Double row bearing ball dividing grease injecting retainer assembling machine

A double-row bearing and cage technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of increasing labor costs, increasing labor force, and reducing efficiency, so as to reduce labor costs, improve production efficiency, and reduce labor costs. The effect of the requested operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

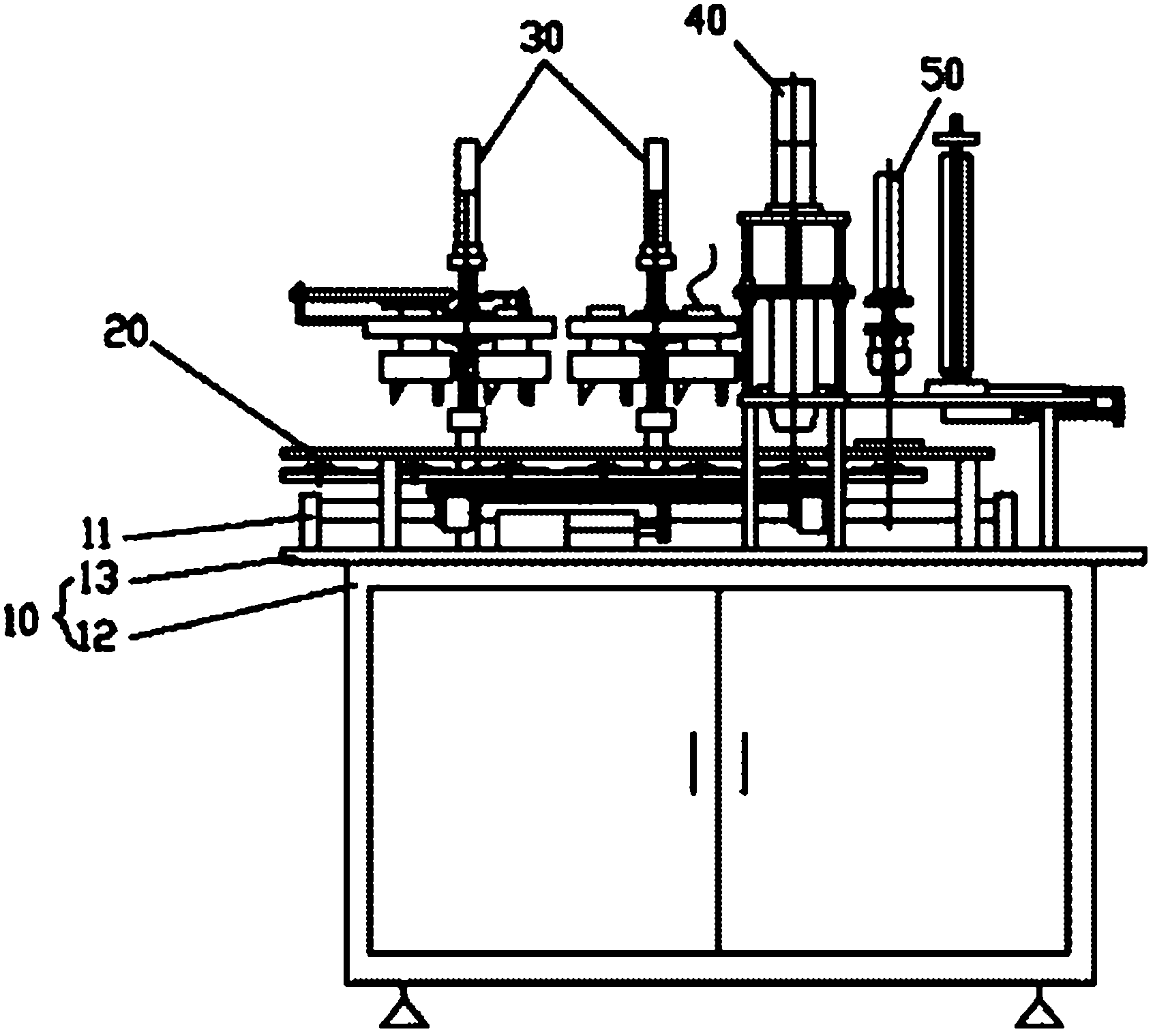

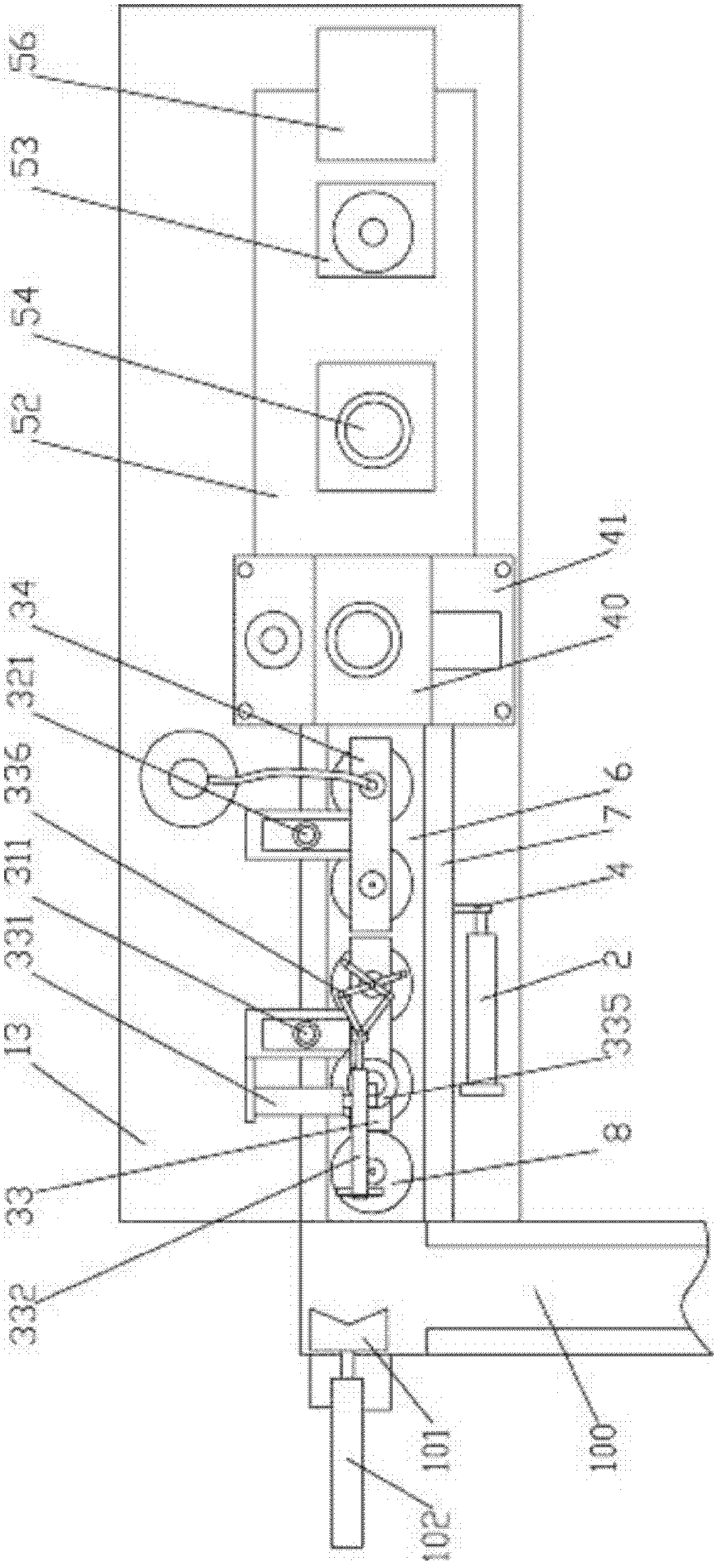

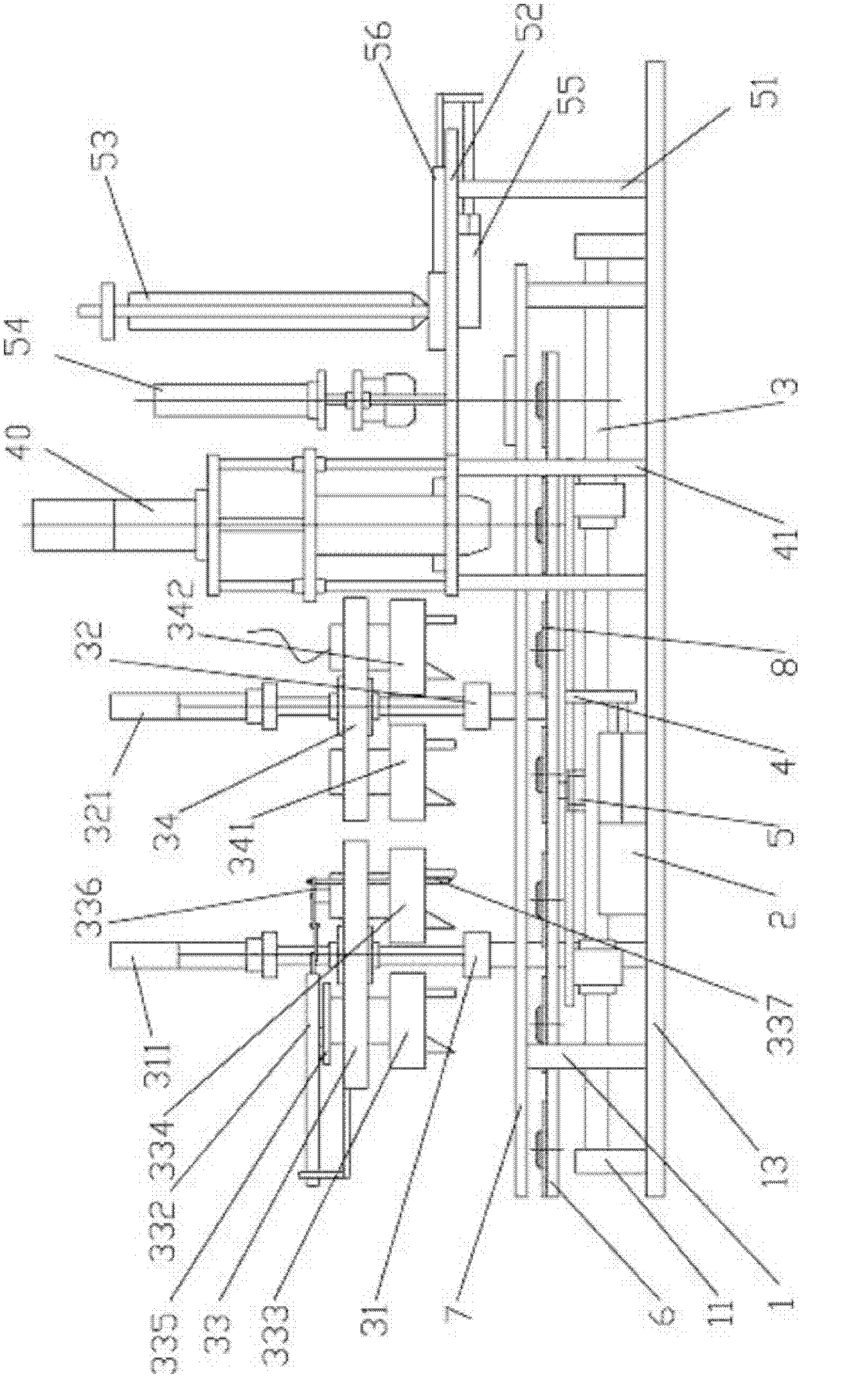

[0018] Example: see Figure 1 to Figure 5 As shown, the installation machine for double-row bearing ball-by-ball grease injection and cage installation includes a frame 10, on which a feeding device 20, a ball-by-ball grease injection device 30, a cage feeding device 40, and a capping device 50 are sequentially arranged. The structure of the feeding device 20 is that the frame 10 is fixed with a feeding rack 1 and a laterally moving cylinder 2, the sliding rod 3 is fixed on the support block 11 on the frame 10, and the sliding rod 3 is inserted with a push connecting plate 4 , the push connecting plate 4 is fixed with an up and down moving cylinder 5, the push rod of the laterally moving cylinder 2 is fixed on the pushing connecting plate 4, and the push rod of the up and down moving cylinder 5 is fixed on the sliding pallet 6; The plate 7 is on both sides above the sliding pallet 6; the bearing support seat 8 is fixed on the sliding pallet 6.

[0019] The structure of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com