Desulfurization and denitrification system

A technology of desulfurization, denitrification, and discharge port, which is applied in gas treatment, membrane technology, dispersed particle separation, etc. It can solve the problems of uncontrollable materials, large quantity, and difficulty in manual dismantling and maintenance or reinstallation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

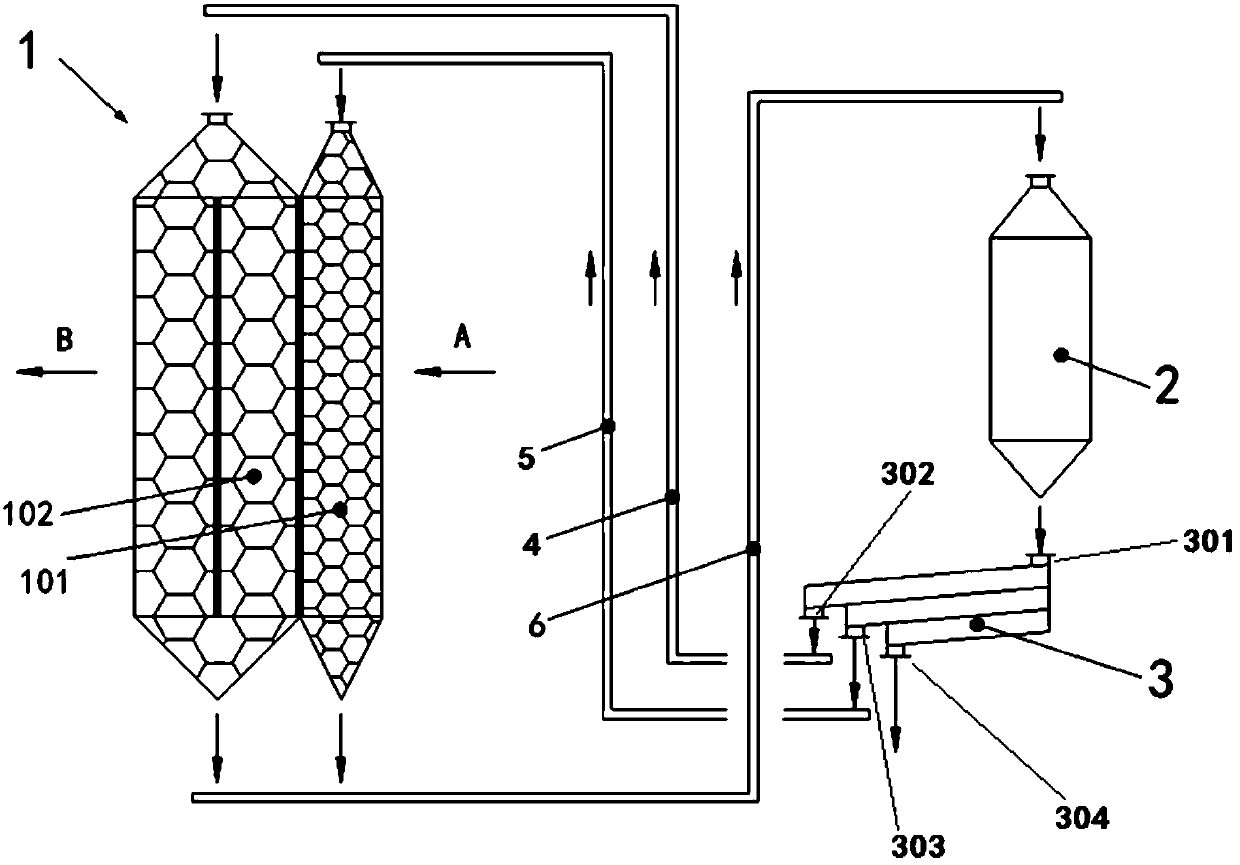

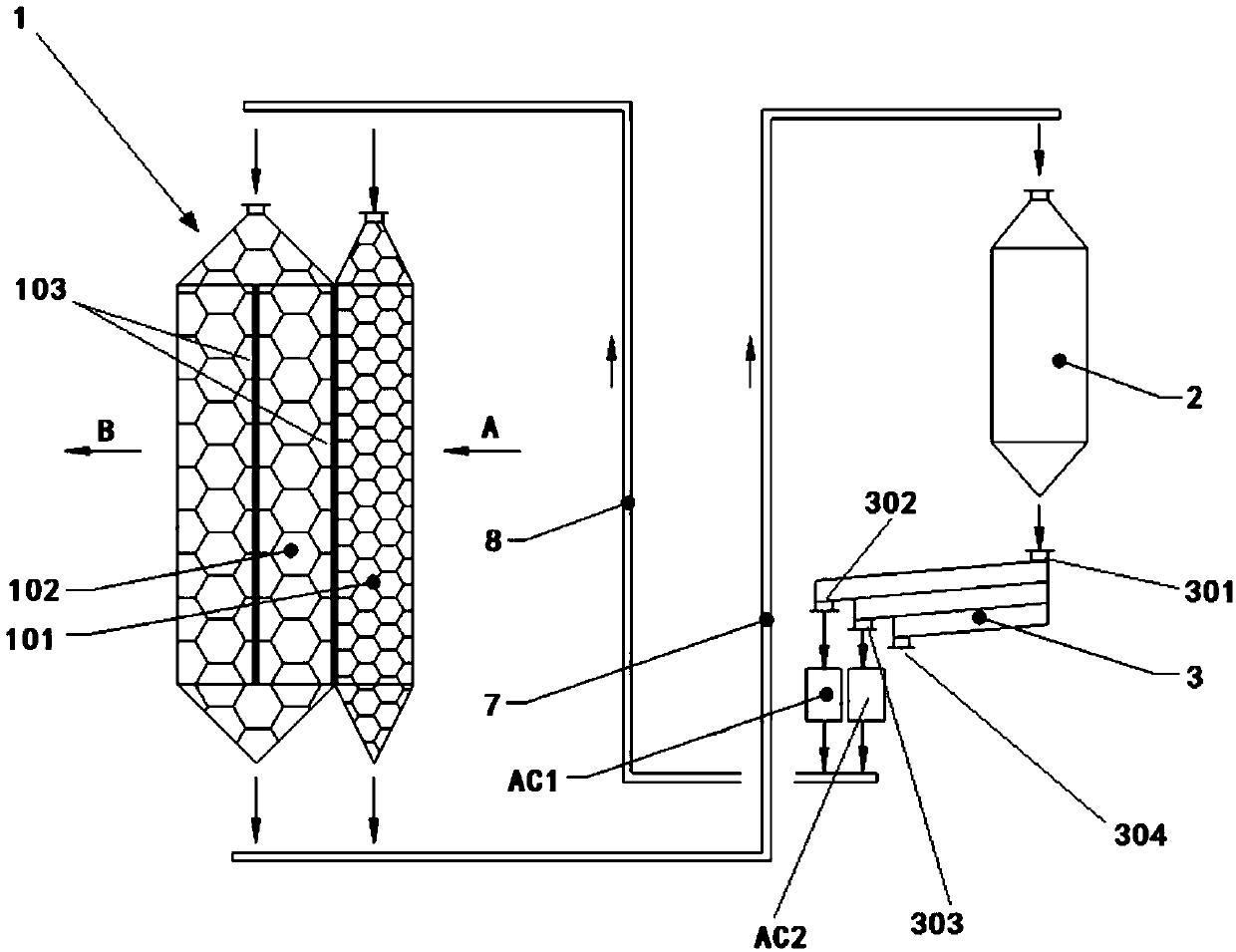

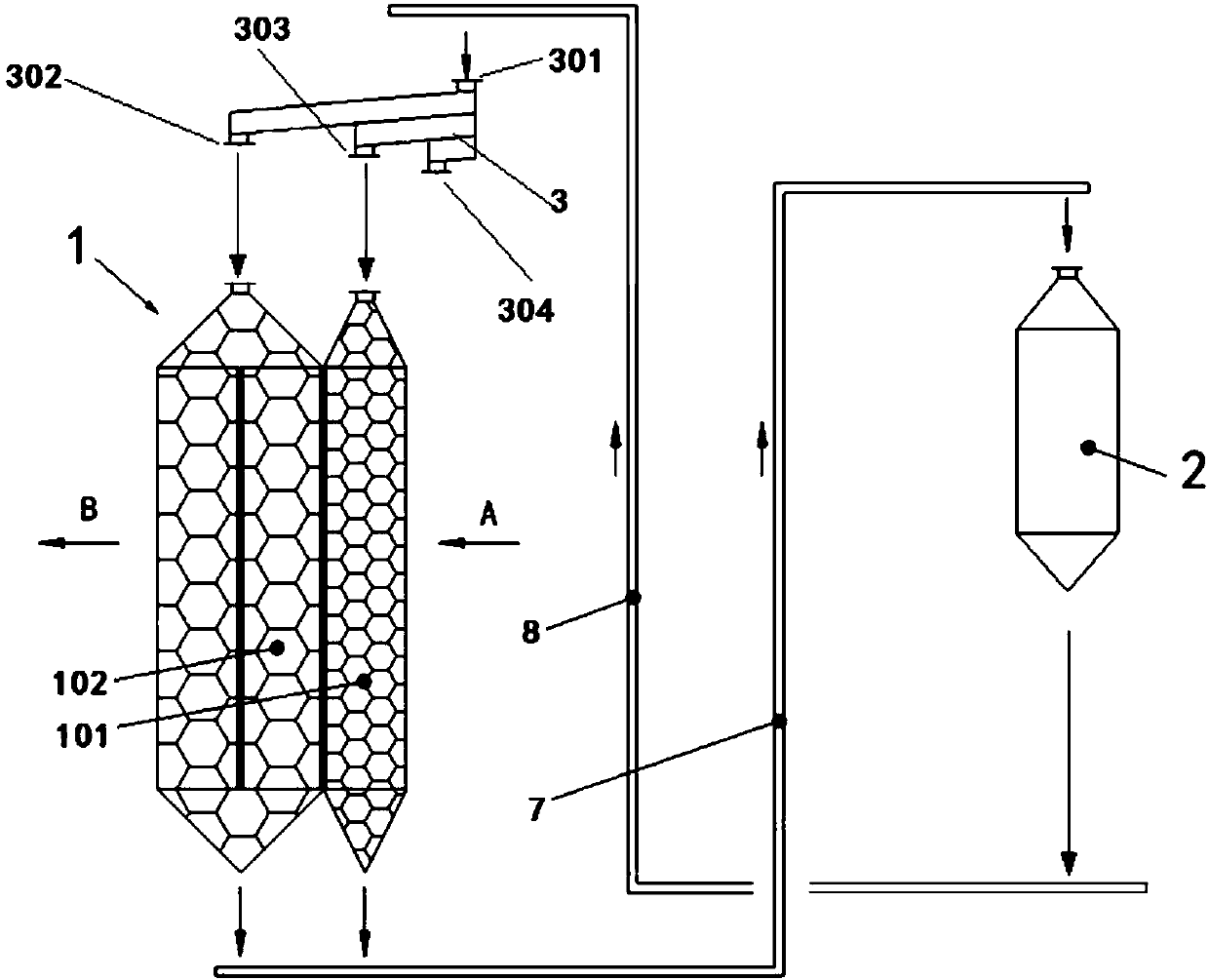

[0137] According to a second embodiment of the present invention, a desulfurization and denitrification system is provided.

[0138]A desulfurization and denitrification system, the system includes an adsorption tower 1, a desorption tower 2, a classifying and screening machine 3, a fourth activated carbon conveyor 7, a fifth activated carbon conveyor 8, a first buffer bin AC1, and a second buffer bin AC2. One side of the adsorption tower 1 is provided with a flue gas inlet A. The other side of the adsorption tower 1 is provided with a flue gas outlet B. The adsorption tower 1 is provided with an adsorption layer front chamber 101 and an adsorption layer rear chamber 102 . The front chamber 101 of the adsorption layer is arranged on the side close to the flue gas inlet A. The rear cavity 102 of the adsorption layer is arranged on the side close to the flue gas outlet B. The classifying and screening machine 3 includes a classifying and screening machine inlet 301 , a classi...

Embodiment A

[0187] Such as Figure 9 As shown in , the size (screen cut-off size) of the finished activated carbon recycled in the desulfurization and denitrification unit is required to be Then design a kind of screen cloth to be used in the one deck screen cloth of vibrating screen 3, wherein the width a and the length L of the rectangular mesh are: 5mm (width a) * 27mm (length L). Wherein D is the diameter of the circular cross-section of the activated carbon cylinder to be retained on the screen, and h is the minimum length of the granular activated carbon cylinder to be retained on the screen. a=0.833h.

Embodiment B

[0189] Such as Figure 9 As shown in , the size (screen cut-off size) of the finished activated carbon recycled in the desulfurization and denitrification unit is required to be Then design a kind of screen cloth and be used in the one deck screen cloth of vibrating screen 3, wherein the width a and the length L of the rectangular screen hole are: 3mm (width a) * 27mm (length L). where D is the diameter of the circular cross-section of the granular activated carbon cylinder to be retained on the screen. a=0.75h. This mesh size screen is designed to retain medium particle size activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com