Smoke gas reverse flowing prevention device of biomass circulating fluid bed boiler

A circulating fluidized bed and biomass technology, which is applied in the direction of fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc., can solve the problems of endangering the personal safety of operating personnel, and achieve the prevention of flue gas backchanneling, Prevent back channeling and facilitate smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

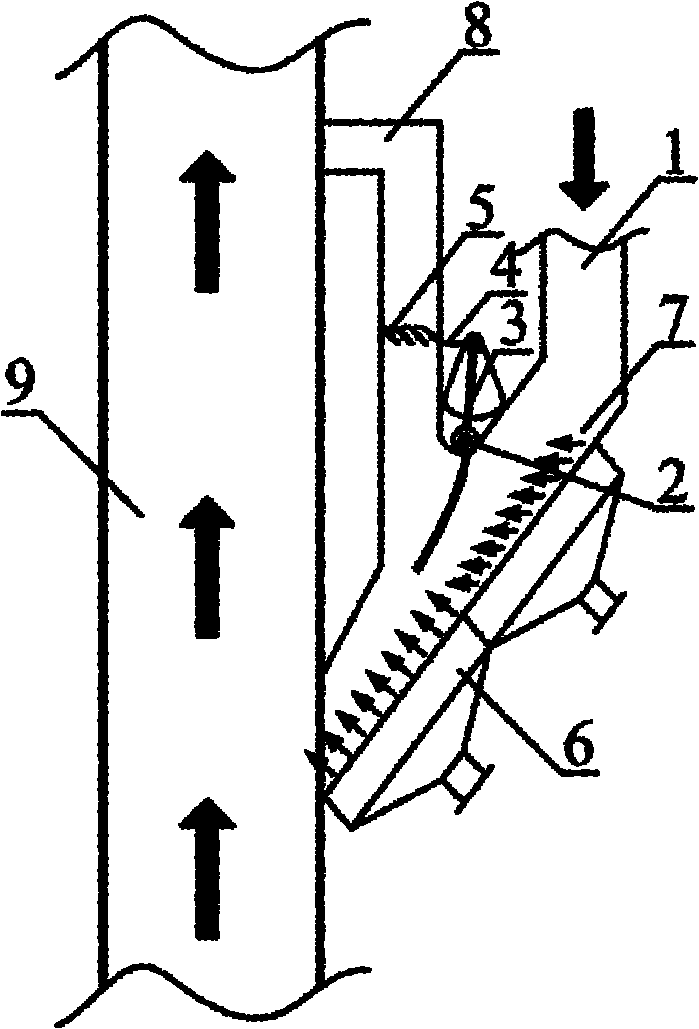

[0039] Refer to the following Figure 1-9 The best embodiment of the anti-channeling device for biomass circulating fluidized bed boiler of the present invention will be described in detail, but the scope of protection of the present invention is not limited to the embodiment.

[0040] As shown in the figure, a flue gas anti-channeling device for a biomass circulating fluidized bed boiler includes a feeding trough 7 arranged on a furnace 9, and the device is also provided with a furnace return flue 8 and a self-balancing smoke retaining door Mechanism 3, linkage damper mechanism 5 and two-stage air distribution mechanism 6.

[0041] One end of the returning furnace flue 8 is connected to the top of the hopper 7 , and the other end is connected to the upper negative pressure area of the furnace 9 .

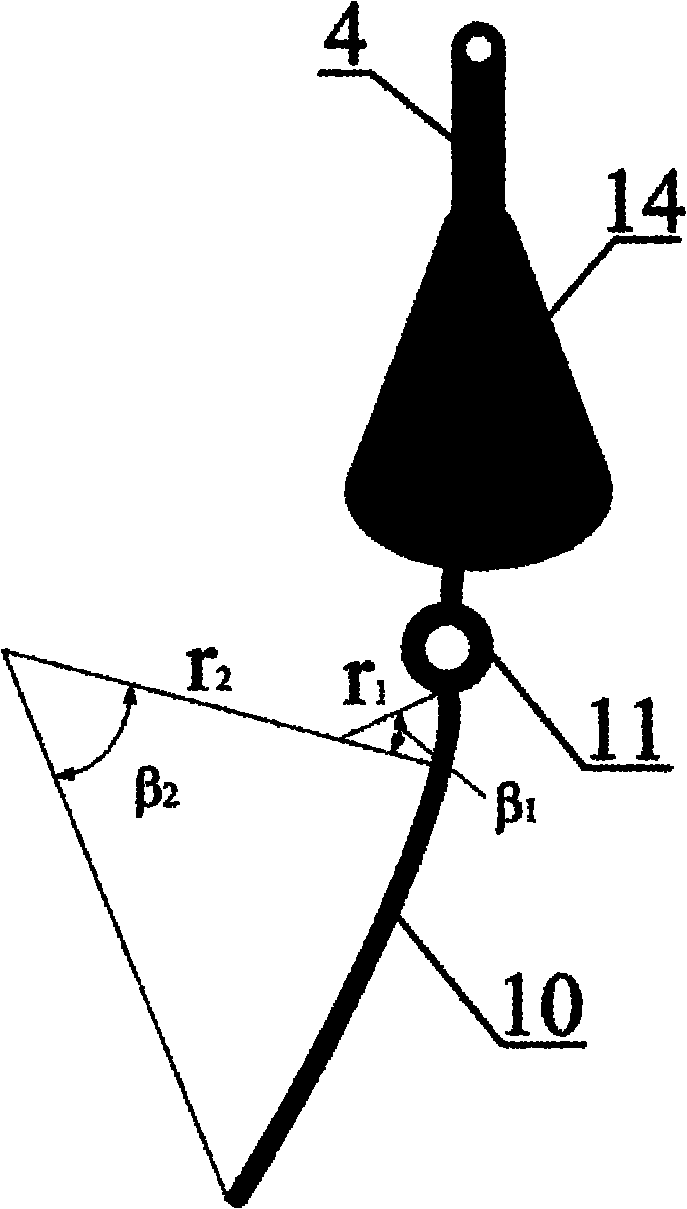

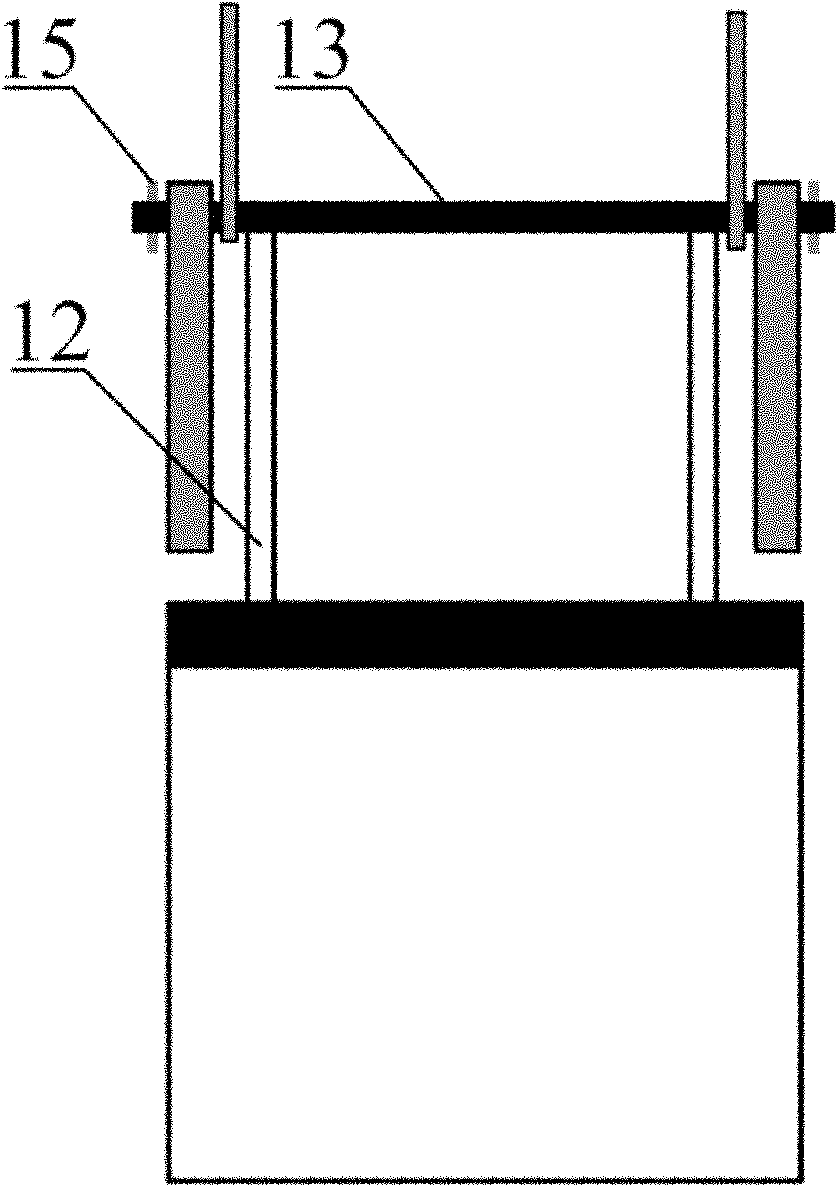

[0042] The self-balancing smoke door mechanism 3 is fixedly connected sequentially by a baffle 10, a sleeve 11, a connecting rod 12 and a round steel 13, and the two ends of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com