Application of laser in low activation martensitic steel welding and welding method

A technology of laser welding and welding methods, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of reduced weld toughness, irradiation embrittlement, harshness, etc., and achieves less welding stress and deformation. , Improve the overall performance, the effect of fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

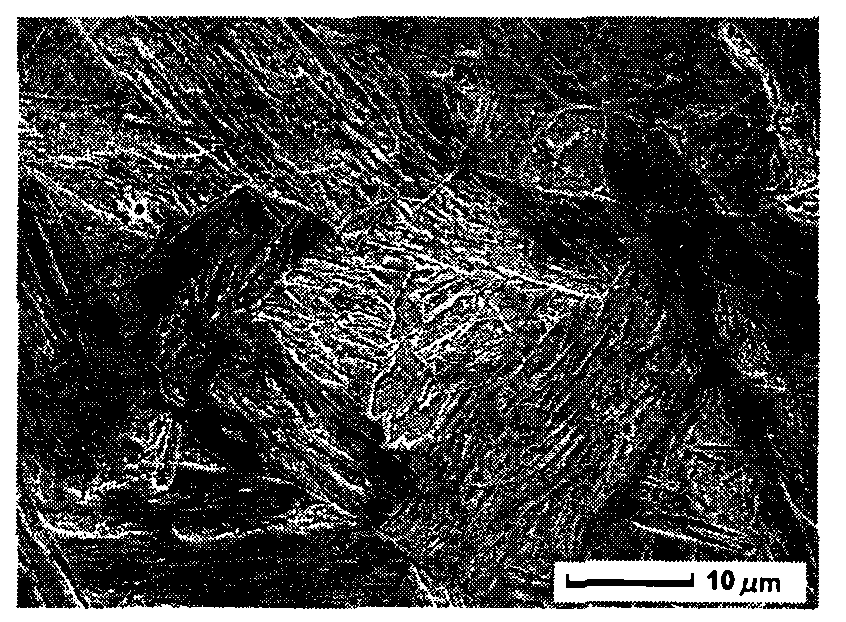

[0021] Embodiment 1 of the present invention: laser welding of CLAM steel: the CLAM steel plate is cut into 80mm × 12mm samples, and the welding joints of the samples are polished with metallographic sandpaper before welding, and cleaned with acetone, and then Nd:YAG is used The laser is used for welding, the defocus is 0mm, the welding thickness is 6mm under the conditions of laser output power P=4KW, welding speed V=9mm / s, spot diameter d=0.5mm, protective gas Argon: 30L / min. After cross-section and microstructure analysis, the results show that the welded joint has no welding defects, no inclusions, no pores, and good fusion. The cross-sectional photos and microstructure pictures of the welded joint are as follows figure 1 and figure 2 Shown; Tensile test was carried out on the welded sample, the sample was broken at the base metal, but not at the weld and heat-affected zone, and the weld performance was good, as shown in image 3 shown.

Embodiment 2

[0022] Embodiment 2 of the present invention: laser welding of CLAM steel: the CLAM steel sheet is cut into 80mm × 12mm samples, and the welding joints of the samples are polished with metallographic sandpaper before welding, and cleaned with acetone, and then Nd:YAG is used Laser welding, defocus amount 0mm, under the conditions of laser output power P=3.5KW, welding speed V=25mm / s, spot diameter d=0.5mm, shielding gas Argon: 30L / min, welding thickness 5mm. After cross-section and microstructure analysis, the results show that the welded joint has no welding defects, no inclusions, no pores, and good fusion. The cross-sectional photos and microstructure pictures of the welded joint are as follows Figure 4 and Figure 5 Shown; Tensile test was carried out on the welded sample, the sample was broken at the base metal, but not at the weld and heat-affected zone, and the weld performance was good, as shown in Figure 6 shown.

Embodiment 3

[0023] Embodiment 3 of the present invention: laser welding of CLAM steel: the CLAM steel sheet is cut into 80mm × 12mm samples, and the welding joints of the samples are polished with metallographic sandpaper before welding, and cleaned with acetone, and then Nd:YAG is used The laser is used for welding, the defocus amount is 0mm, and the welding thickness is 5mm under the conditions of laser output power P=4KW, welding speed V=15mm / s, spot diameter d=0.5mm, shielding gas Argon: 30L / min. The results of microstructure analysis show that the welded joint has no welding defects, no inclusions, no pores, and good fusion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Defocus amount | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com