Method and device for drying polymer

A drying method and polymer technology, which is applied in the field of polymer drying and devices, can solve problems such as blocked pipes, and achieve the effects of avoiding dust explosion, improving drying efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

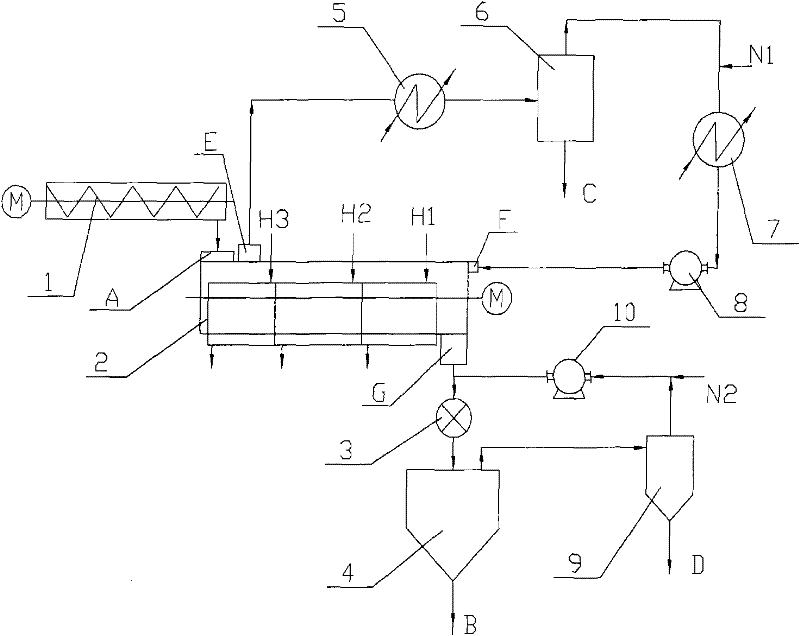

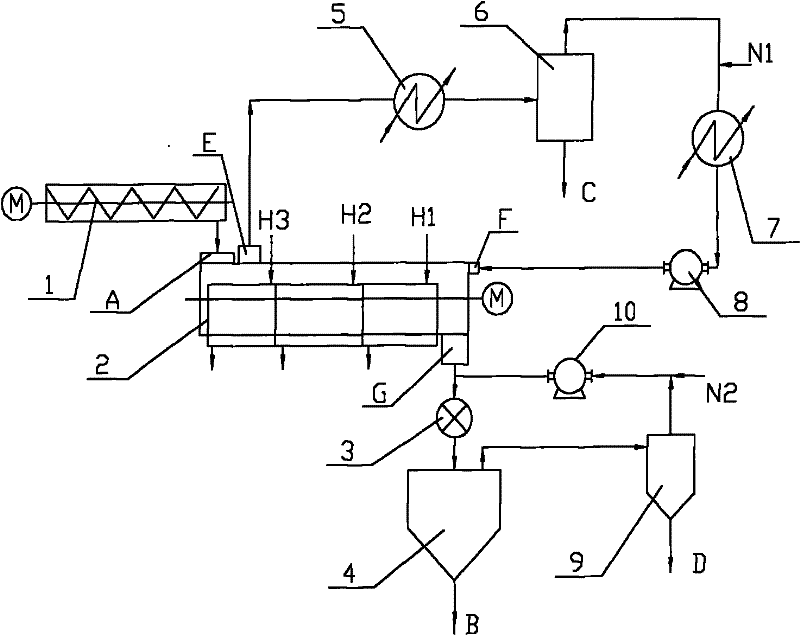

[0036] Such as figure 1 As shown, the washed and filtered polyphenylene ether containing 60% solid content, 40% methanol, and toluene is pushed by the screw propeller 1 to enter the dryer 2 from the feed port A of the dryer, wherein The jacket of the dryer is heated to 190°C by the first-stage heating H3, the second-stage heating H2 is heated to 130°C, and the third-stage heating H1 is heated to 100°C. When the polyphenylene ether is pushed forward by the hollow paddle propeller, at the same time The high-temperature circulating nitrogen is heated to 180°C through the heat exchanger 7, and then pressurized by the fan 8 and enters the F port of the dryer. The circulating nitrogen entrains the organic solvent methanol in the dryer. After the device 5 is cooled, it enters the gas-liquid separation tank 6 for separation. The nitrogen gas comes out from the top of the separation tank, passes through the heat exchanger 7 and enters the dryer again, and the nitrogen replenishment pip...

Embodiment 2

[0038] Such as figure 1 As shown, the washed and filtered polyphenylene ether containing 60% solid content, 40% methanol, and toluene is pushed by the screw propeller 1 to enter the dryer 2 from the feed port A of the dryer, wherein The jacket of the dryer is heated to 190°C by the first-stage heating H3, the second-stage heating H2 is heated to 130°C, and the third-stage heating H1 is heated to 100°C. When the polyphenylene ether is pushed forward by the screw propeller, the high temperature cycle The nitrogen gas is heated to 180°C through the heat exchanger 7, and then pressurized by the fan 8 and enters the F port of the dryer. The circulating nitrogen gas entrains the organic solvent methanol in the dryer, and the toluene comes out from the exhaust port E of the dryer and passes through the heat exchanger 5. After cooling, it enters the gas-liquid separation tank 6 for separation. Nitrogen gas comes out from the top of the separation tank, passes through the heat exchange...

Embodiment 3

[0040] Such as figure 1 As shown, the polyphenylene ether containing 70% solid content after washing and filtering, containing 30% methanol, and toluene is pushed by the screw propeller 1 to enter the dryer 2 from the feed port A of the dryer, wherein The jacket of the dryer is heated to 190°C by the first-stage heating H3, the second-stage heating H2 is heated to 120°C, and the third-stage heating H1 is heated to 90°C. When the polyphenylene ether is pushed forward by the hollow paddle propeller, at the same time The high-temperature circulating nitrogen is heated to 170°C through the heat exchanger 7, and then pressurized by the fan 8 and enters the F port of the dryer. The circulating nitrogen entrains the organic solvent methanol in the dryer. After the device 5 is cooled, it enters the gas-liquid separation tank 6 for separation. The nitrogen gas comes out from the top of the separation tank, passes through the heat exchanger 7 and enters the dryer again, and the nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com