A medium-high temperature flue gas circulation type low-nitrogen staged burner and its process

A staged combustion and flue gas circulation technology, applied in the direction of gas fuel burners, burners, combustion types, etc., can solve the problems of reducing nitrogen oxide production, large footprint, and size restrictions, so as to avoid tempering, reduce The effect of a small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

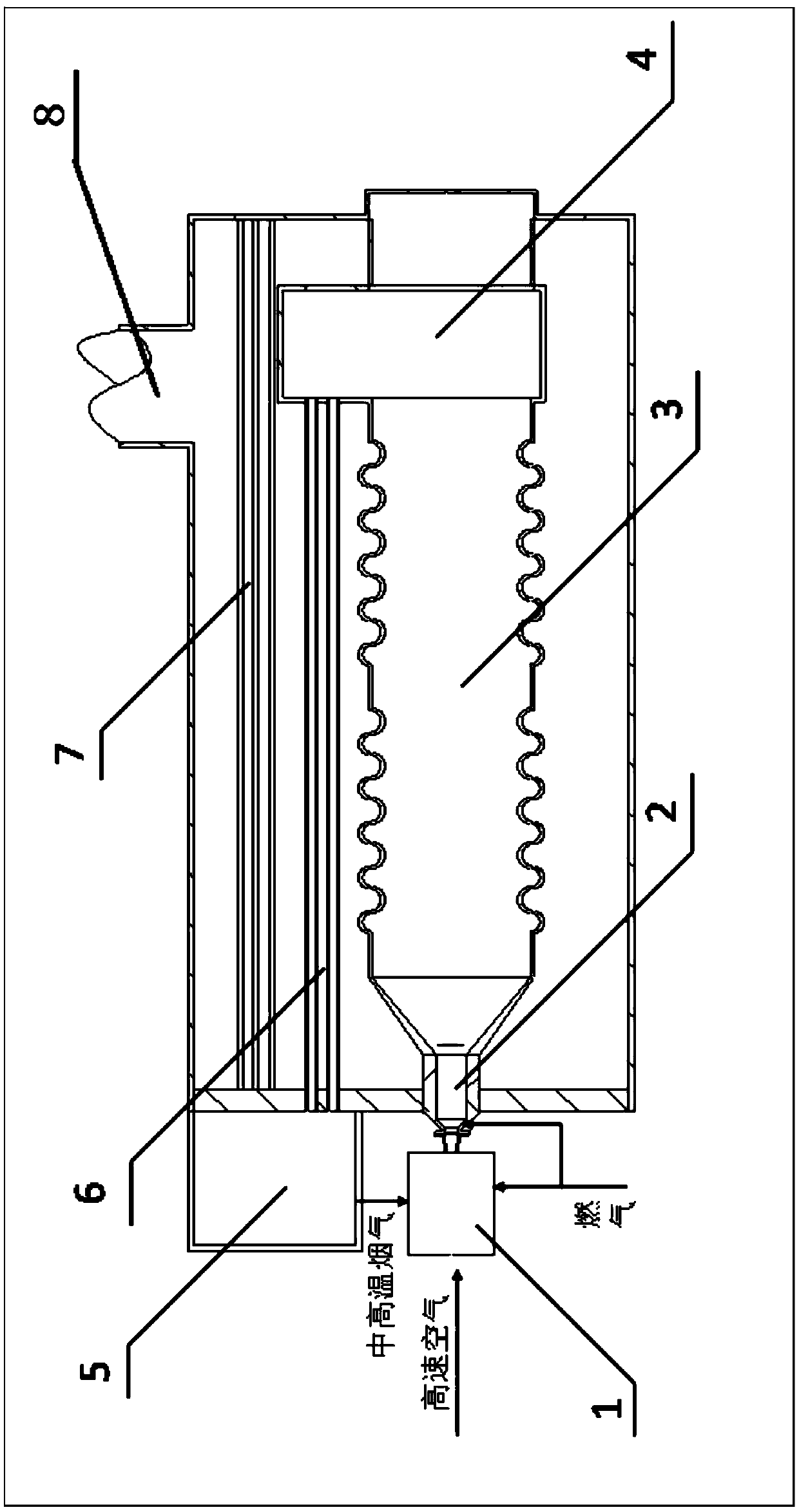

[0022] A medium-high temperature flue gas circulation type low-nitrogen staged burner, its structure is as follows figure 1 As shown, the high-temperature flue gas circulation low-nitrogen staged burner in this embodiment is in the form of a horizontal gas boiler, and the burner includes a staged burner body, an air-flue gas mixing chamber 1 arranged at the front end of the staged burner body, The rear smoke return chamber 4 arranged at the rear end of the staged burner body, the front smoke return chamber 5 communicated with the rear smoke return chamber 4 through the return pipe 6 and the flue gas outlet 8, the front smoke return chamber 5 communicates with the air-flue gas mixing chamber 1, And the front smoke return chamber 5 communicates with the smoke outlet 8 through the smoke outlet pipe 7;

[0023] This embodiment specifically includes the technology of using medium-high temperature flue gas to heat combustion-supporting air, the technology of using high-speed air to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com