Double-walled helical corrugation metal tube and method of processing the same

A technology of spiral corrugated pipe and metal pipe, which is applied in the field of double-walled multi-head spiral corrugated metal pipe and its processing field, can solve the problems of low heat exchange efficiency and low safety factor, and achieves high yield, enhanced pressure bearing capacity, and high processing efficiency. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

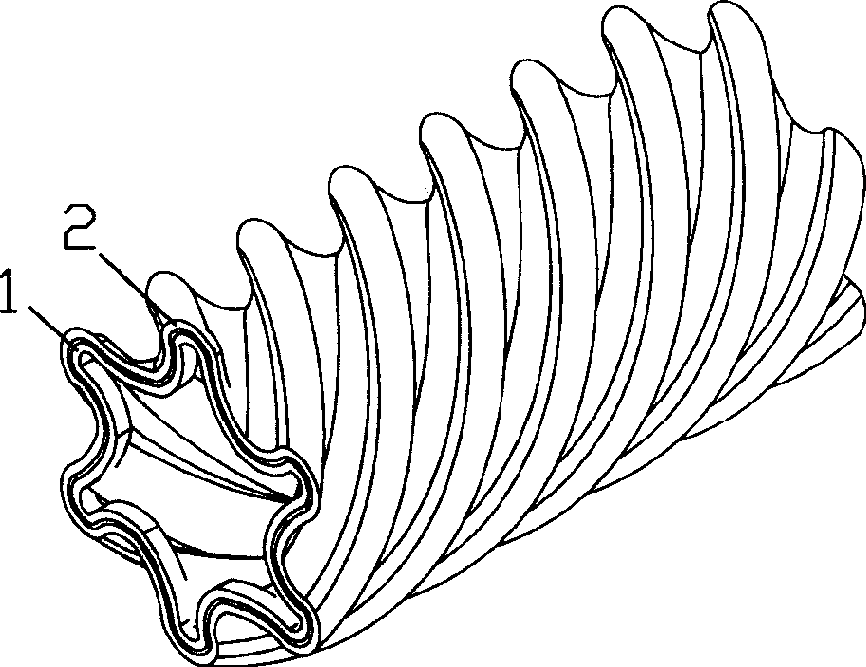

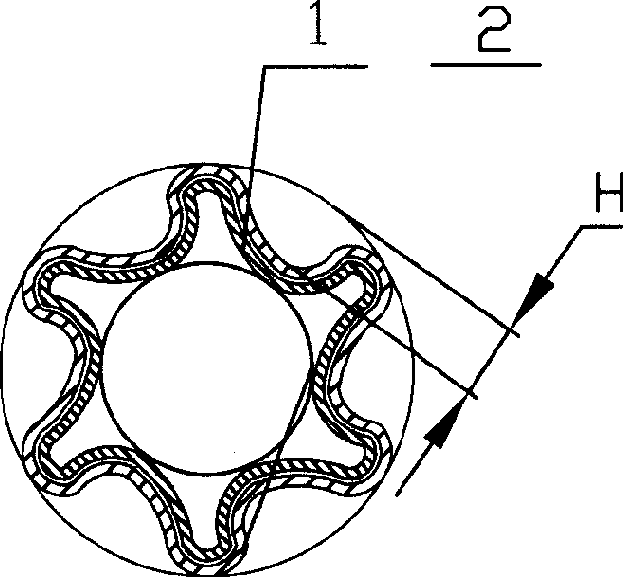

[0019] Such as figure 1 and 2 As shown in and 5, a double-wall spiral corrugated metal pipe includes two inner and outer pipe bodies, and the inner pipe 1 and the outer pipe 2 are both made of copper material. Both the inner tube 1 and the outer tube 2 are spiral corrugated tubes, the gap distance between the inner tube wall and the outer tube wall is 2mm, the tube wall thickness of the inner tube 1 and the outer tube 2 is 0.2mm, the inner tube 1 and the outer tube The corrugations of the pipe 2 coincide, the diameter of the inner pipe is Φ6mm, the angle α between the tangent line of the thread of the inner pipe 1 and the outer pipe 2 and the cross section of the pipe body is 15°, the depth H of the thread is 3mm, and the head of the thread The number is 2 heads. During processing, first set the pitch and depth of the twisted tube on the equipment according to the outer diameter and technical requirements of the tube to be twisted, and then thread the two-layered tube body t...

Embodiment 2

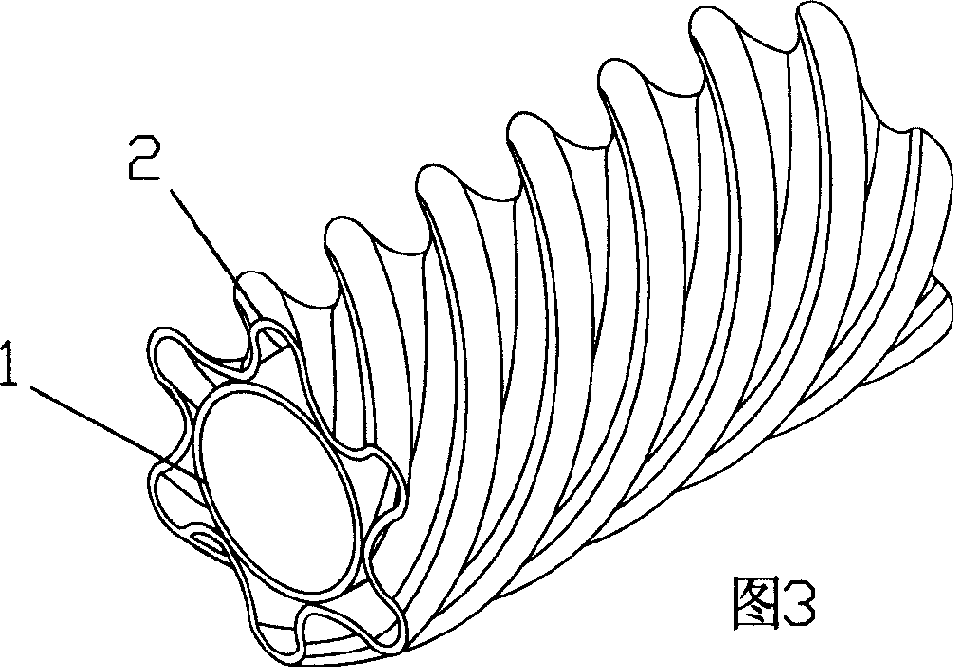

[0021] As shown in Figures 3, 4 and 5, a double-wall spiral corrugated metal pipe includes two layers of pipe bodies, the inner pipe and the outer pipe are made of copper material. The inner tube 1 is a smooth tube, the outer tube 2 is a spiral corrugated tube, the inner tube wall is close to the outer tube wall, and the inner tube wall abuts against the thread protrusion of the outer tube wall, thereby fixing the inner tube. The wall thickness of the inner tube 1 and the outer tube 2 is 1.5 mm, the diameter of the inner tube 1 is Φ50 mm, the angle α between the tangent line of the thread of the outer tube 2 and the cross section of the tube body is 30°, and the depth H of the thread is 8mm, the number of threads is 5. During processing, first set the pitch and depth of the twisted tube on the equipment according to the outer diameter and technical requirements of the tube to be twisted, and then thread the two-layered tube body to be drawn. The lengths of the two layers are t...

Embodiment 3

[0023] Such as figure 1 and 2 As shown in and 5, a double-wall spiral corrugated metal pipe includes two inner and outer pipe bodies, and the inner pipe 1 and the outer pipe 2 are both made of copper material. The inner tube 1 and the outer tube 2 are both spiral corrugated tubes, the gap distance between the inner tube wall and the outer tube wall is 15mm, the tube wall thickness of the inner tube 1 and the outer tube 2 is 3mm, the inner tube 1 and the outer tube 2 The corrugations coincide, the diameter of the inner pipe 1 is Φ80mm, the angle α between the tangent line of the thread of the inner pipe 1 and the outer pipe 2 and the cross section of the pipe body is 45°, the depth H of the thread is 12.5mm, and the thread The number of heads is 12. All the other are the same with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com