Method of fluidizing wind at high pressure using steam to replace air

A fluidized wind and high-pressure technology, which is applied in the direction of combustion methods, fluidized bed combustion equipment, and fuel burned in a molten state, can solve problems such as air duct vibration, coking, and burnout of the hood of the feeder, so as to avoid vibration and noise, improve the operating environment, and increase the effect of desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Since the boiler itself produces steam, the steam passes through the steam turbine to the generator to generate electricity, so the steam can come from the exhaust steam of the steam turbine or intermediate steam extraction, or from the boiler itself or other source generating devices.

[0030] This example takes the 150MW circulating fluidized bed boiler with intermediate reheating of Shanghai Boiler Works Co., Ltd. as an example. The steam is provided by steam turbine exhaust or intermediate extraction:

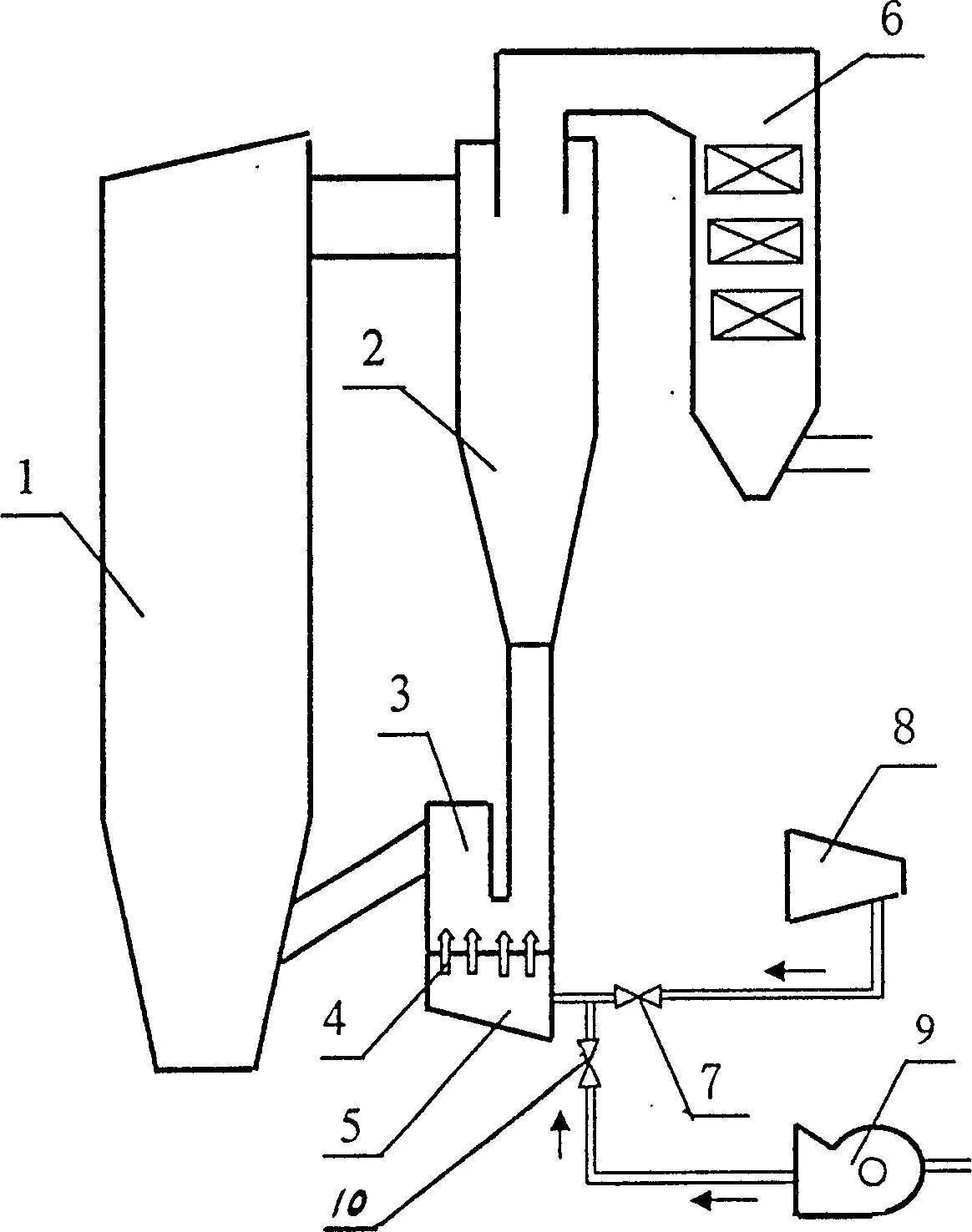

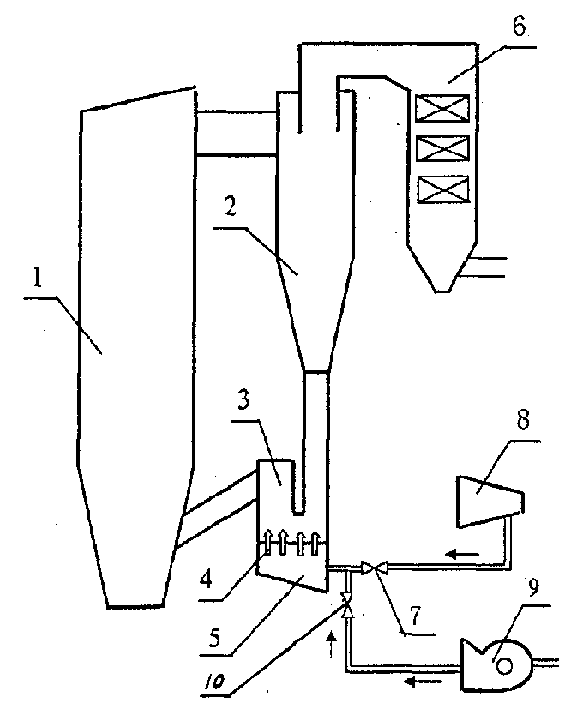

[0031] like figure 1As shown, it is a schematic diagram of a circulating fluidized bed boiler system, which consists of a boiler 1, a cyclone separator 2, a feeder 3, a wind cap and a steam nozzle 4, a wind and steam chamber 5, a tail convection flue 6, a shut-off valve 7, and a steam turbine 8 , a high-pressure fluidizing fan 9, and a shut-off valve 10, the cyclone separator 2 is connected to the upper end of the boiler 1, the upper end of the cyclone separator 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com