Torsion bar pier head heating device

A heating device and torsion bar technology, applied in heating/cooling equipment, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems of long heating time, large heating temperature difference, high cost, etc., and achieve high induction heating efficiency, The temperature at both ends is consistent and the effect of processing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

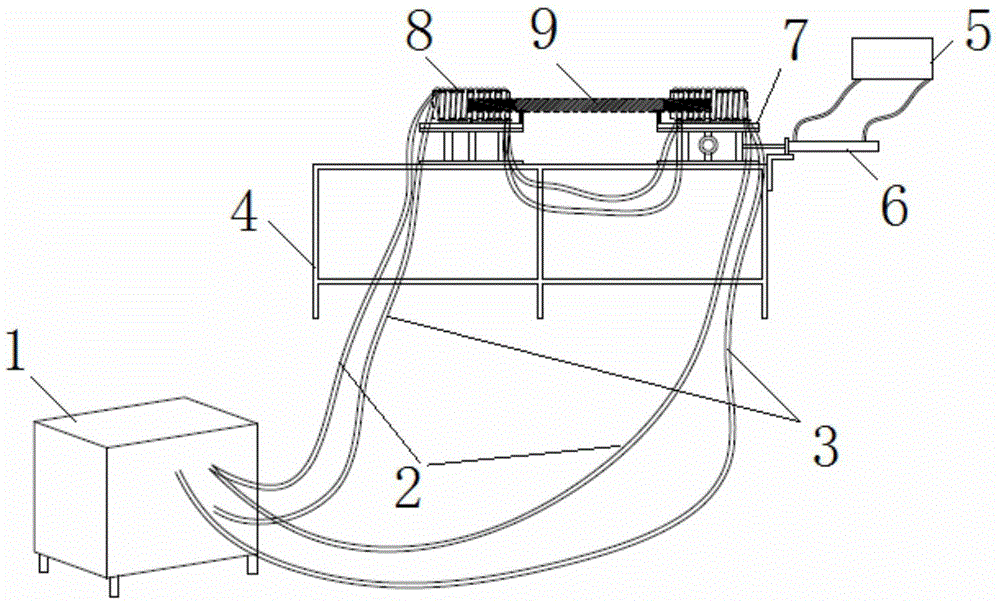

[0016] like figure 1 As shown, the torsion bar head heating device includes a power cabinet 1, a stand 4, and a pair of coil induction heating mechanisms 8 for heating the end of the torsion bar. Both ends of the torsion bar 9 are simultaneously heated by a pair of coils Heating is performed in an induction heating mechanism.

[0017] A pair of brackets 7 are arranged on the platform 4, and a pair of coil induction heating mechanisms are arranged on the pair of brackets respectively, one bracket is fixed on the platform, and the other bracket is movably arranged on the platform. It is convenient for the upper and lower parts of the torsion bar, as well as the heating of the torsion bar with different length specifications.

[0018] The hydraulic cylinder 6 is arranged on the platform, the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com