Double-pH-value wet-strength waste paper recycling pulping method

A wet-strength, waste paper technology, used in waste paper recycling chemical mechanical pulping systems and pulping fields, can solve the problems of reflocculation, high price, fiber damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

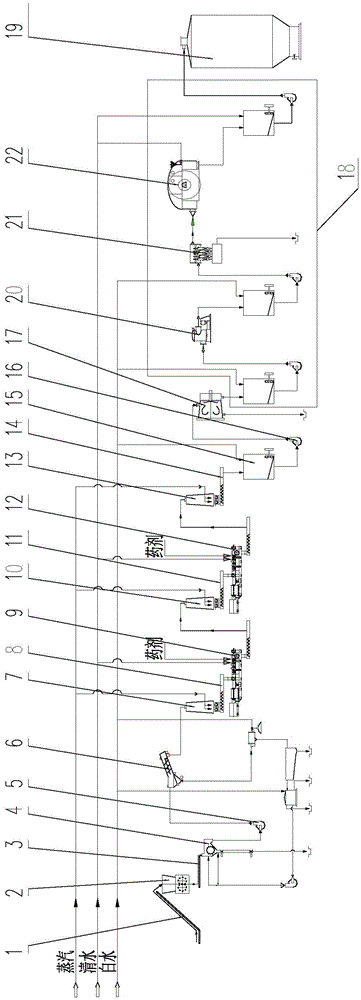

[0073] Example 1: Bleaching paper machine broken paper and scrap repulping recovery containing wet strength agent

[0074] Broken paper and leftovers are transported by the chain conveyor to the hydraulic pulper and broken into paper pieces, and then transported to the drum washing machine 4 to adjust the concentration to 3% for washing and slag removal, and then pumped by the material pump 5 to Inclined spiral dehydrator 6 is dehydrated and concentrated, and then transported to the steam chamber 7 for steaming for 15 minutes, the steam pressure is 0.3MPa, according to the weight percentage of the dry raw material, when entering the steam chamber, spray 0.1% rewetting agent; after steaming, the tablet is sent to the first twin-screw impregnation machine 9 by the third screw conveyor 8, extruded and kneaded into a silk ball and concentrated to about 35% concentration, and then according to the weight of the absolute dry raw material Percentage, add 1% liquid NaOH and appropriat...

Embodiment 2

[0076] Example 2: Recycling of unbleached paper machine broken paper and scraps containing wet strength agents

[0077] Broken paper and leftovers are conveyed by the chain conveyor to the hydraulic pulper and shredded into paper pieces, and sent to the drum washing machine 4 to adjust the concentration to 4% for washing and slag removal, and then pumped by the material pump 5 to the inclined Spiral dehydrator 6 is dehydrated and concentrated, and then transported to the steam chamber 7 for steaming for 25 minutes, the steam pressure is 0.45MPa, according to the weight percentage of the absolute dry raw material, when transported to the steam chamber, spray 0.12% rewetting agent; after steaming, the tablet is sent to the first twin-screw impregnation machine 9 by the third screw conveyor 8, extruded and kneaded into a silk ball and concentrated to about 40% concentration, and then according to the weight of the absolute dry raw material Percentage, 1.2% H is added by metering ...

Embodiment 3

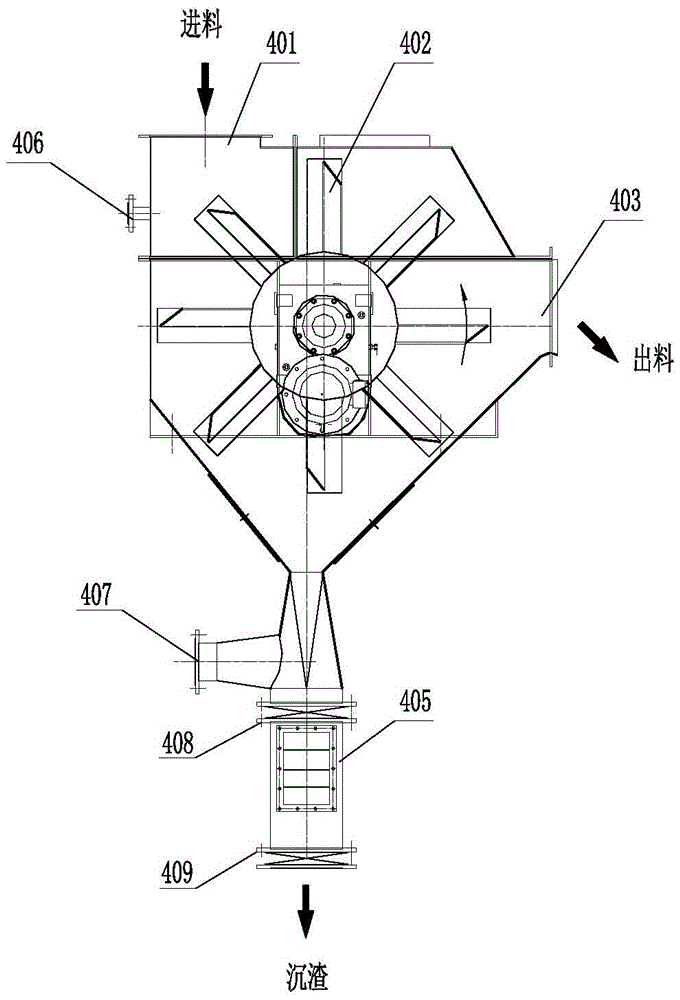

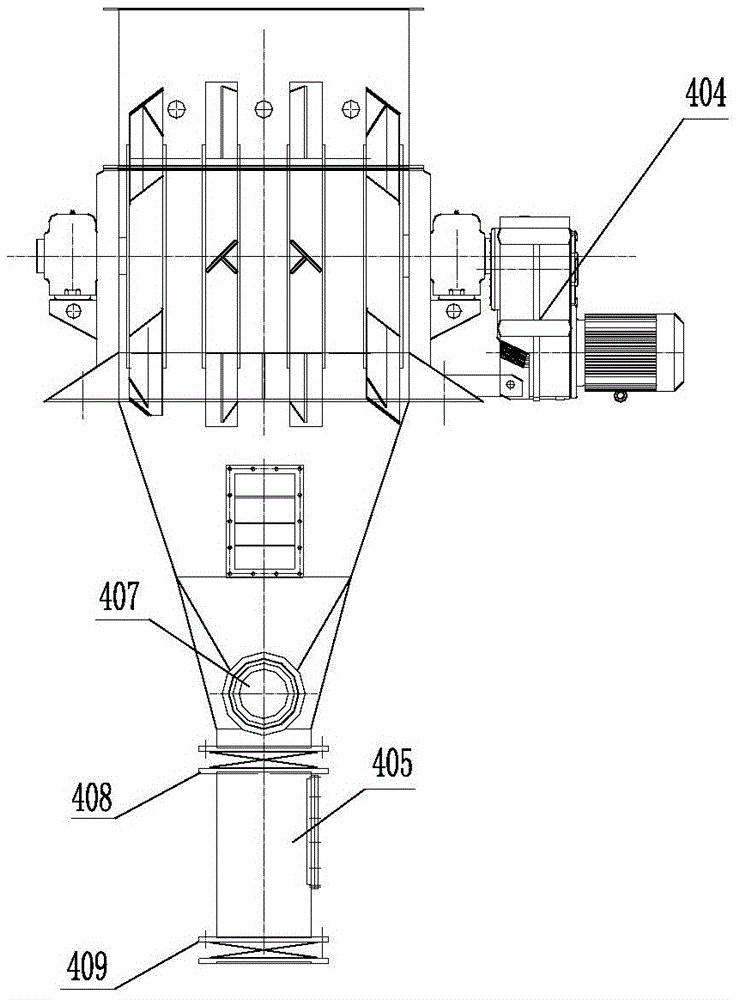

[0079] Example 3: Re-pulping recovery of unbleached waste paper and waste cardboard containing wet strength agents

[0080] The waste paper and waste cardboard are conveyed by the chain-plate conveyor to the shredder and shredded into paper pieces, and sent to the drum washing machine 4 to adjust the concentration to 5% for washing and slag removal, and then pumped by the material pump 5 Dehydration and concentration in the oblique spiral dehydrator 6, and then transported to the steam chamber 7 for steaming for 30 minutes, the steam pressure is 0.6MPa, according to the weight percentage of the absolute dry raw material, when transported to the steam chamber, it is sprayed into the feed port in the form of mist 0.15% rewetting agent; after steaming, the flakes are sent to the first twin-screw impregnation machine 9 by the third screw conveyor 8, extruded and kneaded into silk balls and concentrated to about 45% concentration, and then according to the dry raw material % by wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com