Diffusion-strengthened copper prepared by nano particle stirring method and preparation method thereof

A technology for dispersion strengthening of copper and nanoparticles, which is used in high-strength, high-wear and high-corrosion-resistant metal materials, and high electrical conductivity. It can achieve the effect of improved mechanical properties, low cost and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

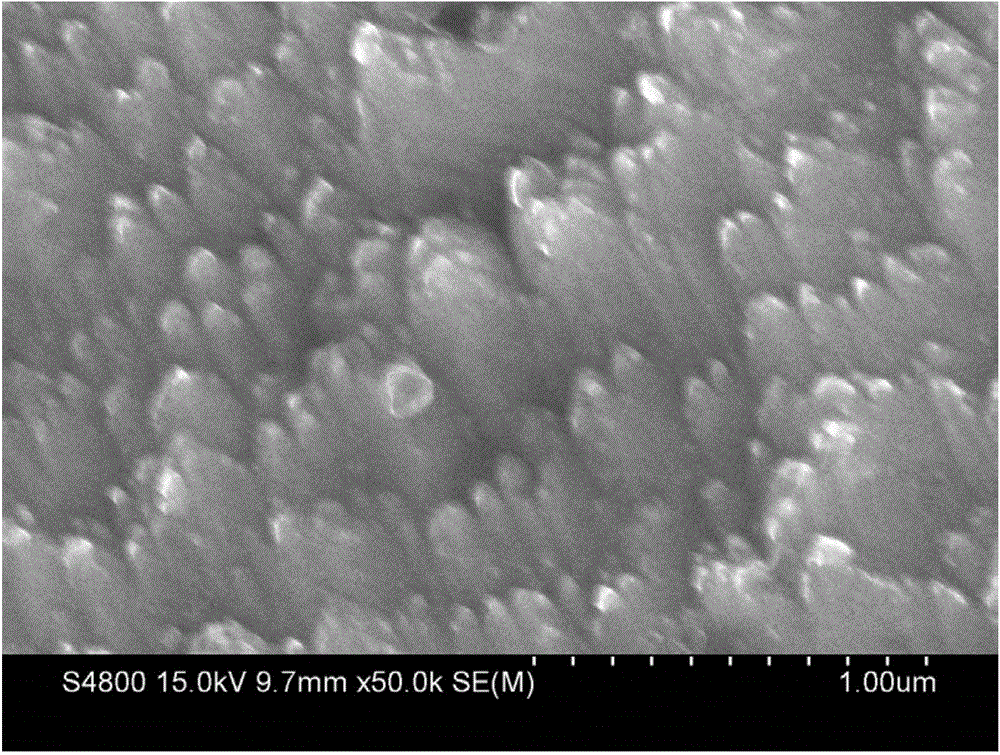

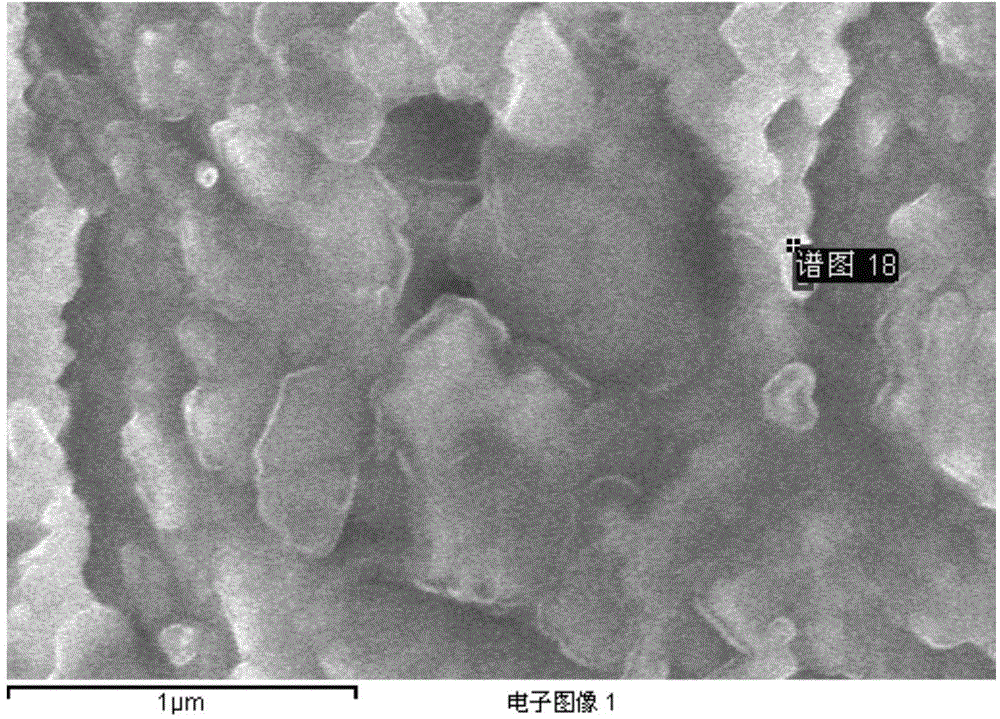

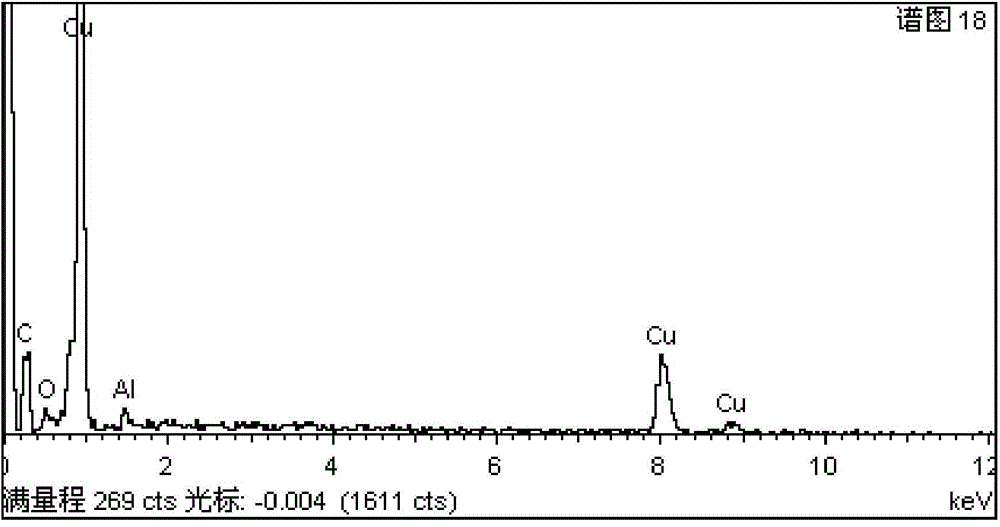

[0016] In the embodiment of the present invention, the process flow for preparing dispersion-strengthened copper by nanoparticle stirring method is as follows: modify the surface of nano-alumina, disperse it in ethanol for 40 minutes with silane coupling agent KH570, put it into a planetary ball mill and grind for 3 hours, and complete surface modification. Pack the surface-modified nano-alumina in a copper tube, the content is 0.15wt% of the total weight of the melt, and prepare according to the above ingredients, first add the copper plate to the smelting to 1180-1200 °C, and cover the surface with a layer of charcoal with a thickness of more than 2mm powder, and then add the packaged nano-Al in the melting furnace in the way of dispersed feeding 2 o 3 After stirring, let it stand for 30 minutes, pour it into a horizontal continuous casting holding furnace, and cast it into a slab at a temperature of 1150 ° C. The conductivity of the slab is 91% IACS, the oxygen content is ...

Embodiment 2

[0018] In the embodiment of the present invention, the process flow for preparing dispersion-strengthened copper by nanoparticle stirring method is as follows: modify the surface of nano-alumina, disperse it in ethanol for 30 minutes with silane coupling agent KH570, put it into a planetary ball mill and grind it for 3.5 hours, and complete surface modification. The surface-modified nano-alumina is packaged in a copper tube. The content is 0.35wt% of the total weight of the melt. It is prepared according to the above ingredients. First, the copper plate is added to the melting temperature to 1180-1200 °C, and the surface layer is covered with a layer of charcoal powder with a thickness of more than 2mm. good nano Al 2 o 3 After stirring, let it stand for 30 minutes, pour it into a vertical holding furnace, and cast it into a slab at a temperature of 1150 ° C. The conductivity of the slab is 88% IACS, and the oxygen content is 290ppm. After rolling and deformation, a slab of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com