Surface energy gradient bionic liquid absorption core and application thereof

A liquid-absorbing core, the next bionic technology, applied in the direction of lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of insufficient capillary suction, back heat conduction, etc., to solve the problem of insufficient capillary suction and reduce flow Effect of resistance, good engineering application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

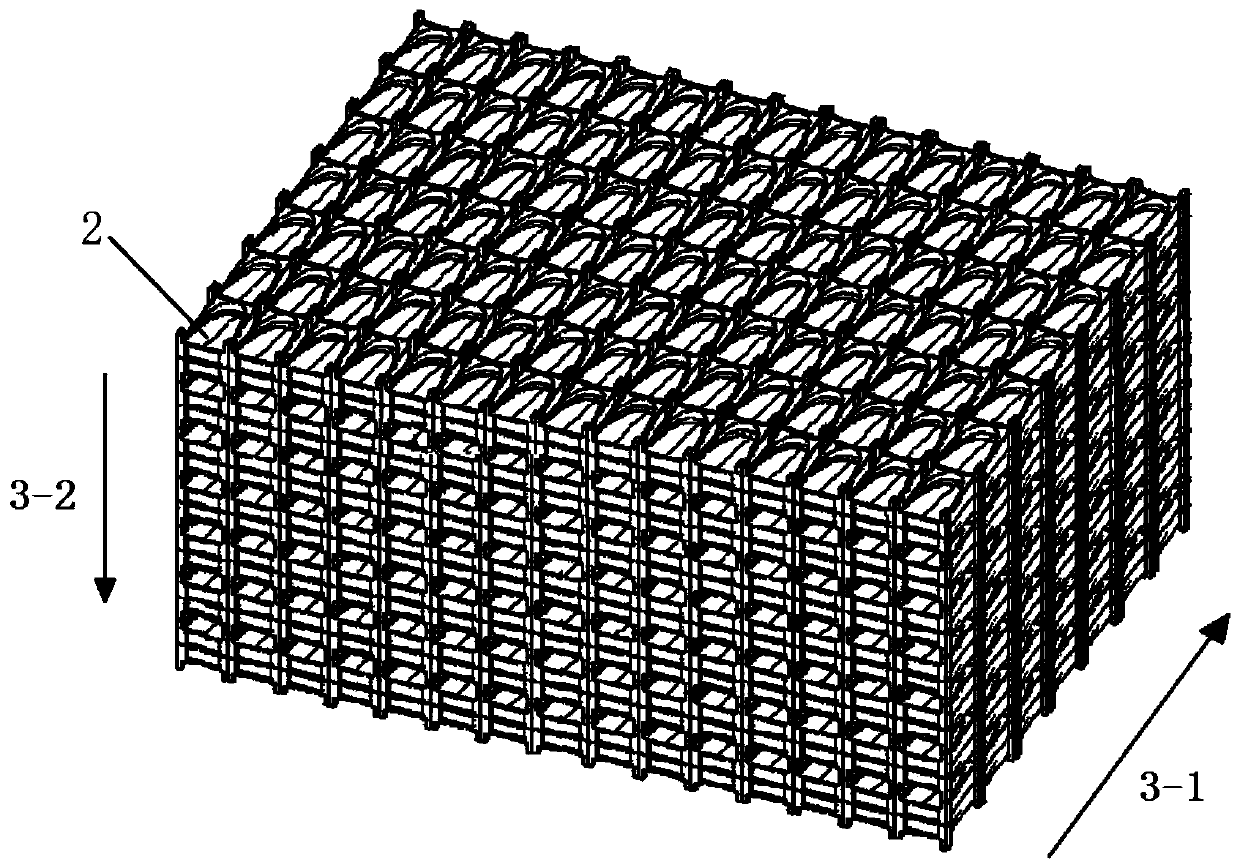

[0030] A kind of surface energy gradient bionic liquid-absorbent core 1 of the present embodiment, such as figure 1 and 2 , including several bionic units 2 arranged in a three-dimensional array.

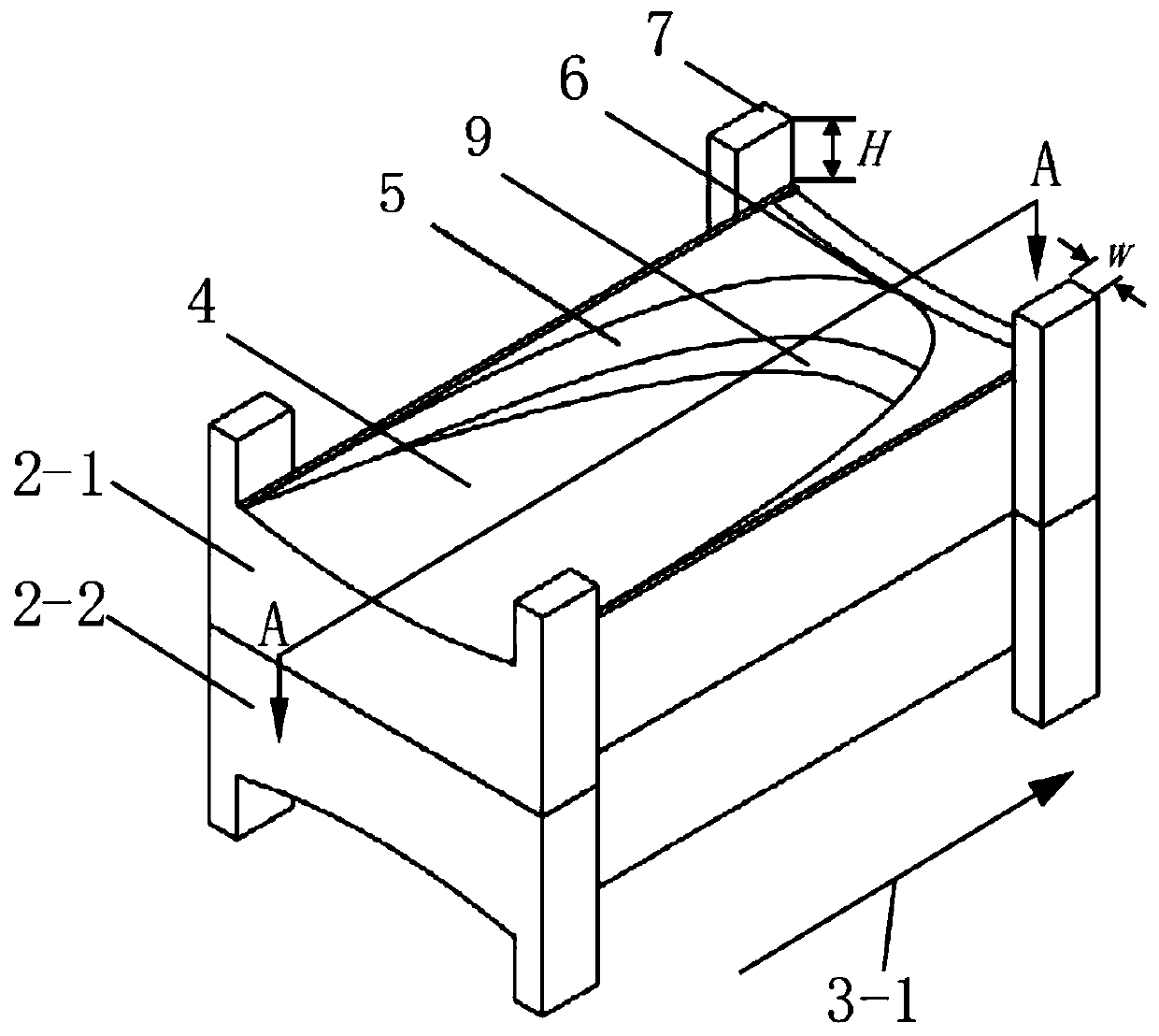

[0031] The bionic unit 2 is provided with diversion grooves, such as image 3 , the projection of the diversion groove is a half ellipse, such as Figure 4 The diversion groove includes a slope 4, a curved surface 5 and a flange 6. The slope 4 has a structure in which the depth of the groove gradually increases along the liquid flow direction 3-1. The end of the slope 4 is connected to a curved surface 5. The curved surface 5 The side close to the slope 4 is a concave surface, and the upper end of the curved surface 5 stretches back toward the slope 4 to form the flange 6, and the flange 6 smoothly connects with the slope 4 of the next bionic unit 2 to form a sharp angle.

[0032] In this embodiment, the junction of the curved surface 5 and the inclined surface 4 is a rounded cor...

Embodiment 2

[0039] In this embodiment, the surface energy gradient bionic liquid-absorbing core 1 in Embodiment 1 is applied to a loop heat pipe evaporator, and the loop heat pipe evaporator includes an evaporator shell 12, a liquid compensation chamber 13, a liquid inlet 14, a heating Rod 15, steam groove 16 and steam outlet 17, such as Figure 7 shown. During operation, the liquid near the steam groove 16 in the liquid-absorbing core 1 absorbs the latent heat of vaporization of the heating rod, and the generated steam carries a large amount of heat through the steam groove 16, flows out from the steam outlet 17, and reaches the condenser through the steam pipe. The vapor is liquefied after releasing the latent heat of vaporization in the condenser, and is stored in the liquid compensation chamber 13 after reaching the liquid inlet 14 through the liquid connecting pipe. Under the action of the capillary suction force of the liquid-absorbing core 1, the liquid travels from the liquid com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com