Flux leakage controller used for controlling workpiece groove induction quenching flux leakage and preparation process thereof

An induction quenching and controller technology, which is used in quenching devices, manufacturing tools, and process efficiency improvements, etc. problems, to reduce distortion and quenching cracking phenomenon, improve working conditions, improve power factor and quenching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

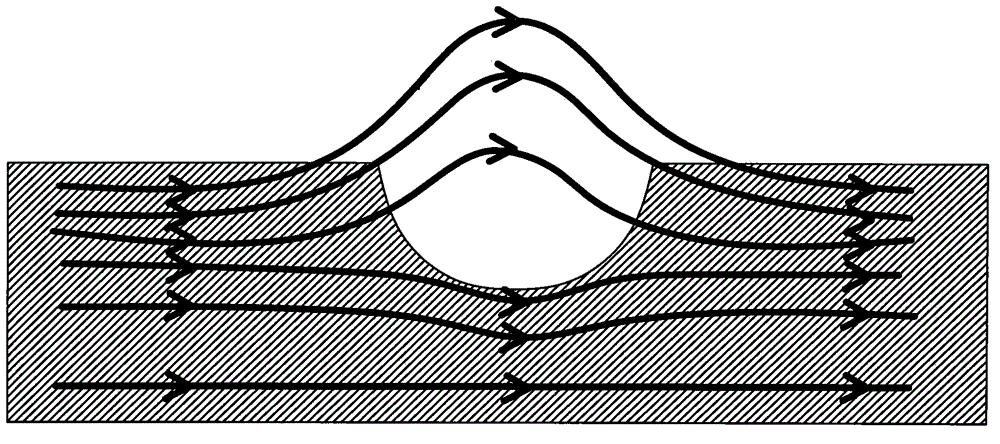

Problems solved by technology

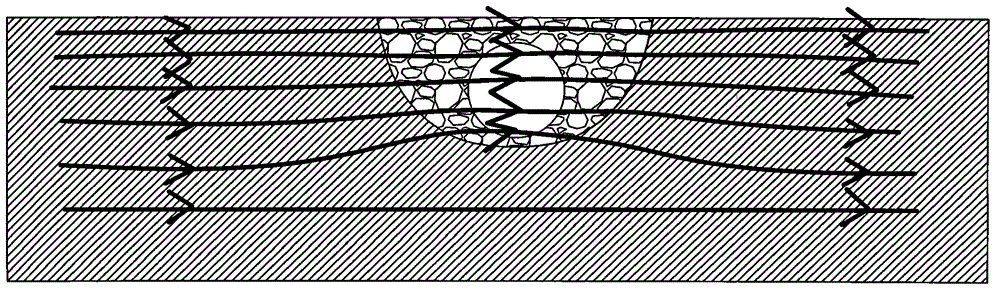

Method used

Image

Examples

Embodiment 1

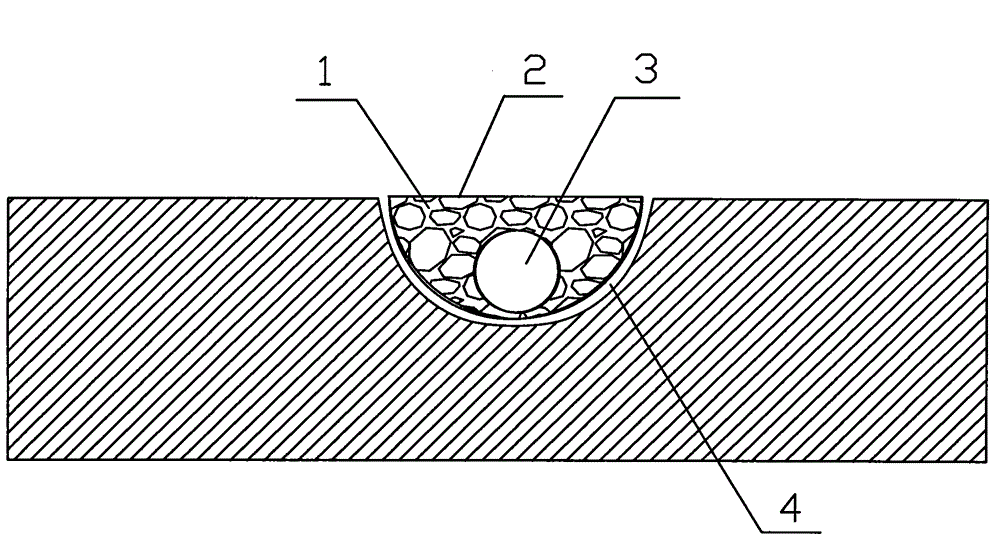

[0031] A magnetic flux leakage controller 2 for controlling magnetic flux leakage during induction quenching of workpiece grooves includes a quartz glass tube 3 and a magnetic conduction device 1 wrapped on the outer layer of the quartz glass tube 3 . The magnetic conducting device is an intermediate frequency magnetic conducting body. The magnetic flux leakage controller 2 is used in coupling with the workpiece groove 4, the workpiece is a ball screw, and the workpiece groove is a screw groove; the gap between the magnetic flux leakage controller 2 and the workpiece groove 4 is 0.2 μm; the groove width of the workpiece groove 4 is 8.0mm, and the wall thickness of the quartz glass tube 3 is 1.0mm. The intermediate frequency magnetizer includes 90wt% intermediate frequency magnetizer powder and 10wt% sodium silicate in terms of weight fraction.

[0032] A preparation process of a magnetic flux leakage controller for controlling the magnetic flux leakage of workpiece grooves, c...

Embodiment 2

[0038] A magnetic flux leakage controller 2 for controlling magnetic flux leakage during induction quenching of workpiece grooves includes a quartz glass tube 3 and a magnetic conduction device 1 wrapped on the outer layer of the quartz glass tube 3 . The magnetic conducting device is a high-frequency magnetic conducting body. The magnetic flux leakage controller 2 is used in coupling with the workpiece groove 4, the workpiece is a ball screw, and the workpiece groove is a screw groove; the gap between the magnetic flux leakage controller 2 and the workpiece groove 4 is 0.5 μm; the groove width of the workpiece bar groove 4 is 16.0 mm, and the wall thickness of the quartz glass tube 3 is 3.0 mm. The high frequency magnetizer includes 90wt% high frequency magnetizer powder, 3wt% aluminum hydroxide, 5wt% copper oxide and 2wt% phosphoric acid in parts by weight.

[0039] A preparation process of a magnetic flux leakage controller for controlling the magnetic flux leakage of work...

Embodiment 3

[0045] A magnetic flux leakage controller 2 for controlling magnetic flux leakage during induction quenching of workpiece grooves includes a quartz glass tube 3 and a magnetic conduction device 1 wrapped on the outer layer of the quartz glass tube 3 . The magnetic guide device 1 is a silicon steel sheet, and evenly distributed mica sheets are arranged between the silicon steel sheets, and the quantity ratio of the silicon steel sheet to the mica sheet is 10:1 to 20:1; the silicon steel sheet and the mica sheet are A hole matched with the quartz glass tube is provided, and the silicon steel sheet and the mica sheet are fixed on the quartz glass tube through the hole and the mud-like intermediate frequency magnetizer. The magnetic flux leakage controller 2 is used in coupling with the workpiece groove 4, the workpiece is a ball screw, and the workpiece groove is a lead screw groove; the gap between the magnetic flux leakage controller 2 and the workpiece groove 4 is 0.3 μm; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com