Energy-saving magnetic shielding device for induction heating crystal furnace

A technology of induction heating and magnetic shielding, applied in induction heating, magnetic field/electric field shielding, crystal growth, etc., can solve problems such as loss of energy, reduce energy efficiency, increase production cost, etc., and achieve the effect of avoiding loss and improving induction heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

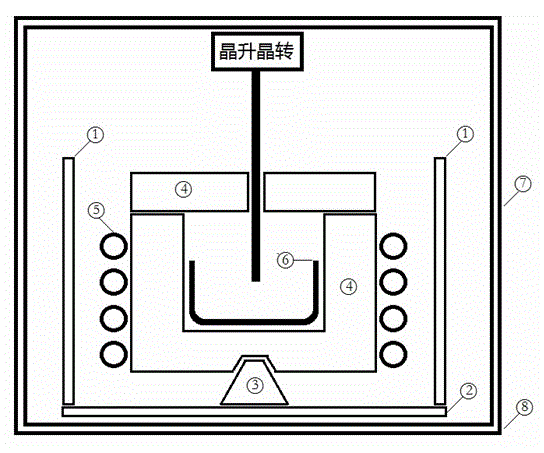

[0021] On the basis of the magnetic induction heating mechanism, the invention invents a magnetic shield to solve the problem that the alternating magnetic field generated by the induction coil wire cannot be concentrated on the heating target, and adds a magnetic shield structure to the induction coil to concentrate the energy in the magnet and guide it Among the target heating parts, the efficiency of induction heating is effectively improved, and the energy loss caused by components such as furnace walls is eliminated.

[0022] According to the different requirements of magnetic induction heating mechanisms for different applications (high-power induction heating equipment such as crystal growth), the present invention designs targeted special magnetic cores. In order to achieve the maximum convergence of electromagnetic energy and improve heating efficiency. Combined with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com