Internal combustion type heating rotating cone type biomass pyrolysis liquefaction device

A biomass pyrolysis, heating and rotating technology, used in biofuels, special forms of dry distillation, petroleum industry, etc., can solve the problems of strict requirements on feed particle size, high temperature sand wear, and reduced bio-oil yield. The effect of good particle size adaptability, reducing energy consumption and cost, and improving bio-oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

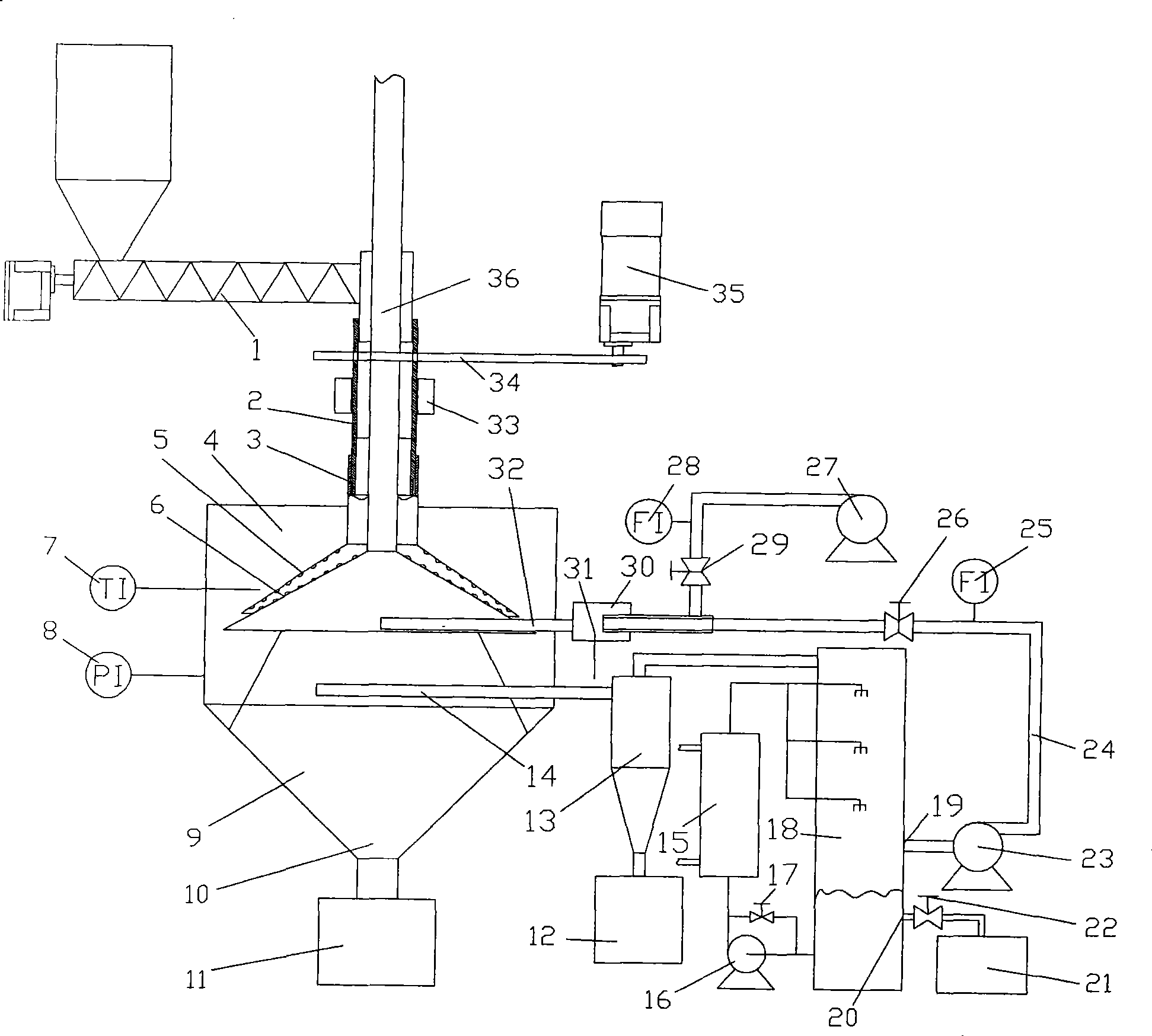

[0033] see figure 1 , using a rectangular or cylinder shaped reactor 4, two concentric cones are set inside the reactor 4, the outer cone is a rotating cone 5 rotating around the axis, and the inner cone is a fixed fixed cone 6; The section is set as the upper barrel 2 and the lower barrel 3, the upper part of the rotating cone 5 is connected with the lower barrel 3, the upper barrel 2 is connected with the screw feeding mechanism 1; the upper part of the fixed cone 6 is connected with the flue gas pipe 36 The end face of the bottom of the fixed cone 6 is closed, and its lower part communicates with the combustion pipe 32 tangentially; a porous filter tube 14 is set in the reactor 4, and the other end of the porous filter tube 14 leads out of the reactor, and is connected with the cyclone outside the reactor. The dust collector 13 is connected, the bottom output terminal of the cyclone dust collector 13 is connected to the carbon collection box 12, and the gas outlet at the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com