Method for effectively increasing material mixing efficiency during medicine preparation

A material mixing and drug technology, applied in the field of pharmaceutical preparations, can solve the problems of material waste, time-consuming and laborious, difficult to find, etc., and achieve the effect of good bonding effect, simple process and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

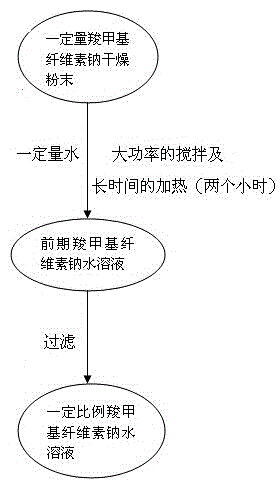

Image

Examples

Embodiment 1

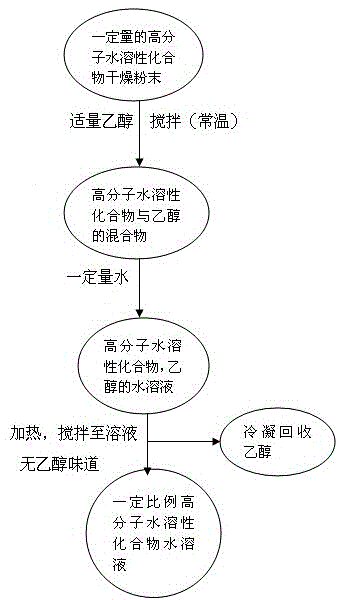

[0030] First, add the polymer water-soluble compound into ethanol at room temperature and stir, then add the mixture of fully dispersed polymer water-soluble compound powder and ethanol liquid into water, heat and stir, and the ethanol will evaporate quickly, leaving a fully dispersed polymer Water-soluble compounds are also quickly dissolved in water with high dissolution efficiency and will not form agglomerates, just heat and stir until the liquid has no ethanol smell.

[0031] Process flow chart of the present invention: see figure 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com