Stainless steel three-dimensional expansion joint used for sealing high temperature ash and slag

A technology of stainless steel and expansion joints, applied in the field of circulating fluidized bed boilers, can solve problems such as excessive sealing, influence on wave node expansion, sealing problems, etc., and achieve the effect of improving reliability and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

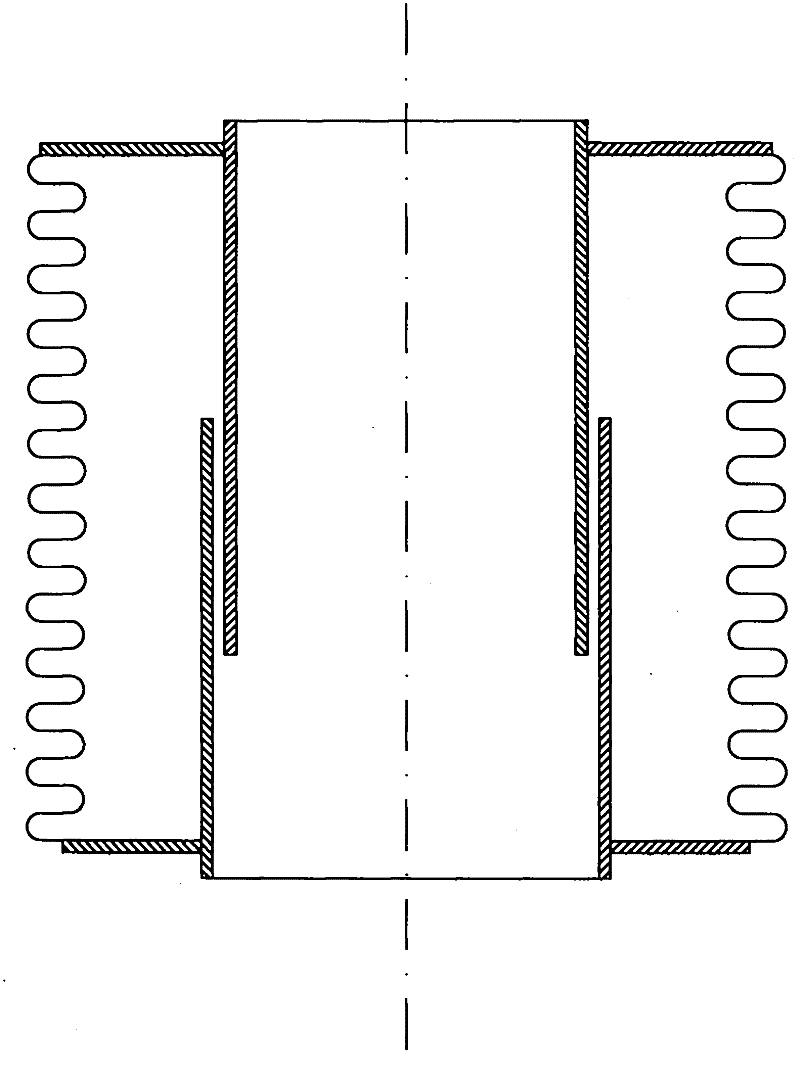

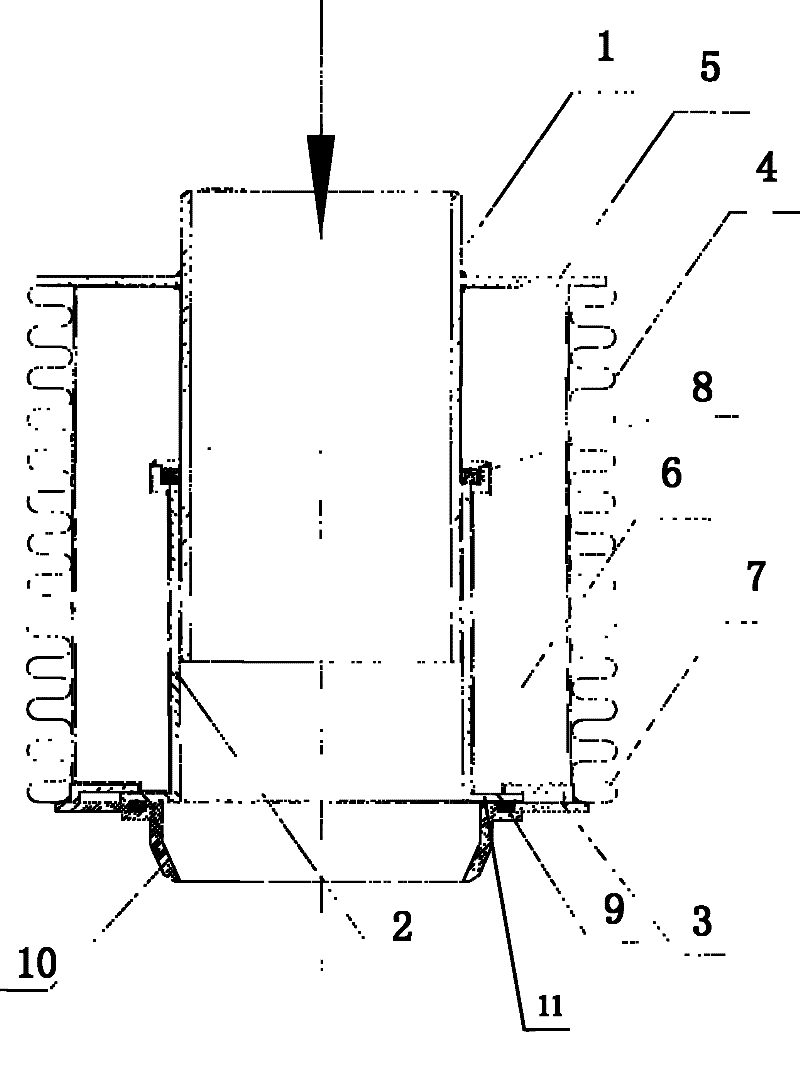

[0014] Such as figure 1 , figure 2 As shown, the high-temperature ash slag stainless steel three-way expansion joint according to the present invention includes an upper inner guide cylinder 1, a lower inner guide cylinder 2, a horizontal expansion chamber 3, a bellows 4, an upper end cover 5, and is tied with a stainless steel wire mesh Tight aluminum silicate fiber needle-punched blanket 6, aluminum silicate fiber needle-punched blanket 7, sealing packing chamber between upper and lower inner guide cylinders 8, horizontal expansion ring 11, expansion joint outlet end cover 10, horizontal expansion ring and expansion joint outlet end A sealing stuffing chamber 9 is provided between the covers.

[0015] Only a 1mm expansion gap is left between the upper and lower inner guide cylinders 1 and 2, which is actually a movable gap, and a sealing packing chamber 8 is provided to reliably seal this gap, preventing the backflow of flue gas and the backflow of fine ash and fine partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com