Contamination-free and high-efficient device for thinning titanium aluminum alloy

A titanium-aluminum alloy, non-polluting technology, applied in the field of pollution-free and high-efficiency refining alloy devices, can solve problems such as damage to ultrasonic equipment, pollution of titanium-aluminum alloy melt, and inability to spread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

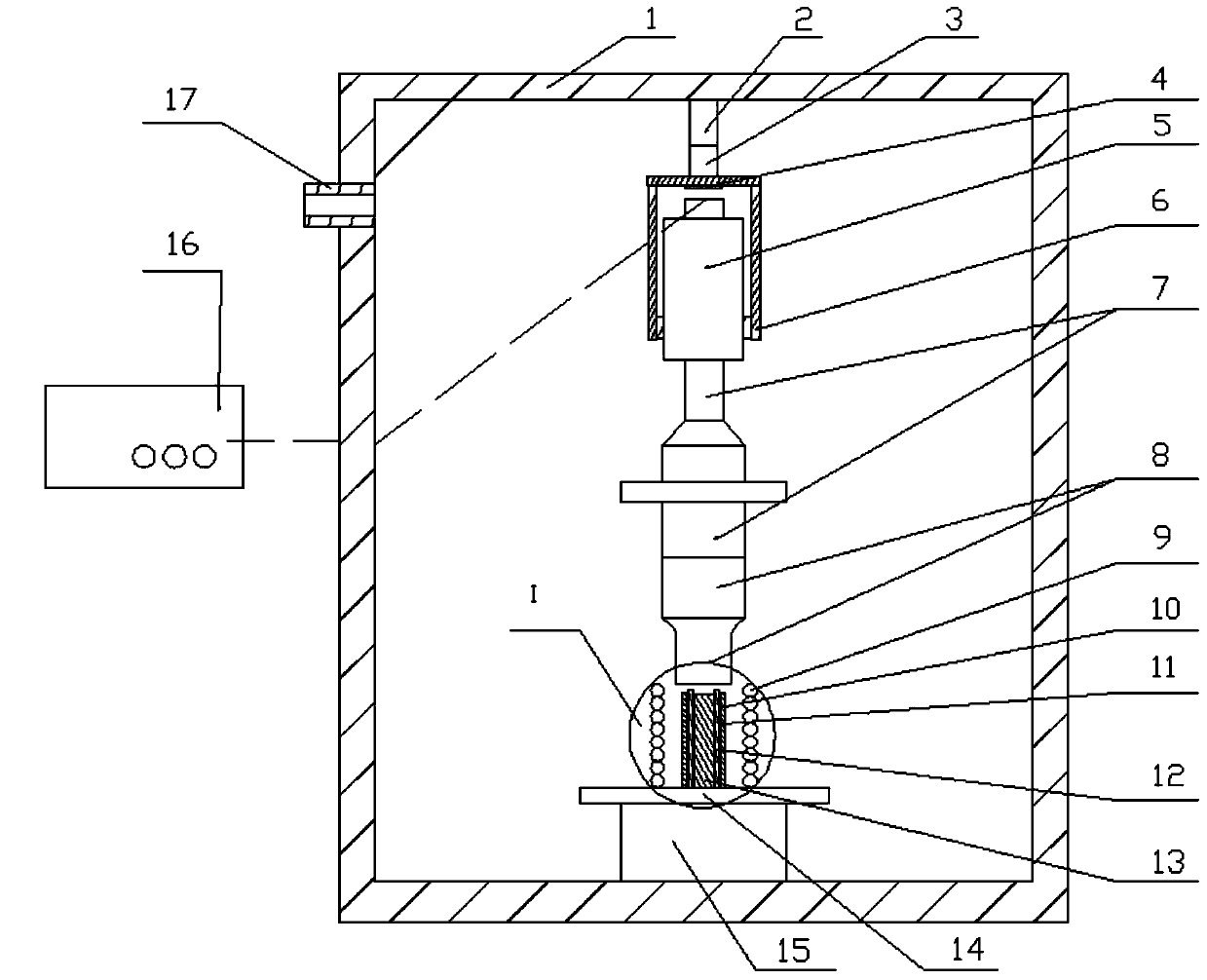

[0017] Specific implementation mode 1: A pollution-free and high-efficiency refining titanium-aluminum alloy device according to this implementation mode, which includes the following parts:

[0018] Tank body 1, vacuum pump 17, ultrasonic generator 16, ultrasonic oscillation equipment and titanium-aluminum alloy melt melting equipment;

[0019] Wherein, the ultrasonic oscillation equipment includes an upper feeding transmission device 2, a connecting rod 3, an insulating pad 4, a transducer 5, a fixing frame 6, an aluminum alloy horn 7 and a T8 steel tool head 8;

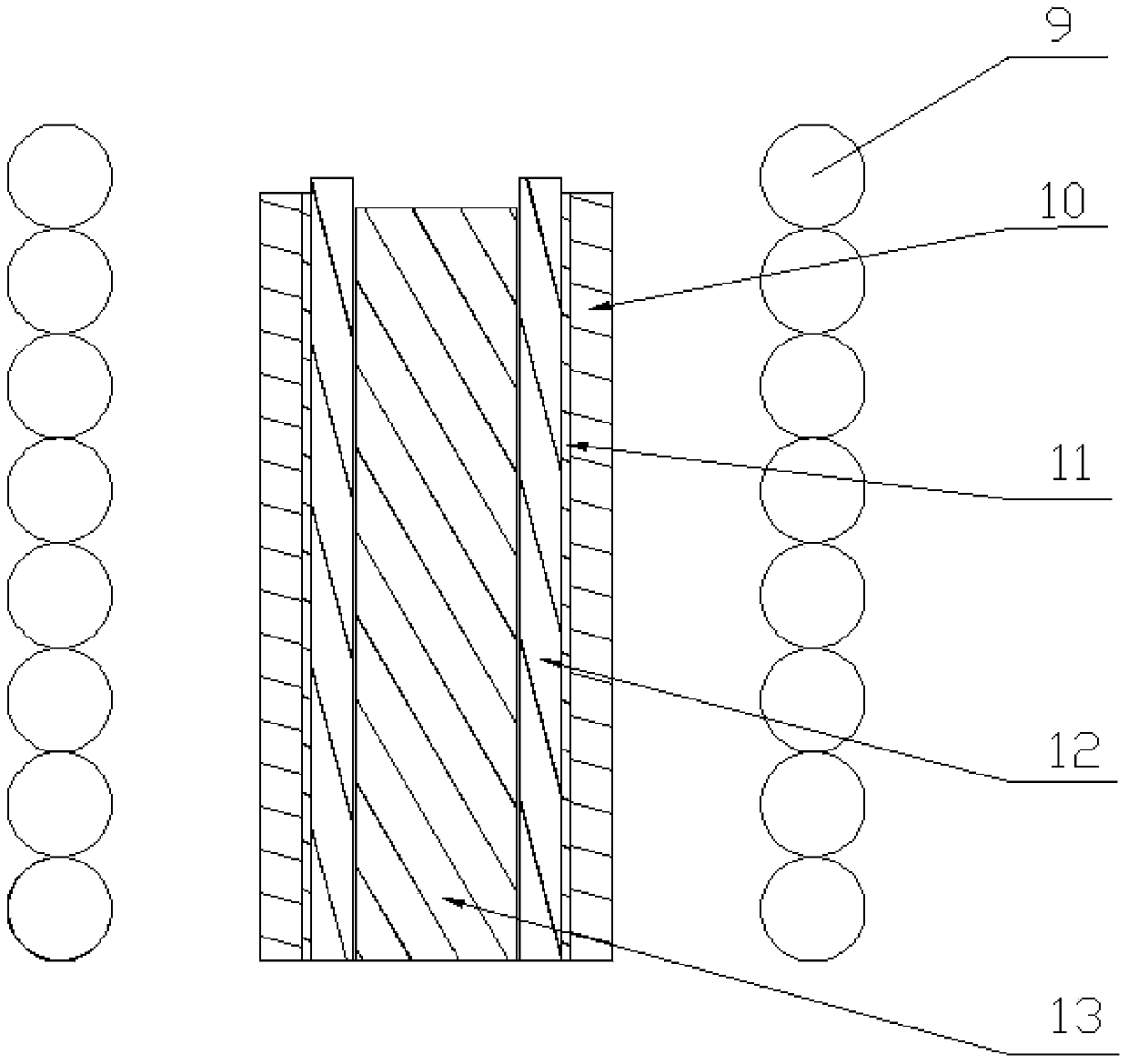

[0020] Wherein, the titanium-aluminum alloy melt melting equipment includes a coil 9, a corundum tube 10, a mullite fiber layer 11, a mold shell 12, a bar material layer 13, a graphite felt 14 and a lower fixing rod 15;

[0021] The upper feeding transmission device 2 is fixed on the upper middle part of the tank body 1, the lower fixing rod 15 is fixed on the lower middle part of the tank body 1, and the centers o...

specific Embodiment approach 2

[0028] Specific embodiment two: this embodiment is different from specific embodiment one in that: the oscillating electric signal with a frequency of 20KHz is generated by the ultrasonic generator 16, which is transmitted to the transducer 5 through the ultrasonic output cable, and the electric signal is transmitted to the transducer 5 by the transducer 5. The signal is transformed into mechanical vibration to drive the fixed frame 6, the connecting rod 3 and the upper feeding transmission device 2 to jointly adjust the working position of the ultrasonic oscillation equipment.

[0029] The amplitude of the mechanical vibration is about 7 to 9 μm, and the amplitude is amplified to 17.5 μm to 22.5 μm after passing through the aluminum alloy horn 7. After the amplification, the ultrasonic wave is exported by the T8 steel tool head 8, and the ultrasonic wave acts on the molten bar On the layer 13, the horn 7 is made of aluminum alloy, and the tool head 8 is made of T8 steel consid...

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the range of adjustable motion speed of the upper feeding transmission device 2 is 0-20 mm / min.

[0032] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter φ | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com