Ultrasonic-assisted fusing device and fusing method of vacuum ultra-high temperature refractory active material

An active material and ultrasonic technology, applied in furnaces, lighting and heating equipment, crucible furnaces, etc., can solve problems such as damage to ultrasonic equipment, pollution of ultra-high temperature refractory active material alloy melts, etc., to avoid melt pollution and ensure purity. The effect of reducing the degree of segregation at grain boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

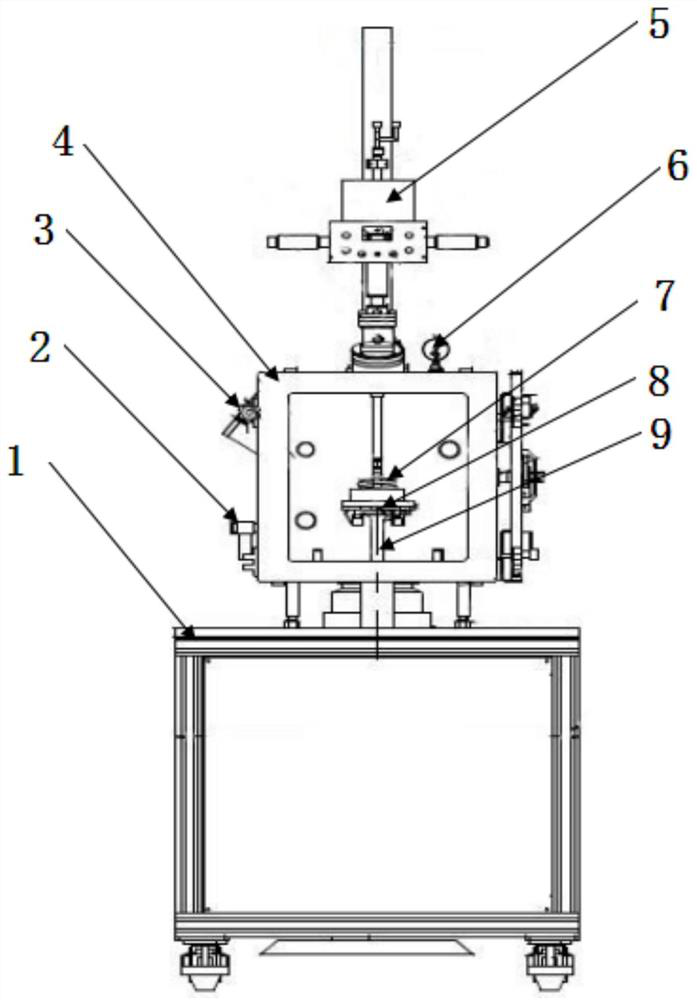

[0029] Embodiment 1: Combining Figure 1 to Figure 3 Illustrating this embodiment, this embodiment includes a movable operating table 1; it also includes a furnace body 4, an observation port 3, a non-consumable arc furnace 5, a pressure gauge 6, a water-cooled copper crucible 8 and an ultrasonic generator 9. The furnace body 4 is installed on the movable operating table 1, the ultrasonic generator 9 is vertically installed on the bottom end surface of the furnace body 4, the water-cooled copper crucible 8 is installed on the ultrasonic generator 9, the raw material 7 is arranged on the water-cooled copper crucible 8, The consumable electric arc furnace 5 vertically passes through the top of the furnace body 4 and extends into the interior of the furnace body 4. There is a distance of 1-20 mm between the lower end of the non-consumable electric arc furnace 5 and the raw material 7, and the observation port 3 is installed On the side wall of the furnace body 4 , a pressure gaug...

specific Embodiment approach 2

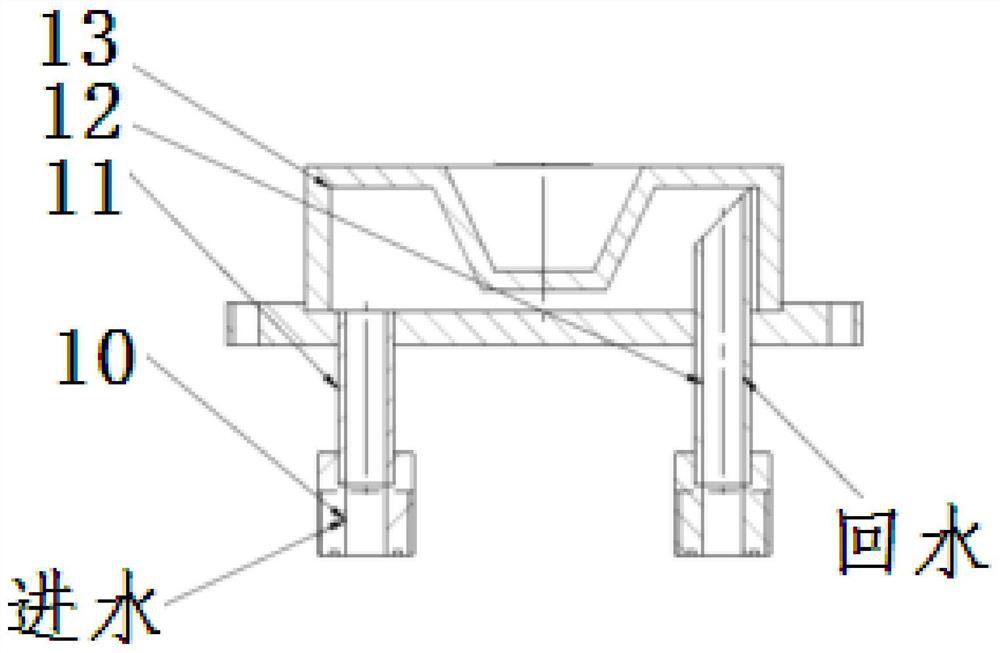

[0030] Specific implementation mode 2: Combining figure 2 Illustrating this embodiment, the water-cooled copper crucible 9 of this embodiment includes a load crucible 13 , a water inlet pipe 11 , a water outlet pipe 12 and two water inlet and outlet joints 10 , and a water inlet pipe 11 and a water outlet pipe 12 are respectively installed at the lower ends of the load crucible 13 . , the bottom ends of the water inlet pipe 11 and the water outlet pipe 12 are respectively installed with a water inlet and outlet joint 10 . This arrangement facilitates water cooling of the crucible. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation three: combination figure 2 Illustrating this embodiment, the load crucible 13 , the water inlet pipe 11 , the water outlet pipe 12 and the two water inlet and outlet joints 10 in this embodiment are all made of red copper. In this way, the overall material of the water-cooled copper crucible in this embodiment is red copper, and cooling water flows through the copper crucible; other compositions and connection relationships are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com