Adipic acid monoesterification production device capable of realizing continuous feeding and application thereof

An adipic acid mono- and production device technology, which is applied in the preparation of carboxylate, organic chemistry, chemical instruments and methods, etc., can solve the problems of methanol gas back-channeling and large gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

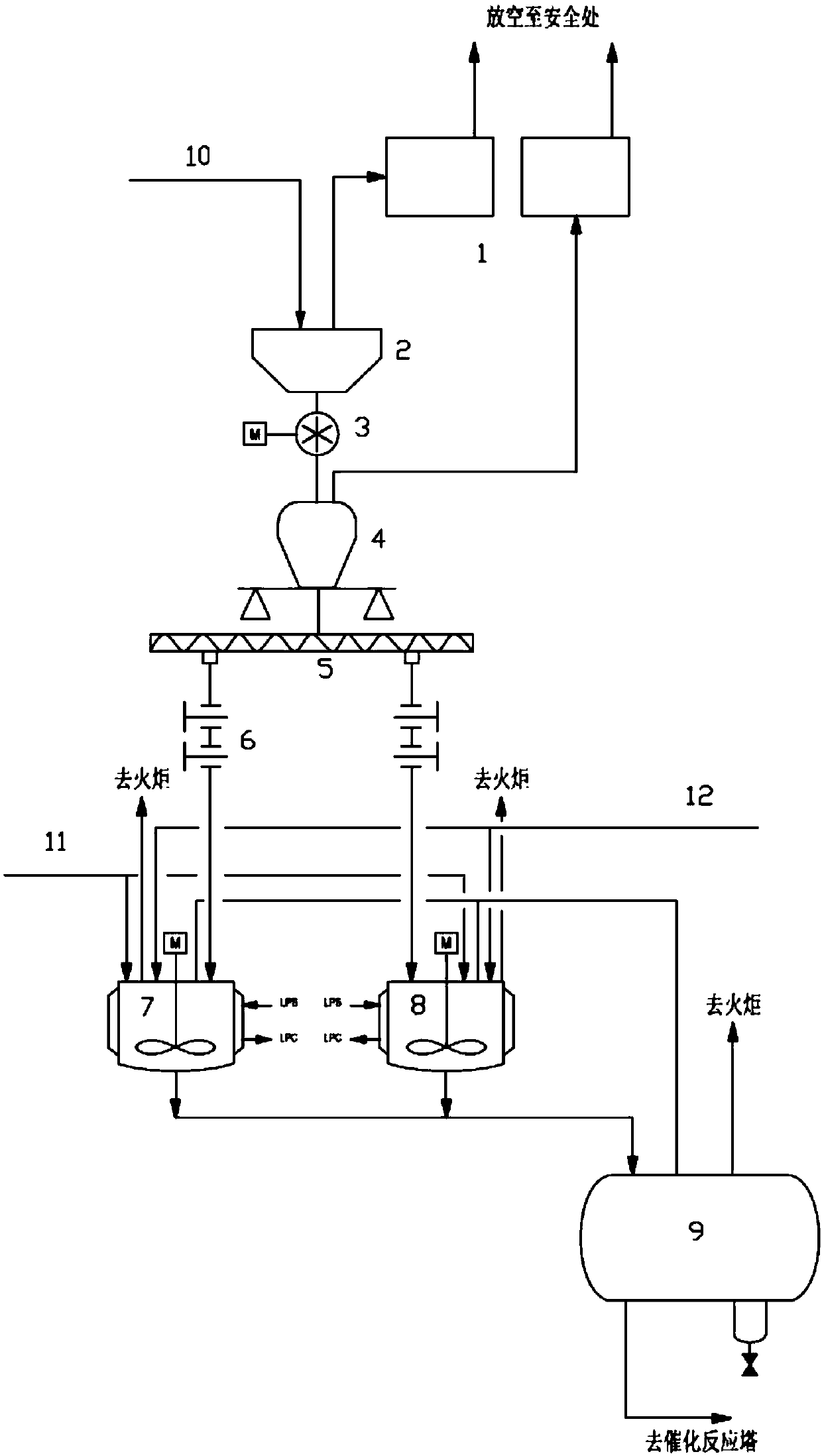

[0029] A kind of adipic acid monoesterification production unit of continuous feeding, such as figure 1 As shown, it includes pre-esterification reaction kettle, weighing hopper, intermediate hopper, pre-esterification buffer tank, and screw conveyor. The outlet of the screw conveyor is connected with the pre-esterification reactor, and the outlet of the pre-esterification buffer tank is connected with the pre-esterification buffer tank; the adipic acid raw material enters at least one The pre-esterification reactor is in contact with the incoming methanol raw material, the output of the pre-esterification buffer tank enters the pre-esterification buffer tank, and the bottom stream of the pre-esterification buffer tank is sent to the catalytic reaction tower as adipate monoesterification product; , there is a rotary valve on the pipeline connecting the weighing hopper and the intermediate hopper, the rotary valve is driven by the motor, so that the impeller with an equal struc...

Embodiment 2

[0033] A kind of adipic acid monoesterification production unit of continuous feeding, such as figure 1 As shown, it includes pre-esterification reaction kettle, weighing hopper, intermediate hopper, pre-esterification buffer tank, and screw conveyor. The outlet of the screw conveyor is connected with the pre-esterification reactor, and the outlet of the pre-esterification buffer tank is connected with the pre-esterification buffer tank; the adipic acid raw material enters at least one The pre-esterification reactor is in contact with the incoming methanol raw material, the output of the pre-esterification buffer tank enters the pre-esterification buffer tank, and the bottom stream of the pre-esterification buffer tank is sent to the catalytic reaction tower as adipate monoesterification product; , there is a rotary valve on the pipeline connecting the weighing hopper and the intermediate hopper. The rotary valve is driven by the motor to make the impeller with an equal struct...

Embodiment 3

[0037] A kind of adipic acid monoesterification production unit of continuous feeding, such as figure 1 As shown, it includes pre-esterification reaction kettle, weighing hopper, intermediate hopper, pre-esterification buffer tank, and screw conveyor. The outlet of the screw conveyor is connected with the pre-esterification reactor, and the outlet of the pre-esterification buffer tank is connected with the pre-esterification buffer tank; the adipic acid raw material enters at least one The pre-esterification reactor is in contact with the incoming methanol raw material, the output of the pre-esterification buffer tank enters the pre-esterification buffer tank, and the bottom stream of the pre-esterification buffer tank is sent to the catalytic reaction tower as adipate monoesterification product; , there is a rotary valve on the pipeline connecting the weighing hopper and the intermediate hopper. The rotary valve is driven by the motor to make the impeller with an equal struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com