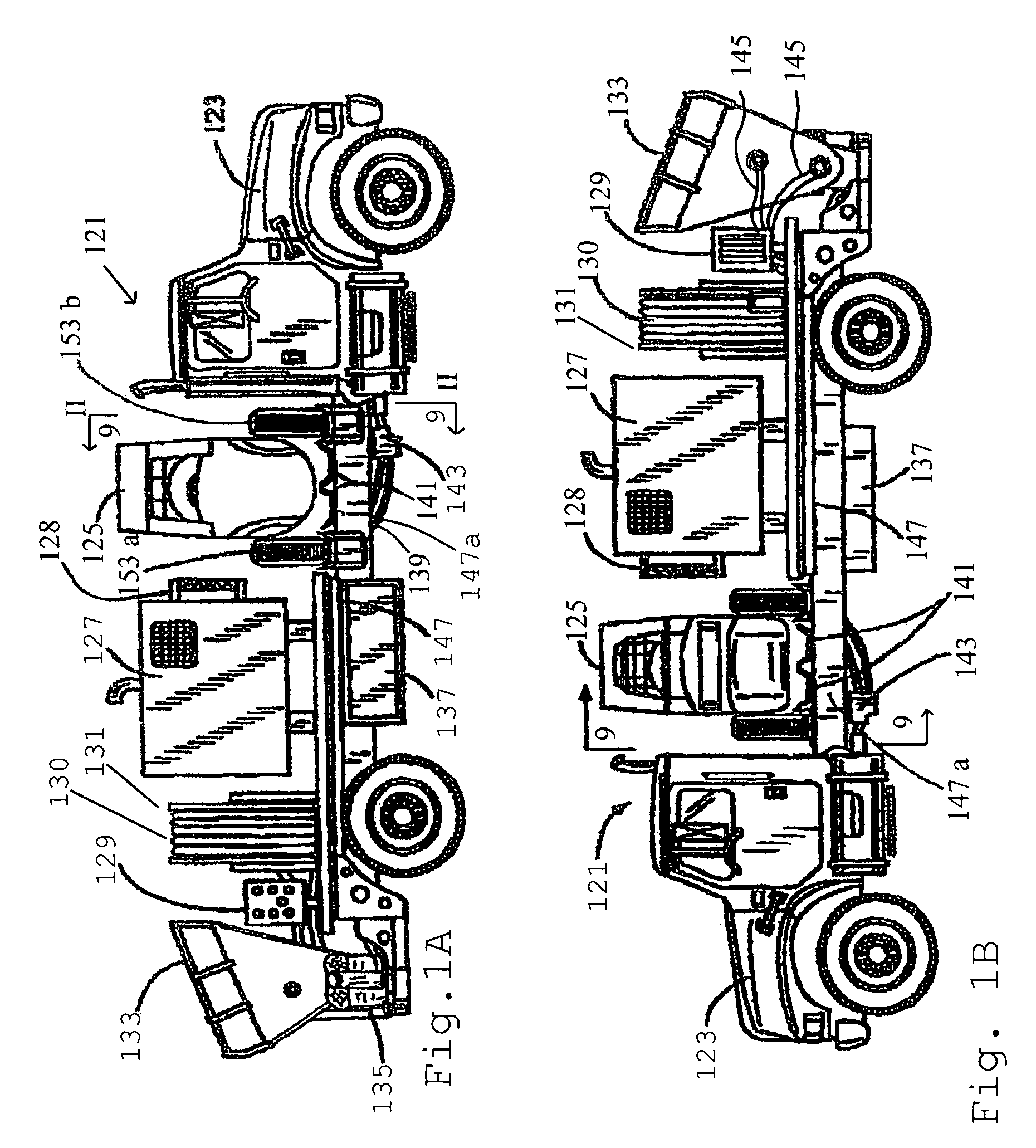

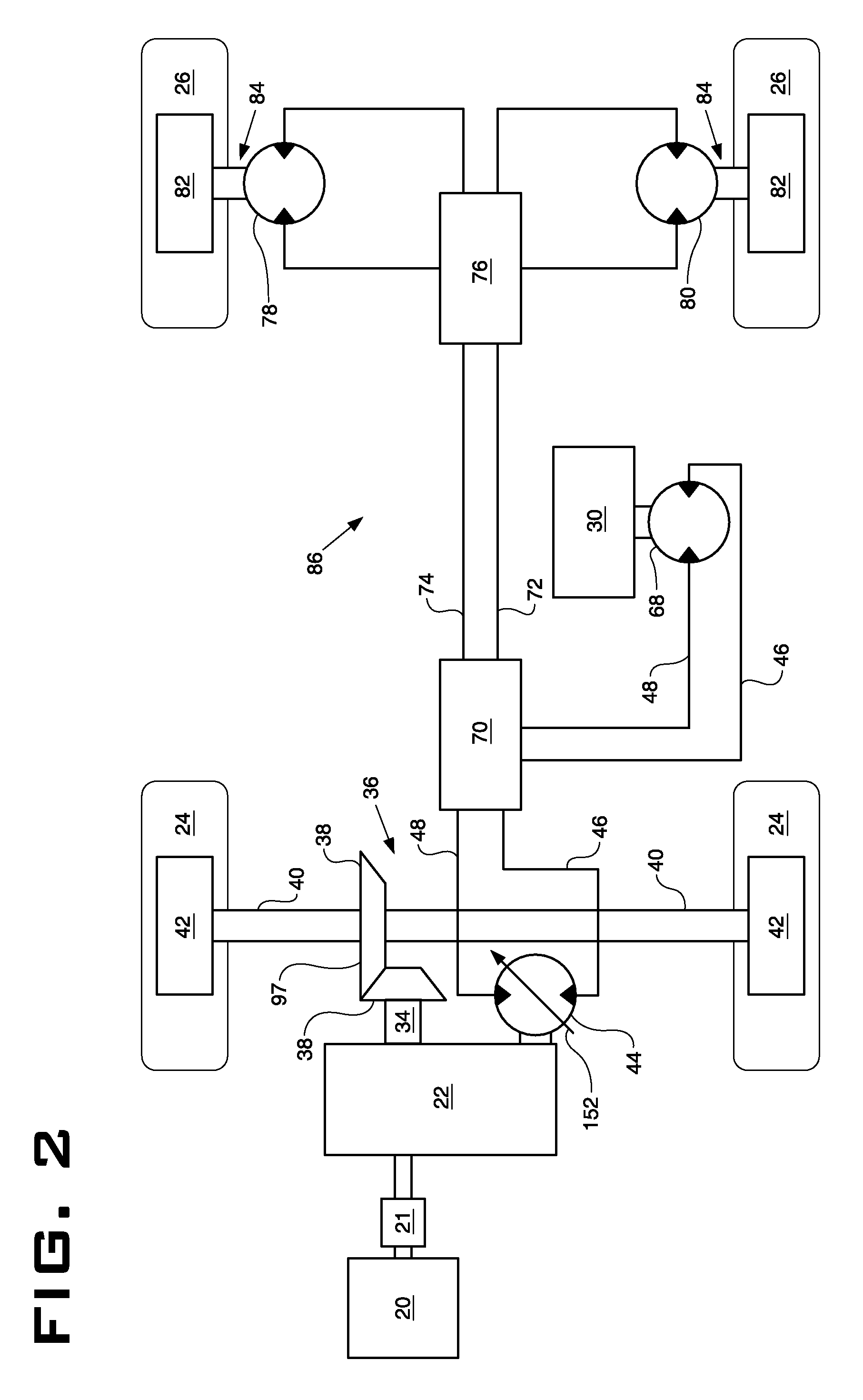

Wheel tractor scraper rear wheel drive assist and method of operation

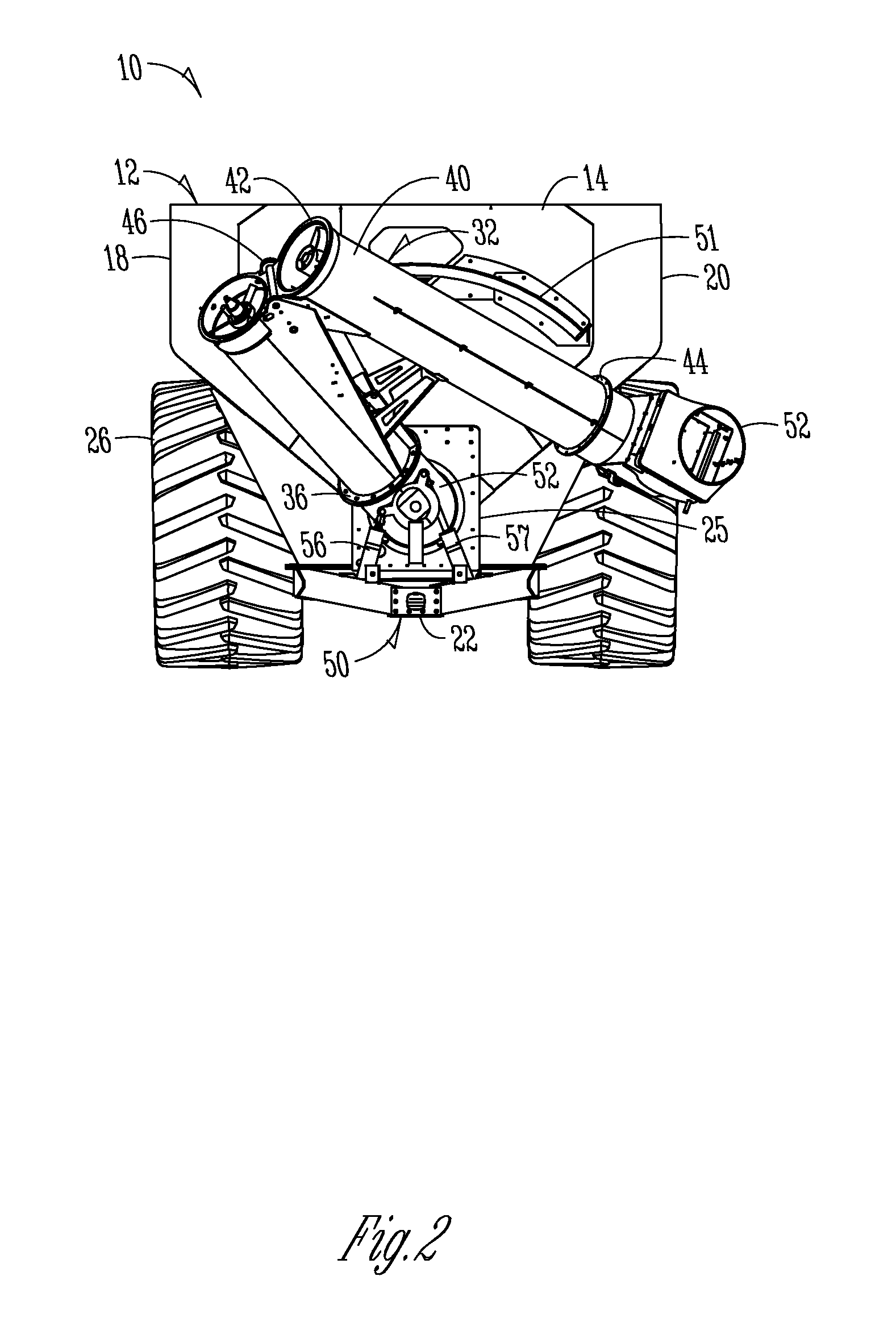

ActiveUS20100018727A1Machines/dredgers working methodsAgricultural machinesWheel tractor-scraperDrive motor

A wheel tractor scraper having a rear wheel drive assist, the wheel tractor scraper includes a tractor portion pivotally coupled to a rear scraper portion, the rear scraper portion having a bowl for hauling material and a fluid powered work tool configured to assist in loading the bowl, the work tool powered by a fluid pump connected to a fluid operated work tool motor. The rear wheel drive assist includes a fluid operated drive motor coupled to the rear wheels of the machine, a diverter valve having a first position at which fluid flow is delivered from the pump to the work tool motor and a second position at which fluid flow is delivered from the pump to the drive motor, and a controller being configured to control the diverter valve to engage the rear wheel drive assist. The machine may be operated by engaging the pump and work tool motor, and then actuating the diverter valve to the second position to divert flow from the work tool motor to the drive motor.

Owner:CATERPILLAR INC

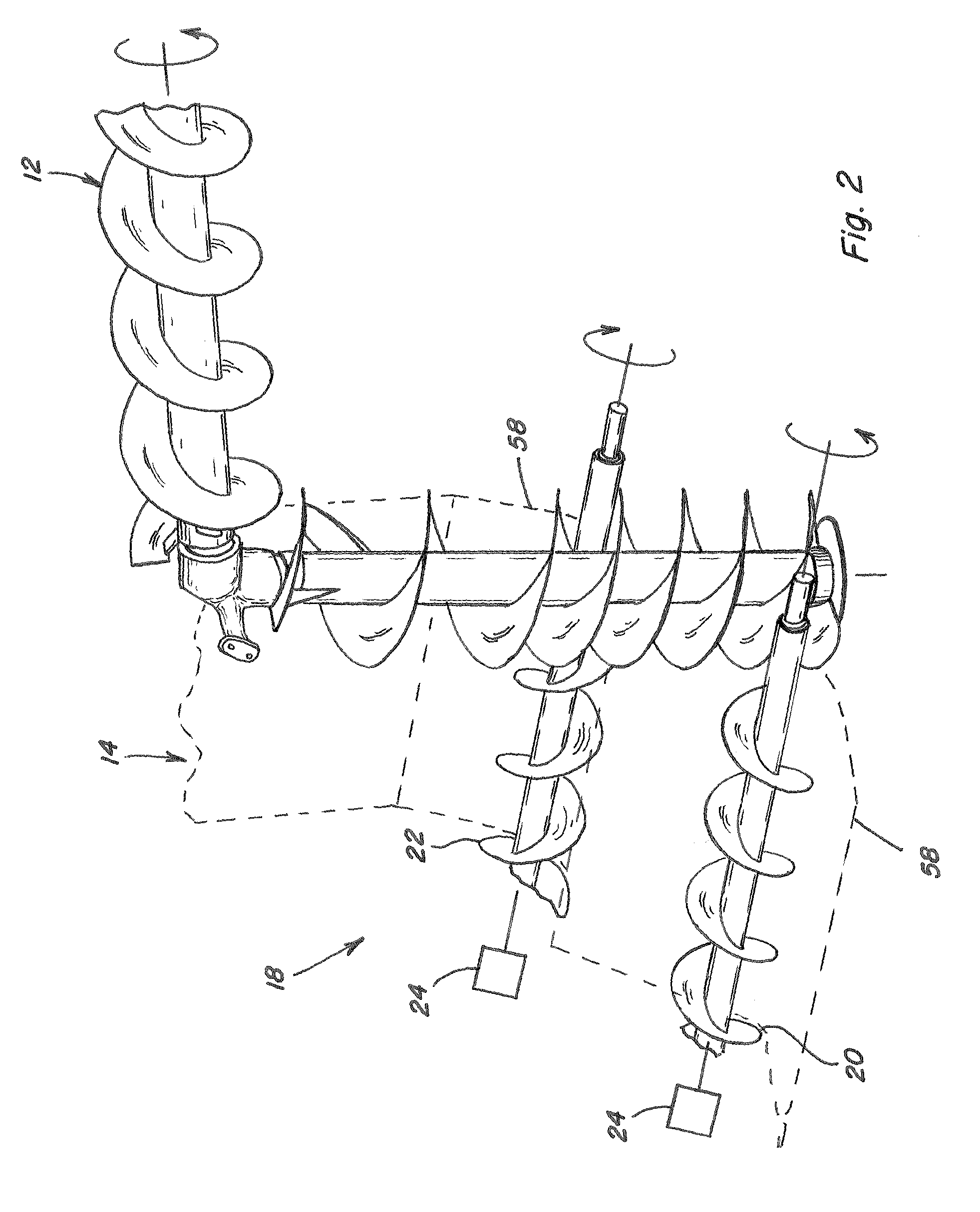

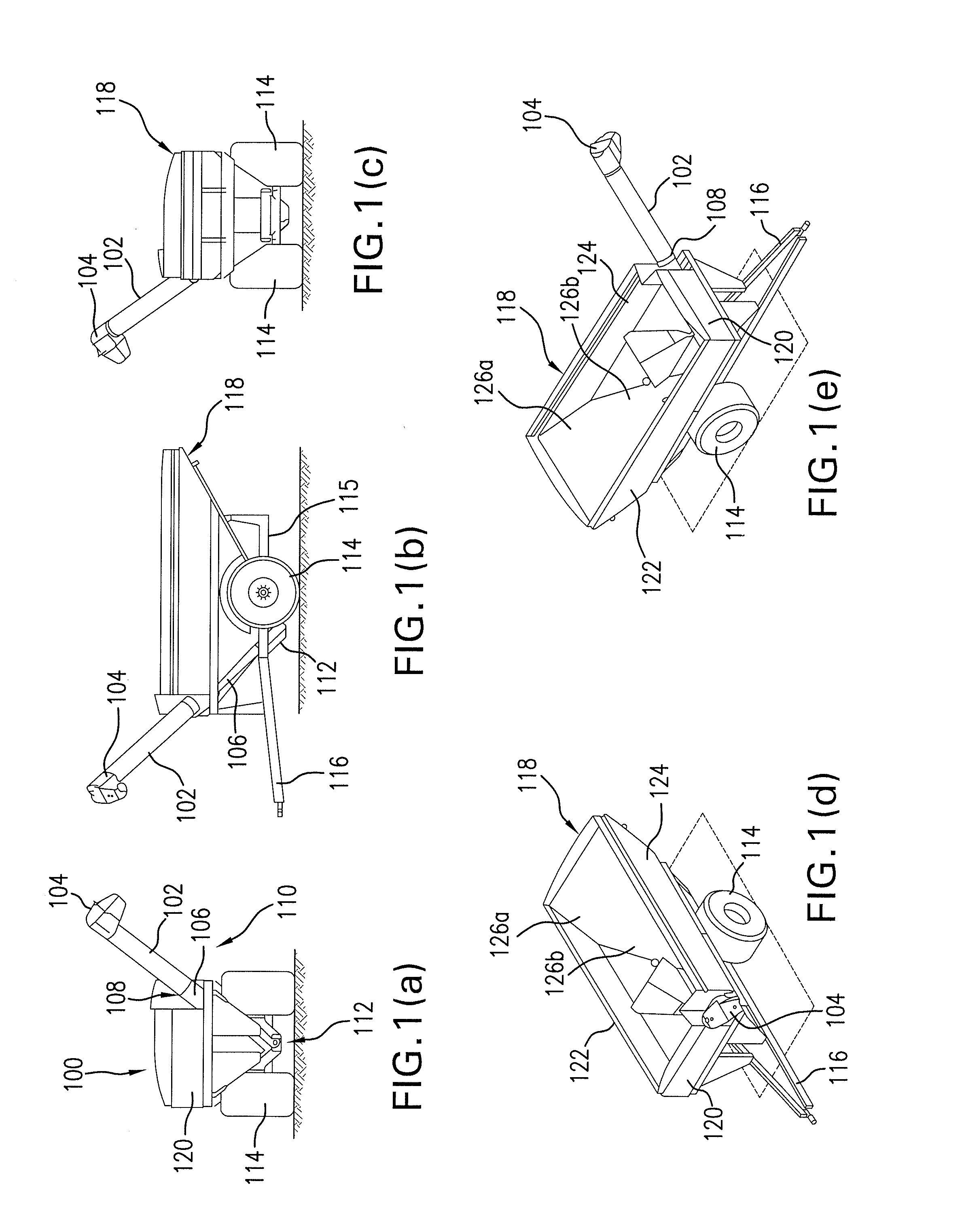

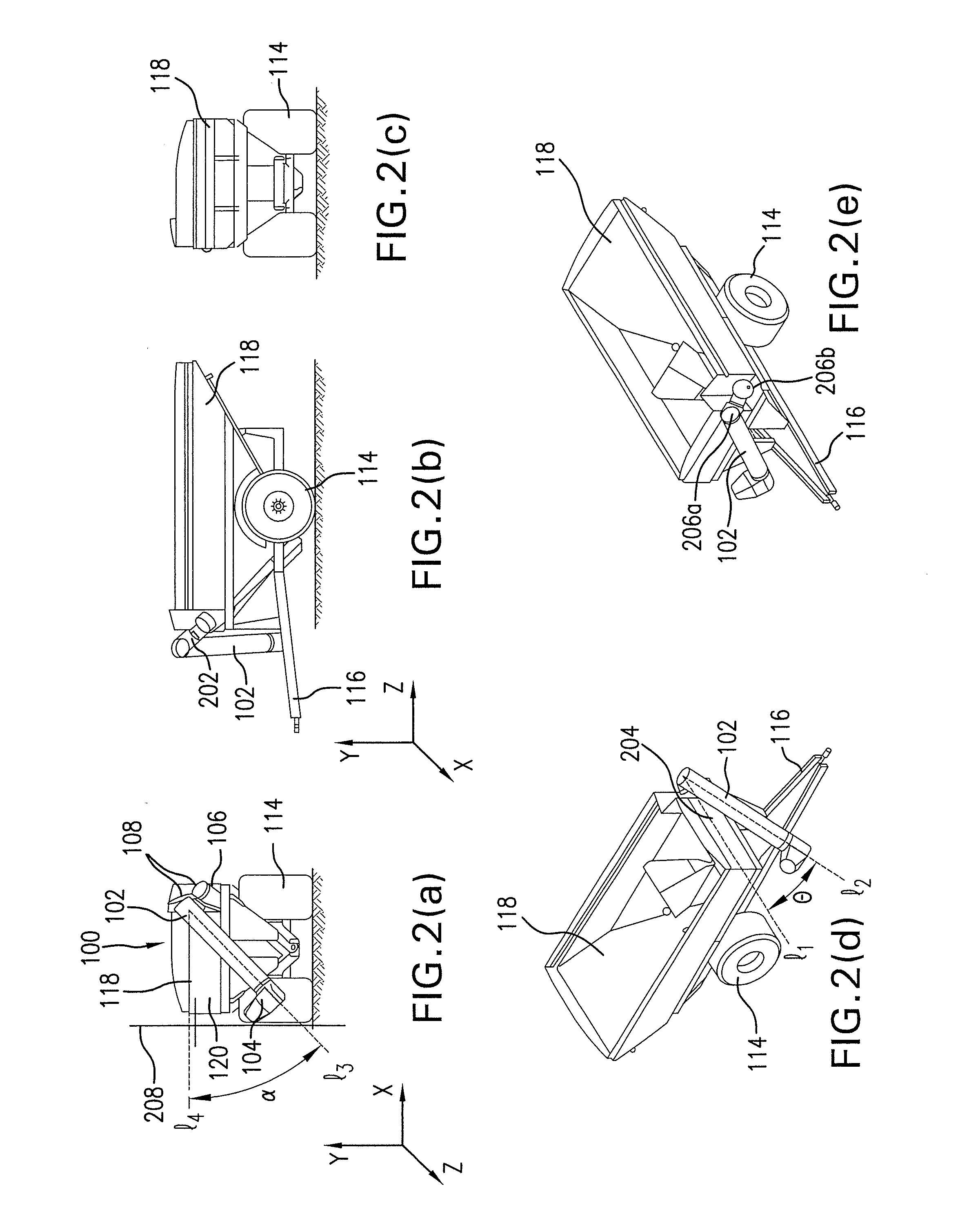

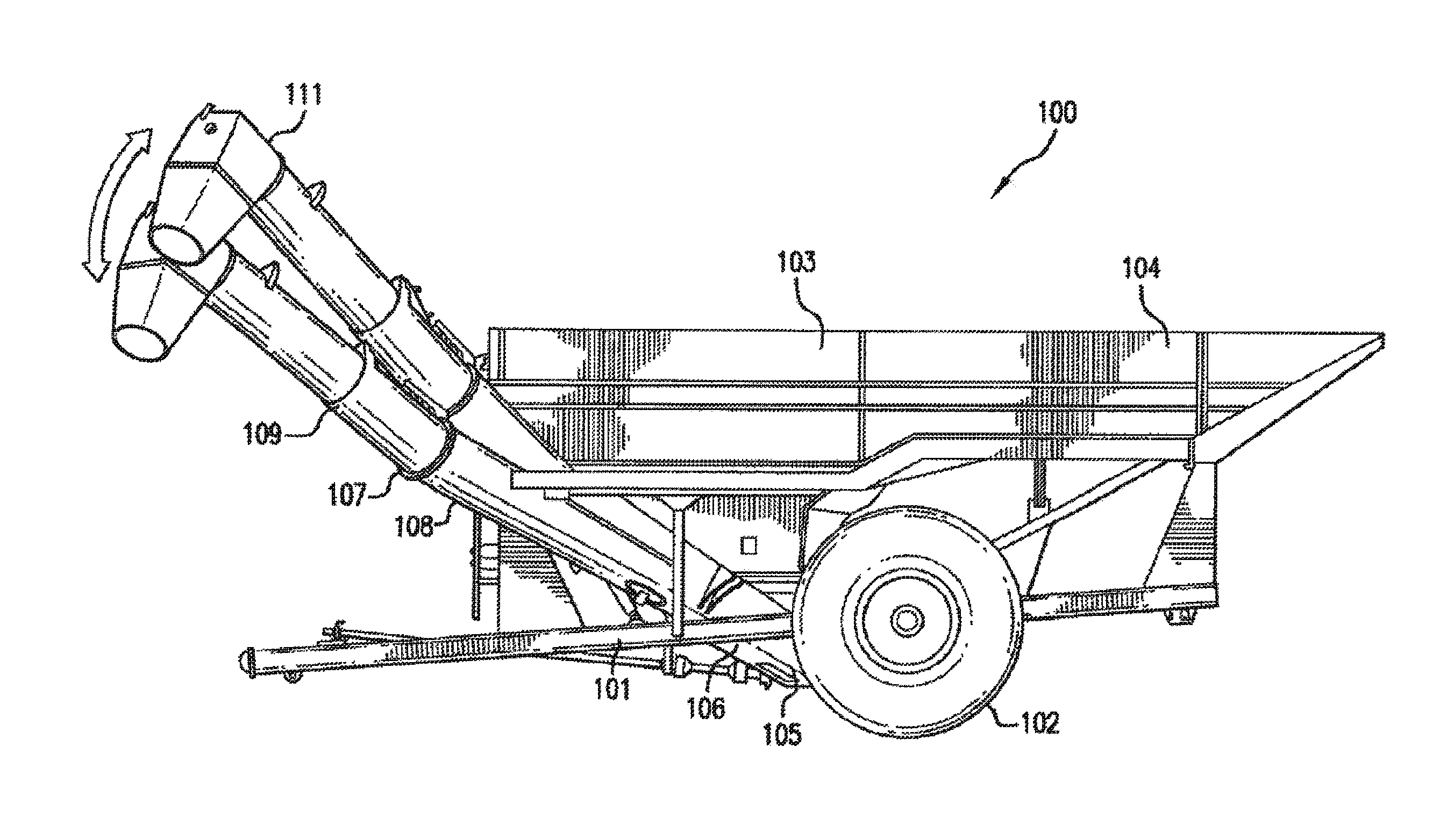

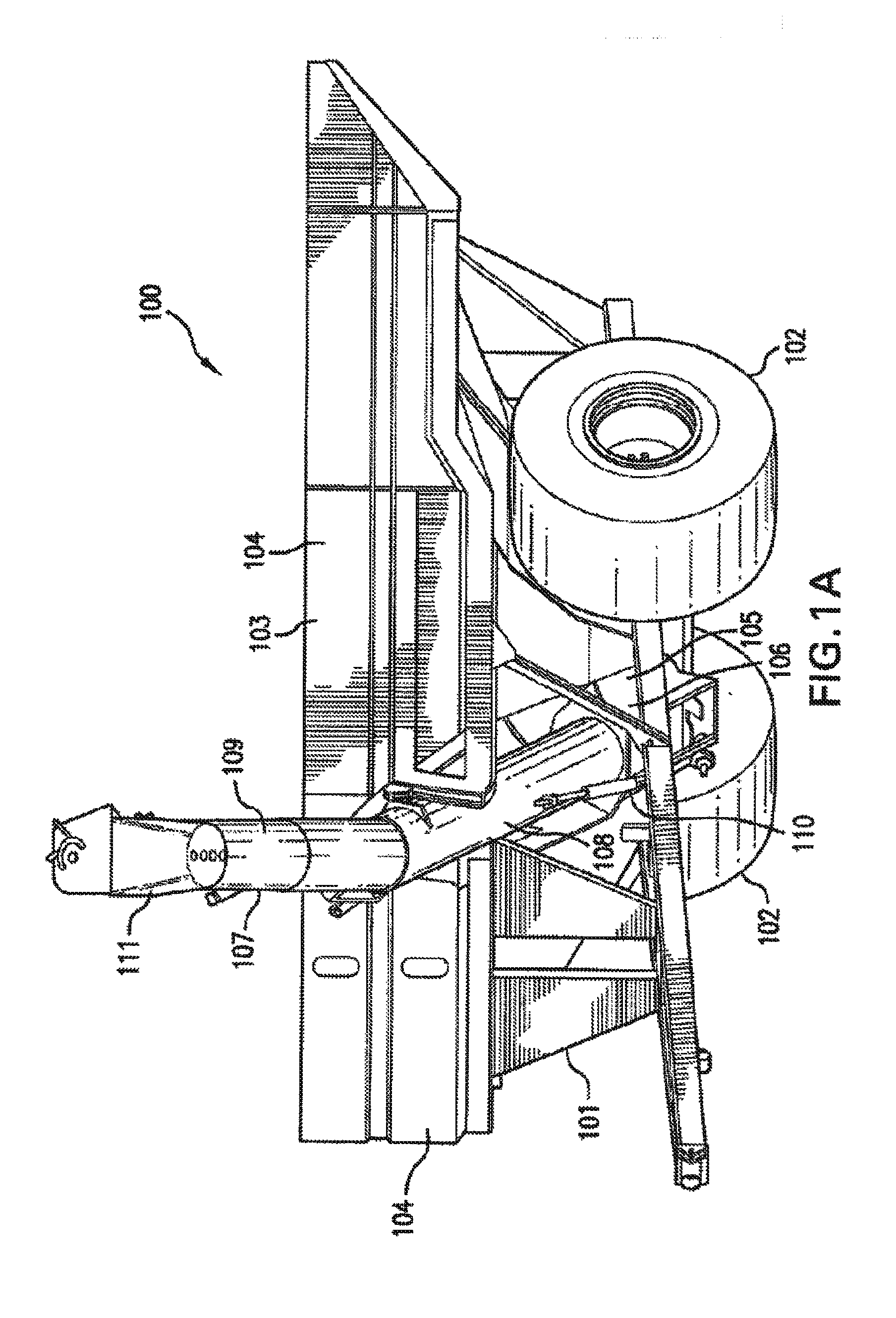

Grain cart with folding auger

InactiveUS20100209223A1Easy to transportEasy to operateAgricultural machinesLoadersEngineeringMechanical engineering

A grain cart and foldable auger assembly having an upper auger assembly portion with a discharge portion, a lower auger assembly portion with an intake portion, and a compound angle joint that allows the upper auger assembly portion to be moved between operating and transport positions. When in an operating position, the upper auger portion and the lower auger portion are offset from each other by an operating offset angle. When in a transport position, the upper auger assembly portion is offset from the lower auger assembly portion by a transport offset angle such that the upper auger assembly portions folded across the front of the grain cart in a non-obstructive and non-protruding manner.

Owner:UNVERFERTH MFG

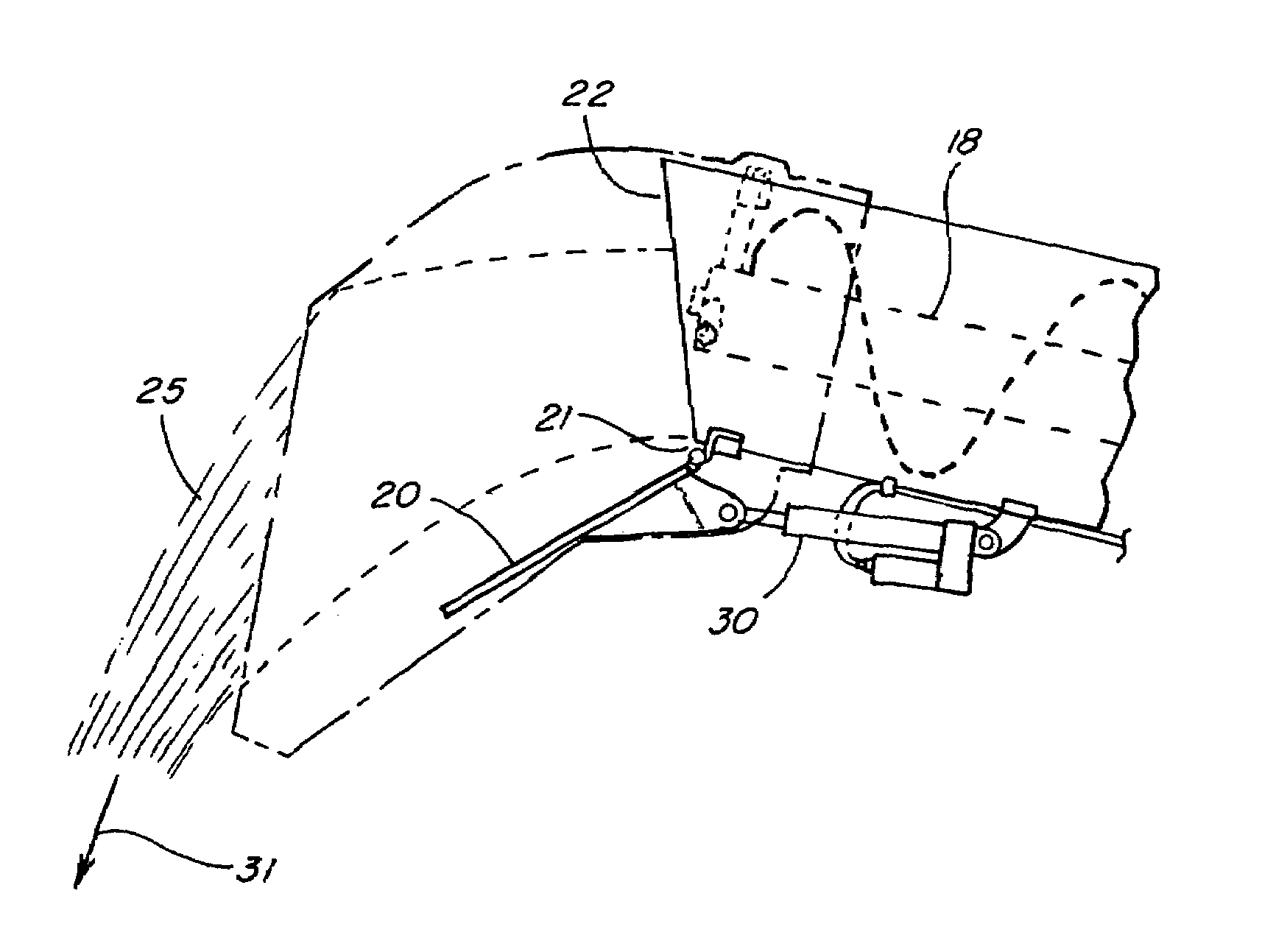

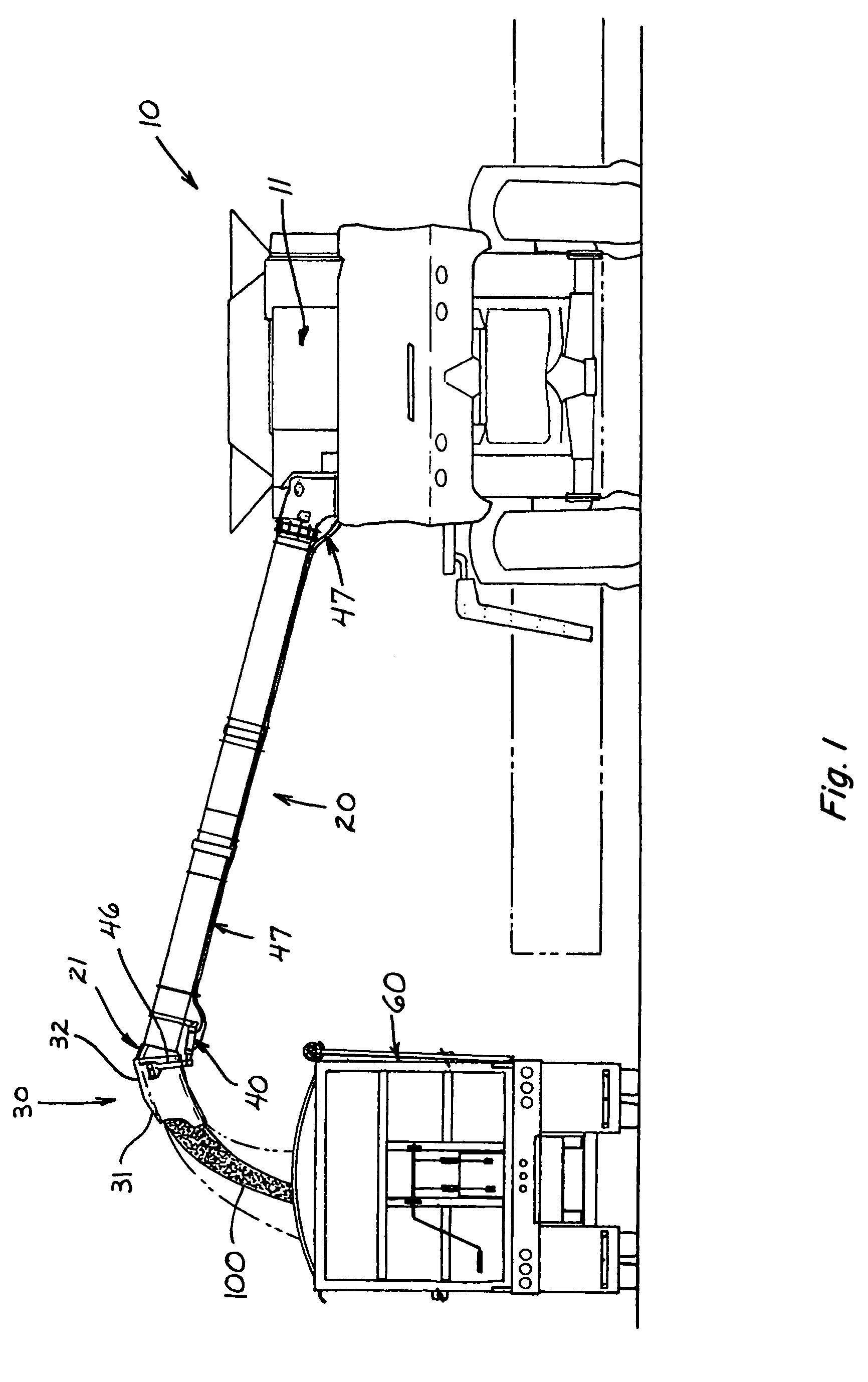

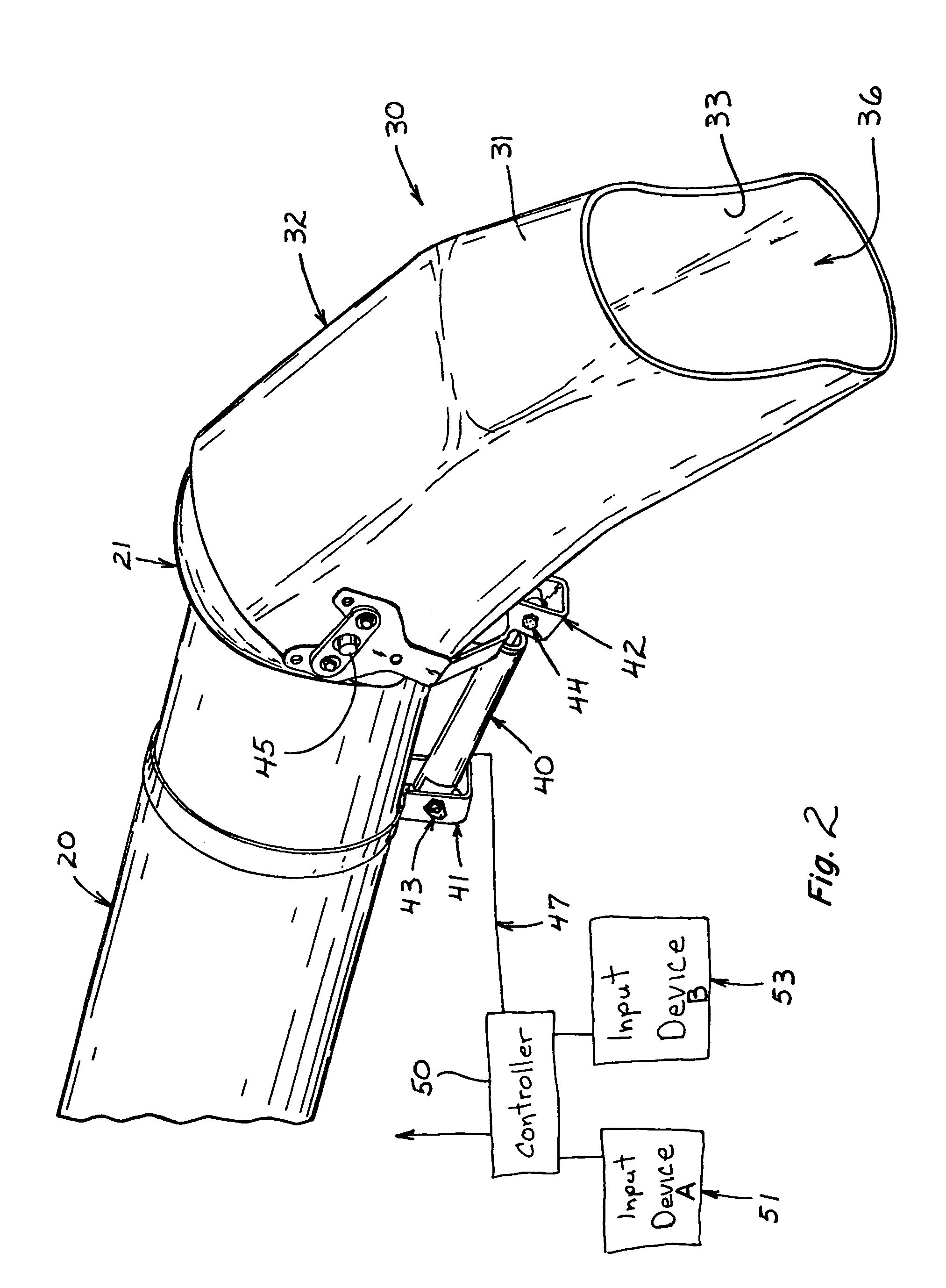

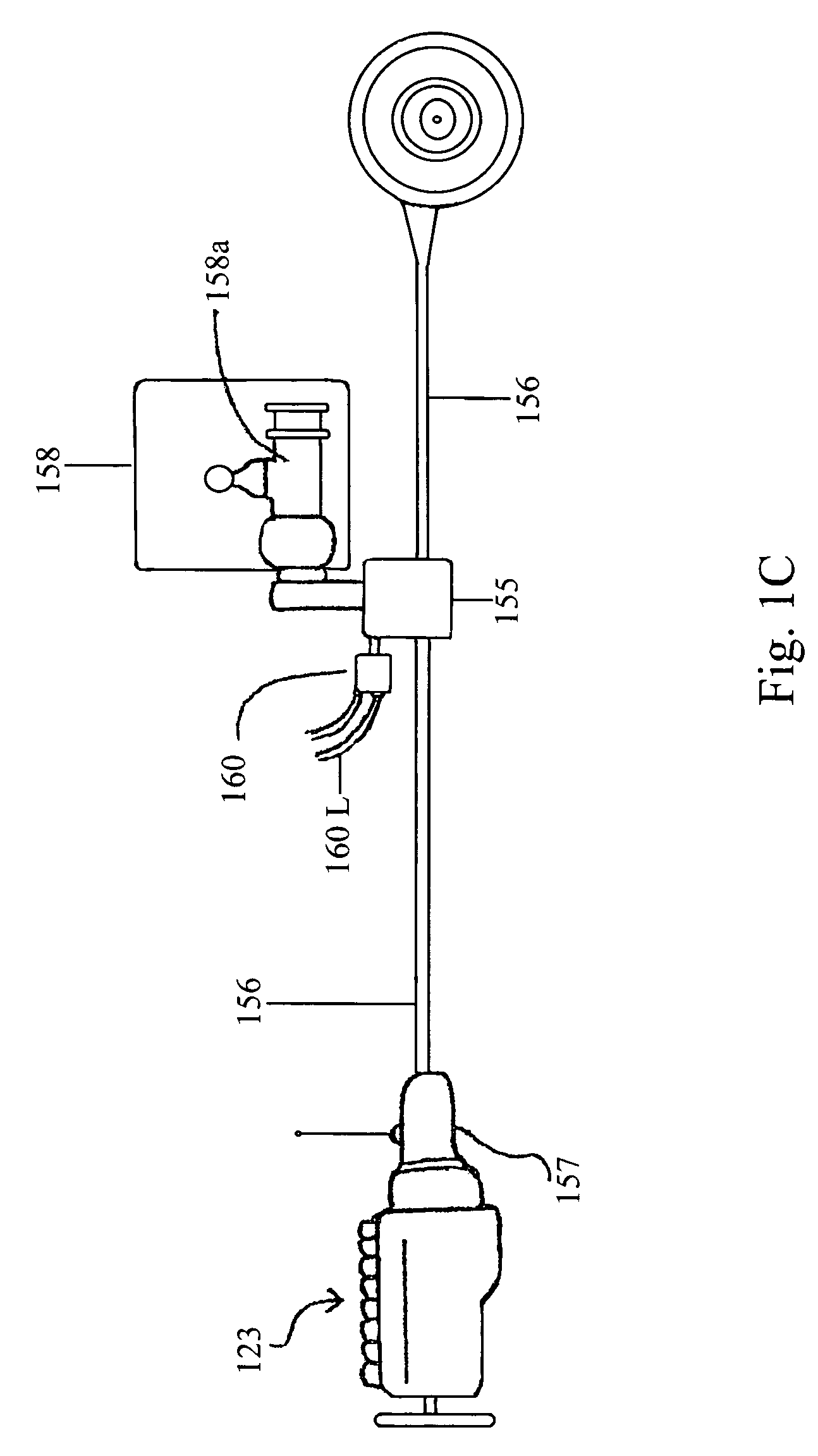

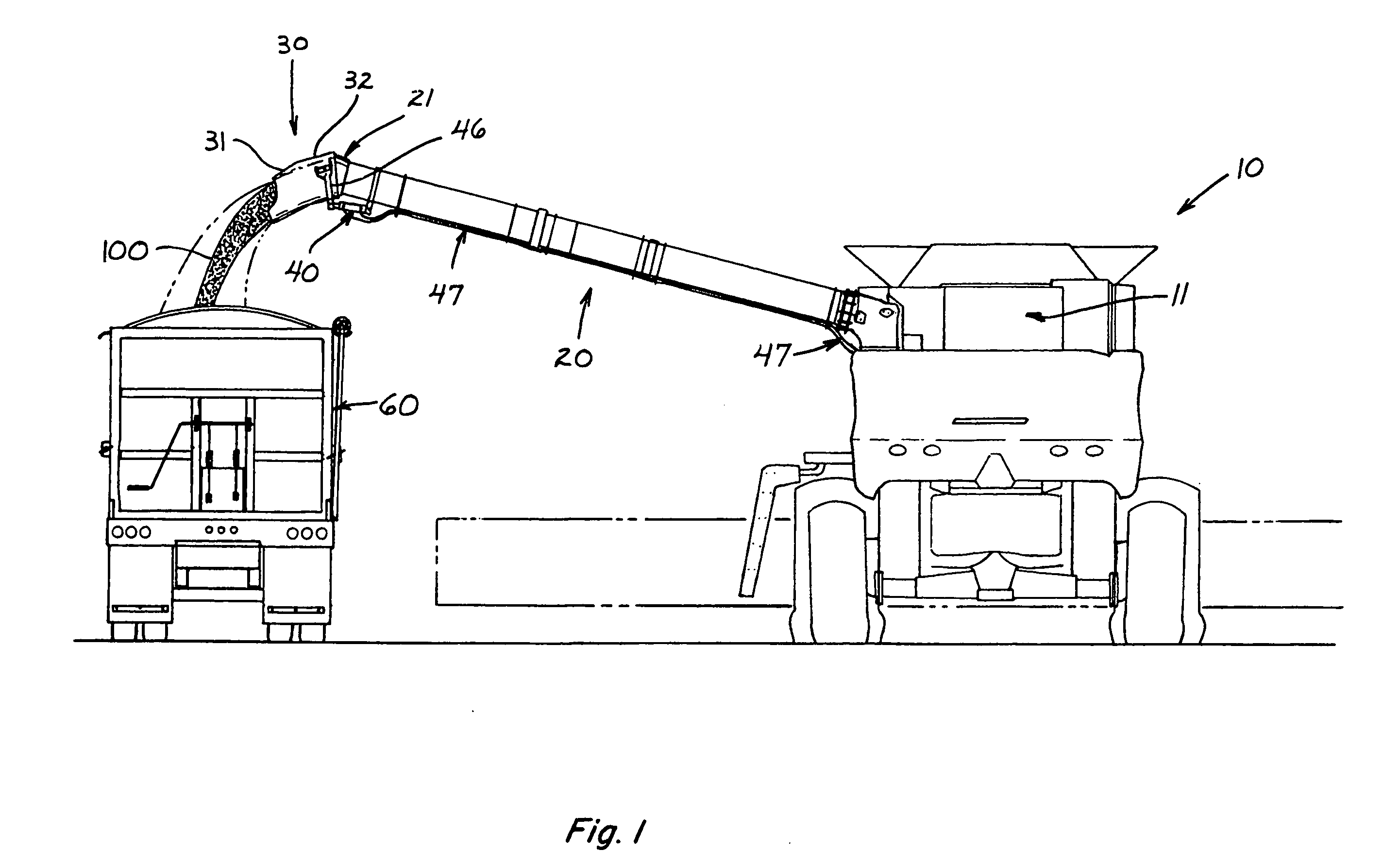

Grain saving, directable unloader boot assembly

A pivoting boot is disclosed for attachment to the unloading auger tube of combine harvesters, and serves as both a grain saving dam against unwanted grain spillage, and a directable spout. The boot permits evenly unloading grain onto, or completely filling, transportation vehicles or storage containers, without having to change the combine position, once it is staged for unloading.

Owner:BLUE LEAF I P INC

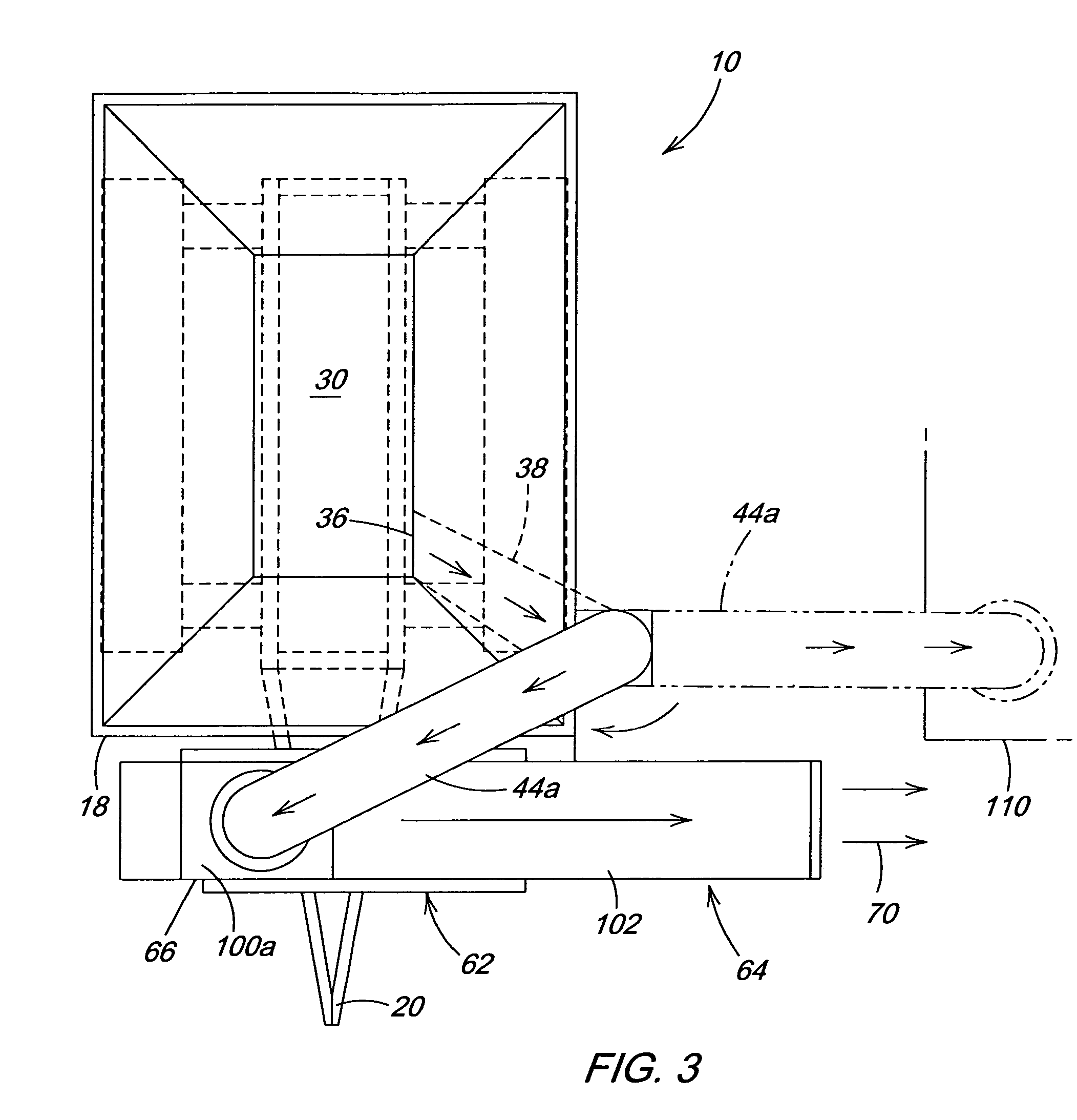

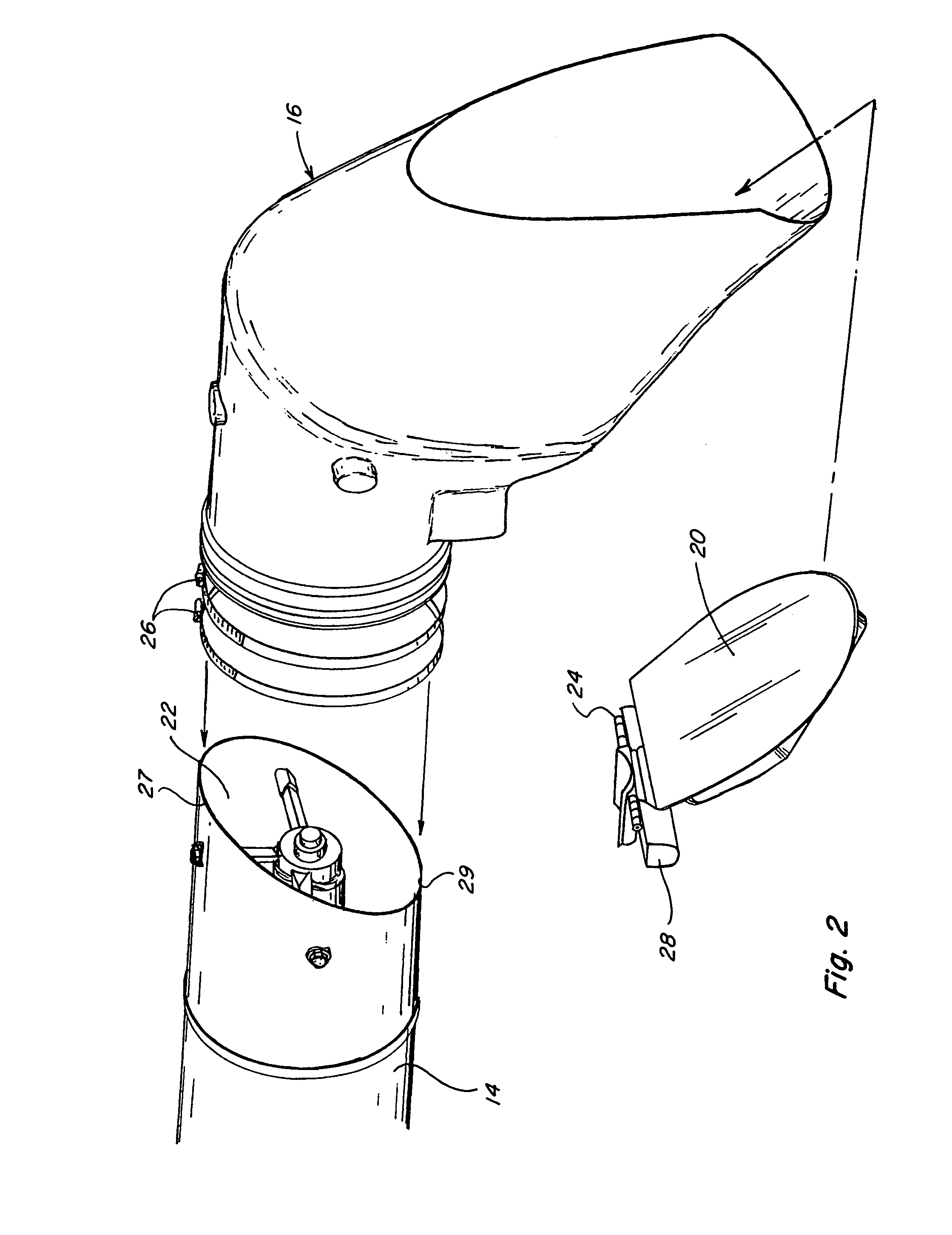

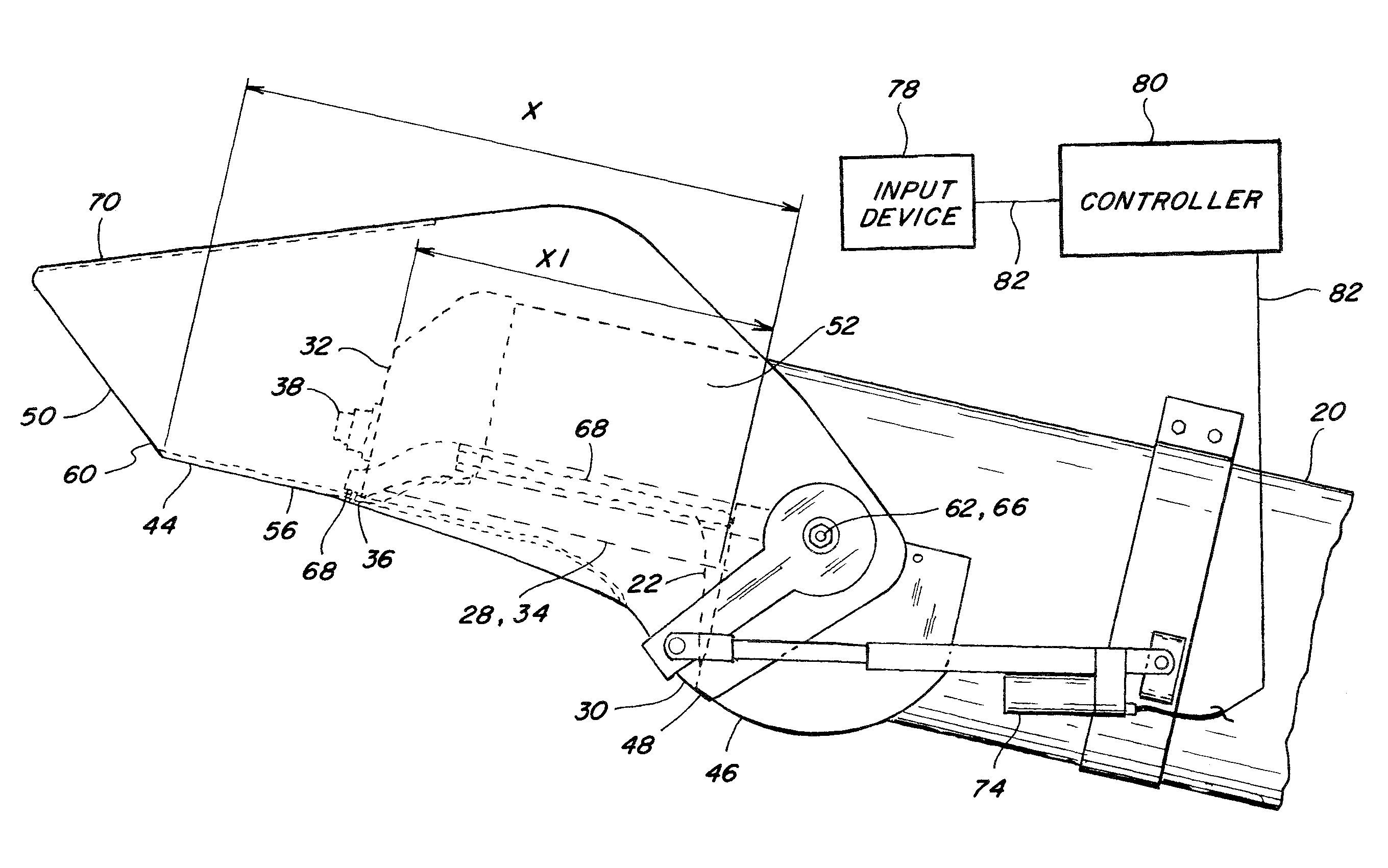

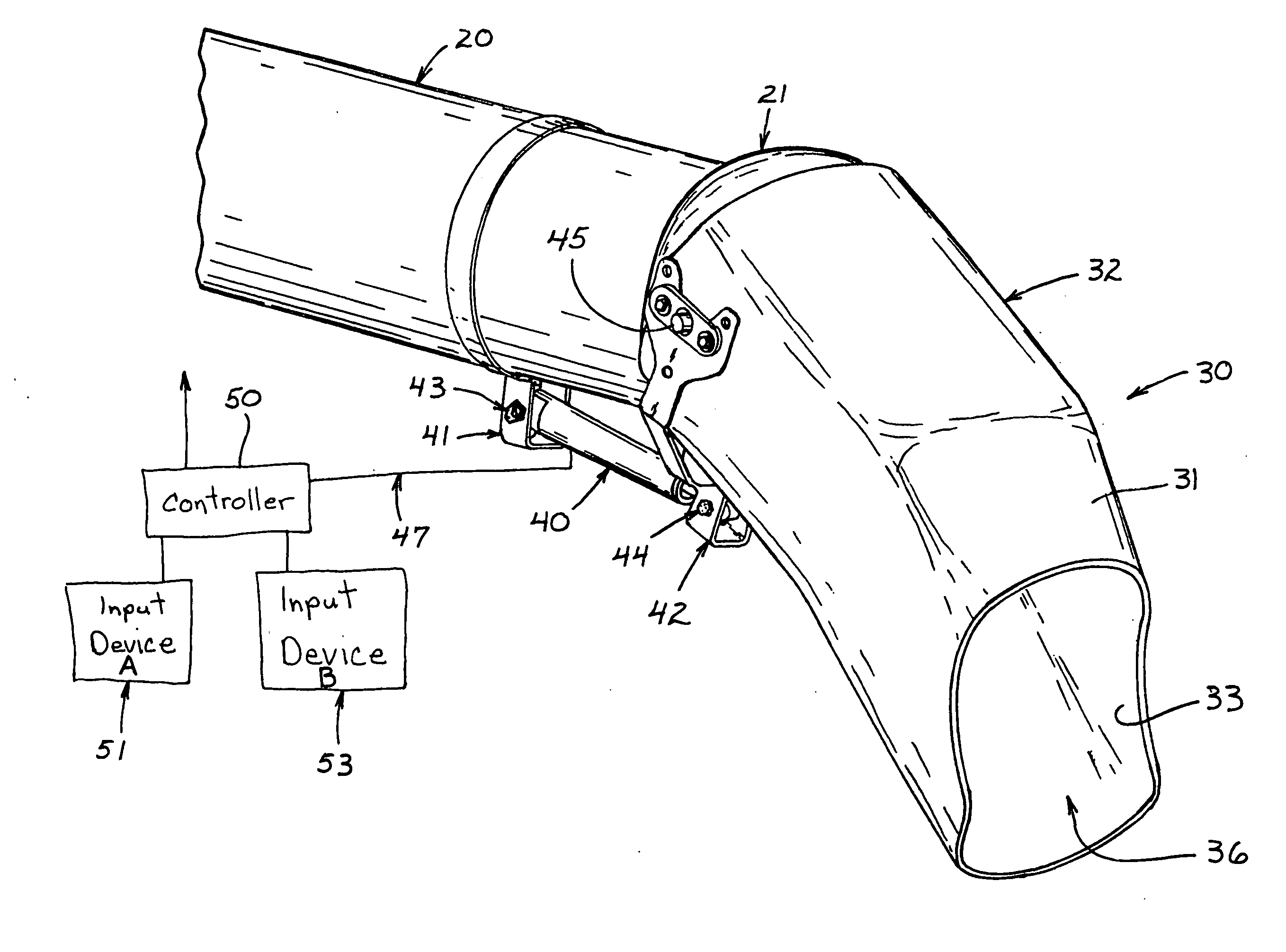

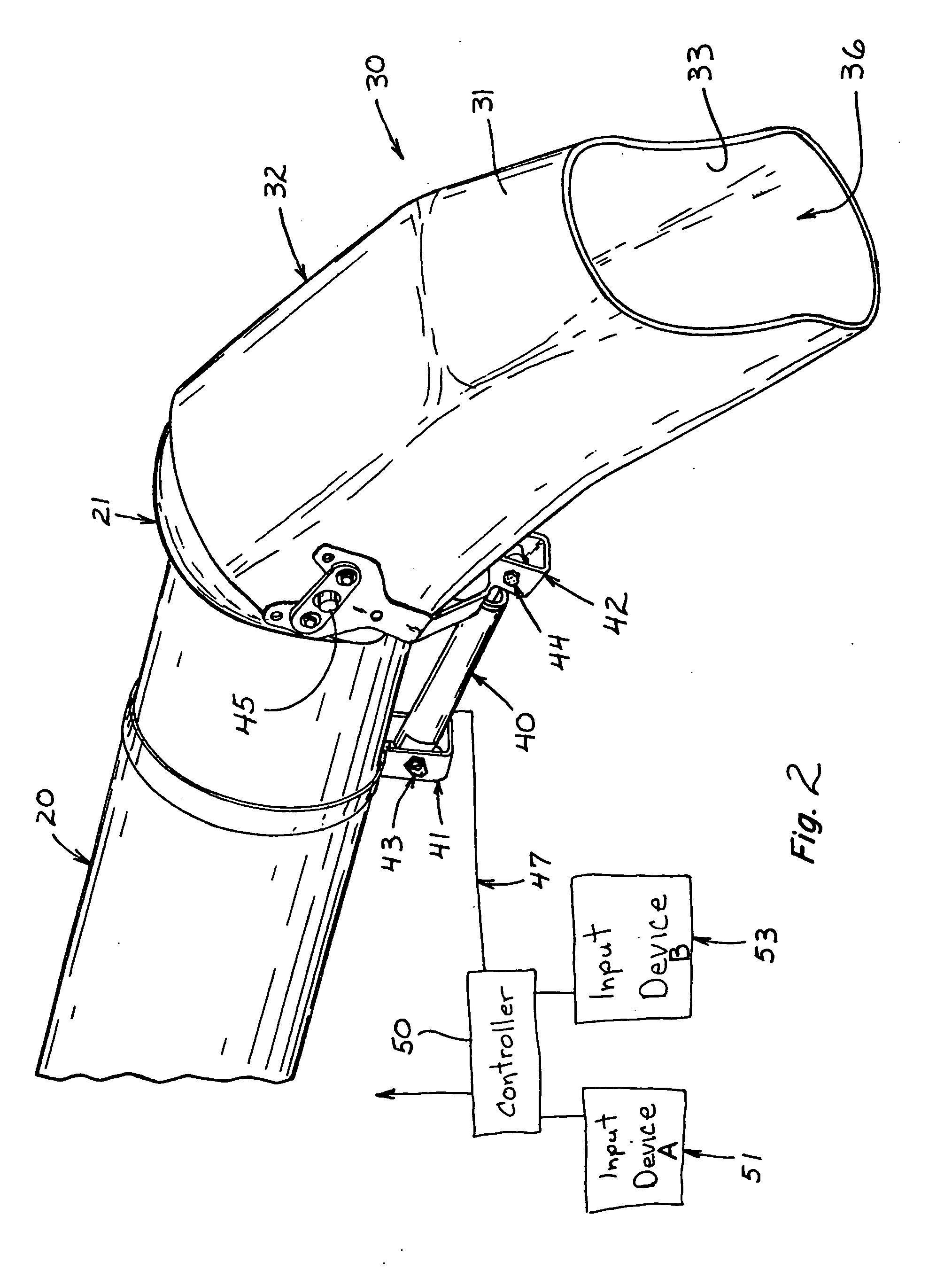

Grain unloading conveyor with directable spout and closure apparatus and system

An unloading conveyor apparatus and system for an agricultural harvester including a spout controllably directable for enabling distributing grain in a desired manner within a region of a receiving storage container, or a transporting truck, wagon, or other vehicle, and configurable as a closure for the conveyor for preventing entry of contaminants and the like. The spout can advantageously extend both the distance and range of variability of grain delivery location, and the free end of the spout can include a cover for improving grain delivery accuracy and wind resistance, and a break open feature to prevent damage. The spout can also be rotatable laterally about the end of the conveyor.

Owner:BLUE LEAF I P INC

Grain tank unloader and clean out control

An unloader control for an unloader conveyor and grain tank conveyor of an agricultural combine, which, when an unload command is received, will automatically initiate operation of the unloader conveyor to commence conveying grain in an inlet end thereof toward the outlet end thereof so as to allow smooth transition of grain from the grain tank conveyer to the inlet end of the unloader conveyor, then automatically initiate operation of the grain tank conveyor for moving grain into the inlet end of the unloader conveyor, and, when a clean out command is received during operation of the unloader conveyor and the grain tank conveyor, will automatically cease operation of the grain tank conveyor, then, after a sufficient time period for the unloader conveyor to convey substantially all of any grain therein through the outlet end, automatically cease operation of the unloader conveyor.

Owner:BLUE LEAF I P INC

Grain cart with directional discharge

A grain cart grain discharge including a pivotable discharge chute having a first position to discharge grain from a first side of a grain cart and a second position to discharge grain from an opposite side of the cart. The discharge chute is movably mounted on a guide and pivotable about the central axis of a grain supply auger mounted at the bottom of a grain hopper. A discharge head rotatably located on an end of the discharge chute opposite the supply auger and a control located on a vehicle, the control controlling the movement of the chute from the first position to the second position and controlling a rotational position of the discharge head without leaving the cab of the vehicle.

Owner:HOLLENBERG DAVID H

Vehicle dispensing system

A flowable material delivering vehicle in combination with a material dispensing system including a fixed conveyor extending continuously from a position located adjacent a vehicle container outlet aperture to a position located adjacent a vehicle cab front end. A dispensing adapter is attached to the vehicle for receiving a portion of the flowable material when the latter emanates from the fixed conveyor. In one embodiment, the dispensing adapter includes a pivotable conveyor pivotally attached to the vehicle and a configuring mechanism. The configuring mechanism allows the pivotable conveyor to pivot between a stowed configuration wherein it lies in a generally proximal and parallel relationship relative to an edge of the vehicle and a working configuration wherein the pivotable conveyor extends away from the vehicle so as to allow discharging of the flowable material away from the vehicle. In another embodiment, the dispensing adapter includes a dispensing chute defining a chute inlet end positioned adjacent the fixed conveyor discharge section, a laterally and downwardly extending chute body and a chute outlet end positioned laterally relative to the vehicle.

Owner:YAHOO INC

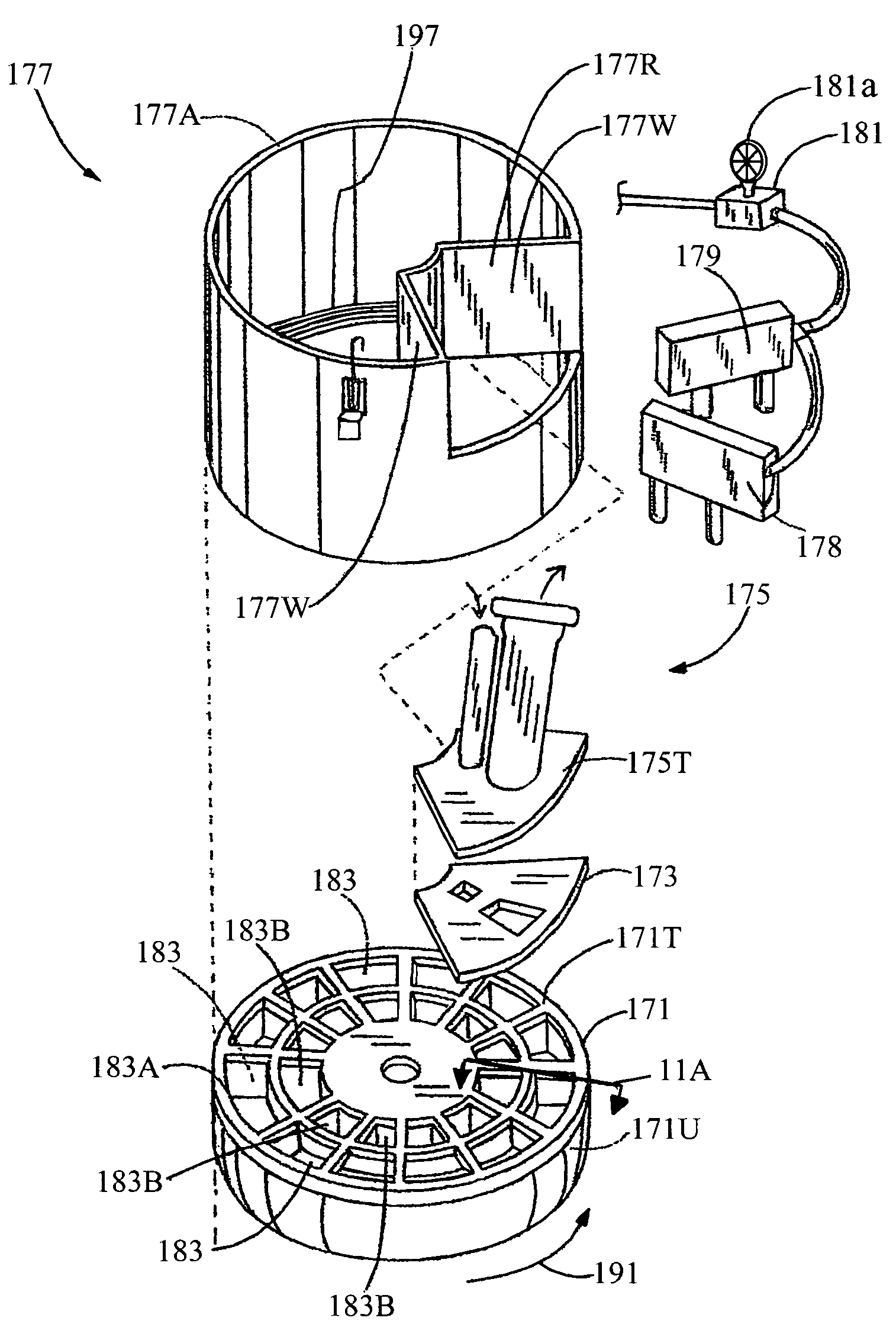

Apparatus and method for moving and placing granulate material

ActiveUS7094004B2Easy to operatePrevent leakageBulk conveyorsTransportation itemsParticulatesAirlock

A method and system are disclosed for moving and placing in hard to reach locations granular and other particulate material such as sand, gravel, earth and similar materials. The system includes an improved augar for moving the material and an improved rotary airlock mechanism designed to withstand the abrasive action of the particulate material and at the same time move the material several hundred feet through a flexible conduit for placement in a pre-designated location. A system and apparatus is also disclosed for transporting on one vehicle all of the devices needed at a remote site for operation the particulate placement system, including a front loader.

Owner:AIR PUMP HLDG LLC

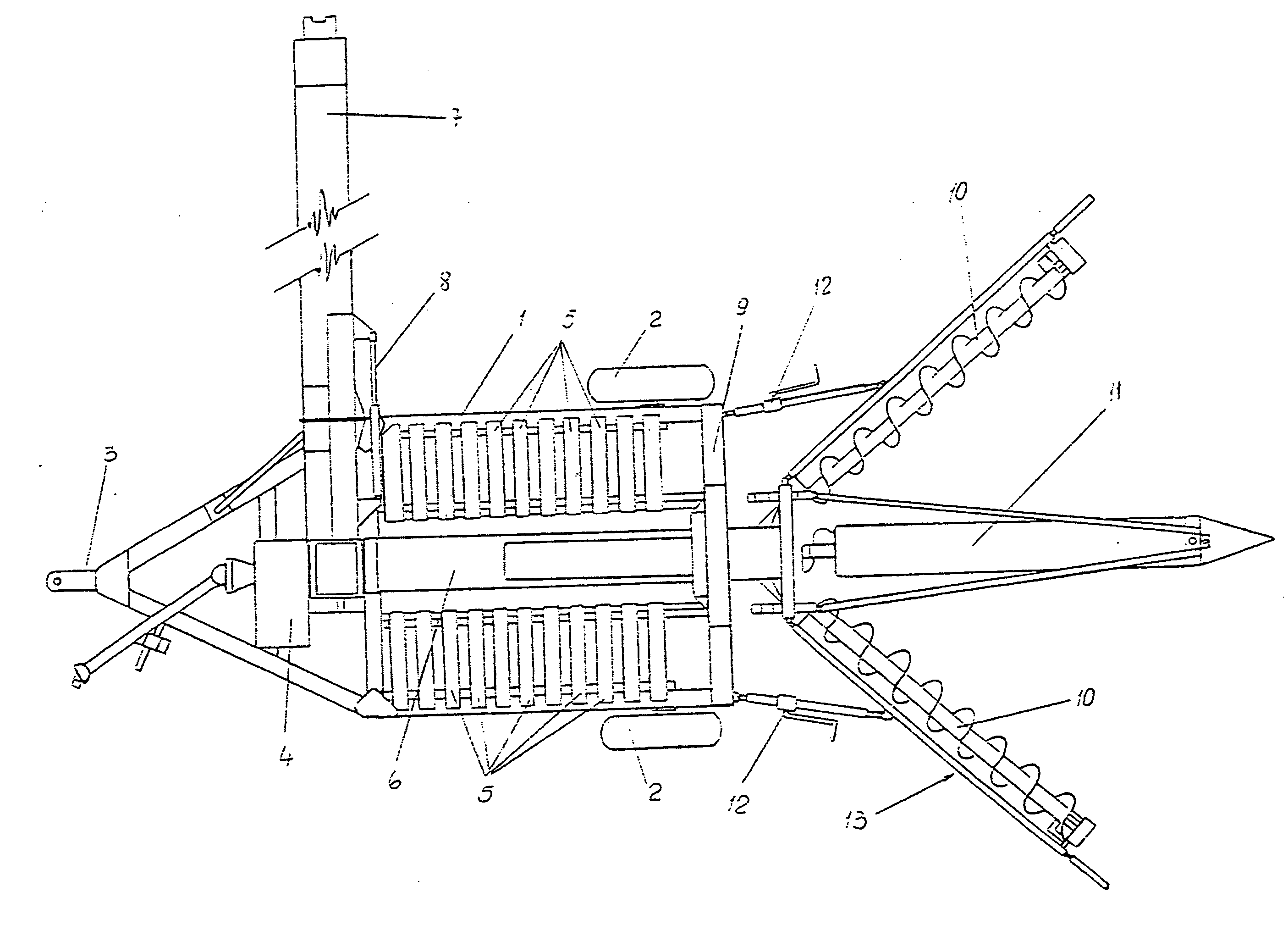

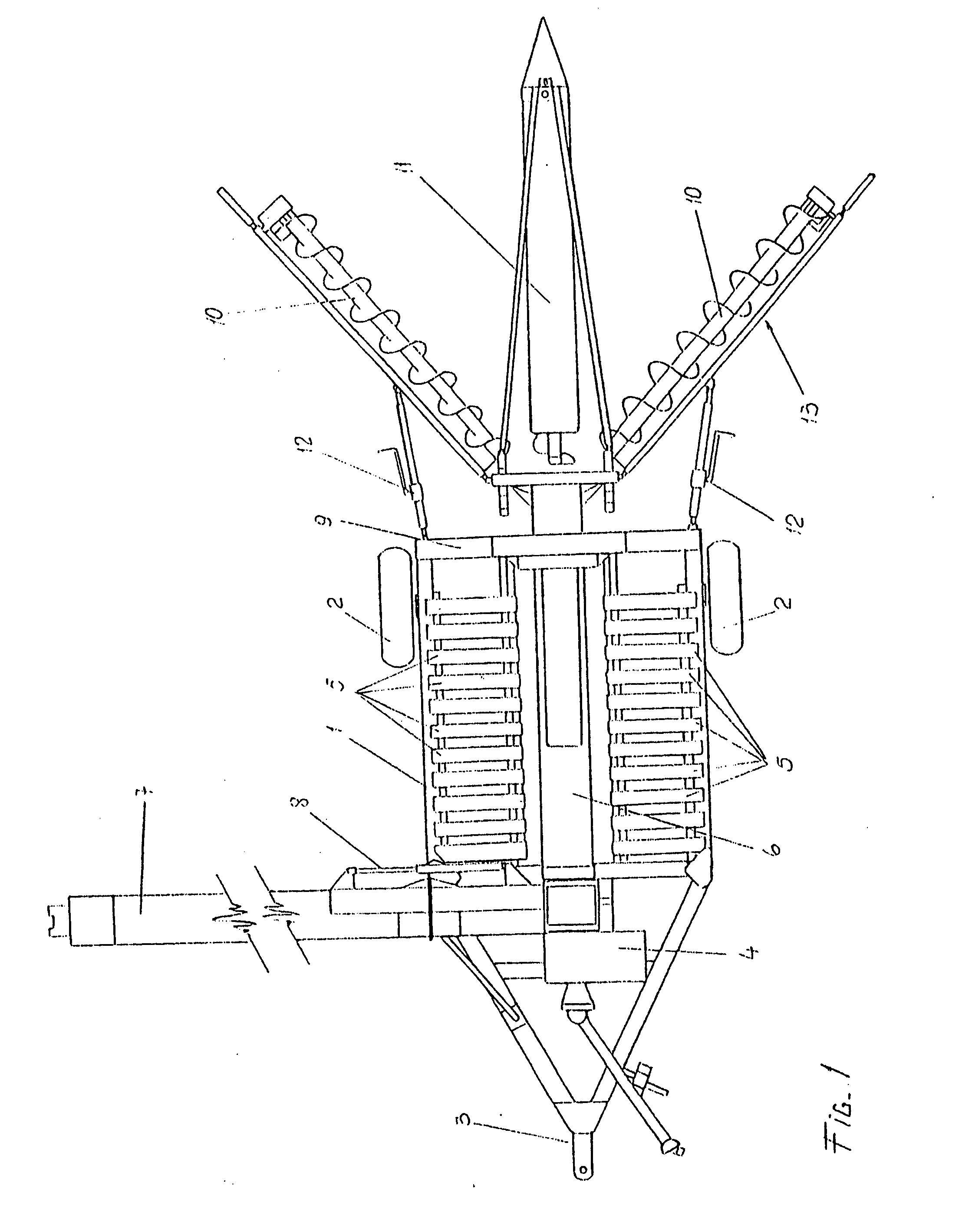

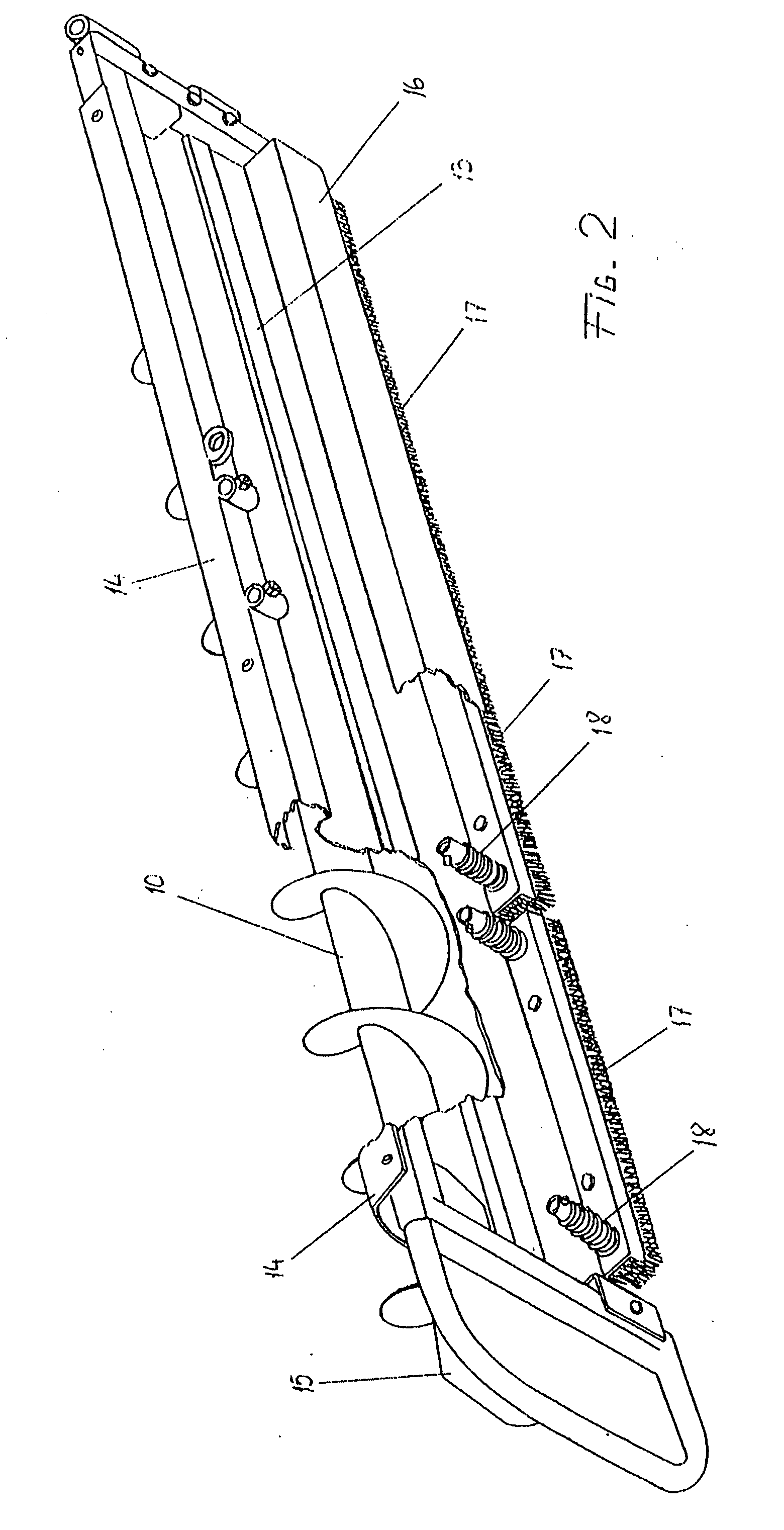

Extractor of dry grains from a silo bag

InactiveUS20090041566A1Agriculture tools and machinesFertiliser distributersHydraulic cylinderHydraulic circuit

Owner:CARLOS MAINERO & CIA SAICFI

Method of controlling a conveyance rate of grain of an unloader system

A method of controlling a conveyance rate of grain of an unloader system, including providing a grain holding device and an unloader in communication with the grain holding device, the unloader having an inlet for receiving grain from the grain holding device and an outlet for discharging grain. An apparatus within the grain holding device is operable for controllably feeding grain within the grain holding device to the unloader. The method includes monitoring a parameter associated with a power source of the apparatus, and comparing the parameter of the power source to a maximum predetermined threshold value. The method includes automatically controlling the conveyance rate of grain of the apparatus to the unloader.

Owner:BLUE LEAF I P INC

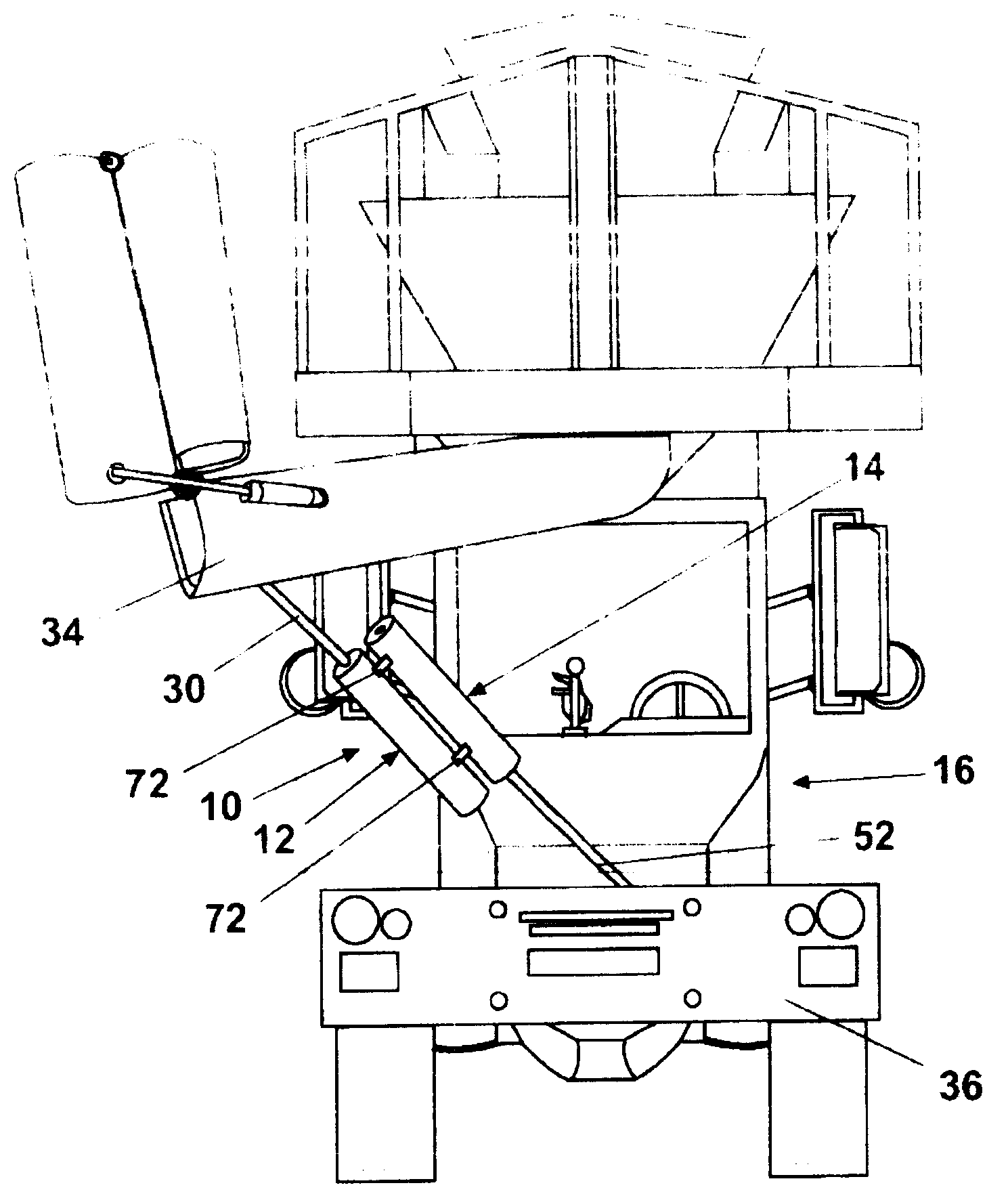

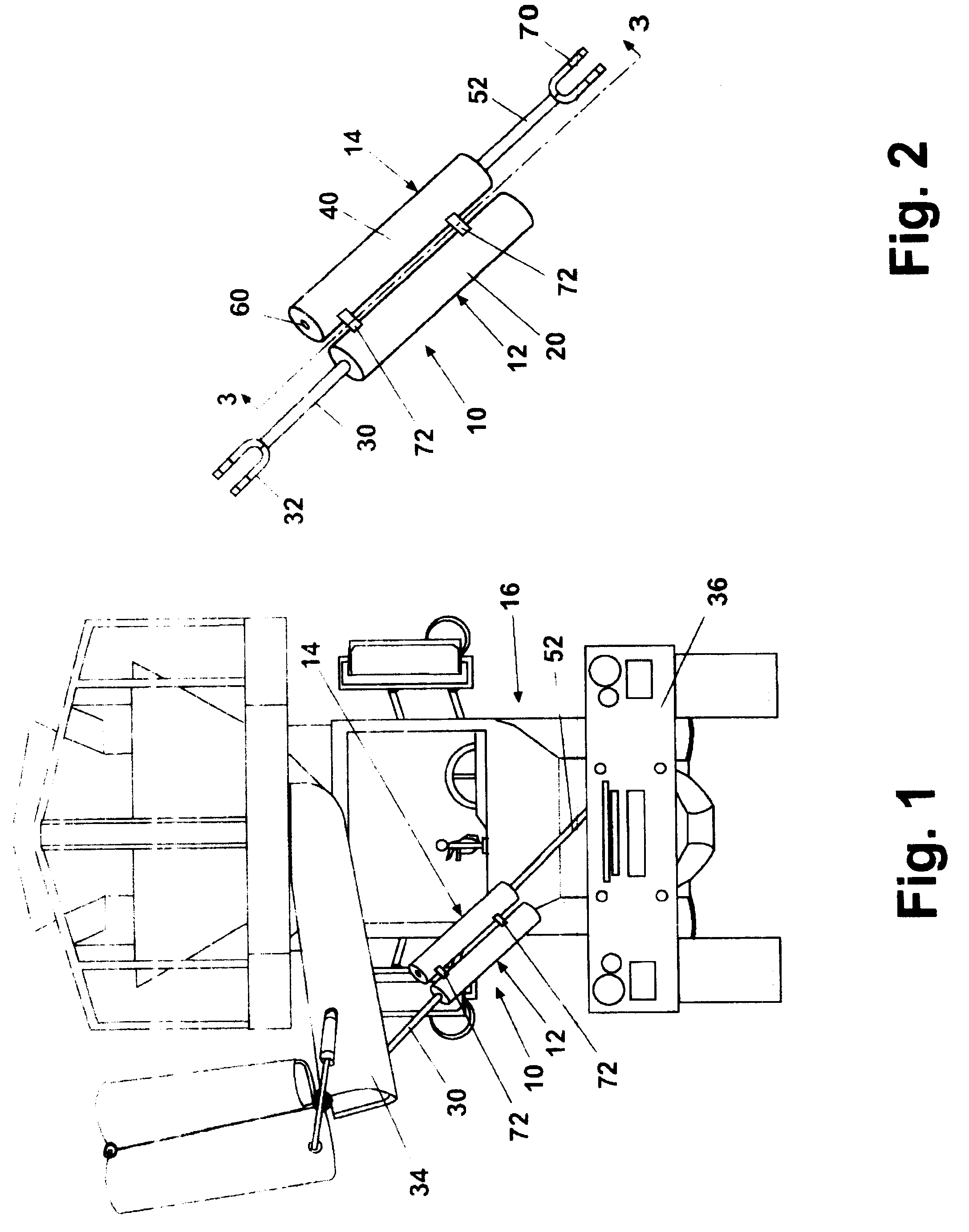

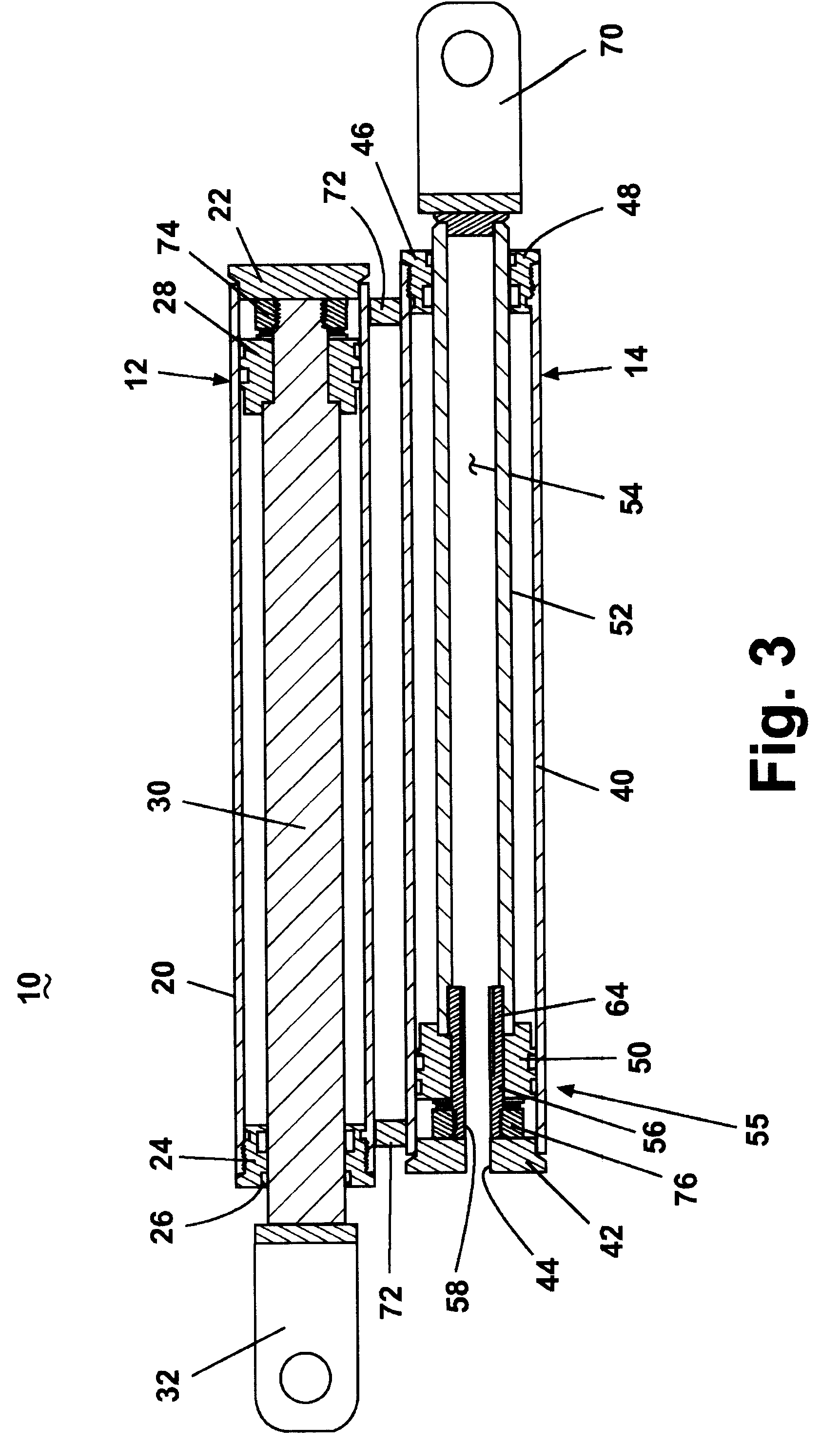

Hydraulic actuator assembly with rotation restraint

InactiveUS7033066B2Prevent movementPrevent rotationDischarging apparatusMixing operation control apparatusActuatorControl theory

A hydraulic actuator assembly comprises a pair of hydraulic actuators having cylinders, pistons, and piston rods that are ganged together for extension of their respective piston rods in longitudinally opposite directions wherein at least one of the actuators comprises an anti-rotation mechanism that prevents rotation of the actuator assembly about its longitudinal axis. The anti-rotation mechanism comprises an axial anti-rotation rod rigidly attached to a cylinder having a non-circular cross-section slidably complementary to a non-circular aperture in a hollow piston rod. The piston rod can travel longitudinally along the anti-rotation rod, but is prevented from rotating by the non-circular cross-section.

Owner:HELDER BRUCE A

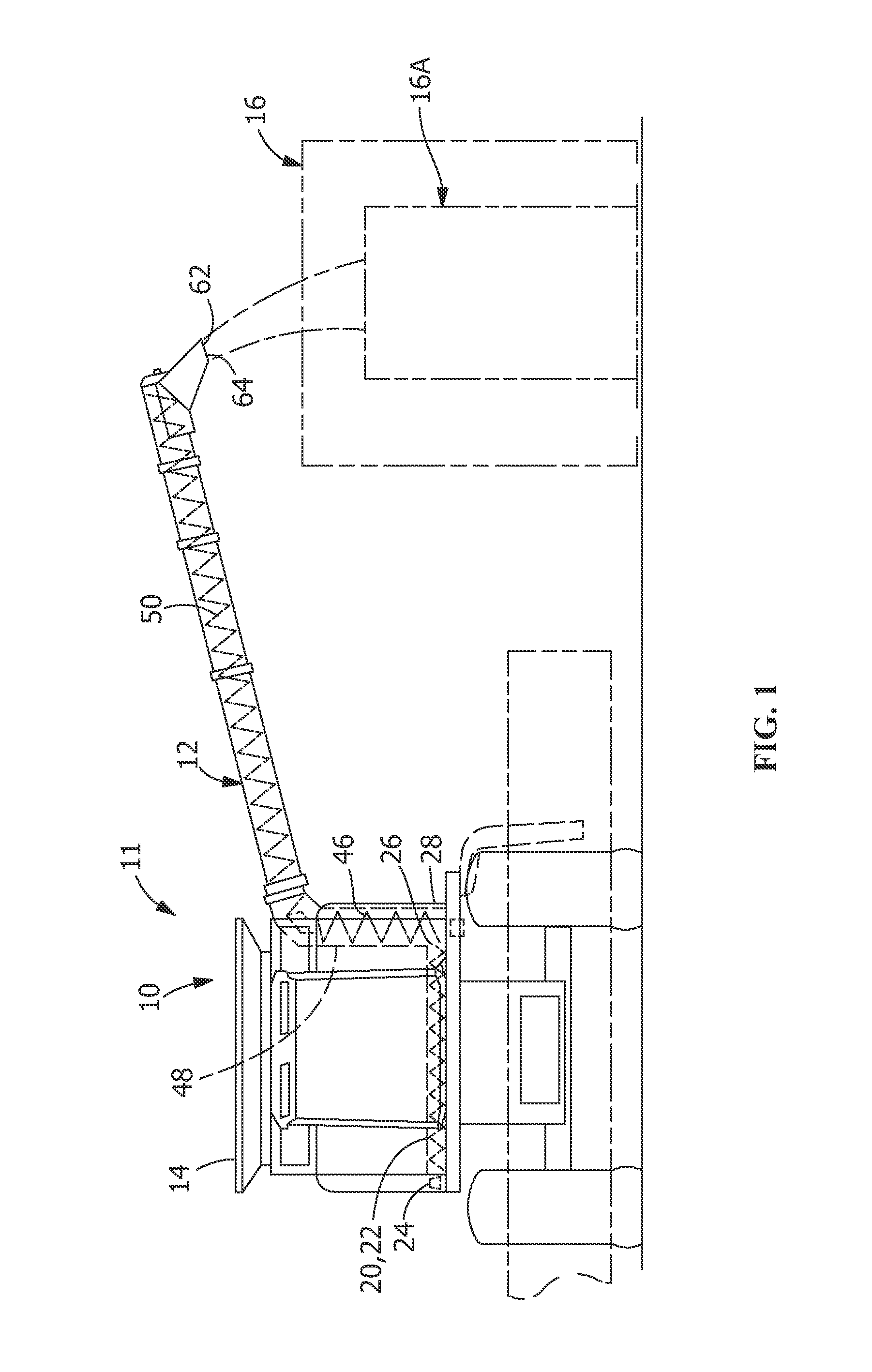

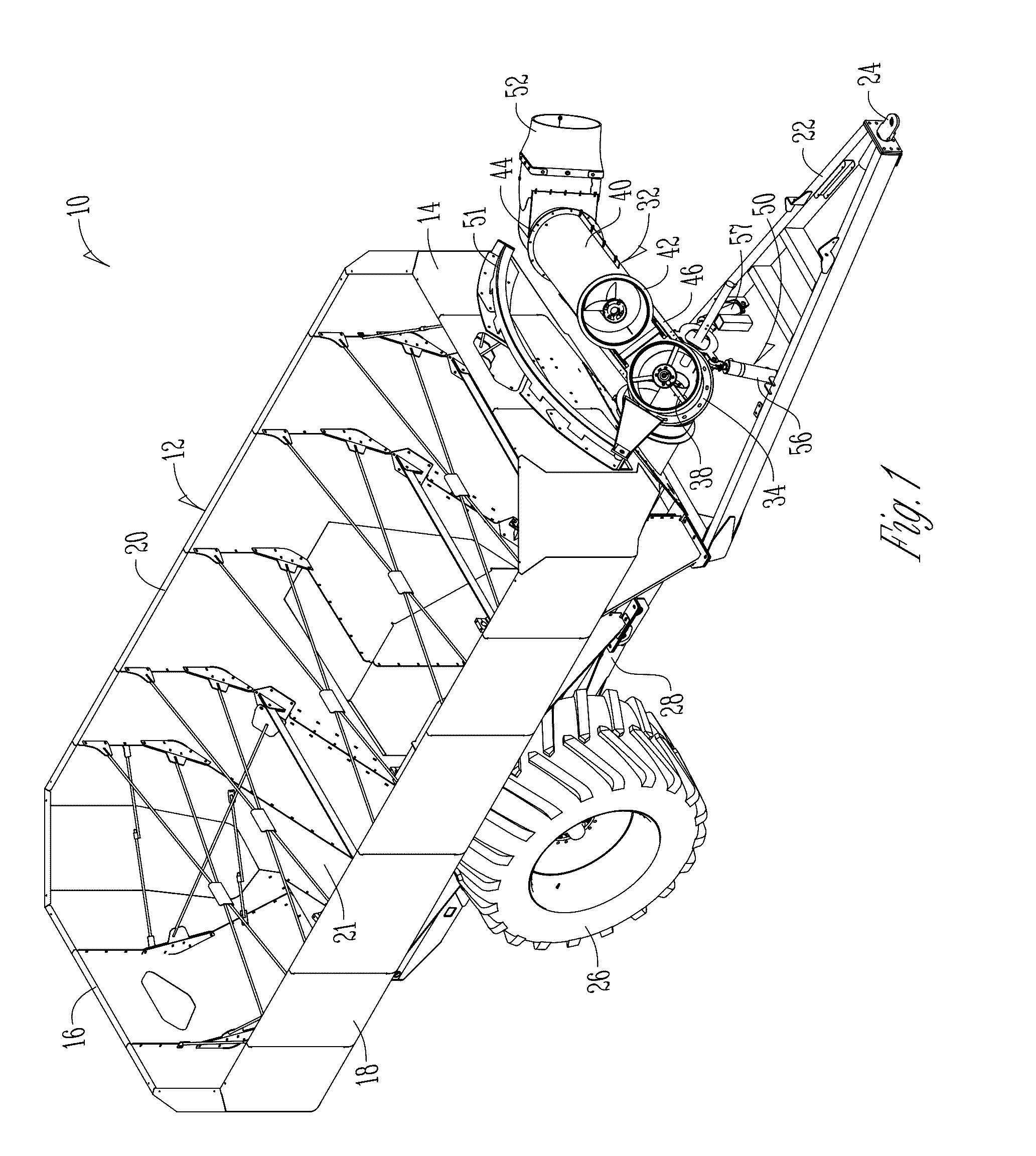

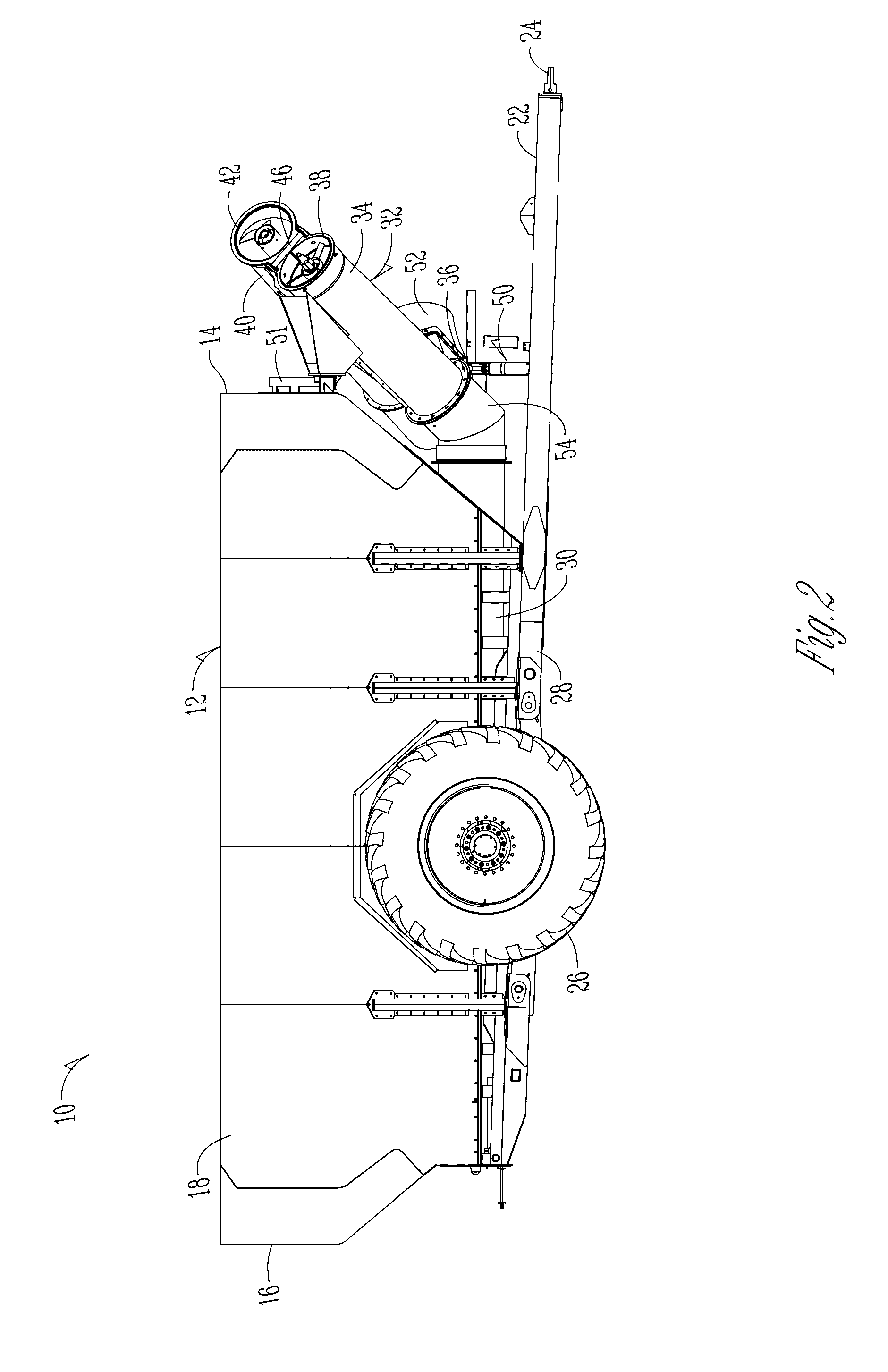

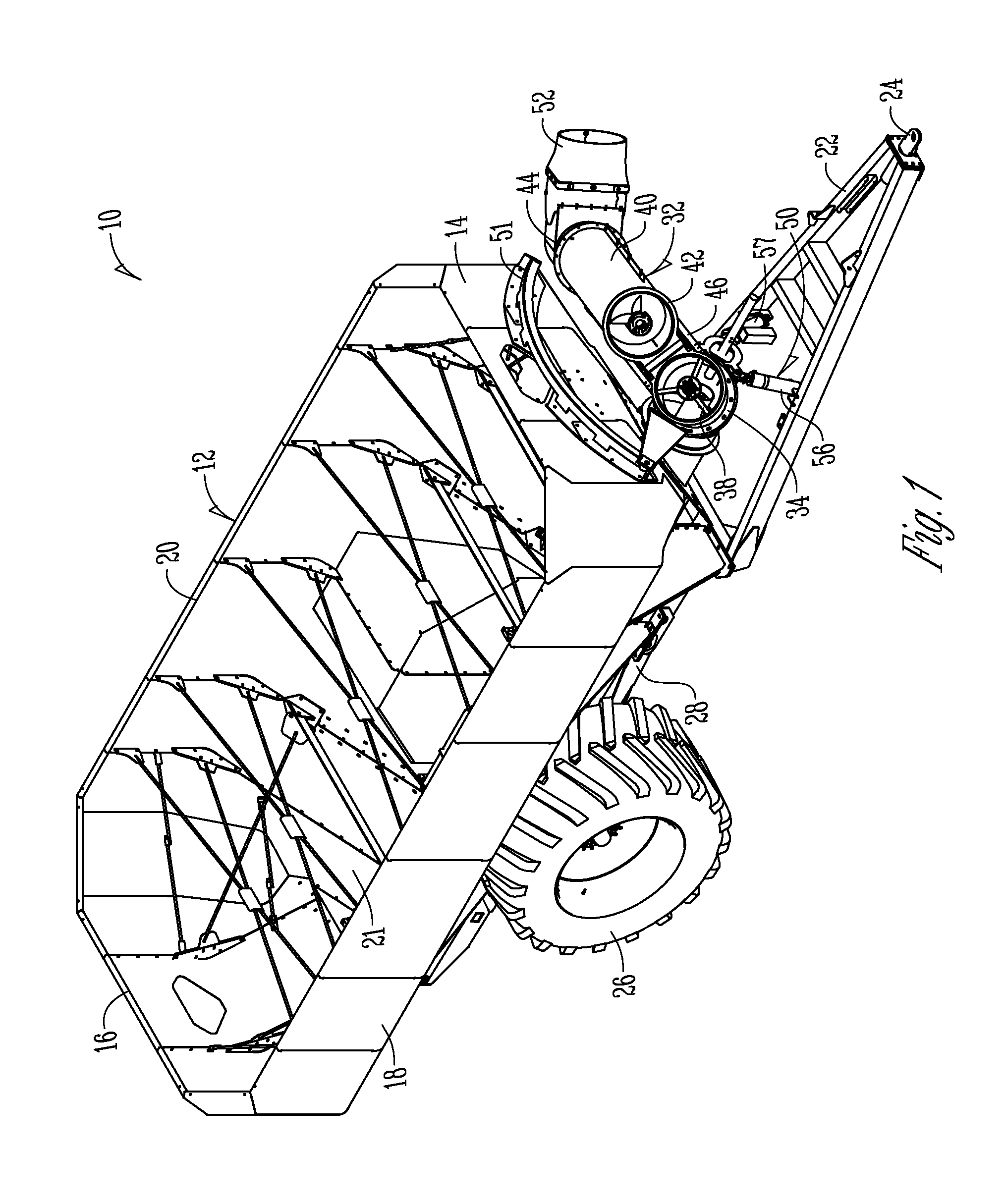

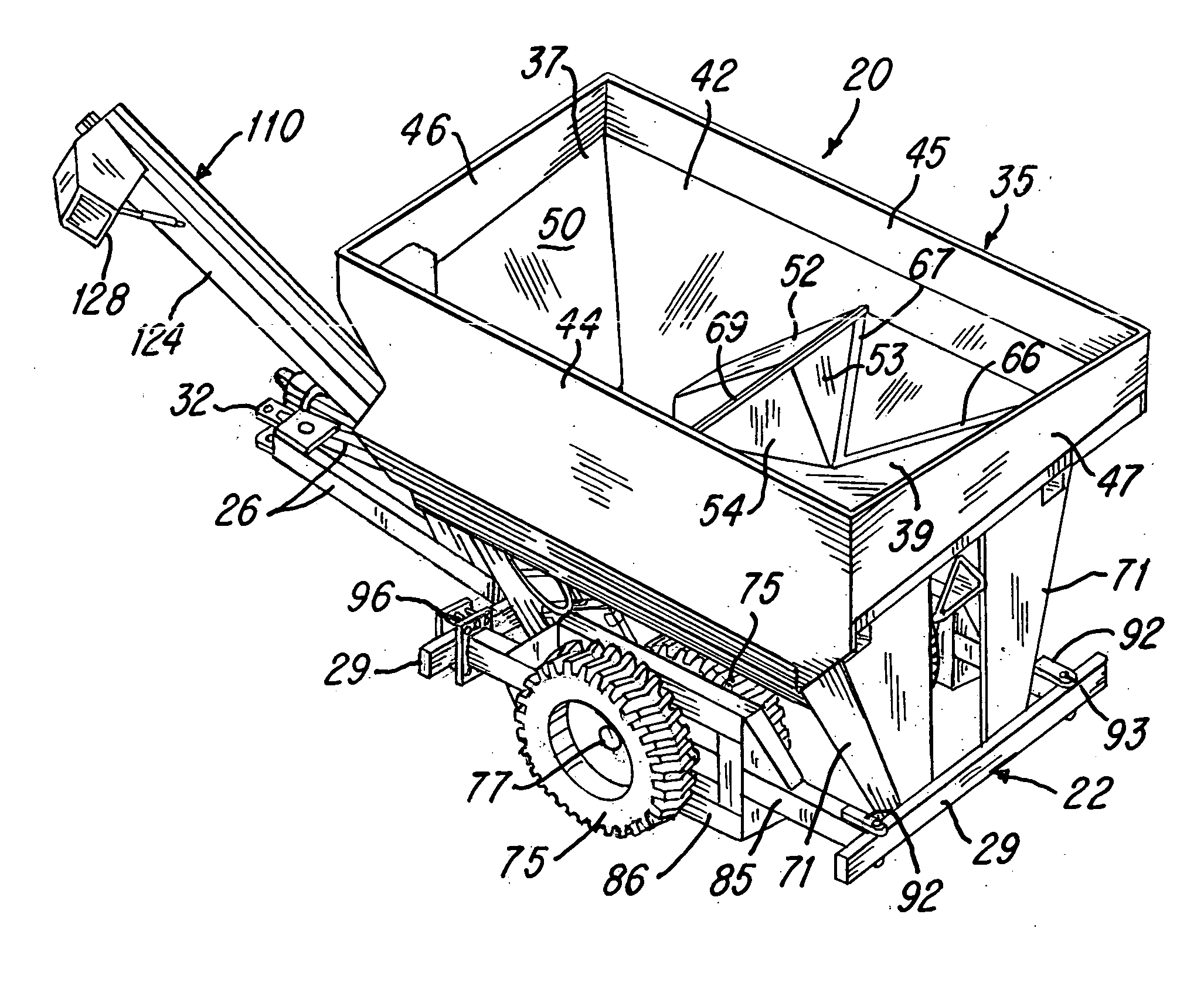

Adjustable grain cart auger

InactiveUS20170055454A1Overcome the deficiencies in the art.Agricultural machinesLoadersEngineeringTruck

An agricultural wagon for moving particulate material from within the wagon to a separate storage vessel is provided. The wagon includes a bin defined by walls. The wagon may also include one or two augers, such as a floor and lift auger for moving the material from within the bin to the storage vessel. The floor auger may include a hydraulically controlled flow gate assembly for selectively covering the floor auger. The lift auger is foldable and includes an adjustable hinge assembly to attach an upper and lower section of the auger. The hinge assembly includes slotted holes for adjustment, such that the upper auger section may be moveable relative to a lower auger section. The lift auger may further be moveable relative to the bin such that it can dispense the material from either the left or right sides of the bin.

Owner:KINZE MFG INC

Grain saving, directable unloader boot assembly

ActiveUS20090272619A1Preventing inadvertent grain spillageMowersPackagingEngineeringCombine harvester

A pivoting boot is disclosed for attachment to the unloading auger tube of combine harvesters, and serves as both a grain saving dam against unwanted grain spillage, and a directable spout. The boot permits evenly unloading grain onto, or completely filling, transportation vehicles or storage containers, without having to change the combine position, once it is staged for unloading.

Owner:BLUE LEAF I P

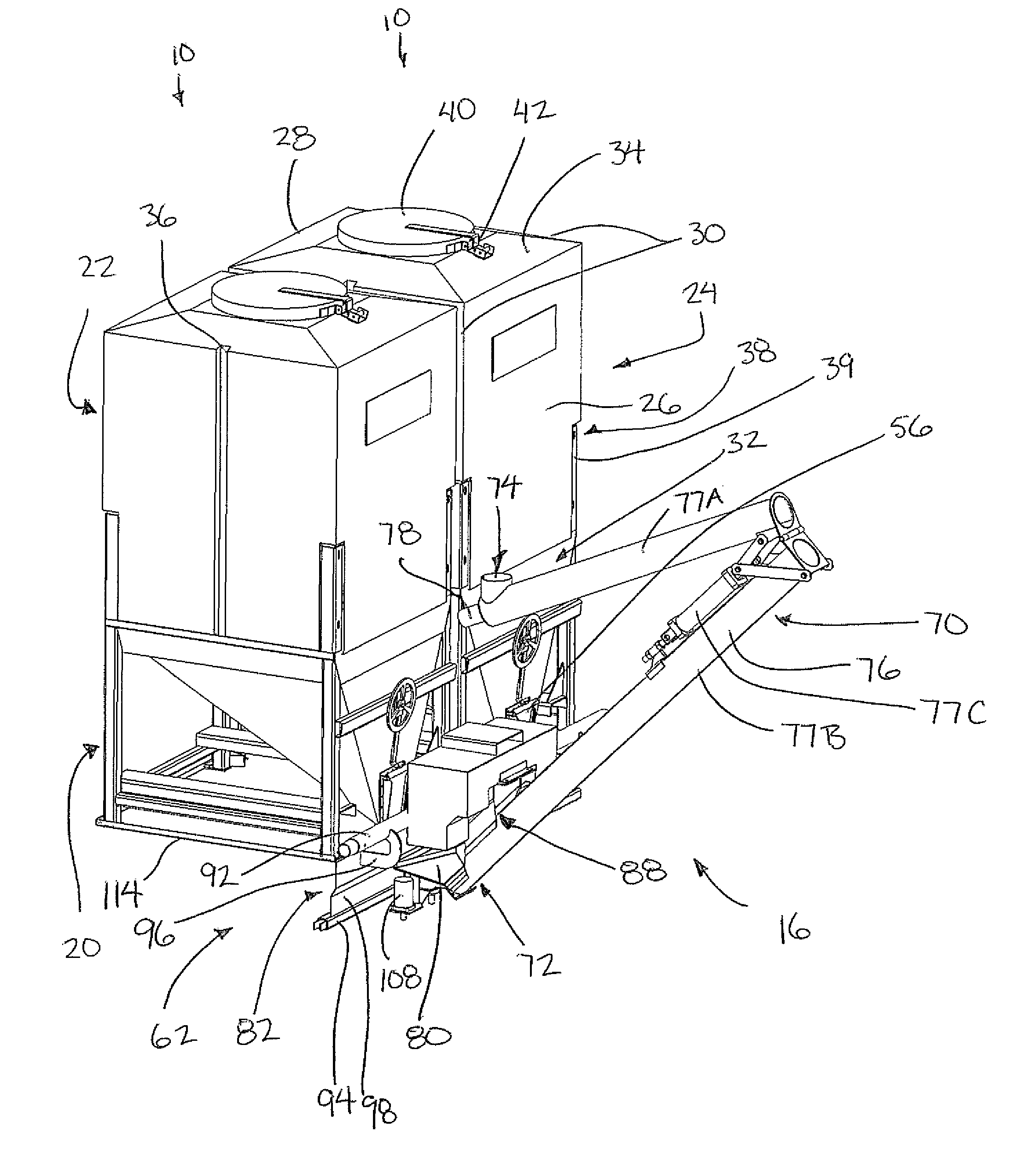

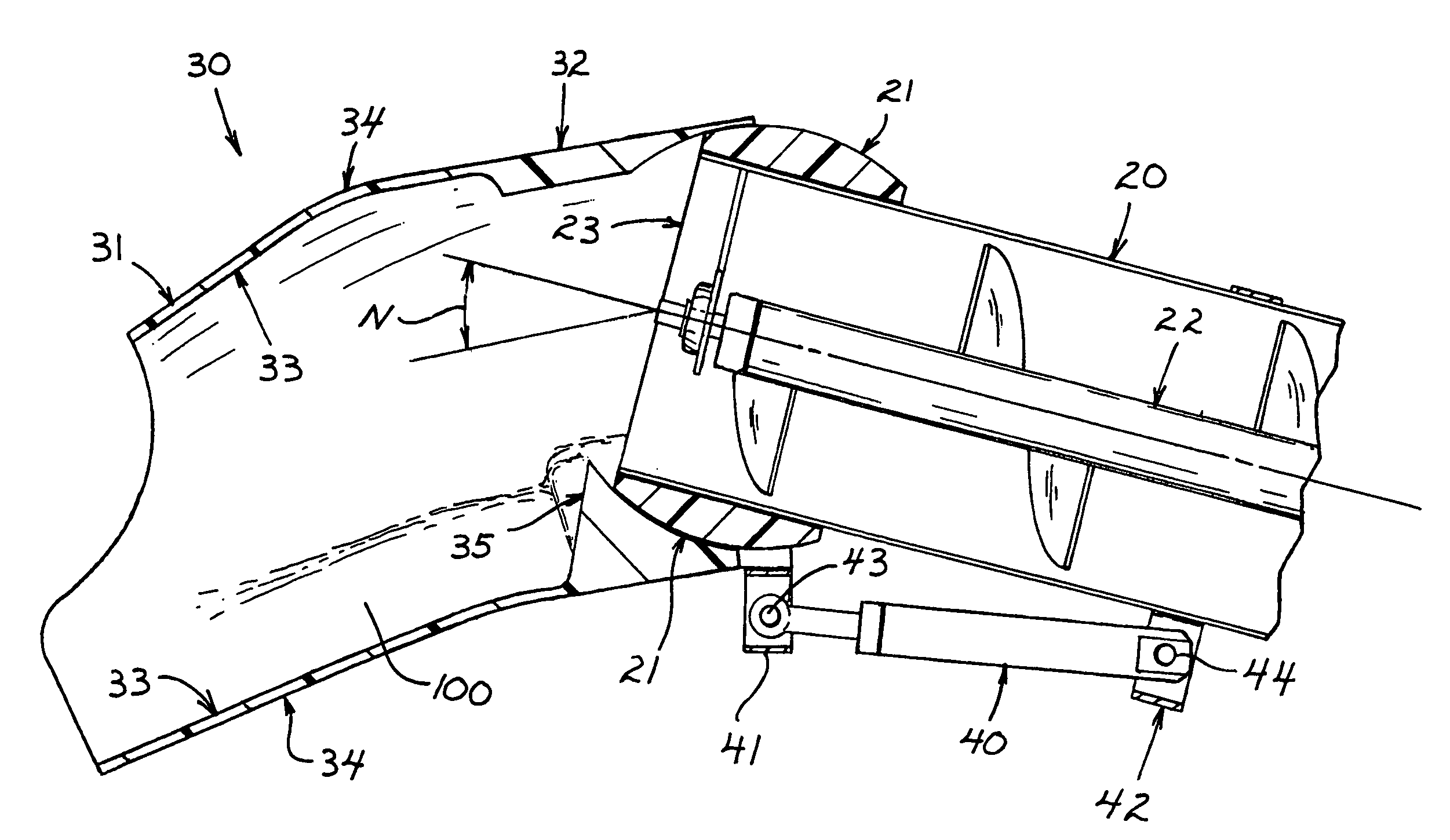

Cart with folding auger having adjustable elevation

A cart having an adjustable elevation auger. A junction box may located within the opening of a sump of a bin of a cart. The junction box may have an open top, closed bottom and sides, and back wall. The back wall of the junction box may be secured to a bin wall by a hinge such that the junction box may pivot about a pivot axis. An auger housing may be connected to and extend from the junction box. An auger may extend through the auger housing and have an intake end disposed within the junction box. The auger housing and auger may pivot with the junction box about a pivot axis between a lowered position and an elevated position. The auger may be a corner auger and may be a folding auger.

Owner:UNVERFERTH MFG

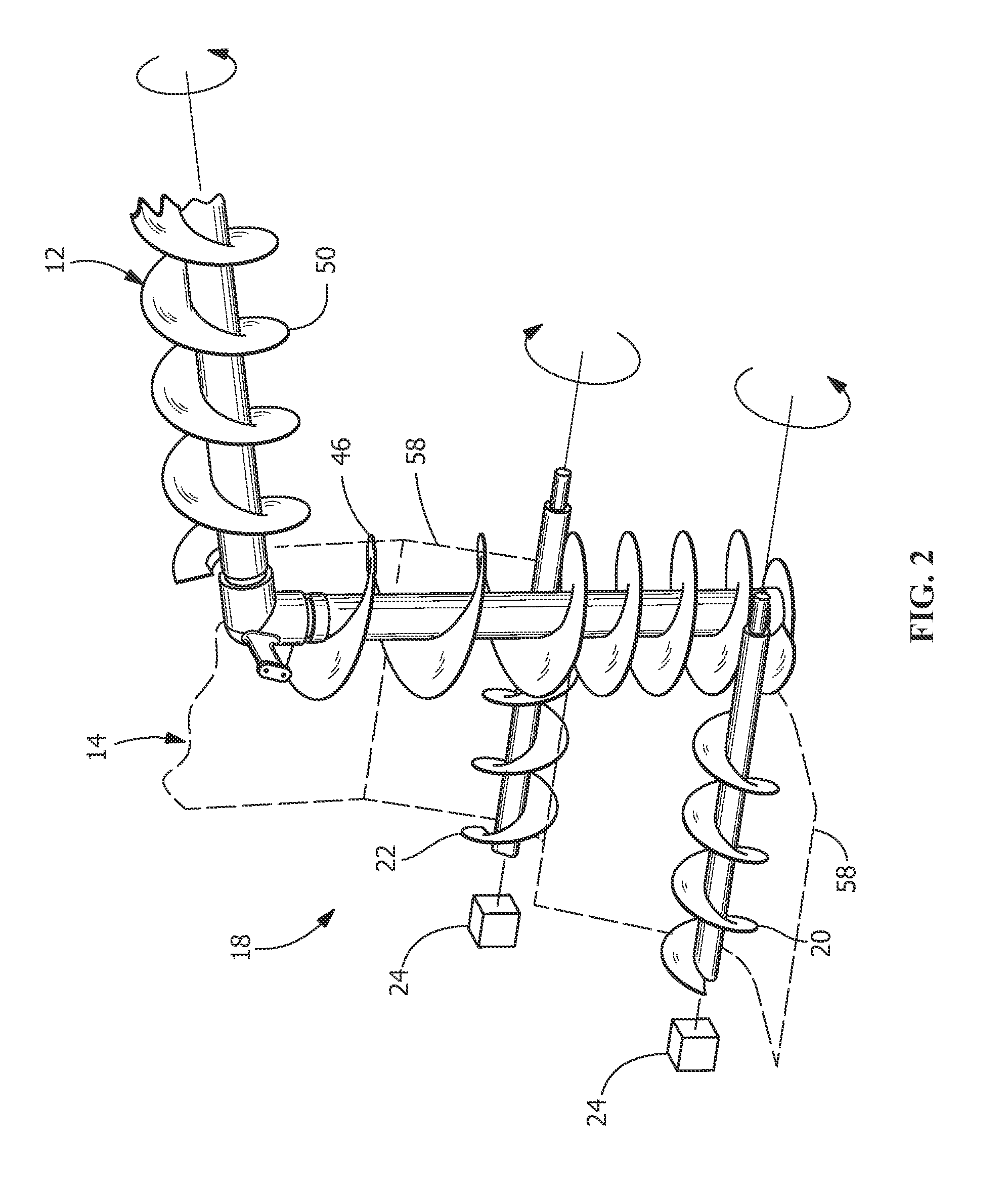

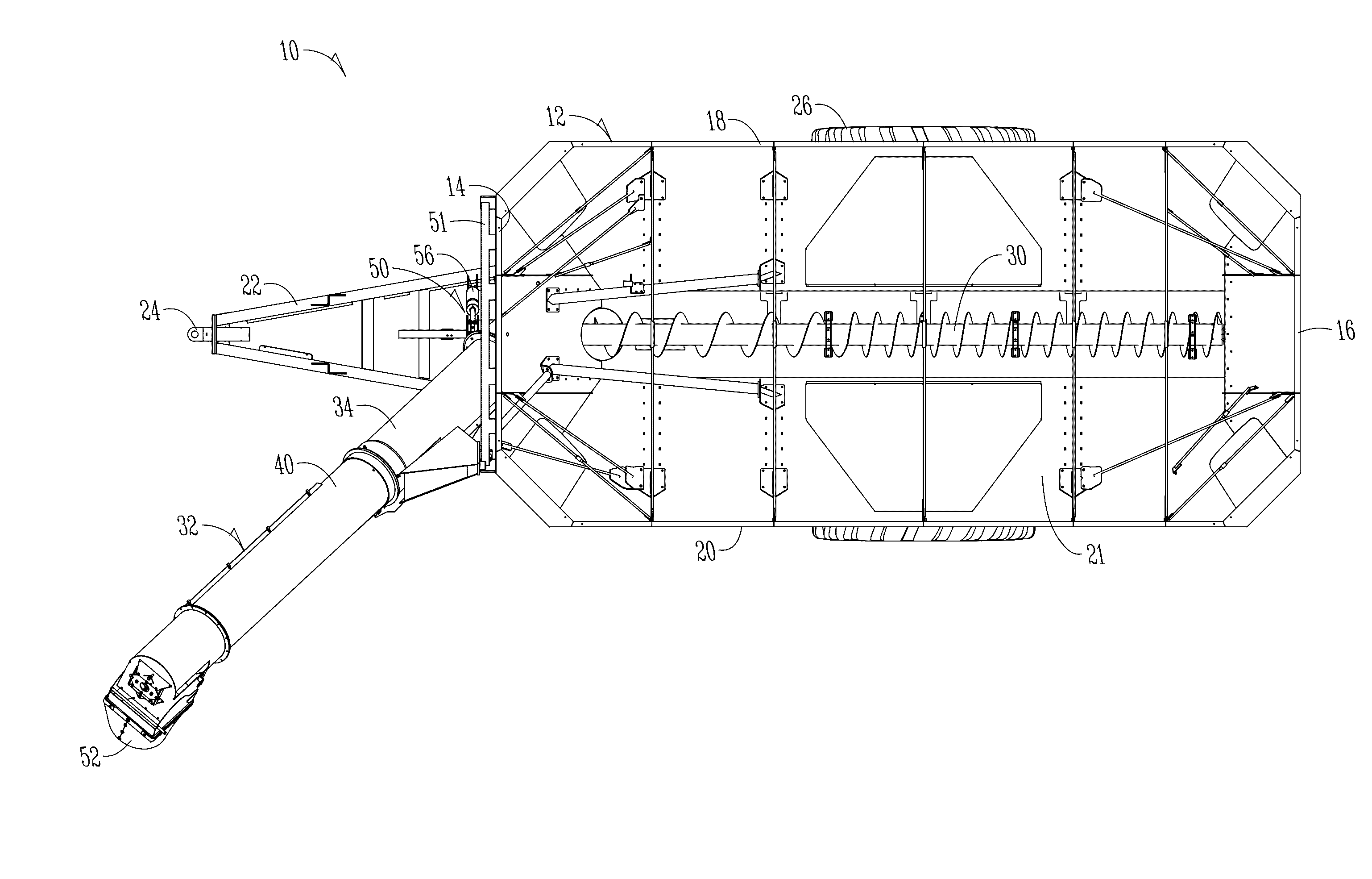

Grain cart with auger delivery on either side

ActiveUS20150203019A1Easy to unloadQuick and easy manipulationRefuse receptaclesBulk conveyorsEngineeringActuator

An agricultural wagon for moving particulate material from within the wagon to a separate storage vessel is provided. The wagon includes a bin defined by walls. The wagon may also include one or two augers, such as a floor and lift auger for moving the material from within the bin to the storage vessel. The lift auger is movable relative to the storage bin such that it can dispense the material via a hood from either the left or right sides of the bin, such as at either the left or right and front corners of the bin. A mechanism including actuators and a guide can aid in moving the auger to the desired side for dispensing. The lift auger can further be folded in front of the bin when in a transport configuration, such as traveling on a road.

Owner:KINZE MFG INC

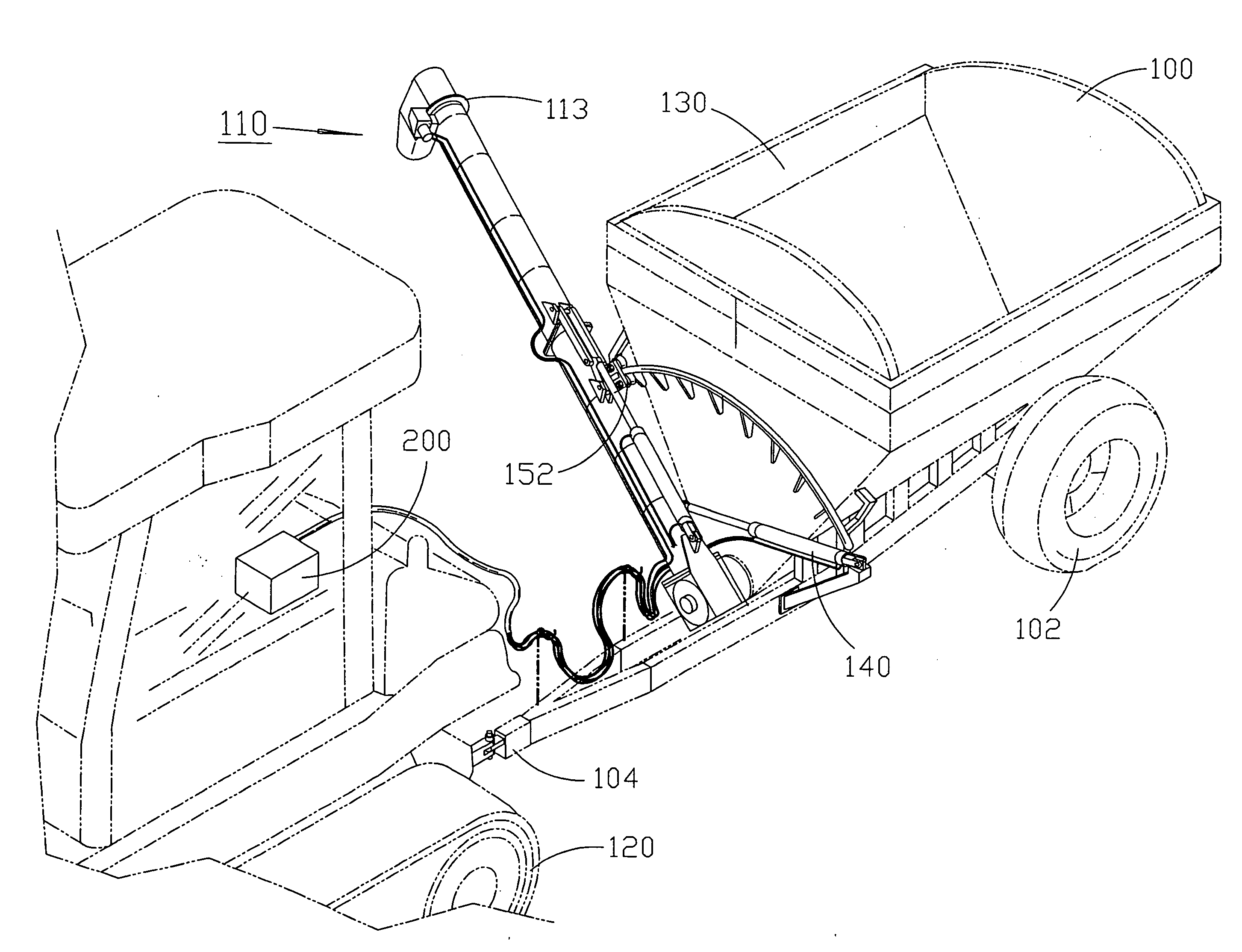

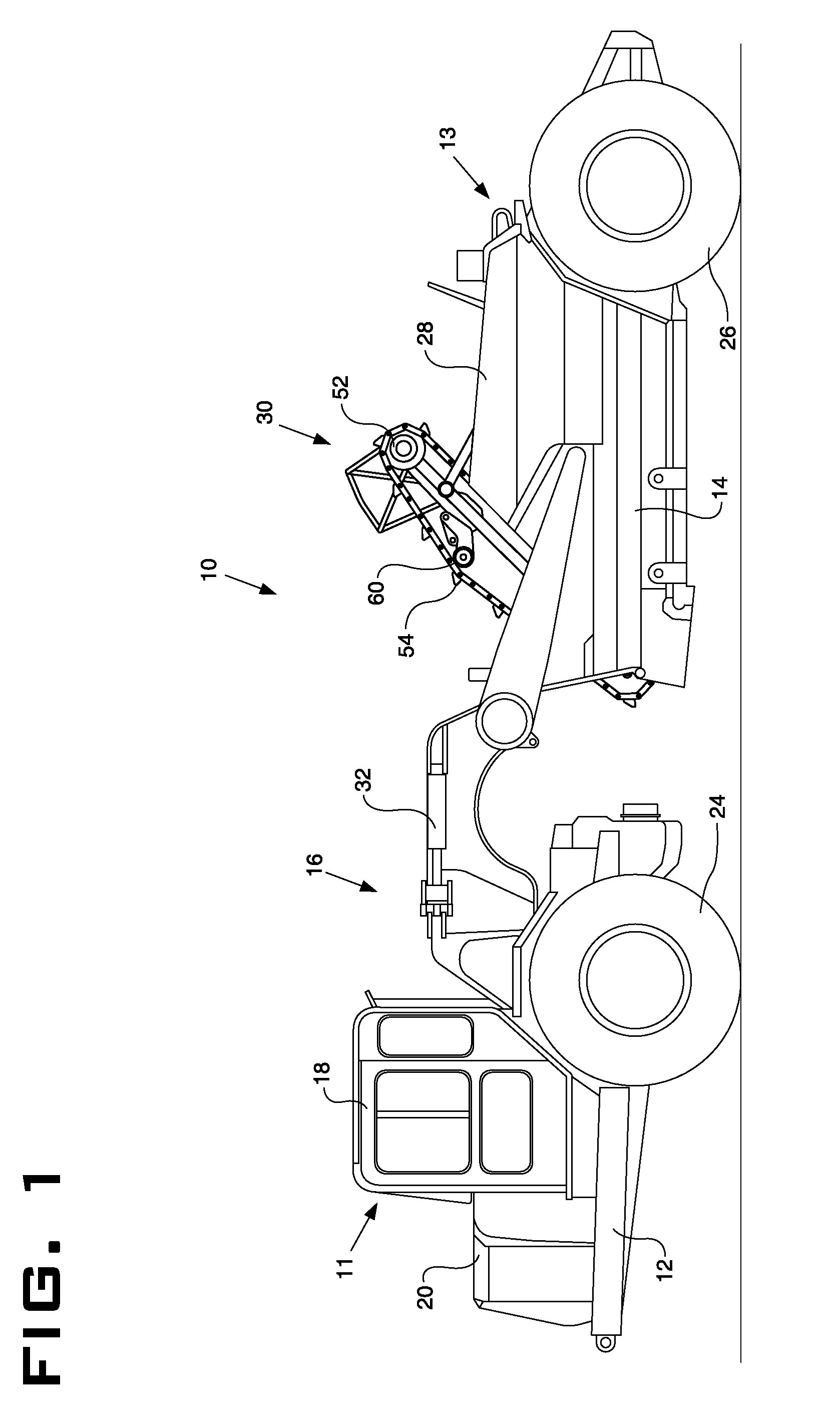

Grain cart with automated unloading assistance

ActiveUS20190322461A1Prevent overflowEvenly filledLoadersControl devices for conveyorsEngineeringTruck

A control assembly provides autonomous control of various functions of a grain cart and / or provides guidance to an operator of the grain cart during the unloading of a grain cart. The control assembly collects input from one or more sensors including a speed sensor to monitor speed of a PTO that drives the unloading auger of the grain cart, a height sensor that measures the height of material discharged from the grain cart into a receptacle such as a grain truck, and / or a boundary sensors that measure lateral position of the grain cart relative to the receptacle or grain truck. Based on the input, the control assembly may vary the position of the discharge gate of the grain cart, or provide guidance to the operator to steer and position the grain cart relative to an adjacent grain truck.

Owner:ELMERS WELDING & MFG LTD

Harvesting corn cobs

A cart is towed behind a combine harvester for collecting corn cobs and includes a conveyer belt feeding into a system for separating cobs from residue to be discharged and a tank for receiving and transporting the cobs. An unload auger is provided from the tank to one side of the cart while the cart moves forward. Power for driving the cart is obtained from a chopper drive of the combine harvester. The separating arrangement includes a series of sequential blower fans for blowing air through the discharged material as it is discharged from a conveyor and into a spreading guide disperses the residue. The cobs are conveyed using a series of augers where the auger to flight distance is at least 2 inches and particularly a pair of augers feed the cobs through a front wall of the tank so as to push cobs upwardly into the tank.

Owner:REDEKOP ENTERPRISES

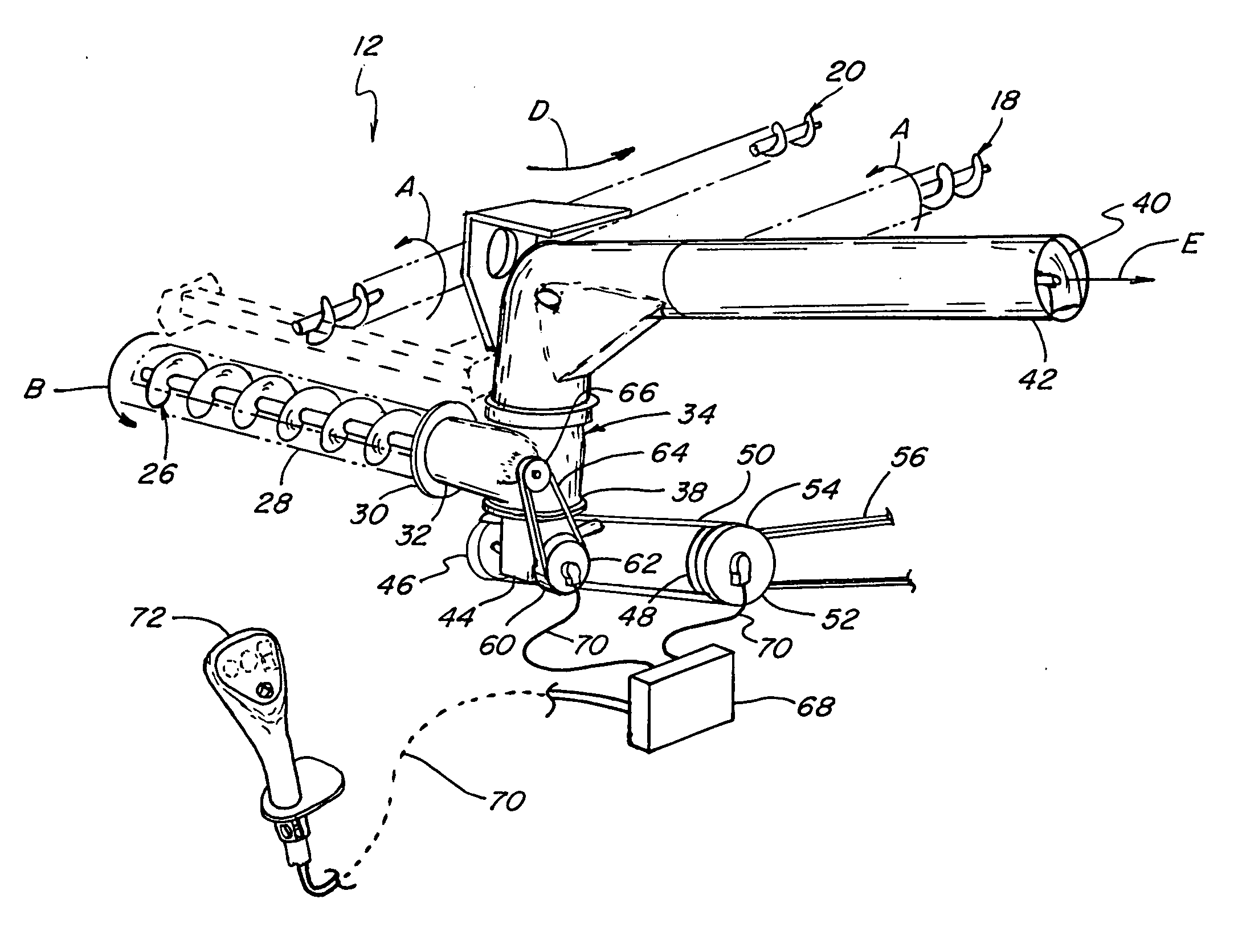

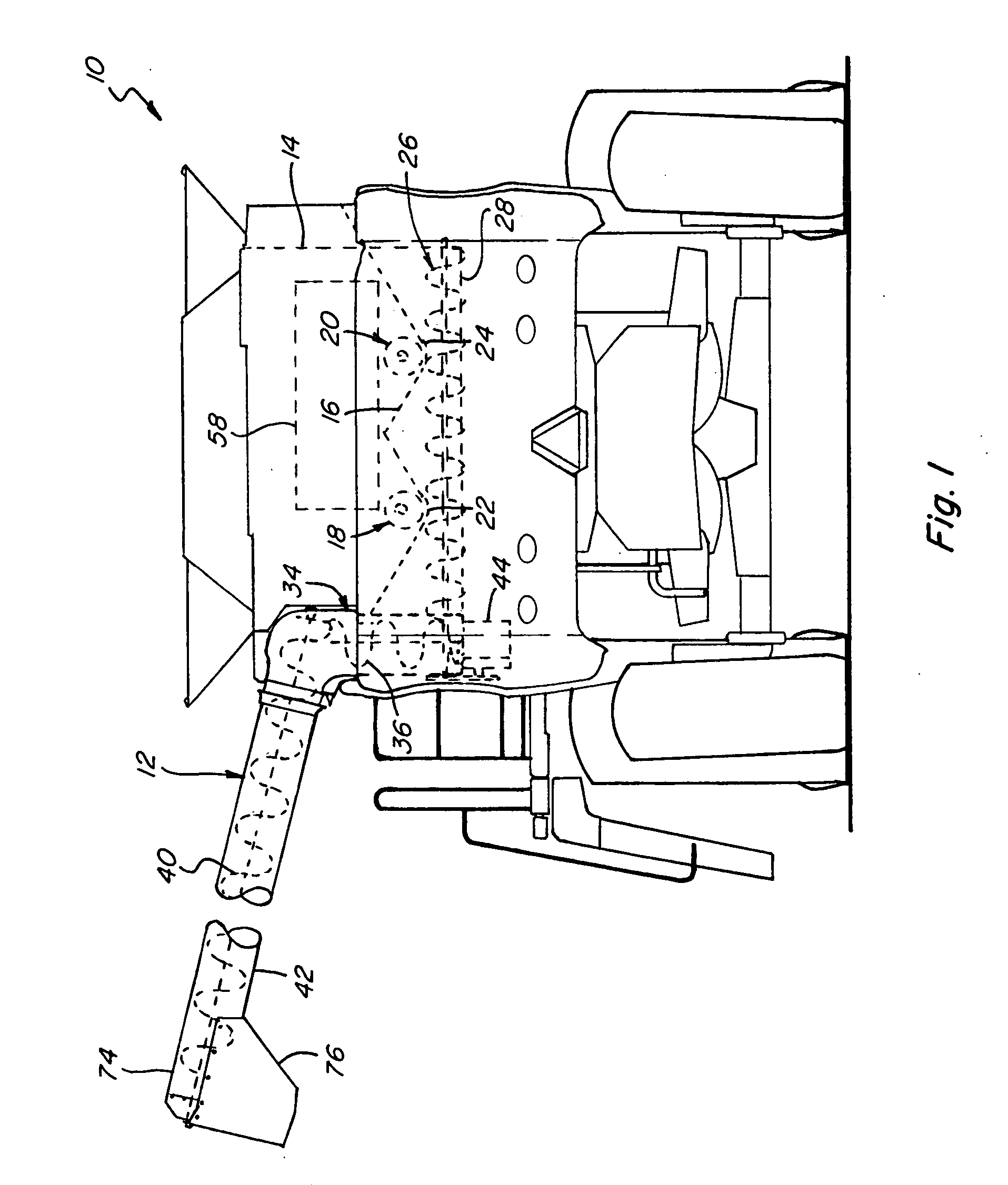

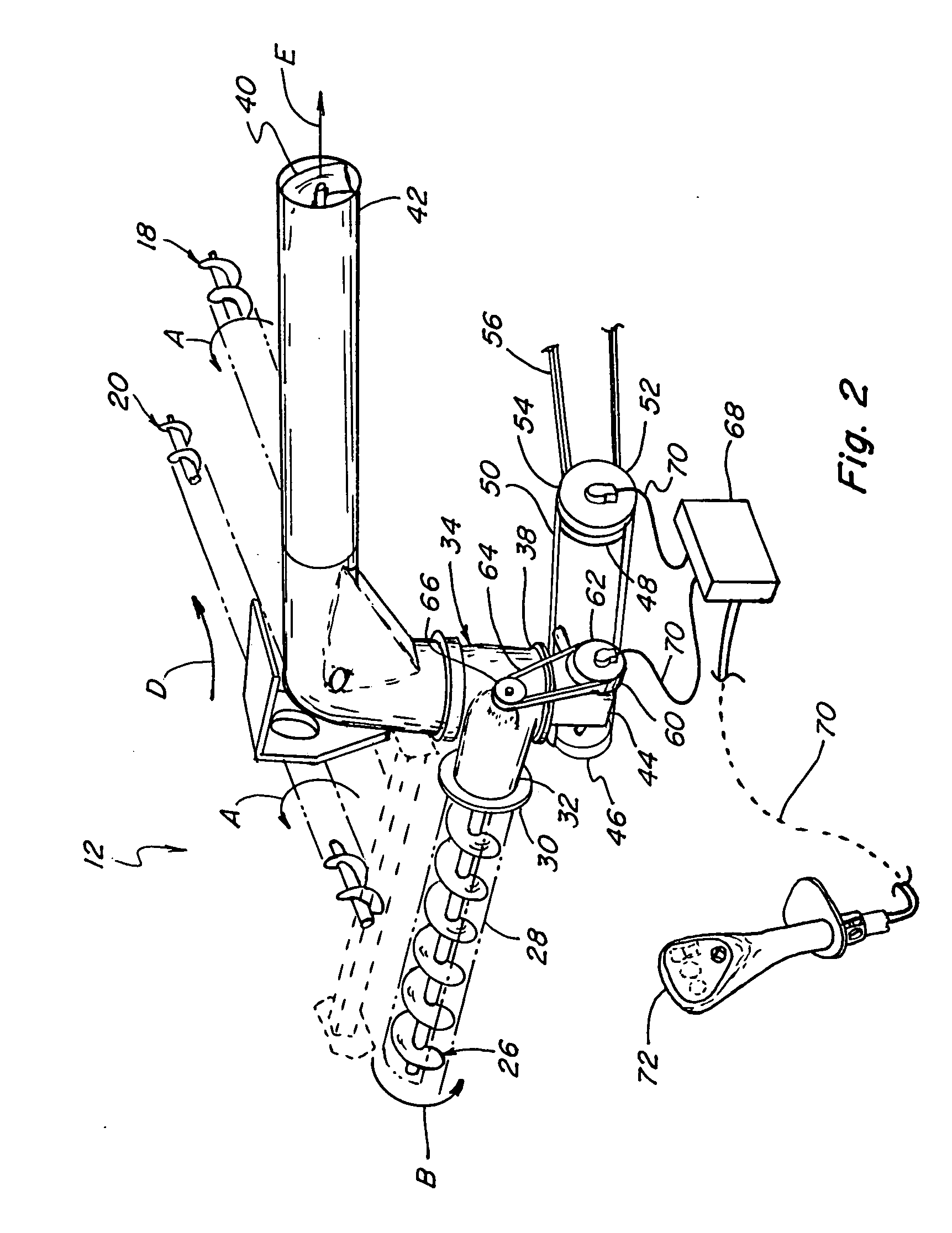

Hydraulic system having manifold with remote control for grain cart

InactiveUS20090321154A1Enhances user safety and comfortReduce in quantityAuxillary drivesServomotor componentsRemote controlControl engineering

A grain cart is provided having a plurality of moveable devices positioned thereon which are hydraulically controlled. A manifold is mounted to the grain cart and hydraulically connected to more than one of the plurality of moveable devices. A remote control is provided in communication with the manifold to hydraulically control movement of the moveable devices hydraulically connected to the manifold. A remote control for controlling functions of a grain cart and a method of assembling of a control assembly are also disclosed.

Owner:DETHMERS MFG

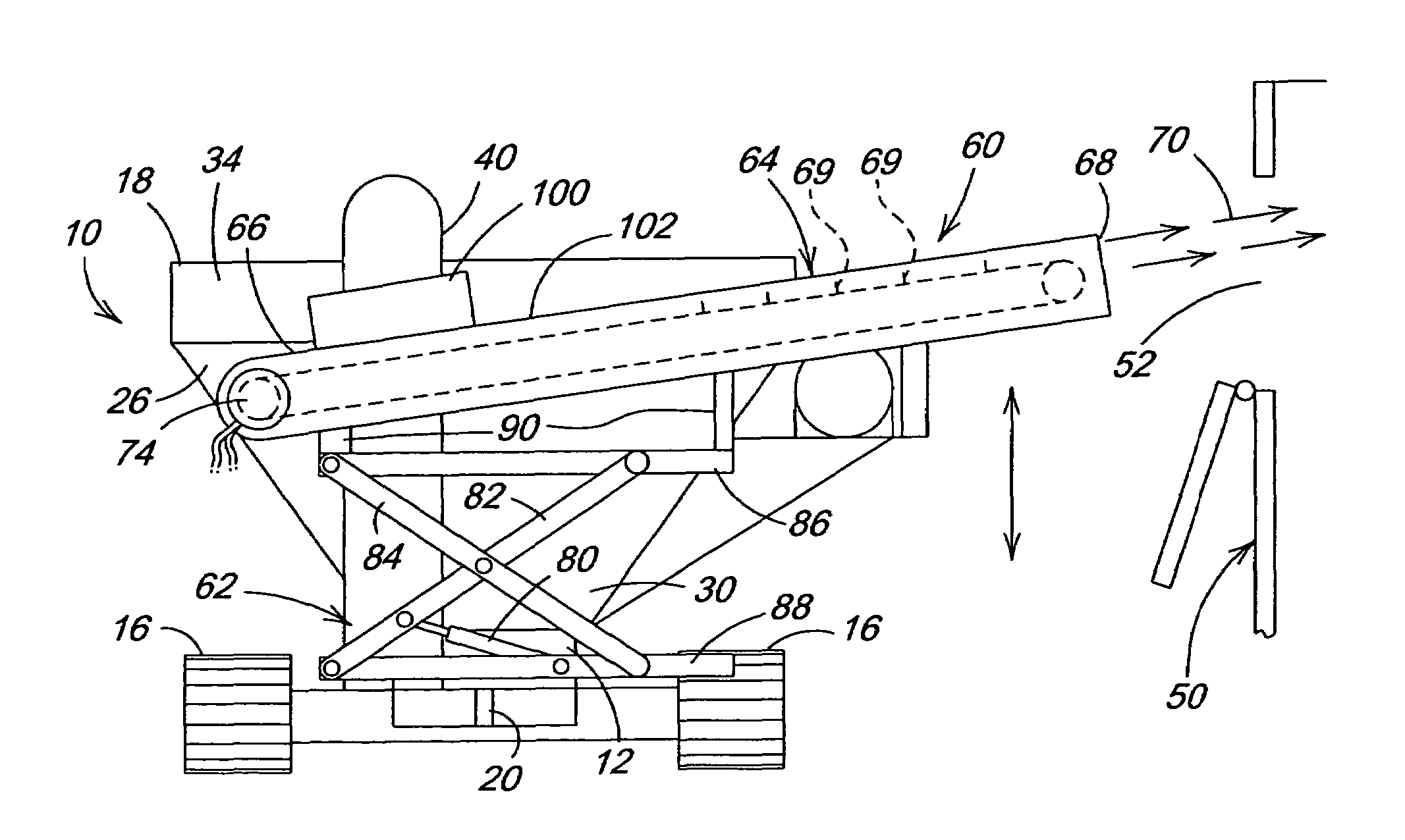

Grain Cart With Folding Auger Having Adjustable Elevation

ActiveUS20150237804A1Less damaged grainMore grain visibilityLoadersRefuse receptaclesEngineeringCart

According to one aspect, a cart for transporting and conveying agricultural materials is provided. The cart includes a frame and a plurality of wheels coupled with the frame. The cart further includes a bin supported on the frame and including a plurality of bin walls defining a storage space for an agricultural material. The cart further includes a conveyor assembly having an intake end configured to receive agricultural material from the bin and a discharge end configured to discharge agricultural material, the conveyor assembly including a lower conveyor section, an intermediate conveyor section, and an upper conveyor section. The lower conveyor section includes a lower conveyor housing and a lower conveyor extending within the lower conveyor housing, the intermediate conveyor section includes an intermediate conveyor housing, and the upper conveyor section includes an upper conveyor housing and an upper conveyor extending within the upper conveyor housing. The cart further includes a folding assembly coupled to an end of the intermediate conveyor housing and having a fold axis, the folding assembly configured to move the upper conveyor section between a stored position and an operating position. The cart further includes a tilting assembly coupled to an end of the intermediate conveyor housing and having a tilt axis, the tilting assembly configured to pivot the upper conveyor section relative to the tilt axis when the upper conveyor section is in the operating position.

Owner:UNVERFERTH MFG

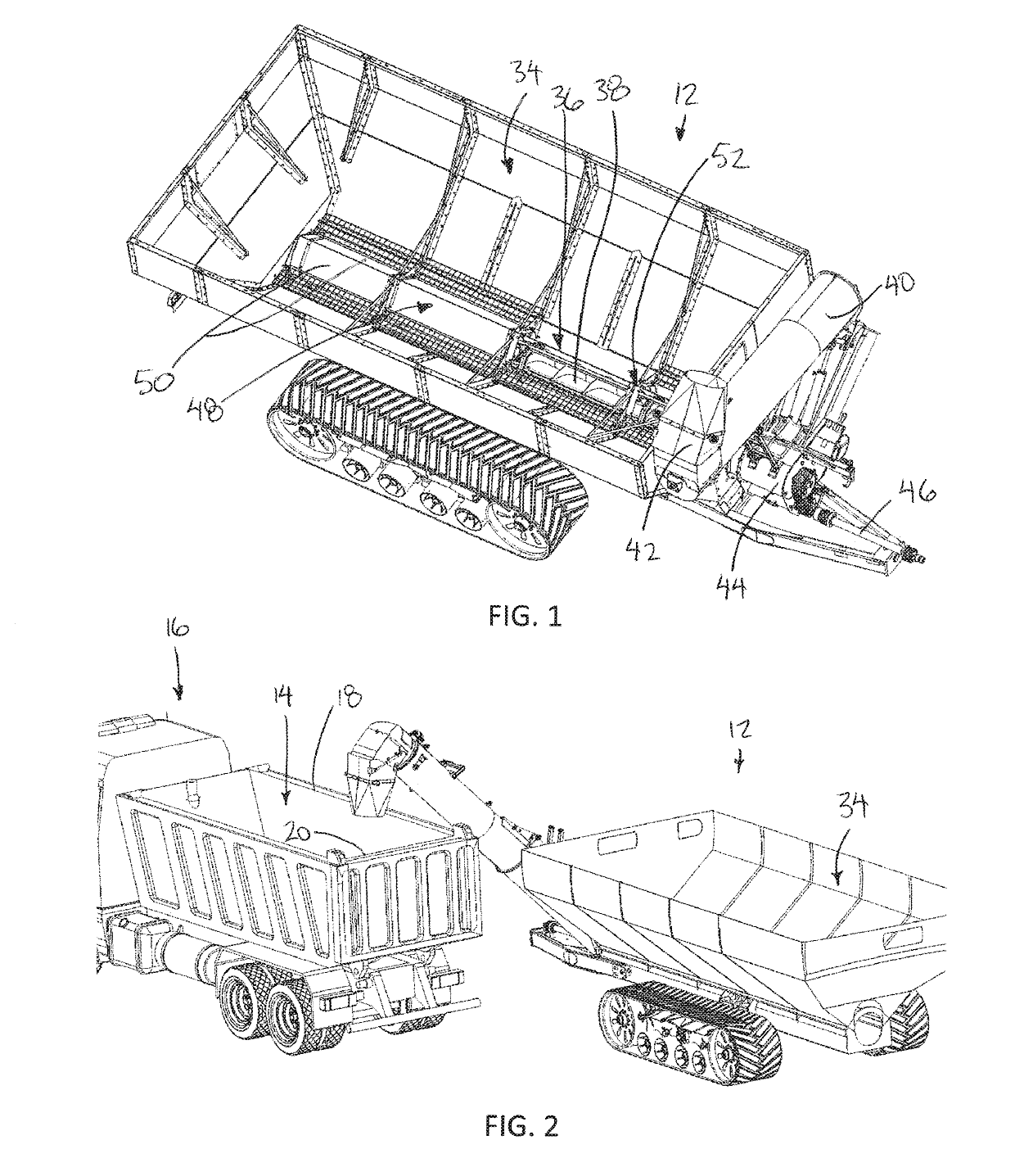

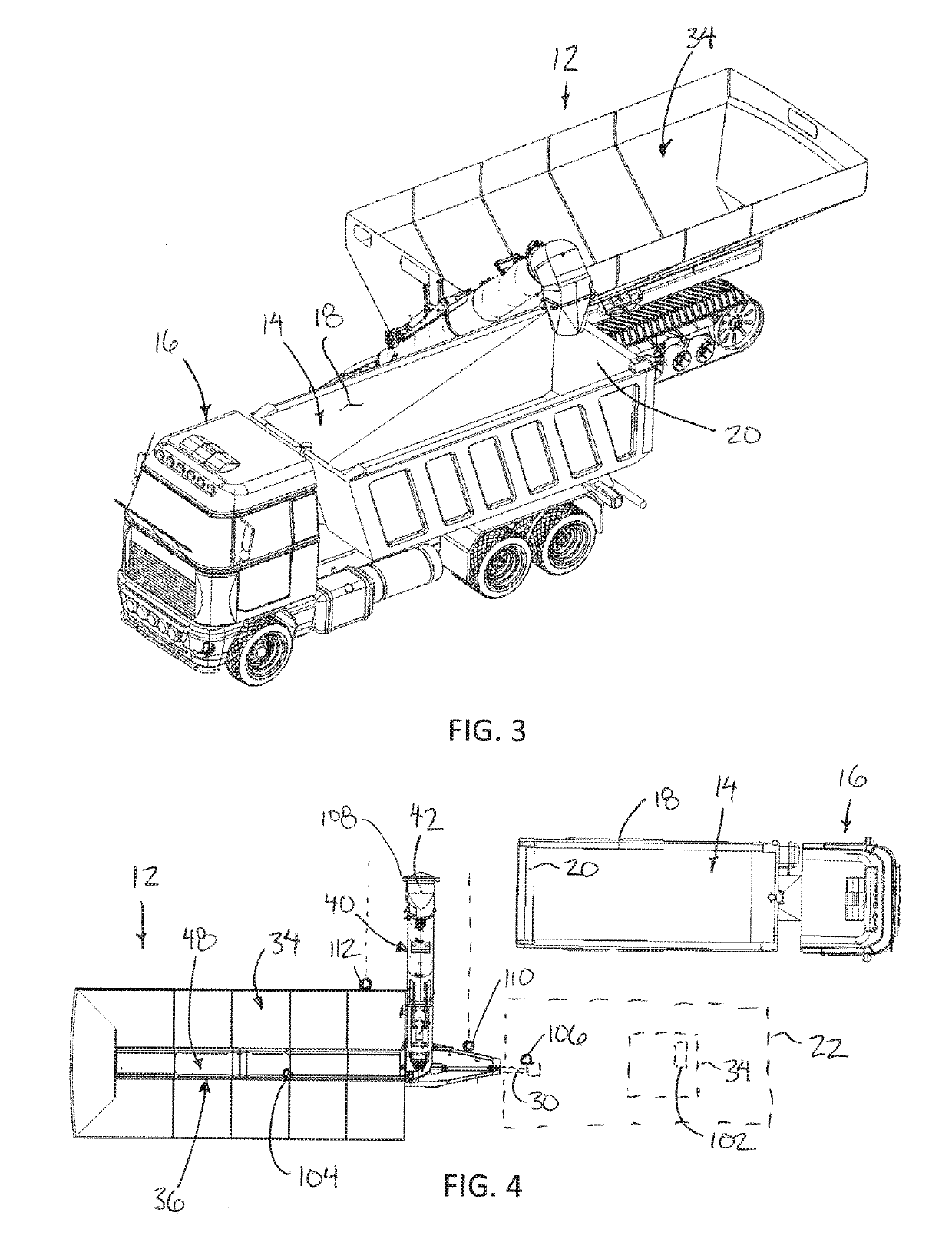

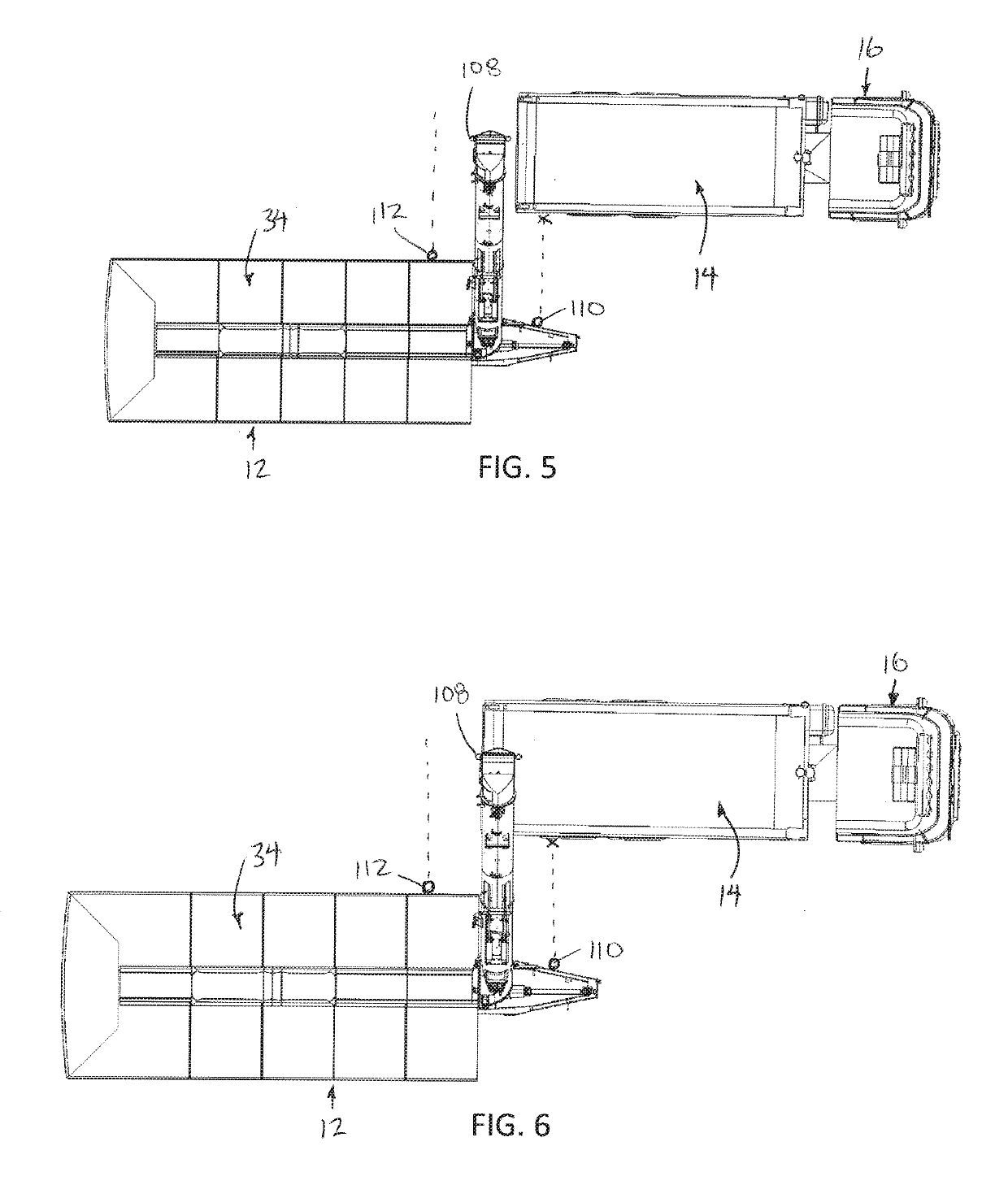

Transfer Vehicle

InactiveUS20080095599A1Simple technical structureRefuse receptaclesDifferential gearingsEngineeringElectrical drive

A transfer vehicle is pulled by a towing vehicle. The transfer vehicle comprises a container and an unloading conveyor. The container serves to receive bulk goods. The unloading conveyor serves to unload the bulk goods located in the container. In order to allow a simple technical construction and a variable drive of the unloading conveyor, an electrical drive is coupled to the unloading conveyor and serves exclusively for driving the unloading conveyor.

Owner:DEERE & CO

Grain wagon with improved grain container

A grain wagon includes a wheel supported frame supporting a container having inclined front and rear walls connected by opposite inclined side walls. Each side wall has inwardly projecting wall portions defining a wheel well for receiving longitudinally offset dual wheels or extra wide wheels. The rear wall includes a portion sloping between the wheel well wall portions to a forward grain removal zone, and generally triangular diverter walls extend from the rear wall to the wheel well wall portions. A corner discharge auger conveyor extends from the grain removal zone and has an upper portion which pivots to a stored position adjacent the front wall of the container. The dual wheels are positioned within the wheel wells by support members having end portions pivotally connected to the wagon frame and opposite end portions connected to the frame by laterally slidable clamping plates.

Owner:J & M MANUFACTURING CO INC

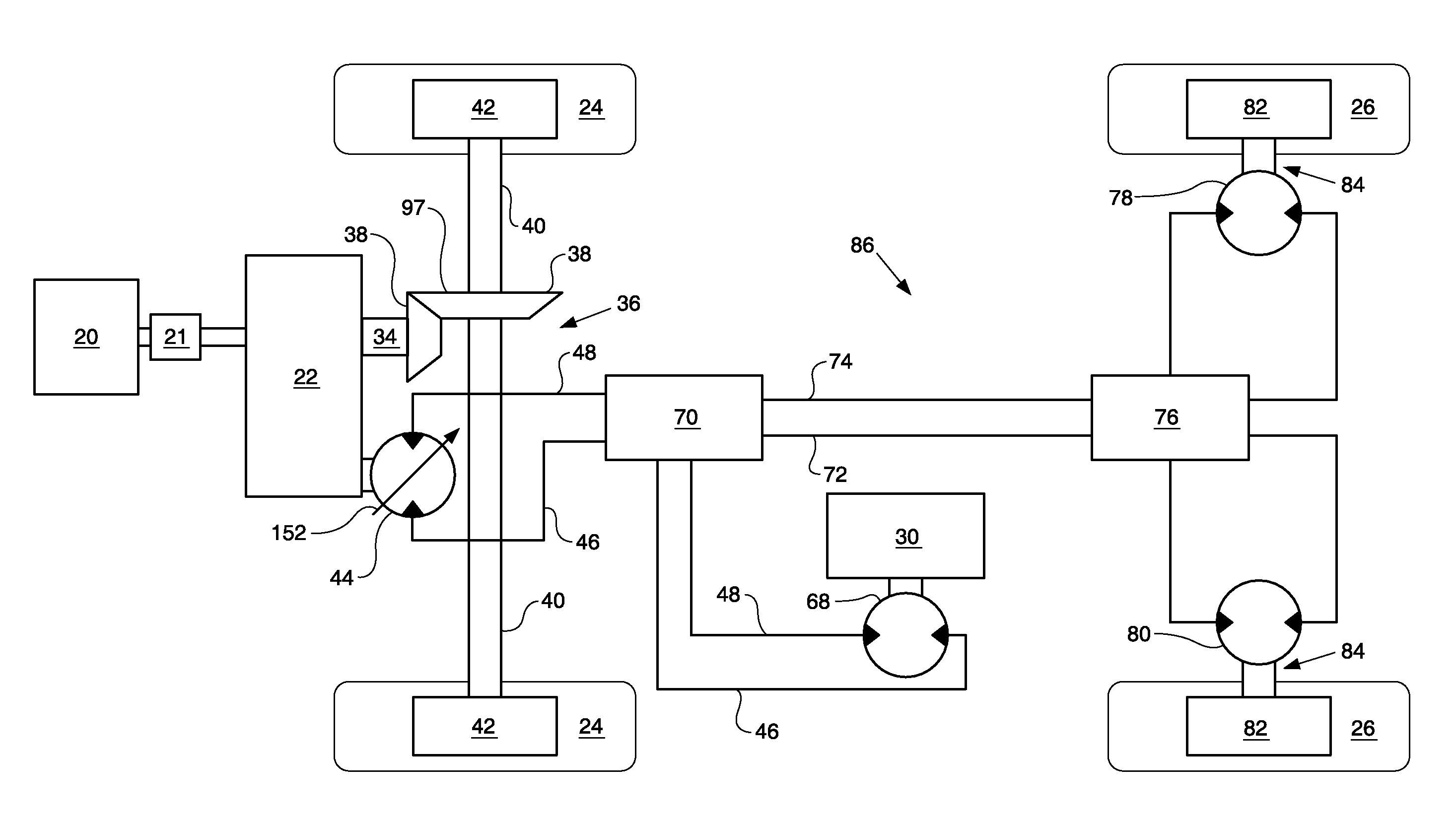

Wheel tractor scraper rear wheel drive assist and method of operation

ActiveUS8061466B2Machines/dredgers working methodsAgricultural machinesWheel tractor-scraperDrive motor

A wheel tractor scraper having a rear wheel drive assist, the wheel tractor scraper includes a tractor portion pivotally coupled to a rear scraper portion, the rear scraper portion having a bowl for hauling material and a fluid powered work tool configured to assist in loading the bowl, the work tool powered by a fluid pump connected to a fluid operated work tool motor. The rear wheel drive assist includes a fluid operated drive motor coupled to the rear wheels of the machine, a diverter valve having a first position at which fluid flow is delivered from the pump to the work tool motor and a second position at which fluid flow is delivered from the pump to the drive motor, and a controller being configured to control the diverter valve to engage the rear wheel drive assist. The machine may be operated by engaging the pump and work tool motor, and then actuating the diverter valve to the second position to divert flow from the work tool motor to the drive motor.

Owner:CATERPILLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com