Plate heat exchanger

A technology of plate heat exchanger and heat exchange zone, applied in the direction of heat exchanger type, indirect heat exchanger, heat exchange equipment, etc., to achieve good mixing effect, strengthen heat exchange effect, and reduce the effect of fluid flow pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

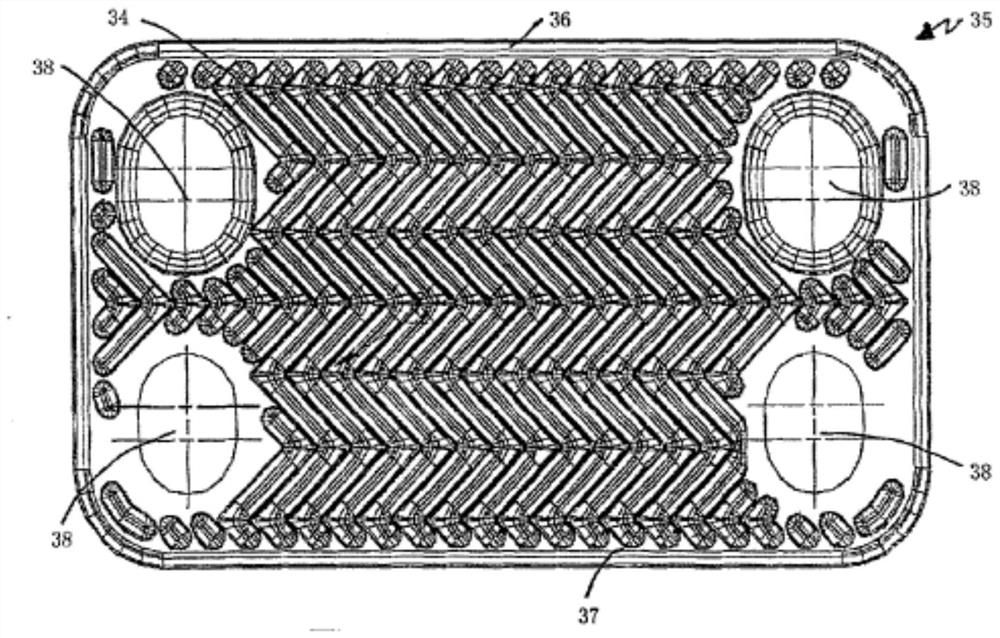

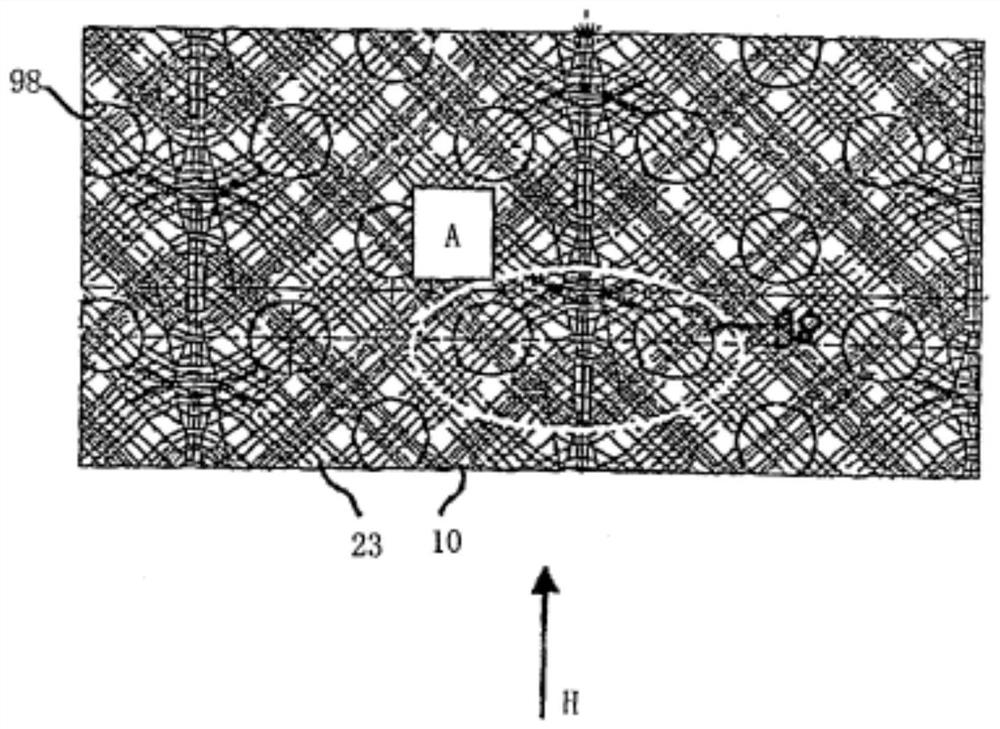

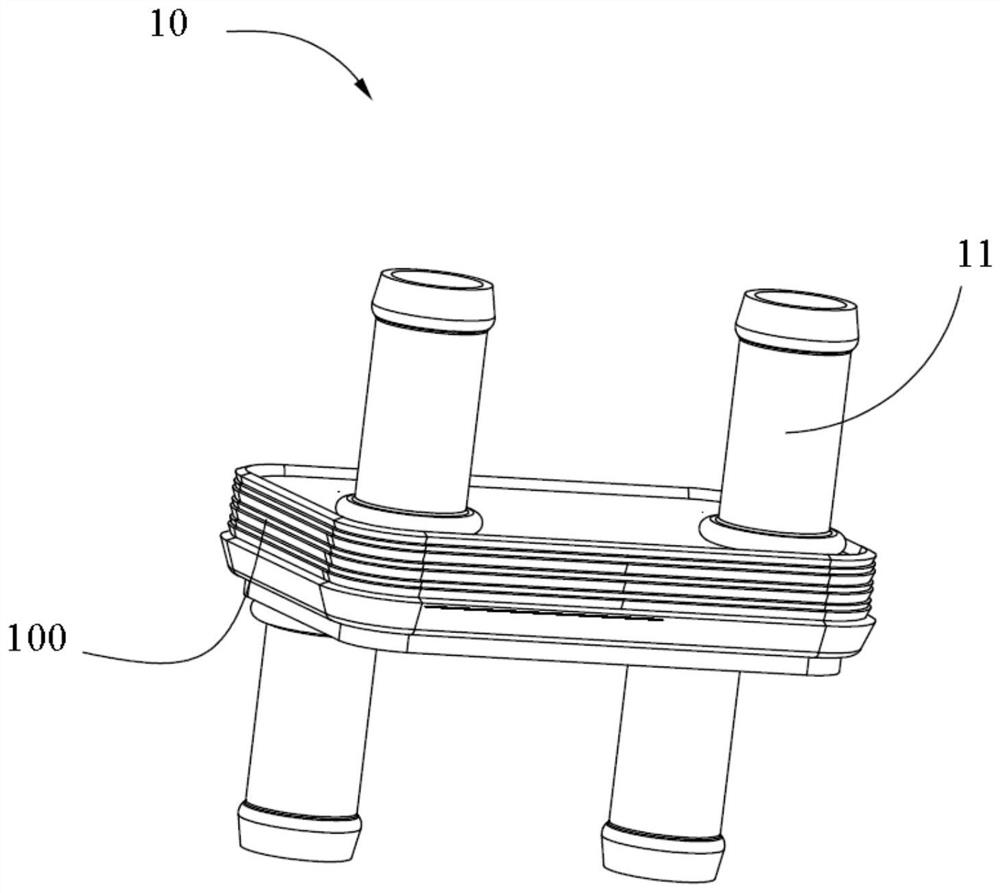

[0031] For plate heat exchangers, the herringbone wave technology forms the plate by arranging periodically alternating "herringbone" ridges and grooves on the plate. Two adjacent circulation plates are assembled by means of herringbone sharp angles to form a fluid channel, which has the technical characteristics of high turbulence and enhanced heat transfer effect. It is widely used in refrigeration and air conditioning, refrigeration, automobiles, aerospace, etc. broadly used.

[0032] For a plate heat exchanger with a corrugated structure similar to a herringbone wave shape, the flow of fluid is decomposed into furrow flow along the channel and roughly along the path between the inlet and outlet of the plate. The longitudinal flow (longitude flow) in the main flow direction formed between them.

[0033] Under the wave distance parameters that meet the mold forming and structural strength requirements, the plate with an obtuse angle of the herringbone wave has a large flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com