Device and method for preparing methane through catalytic gasification of oxygen carrier coal

A technology of catalytic gas and oxygen carrier, applied in the field of coal-to-methane production, can solve the problems of poor operation stability, low carbon conversion rate, low methane yield, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

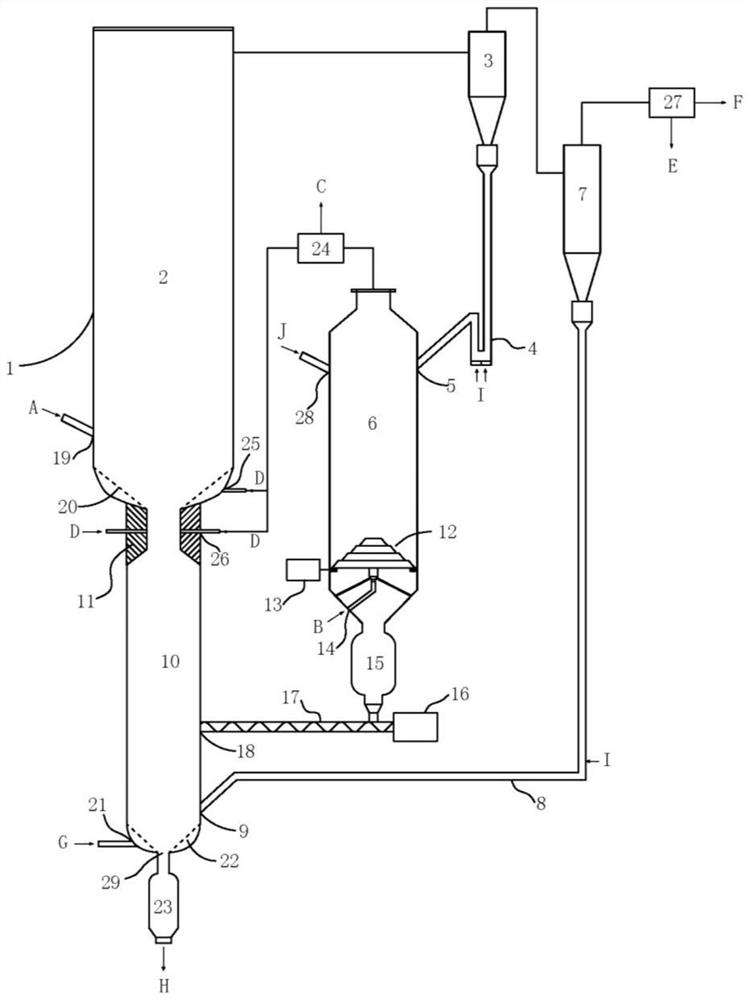

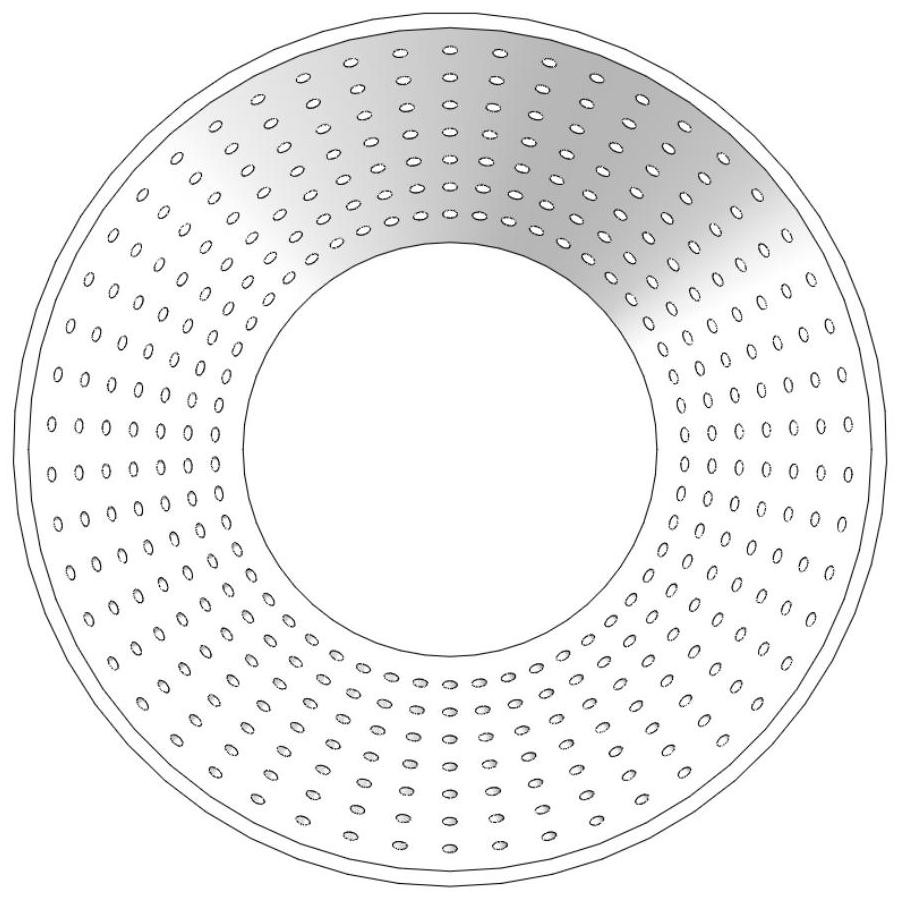

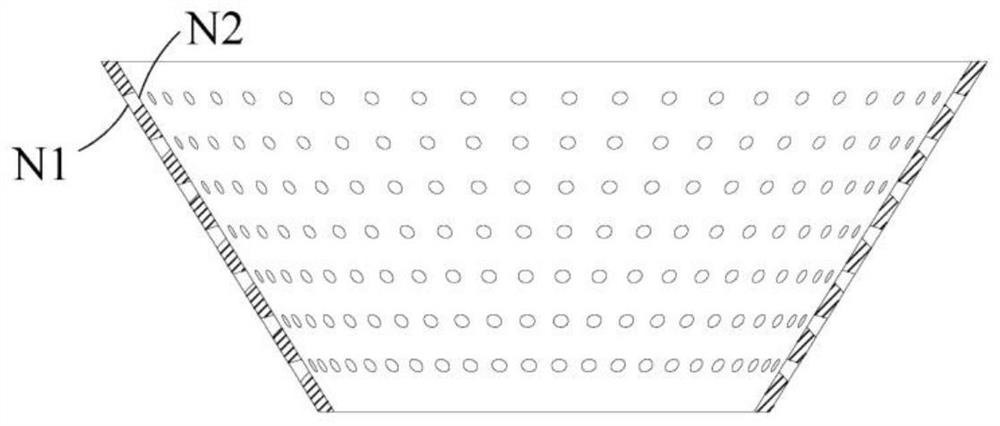

[0084] A new oxygen carrier coal catalytic gasification methane reaction device, the pyrolysis methane section 2 in the upper part of the gasifier 1 has an inner diameter of 2.0m and a height of 8m, and the oxidation gasification section 10 in the lower part of the gasifier 1 has an inner diameter of 1.2m and a height of 6m. The raw material inlet 19 is located at 1 / 10 of the height of the pyrolysis methane section 2 on the upper part of the gasifier 1, and the moving bed hydrogen production furnace 6 has an inner diameter of 1.5m and a height of 6m. The second hydrogen inlet 26 at the throat structure 11 is fed with a hydrogen ratio of 30%, the outer hole N1 of the gas distributor in the pyrolytic methane section 2 has an aperture of 2mm, the inner hole N2 has an aperture of 0.5mm, and the grate offset distance is 0.

[0085] Inner Mongolia lignite is selected as raw material and put into the gasification reduction furnace from the raw material inlet 19, and the oxidation carr...

Embodiment 2

[0087] A new oxygen carrier coal catalytic gasification methane reaction device, the pyrolysis methane section 2 in the upper part of the gasifier 1 has an inner diameter of 2.0m and a height of 8m, and the oxidation gasification section 10 in the lower part of the gasifier 1 has an inner diameter of 1.2m and a height of 6m. The raw material inlet 19 is located at 1 / 10 of the height of the pyrolysis methane section 2 on the upper part of the gasifier 1, and the moving bed hydrogen production furnace 6 has an inner diameter of 1.5m and a height of 6m. The second hydrogen inlet 26 at the throat structure 11 is fed with a hydrogen ratio of 0%, the outer hole N1 of the gas distributor in the pyrolytic methane section 2 has an aperture of 2mm, the inner hole N2 has an aperture of 0.5mm, and the grate offset distance is 0.

[0088] Inner Mongolia lignite is selected as raw material and put into the gasification reduction furnace from the raw material inlet 19, and the oxidation carri...

Embodiment 3

[0090] A new oxygen carrier coal catalytic gasification methane reaction device, the pyrolysis methane section 2 in the upper part of the gasifier 1 has an inner diameter of 2.0m and a height of 8m, and the oxidation gasification section 10 in the lower part of the gasifier 1 has an inner diameter of 1.2m and a height of 6m. The raw material inlet 19 is located at 1 / 10 of the height of the pyrolysis methane section 2 on the upper part of the gasifier 1, and the moving bed hydrogen production furnace 6 has an inner diameter of 1.5m and a height of 6m. The second hydrogen inlet 26 at the throat structure 11 is fed with a hydrogen ratio of 30%, the outer hole N1 of the gas distributor in the pyrolytic methane section 2 has an aperture of 2mm, the inner hole N2 has an aperture of 0.5mm, and the grate offset distance is 0.

[0091] Inner Mongolia lignite is selected as raw material and put into the gasification reduction furnace from the raw material inlet 19, and the oxidation carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com